check engine YAMAHA XMAX 400 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: XMAX 400, Model: YAMAHA XMAX 400 2020Pages: 118, PDF Size: 9.04 MB

Page 57 of 118

For your safety – pre-operation checks

5-1

5

EAU63440

Inspect your vehicle each time you use it to make sure the vehicle is in safe oper-

ating condition. Always follow the inspection and maintenance procedures and

schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility

of an accident or equipment damage. Do not operate the vehicle if you find

any problem. If a problem cannot be corrected by the procedures provided

in this manual, have the vehicle inspected by a Yamaha dealer.

Before using this vehicle, check the following points:

ITEM CHECKS PAGE

Fuel• Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank overflow hose for obstructions, cracks

or damage, and check hose connection.4-19,

4-20

Engine oil• Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage.7-10

Final transmission oil• Check vehicle for oil leakage. 7-12

Coolant• Check coolant level in reservoir.

• If necessary, add recommended coolant to specified

level.

• Check cooling system for leakage.7-13

Front brake• Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage.7-21,

7-23,

7-23

Rear brake• Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage.7-21,

7-23,

7-23

Throttle grip• Make sure that operation is smooth.

• Check throttle grip free play.

• If necessary, have Yamaha dealer adjust throttle grip

free play and lubricate cable and grip housing.7-17,

7-26

UBL1E0E0.book Page 1 Thursday, May 11, 2017 8:51 AM

Page 60 of 118

Operation and important riding points

6-2

6

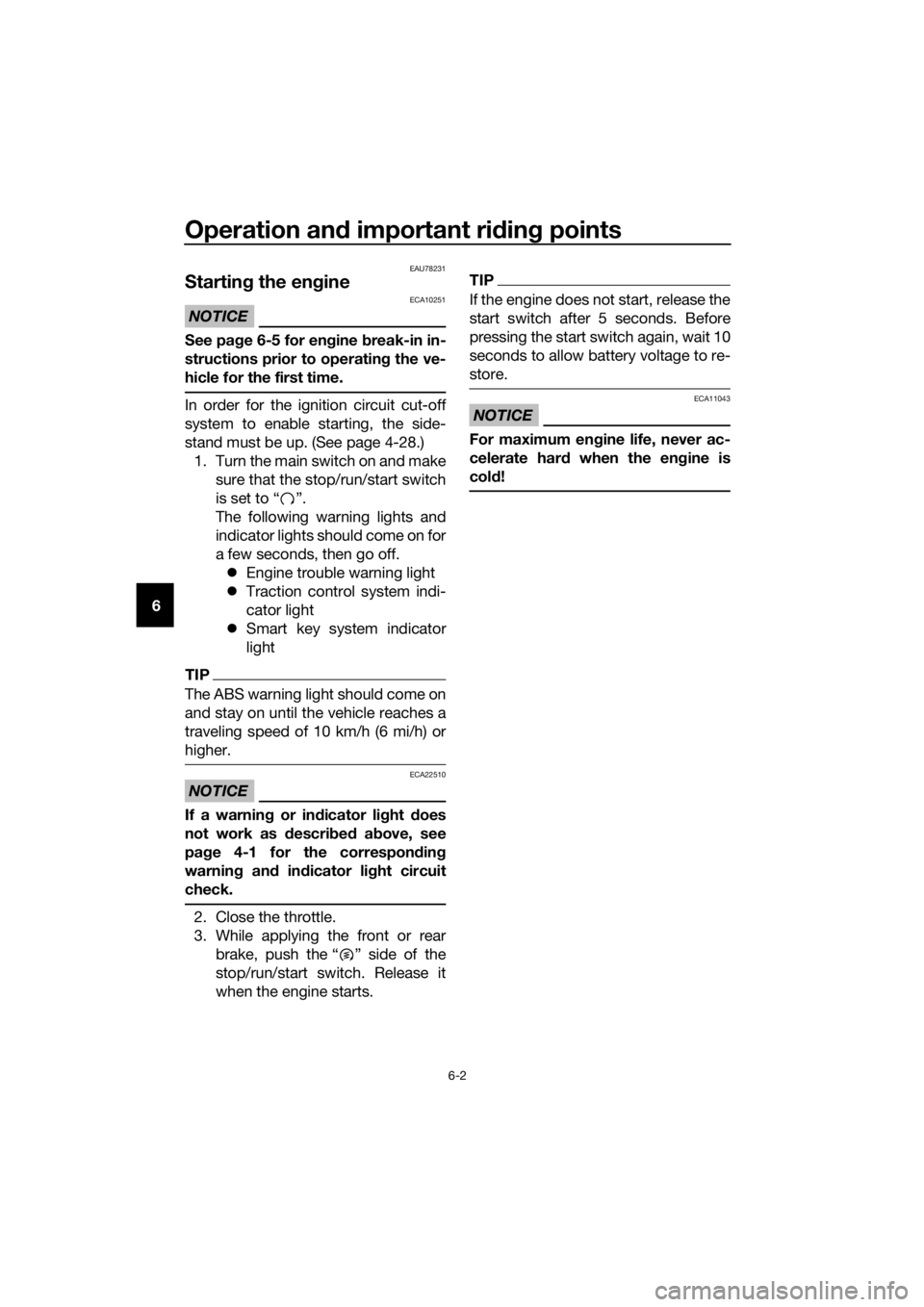

EAU78231

Starting the engine

NOTICE

ECA10251

See page 6-5 for engine break-in in-

structions prior to operating the ve-

hicle for the first time.

In order for the ignition circuit cut-off

system to enable starting, the side-

stand must be up. (See page 4-28.)

1. Turn the main switch on and make

sure that the stop/run/start switch

is set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off.

Engine trouble warning light

Traction control system indi-

cator light

Smart key system indicator

light

TIP

The ABS warning light should come on

and stay on until the vehicle reaches a

traveling speed of 10 km/h (6 mi/h) or

higher.

NOTICE

ECA22510

If a warning or indicator light does

not work as described above, see

page 4-1 for the corresponding

warning and indicator light circuit

check.

2. Close the throttle.

3. While applying the front or rear

brake, push the “ ” side of the

stop/run/start switch. Release it

when the engine starts.

TIP

If the engine does not start, release the

start switch after 5 seconds. Before

pressing the start switch again, wait 10

seconds to allow battery voltage to re-

store.

NOTICE

ECA11043

For maximum engine life, never ac-

celerate hard when the engine is

cold!

UBL1E0E0.book Page 2 Thursday, May 11, 2017 8:51 AM

Page 63 of 118

Operation and important riding points

6-5

6

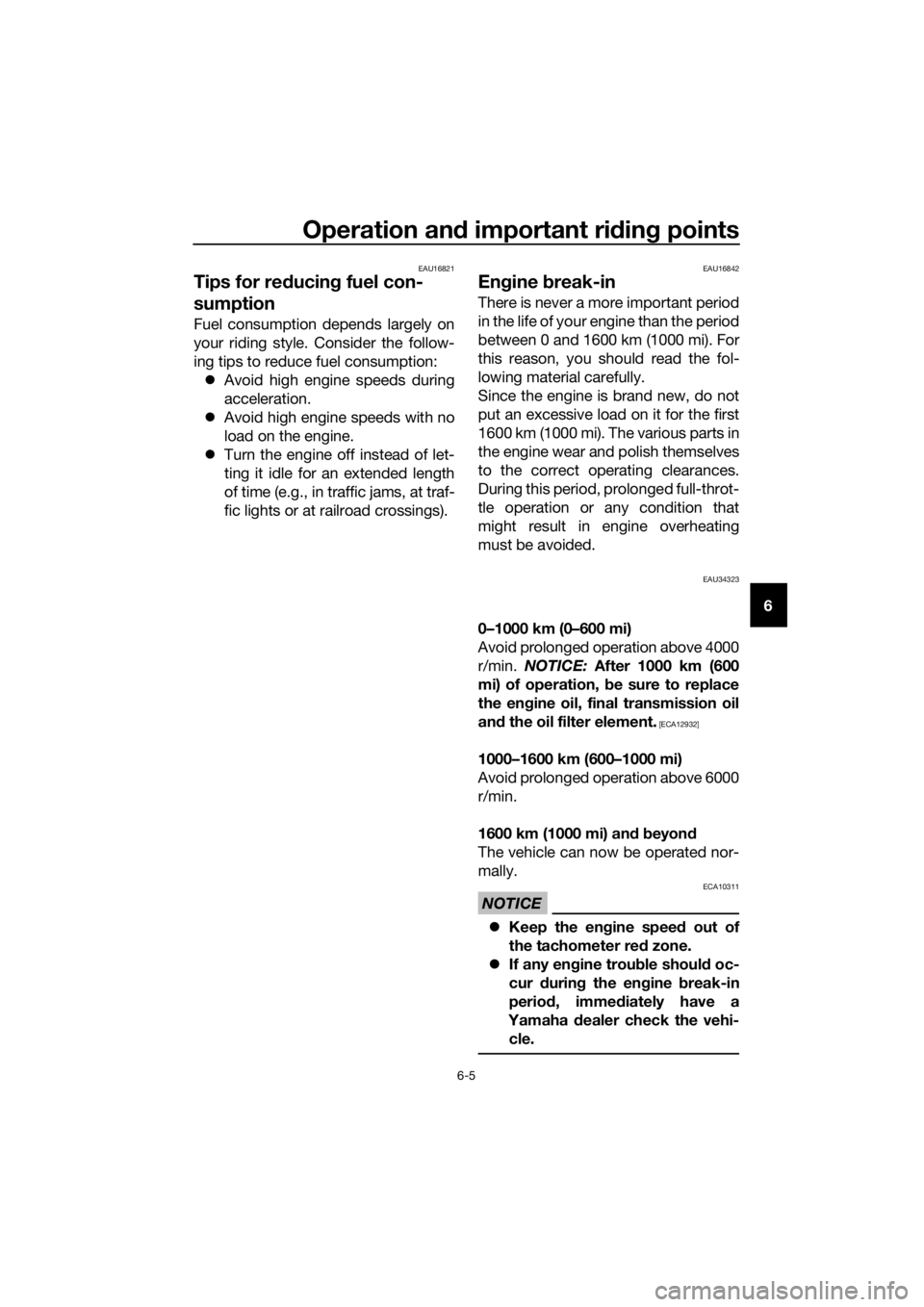

EAU16821

Tips for reducing fuel con-

sumption

Fuel consumption depends largely on

your riding style. Consider the follow-

ing tips to reduce fuel consumption:

Avoid high engine speeds during

acceleration.

Avoid high engine speeds with no

load on the engine.

Turn the engine off instead of let-

ting it idle for an extended length

of time (e.g., in traffic jams, at traf-

fic lights or at railroad crossings).

EAU16842

Engine break-in

There is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the fol-

lowing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that

might result in engine overheating

must be avoided.

EAU34323

0–1000 km (0–600 mi)

Avoid prolonged operation above 4000

r/min. NOTICE: After 1000 km (600

mi) of operation, be sure to replace

the engine oil, final transmission oil

and the oil filter element.

[ECA12932]

1000–1600 km (600–1000 mi)

Avoid prolonged operation above 6000

r/min.

1600 km (1000 mi) and beyond

The vehicle can now be operated nor-

mally.

NOTICE

ECA10311

Keep the engine speed out of

the tachometer red zone.

If any engine trouble should oc-

cur during the engine break-in

period, immediately have a

Yamaha dealer check the vehi-

cle.

UBL1E0E0.book Page 5 Thursday, May 11, 2017 8:51 AM

Page 67 of 118

Periodic maintenance and adjustment

7-3

7

EAU71031

TIP

The annual checks must be performed every year, except if a distance-

based maintenance is performed instead.

From 50000 km (30000 mi), repeat the maintenance intervals starting from

10000 km (6000 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as

they require special tools, data and technical skills.

EAU71071

Periodic maintenance chart for the emission control system

NO. ITEM

1*Fuel line• Check fuel hoses for cracks or

damage.

• Replace if necessary.√√√√√

2*Spark plug• Check condition.

• Adjust gap and clean.√√

• Replace.√√

3*Valve clearance• Check and adjust. Every 40000 km (24000 mi)

4*Fuel injection• Check engine idle speed.√√√√√√

5*Exhaust system• Check for leakage.

• Tighten if necessary.

• Replace gasket if necessary.√√√√√

6*Evaporative emis-

sion control sys-

tem• Check control system for dam-

age.

• Replace if necessary.√√

7*Air induction sys-

tem• Check the air cut-off valve, reed

valve, and hose for damage.

• Replace any damaged parts if

necessary.√√√√√X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER

READINGS

ANNUAL CHECK

110203040

0.66121824

UBL1E0E0.book Page 3 Thursday, May 11, 2017 8:51 AM

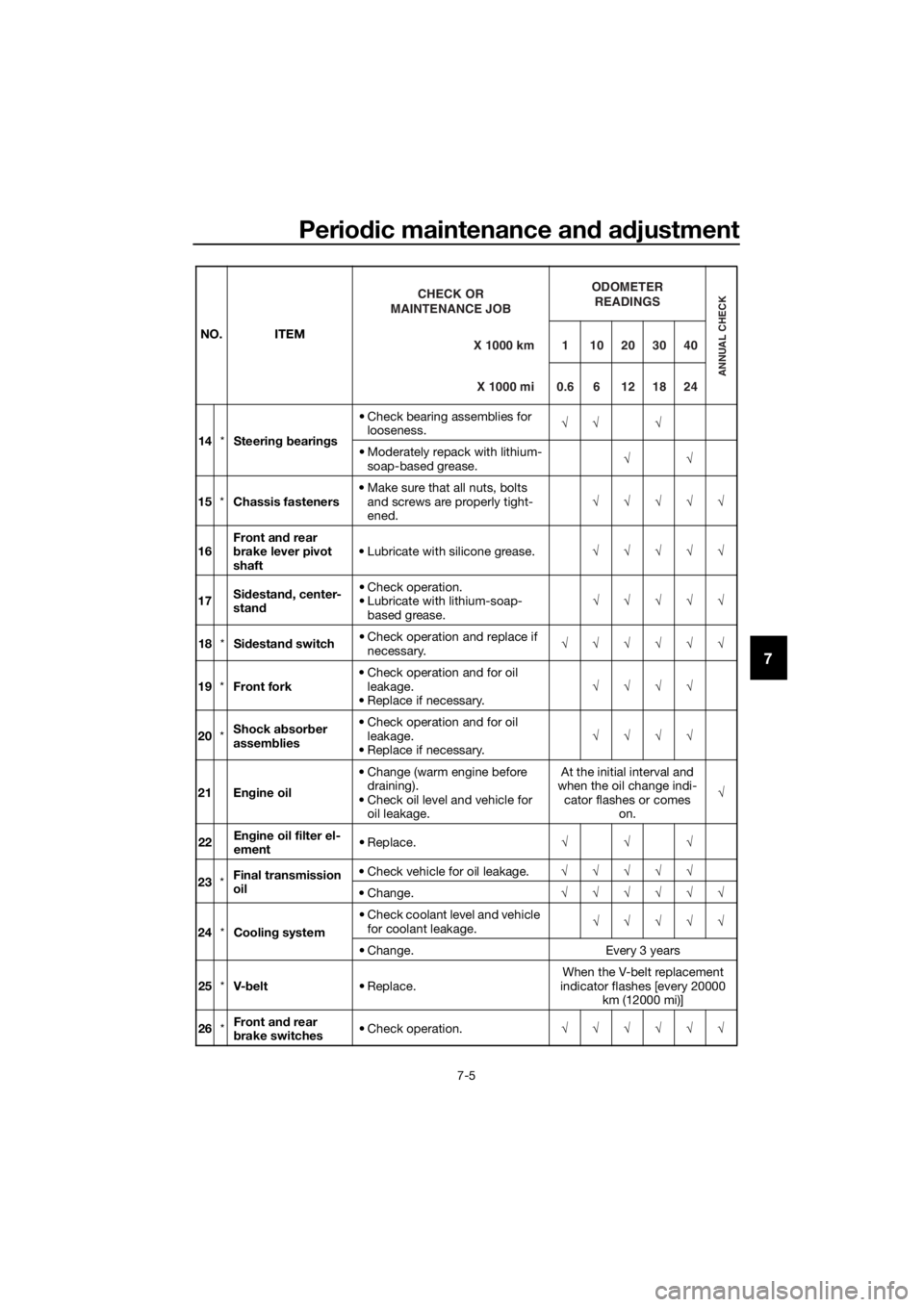

Page 69 of 118

Periodic maintenance and adjustment

7-5

7

14*Steering bearings• Check bearing assemblies for

looseness.√√ √

• Moderately repack with lithium-

soap-based grease.√√

15*Chassis fasteners• Make sure that all nuts, bolts

and screws are properly tight-

ened.√√√√√

16Front and rear

brake lever pivot

shaft• Lubricate with silicone grease.√√√√√

17Sidestand, center-

stand• Check operation.

• Lubricate with lithium-soap-

based grease.√√√√√

18*Sidestand switch• Check operation and replace if

necessary.√√√√√√

19*Front fork• Check operation and for oil

leakage.

• Replace if necessary.√√√√

20*Shock absorber

assemblies• Check operation and for oil

leakage.

• Replace if necessary.√√√√

21 Engine oil• Change (warm engine before

draining).

• Check oil level and vehicle for

oil leakage.At the initial interval and

when the oil change indi-

cator flashes or comes

on.√

22Engine oil filter el-

ement• Replace.√√√

23*Final transmission

oil• Check vehicle for oil leakage.√√√√√

• Change.√√√√√√

24

*Cooling system• Check coolant level and vehicle

for coolant leakage.√√√√√

• Change. Every 3 years

25*V-belt• Replace.When the V-belt replacement

indicator flashes [every 20000

km (12000 mi)]

26*Front and rear

brake switches• Check operation.√√√√√√ NO. ITEM

X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER

READINGS

ANNUAL CHECK

110203040

0.66121824

UBL1E0E0.book Page 5 Thursday, May 11, 2017 8:51 AM

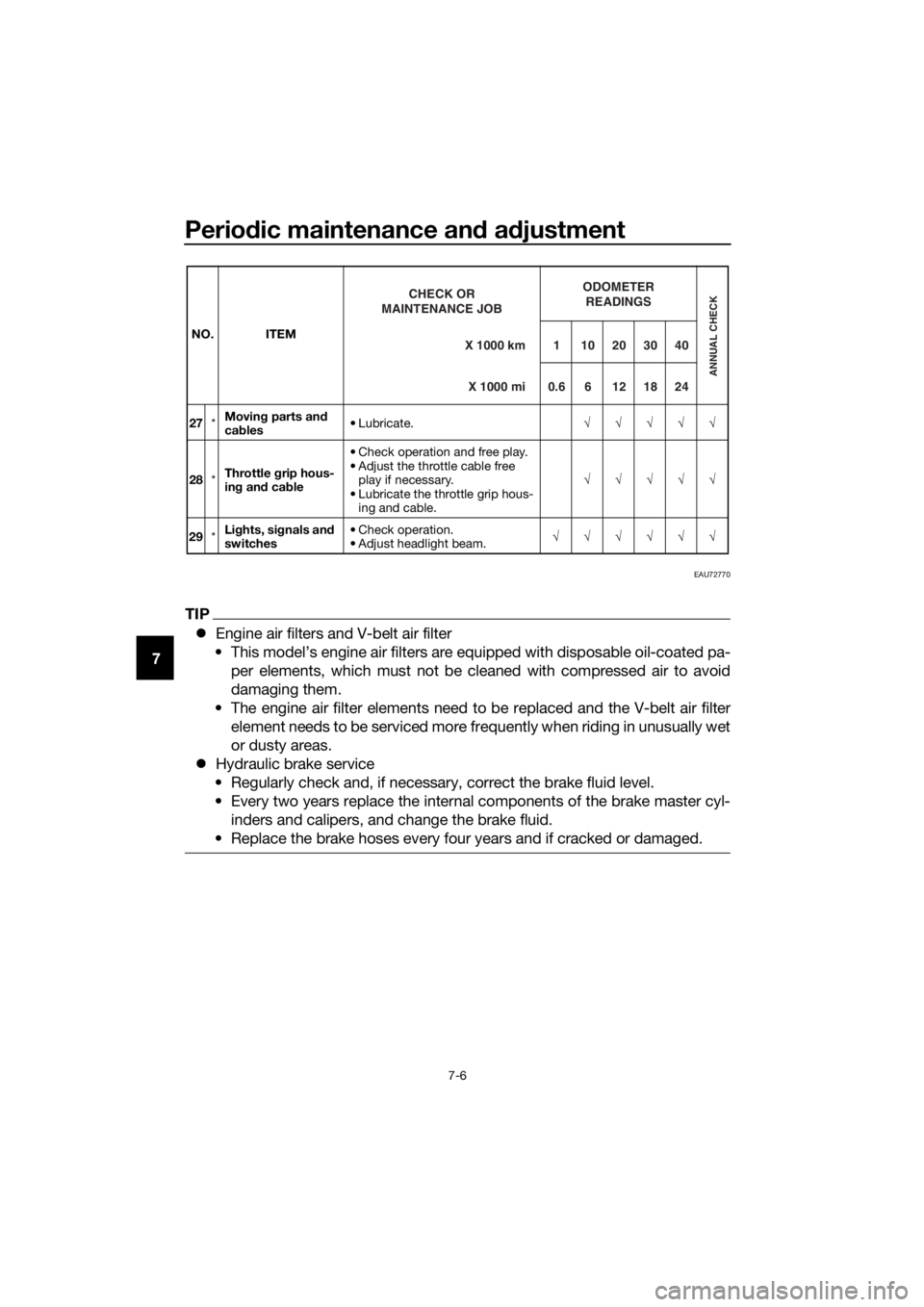

Page 70 of 118

Periodic maintenance and adjustment

7-6

7

EAU72770

TIP

Engine air filters and V-belt air filter

• This model’s engine air filters are equipped with disposable oil-coated pa-

per elements, which must not be cleaned with compressed air to avoid

damaging them.

• The engine air filter elements need to be replaced and the V-belt air filter

element needs to be serviced more frequently when riding in unusually wet

or dusty areas.

Hydraulic brake service

• Regularly check and, if necessary, correct the brake fluid level.

• Every two years replace the internal components of the brake master cyl-

inders and calipers, and change the brake fluid.

• Replace the brake hoses every four years and if cracked or damaged.

27*Moving parts and

cables• Lubricate.√√√√√

28*Throttle grip hous-

ing and cable• Check operation and free play.

• Adjust the throttle cable free

play if necessary.

• Lubricate the throttle grip hous-

ing and cable.√√√√√

29*Lights, signals and

switches• Check operation.

• Adjust headlight beam.√√√√√√ NO. ITEM

X 1000 km CHECK OR

MAINTENANCE JOB

X 1000 miODOMETER

READINGS

ANNUAL CHECK

110203040

0.6 6 12 18 24

UBL1E0E0.book Page 6 Thursday, May 11, 2017 8:51 AM

Page 72 of 118

Periodic maintenance and adjustment

7-8

7

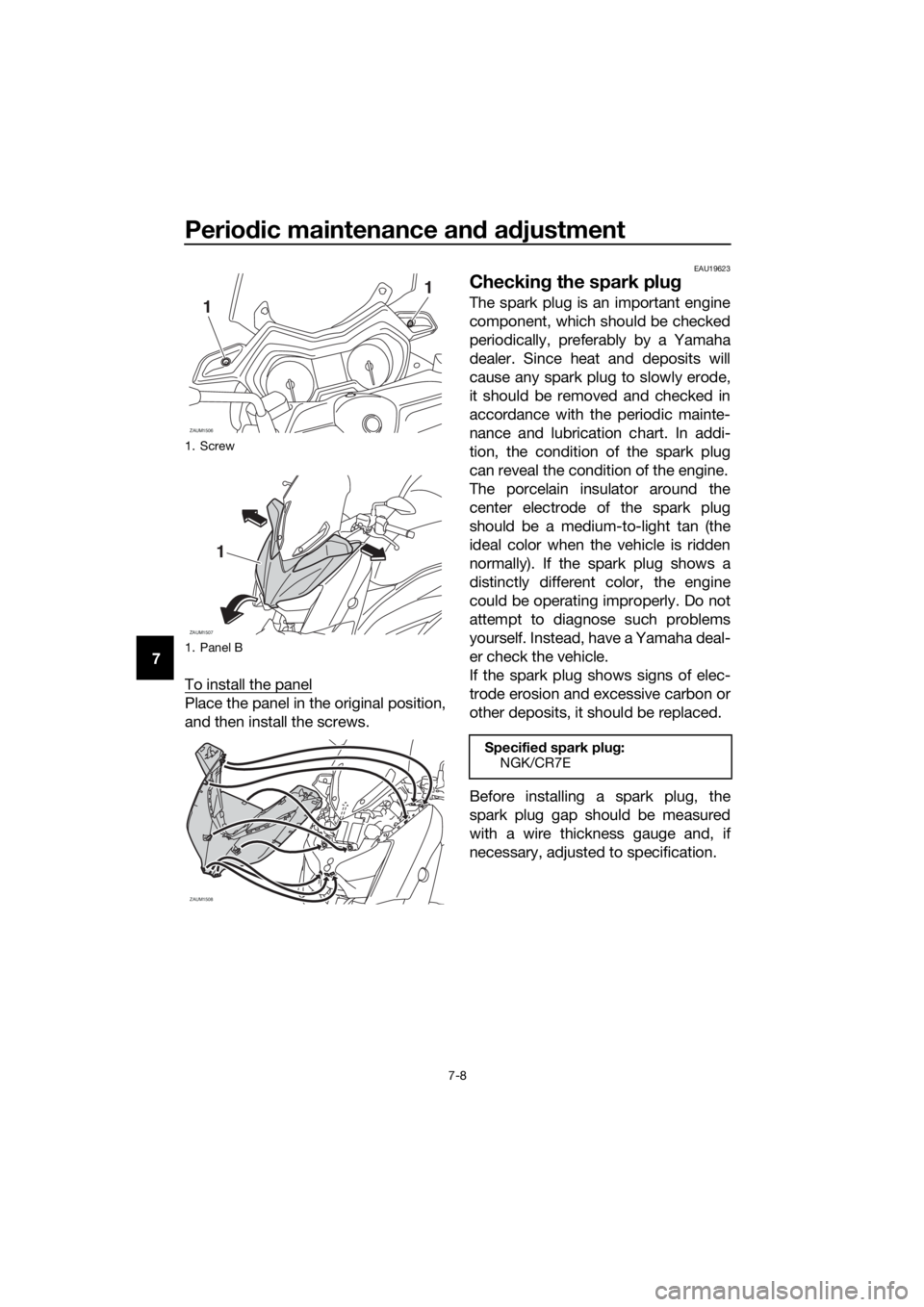

To install the panel

Place the panel in the original position,

and then install the screws.

EAU19623

Checking the spark plug

The spark plug is an important engine

component, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

it should be removed and checked in

accordance with the periodic mainte-

nance and lubrication chart. In addi-

tion, the condition of the spark plug

can reveal the condition of the engine.

The porcelain insulator around the

center electrode of the spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally). If the spark plug shows a

distinctly different color, the engine

could be operating improperly. Do not

attempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If the spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification.

1. Screw

1. Panel B

ZAUM1506

1

1

ZAUM1507

1

ZAUM1508

Specified spark plug:

NGK/CR7E

UBL1E0E0.book Page 8 Thursday, May 11, 2017 8:51 AM

Page 74 of 118

Periodic maintenance and adjustment

7-10

7

EAUM3940

Engine oil and oil filter ele-

ment

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart and when the oil change

indicator comes on.

To check the engine oil level

1. Place the vehicle on the center-

stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, remove the oil filler cap, wipe

the dipstick clean, insert it back

into the oil filler hole (without

screwing it in), and then remove it

again to check the oil level.

TIP

The engine oil should be between the

tip of the dipstick and the maximum

level mark.

4. If the engine oil is not between the

tip of the dipstick and the maxi-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

5. Insert the dipstick into the oil filler

hole, and then tighten the oil filler

cap.

To change the engine oil (with or

without oil filter element replace-

ment)

1. Place the vehicle on the center-

stand.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

4. Remove the engine oil filler cap,

the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIP

Skip steps 5…7 if the oil filter element is

not being replaced.

5. Remove the oil filter element cover

by removing the bolts. NOTICE:

When removing the oil filter ele-1. Engine oil filler cap

2. Dipstick

3. Maximum level mark

4. Tip of the engine oil dipstick

ZAUM1028

3

4

1

2

1. Engine oil drain bolt

2. Gasket

12

UBL1E0E0.book Page 10 Thursday, May 11, 2017 8:51 AM

Page 76 of 118

Periodic maintenance and adjustment

7-12

710. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

11. Reset the oil change indicator.

(See page 4-7.)

TIP

If the engine oil is changed before the

oil change indicator comes on (i.e. be-

fore the periodic oil change interval has

been reached), the indicator must be

reset after the oil change for the next

periodic oil change to be indicated at

the correct time.

EAU20067

Final transmission oil

The final transmission case must be

checked for oil leakage before each

ride. If any leakage is found, have a

Yamaha dealer check and repair the

scooter. In addition, the final transmis-

sion oil must be changed as follows at

the intervals specified in the periodic

maintenance and lubrication chart.

1. Start the engine, warm up the final

transmission oil by riding the

scooter for several minutes, and

then stop the engine.

2. Place the scooter on the center-

stand.

3. Place an oil pan under the final

transmission case to collect the

used oil.

4. Remove the final transmission oil

filler cap and its O-ring from the fi-

nal transmission case.

5. Remove the final transmission oil

drain bolt and its gasket to drain

the oil from the final transmission

case.

1. Final transmission oil filler cap

2. O-ring

3. Final transmission oil drain bolt

4. Gasket

2

1

3

4

UBL1E0E0.book Page 12 Thursday, May 11, 2017 8:51 AM

Page 77 of 118

Periodic maintenance and adjustment

7-13

7 6. Install the final transmission oil

drain bolt and its new gasket, and

then tighten the bolt to the speci-

fied torque.

7. Refill with the specified amount of

the recommended final transmis-

sion oil. WARNING! Make sure

that no foreign material enters

the final transmission case.

Make sure that no oil gets on

the tire or wheel.

[EWA11312]

8. Install the final transmission oil fill-

er cap and its new O-ring, and

then tighten the oil filler cap.

9. Check the final transmission case

for oil leakage. If oil is leaking,

check for the cause.

EAU20071

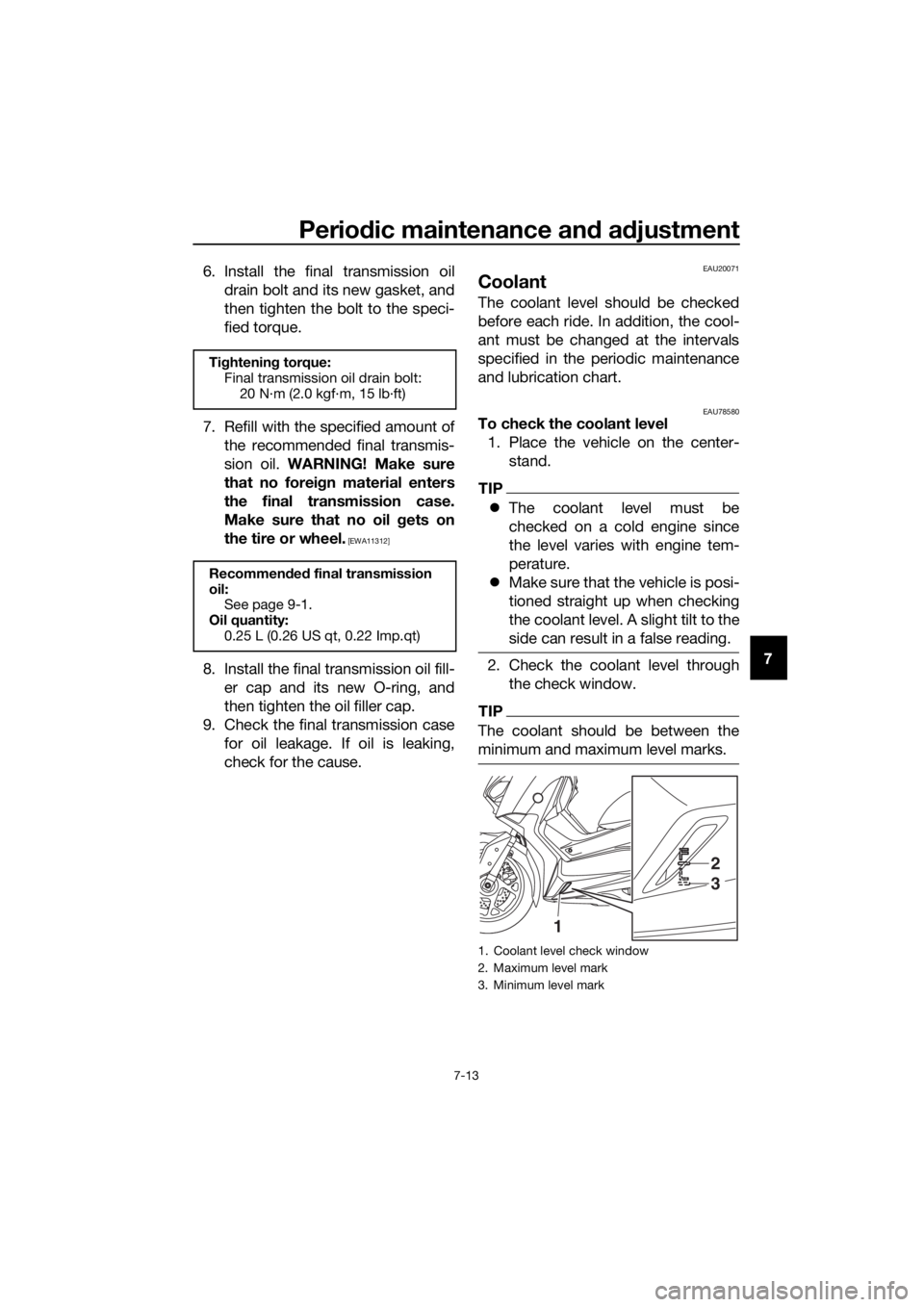

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU78580To check the coolant level

1. Place the vehicle on the center-

stand.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level through

the check window.

TIP

The coolant should be between the

minimum and maximum level marks.

Tightening torque:

Final transmission oil drain bolt:

20 N·m (2.0 kgf·m, 15 lb·ft)

Recommended final transmission

oil:

See page 9-1.

Oil quantity:

0.25 L (0.26 US qt, 0.22 Imp.qt)

1. Coolant level check window

2. Maximum level mark

3. Minimum level mark

1

2

3

UBL1E0E0.book Page 13 Thursday, May 11, 2017 8:51 AM