lock YAMAHA XSR 700 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: XSR 700, Model: YAMAHA XSR 700 2017Pages: 100, PDF Size: 7.24 MB

Page 30 of 100

Instrument and control functions

3-15

3

EAU63040

ABSThe Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake ped-

al. In this situation, continue to apply

the brakes and let the ABS work; do

not “pump” the brakes as this will re-

duce braking effectiveness.

WARNING

EWA16051

Always keep a sufficient distance

from the vehicle ahead to match the

riding speed even with ABS.

The ABS performs best with

long braking distances.

On certain surfaces, such as

rough or gravel roads, the brak-

ing distance may be longer with

the ABS than without.The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIPThe ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “click-

ing” noise can be heard from the

hydraulic control unit, and if the

brake lever or brake pedal is even

slightly applied, a vibration can be

felt at the lever and pedal, but

these do not indicate a malfunc-

tion.

This ABS has a test mode which

allows the owner to experience

the pulsation at the brake lever or

brake pedal when the ABS is op-

erating. However, special tools are

required, so please consult your

Yamaha dealer.NOTICE

ECA20100

Be careful not to damage the wheel

sensor or wheel sensor rotor; other-

wise, improper performance of the

ABS will result.

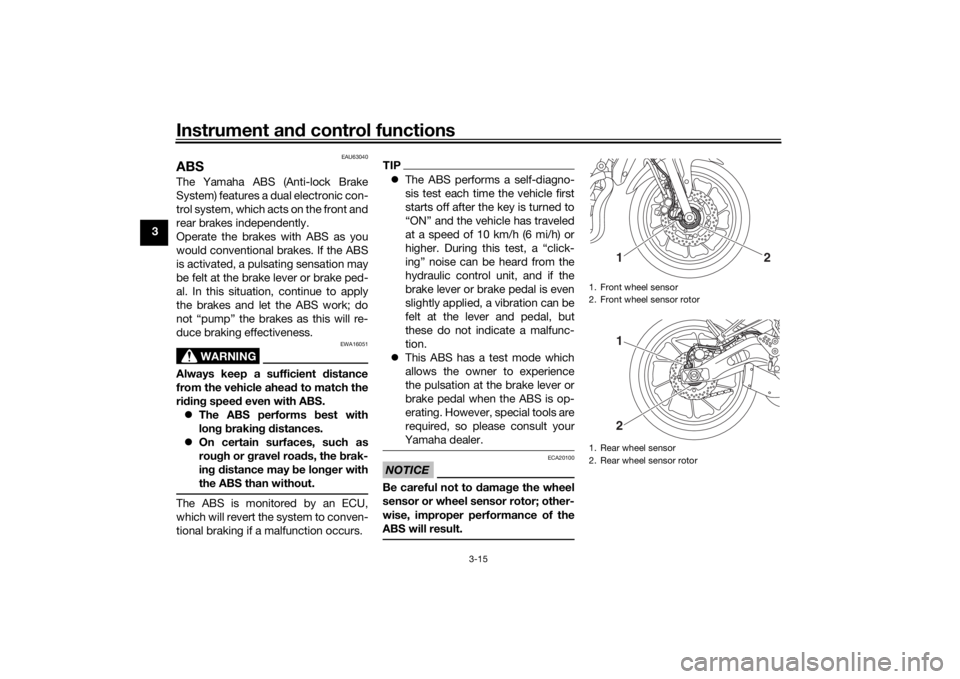

1. Front wheel sensor

2. Front wheel sensor rotor

1. Rear wheel sensor

2. Rear wheel sensor rotor

1

2

12

UB34E0E0.book Page 15 Friday, July 10, 2015 10:31 AM

Page 31 of 100

Instrument and control functions

3-16

3

EAU13075

Fuel tank capTo open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be

released and the fuel tank cap can be

opened.

To close the fuel tank cap

1. Push the fuel tank cap into posi-

tion with the key inserted in the

lock.

2. Turn the key counterclockwise to

the original position, remove it,

and then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11092

Make sure that the fuel tank cap is

properly closed after filling fuel.

Leaking fuel is a fire hazard.

EAU13222

FuelMake sure there is sufficient gasoline in

the tank.

WARNING

EWA10882

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, follow

these instructions.1. Before refueling, turn off the en-

gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters

and clothes dryers.

2. Do not overfill the fuel tank. When

refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank.

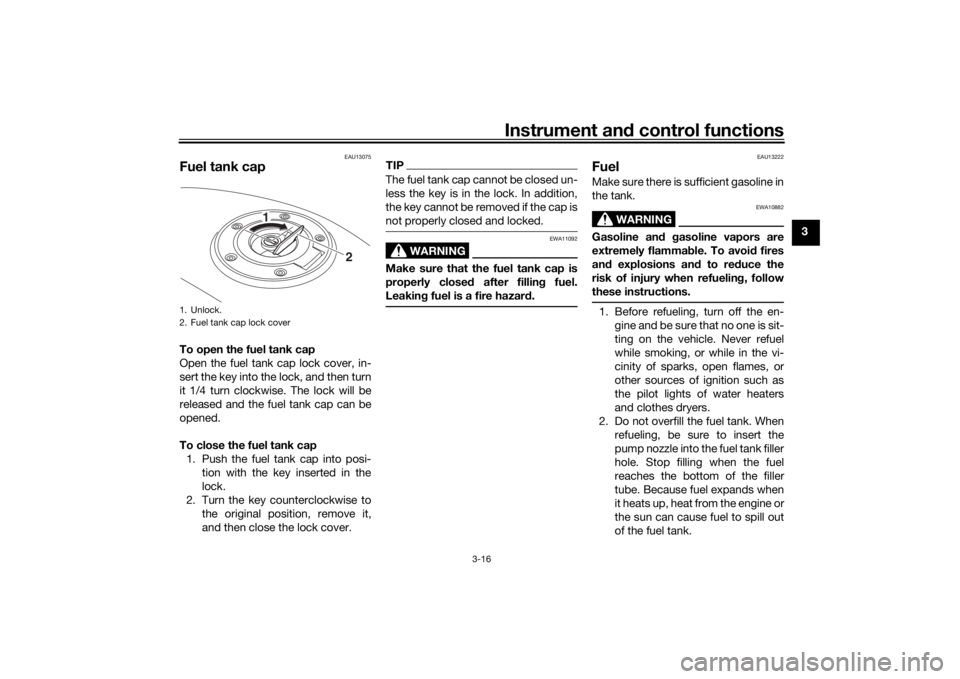

1. Unlock.

2. Fuel tank cap lock cover

2 1

UB34E0E0.book Page 16 Friday, July 10, 2015 10:31 AM

Page 33 of 100

Instrument and control functions

3-18

3

EAU55512

Fuel tank breather hose and

overflow hoseBefore operating the motorcycle:

Check each hose connection.

Check each hose for cracks or

damage, and replace if necessary.

Make sure that the end of each

hose is not blocked, and clean if

necessary.

Make sure that each hose is rout-

ed through the clamp.

Make sure that the paint mark on

each hose is below the clamp.

EAU13434

Catalytic converterThis model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10863

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

Make sure that the exhaust sys-

tem has cooled down before

doing any maintenance work.

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up of

heat.

NOTICE

ECA10702

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

pairable damage to the catalytic

converter.

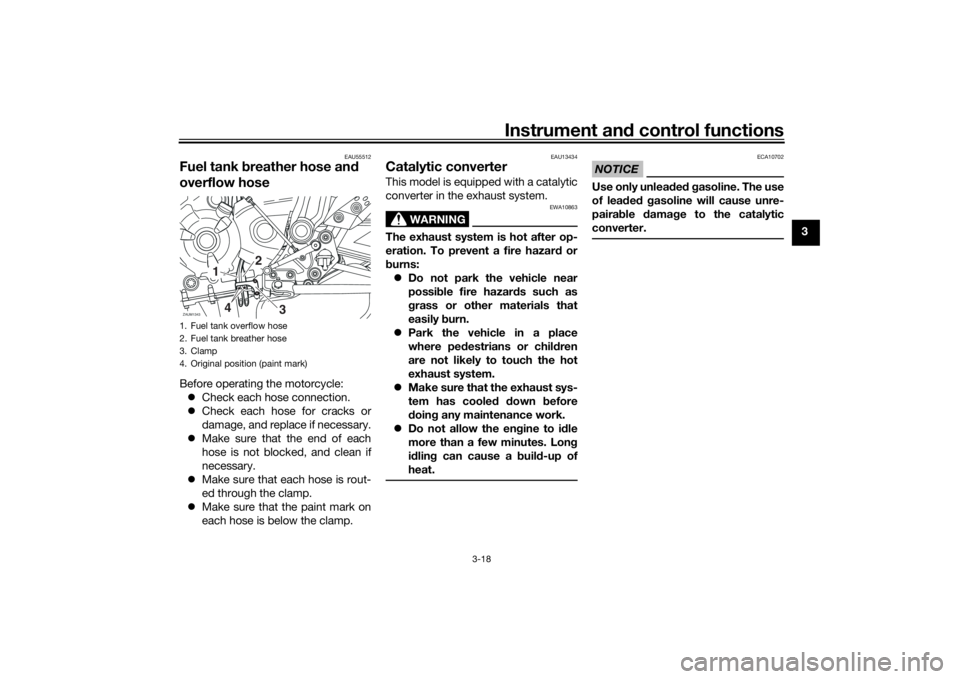

1. Fuel tank overflow hose

2. Fuel tank breather hose

3. Clamp

4. Original position (paint mark)ZAUM1343

1

2

3

4

UB34E0E0.book Page 18 Friday, July 10, 2015 10:31 AM

Page 34 of 100

Instrument and control functions

3-19

3

EAUM3740

SeatTo remove the seat

Insert the key into the seat lock, turn it

counterclockwise, and then pull the

seat off.

To install the seat

Insert the projection on the front of the

seat into the seat holder, orient the

seat in order to insert the seat bracket

into the seat lock, push the rear of the

seat down to lock it in place, and then

remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

EAUM3640

Helmet holding cableA helmet holding cable is located un-

der the seat. Use this cable in conjunc-

tion with the screwdriver to secure a

helmet to the vehicle.

To secure a helmet with the helmet

holding cable

1. Remove the seat. (See page 3-19.)

2. Remove the screwdriver from its

holders by pulling it up from the

left side, and then remove the hel-

met holding cable from the screw-

driver.

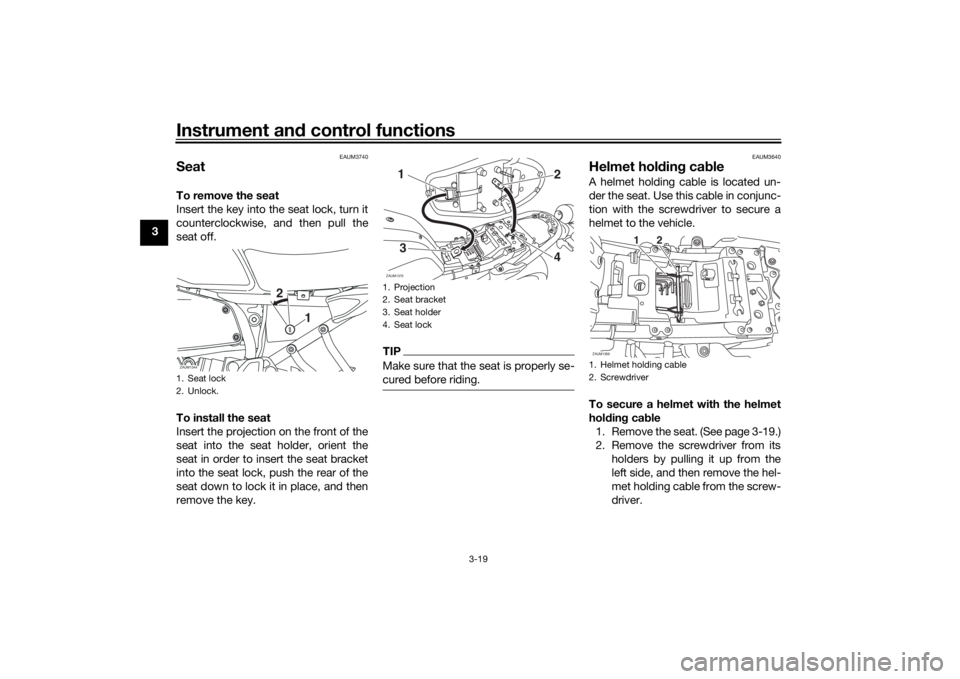

1. Seat lock

2. Unlock.ZAUM1344

2

1

1. Projection

2. Seat bracket

3. Seat holder

4. Seat lockZAUM1373

1

2

4

3

1. Helmet holding cable

2. ScrewdriverZAUM1359

12

UB34E0E0.book Page 19 Friday, July 10, 2015 10:31 AM

Page 56 of 100

Periodic maintenance and adjustment

6-9

6

EAU36111

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

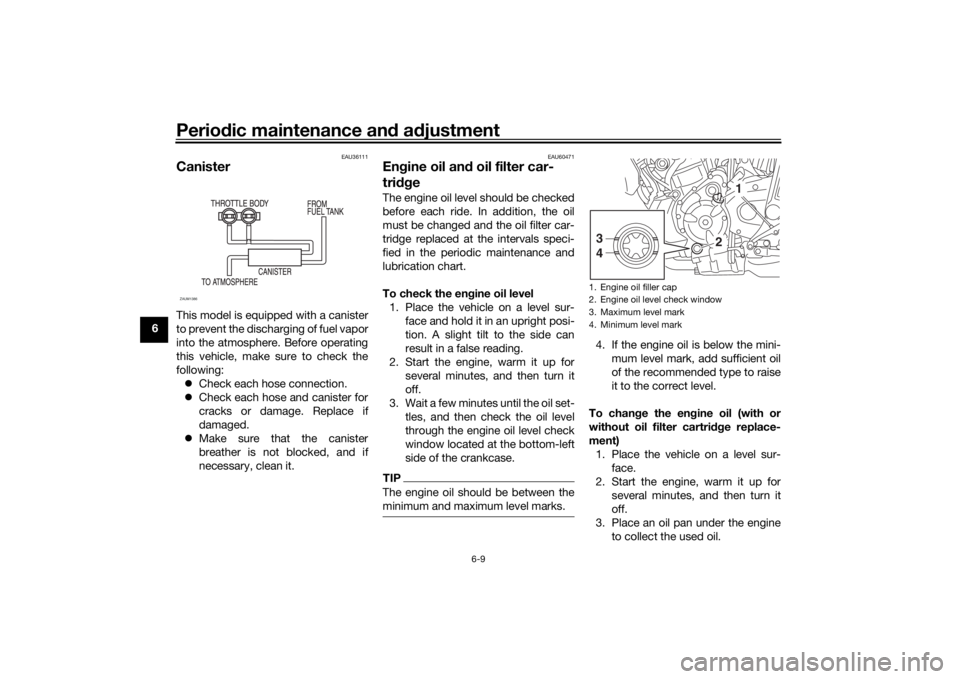

EAU60471

Engine oil and oil filter car-

tridgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level

1. Place the vehicle on a level sur-

face and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Wait a few minutes until the oil set-

tles, and then check the oil level

through the engine oil level check

window located at the bottom-left

side of the crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-

mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To change the engine oil (with or

without oil filter cartridge replace-

ment)

1. Place the vehicle on a level sur-

face.

2. Start the engine, warm it up for

several minutes, and then turn it

off.

3. Place an oil pan under the engine

to collect the used oil.

ZAUM1386

1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

1

2 3

4

UB34E0E0.book Page 9 Friday, July 10, 2015 10:31 AM

Page 66 of 100

Periodic maintenance and adjustment

6-19

6

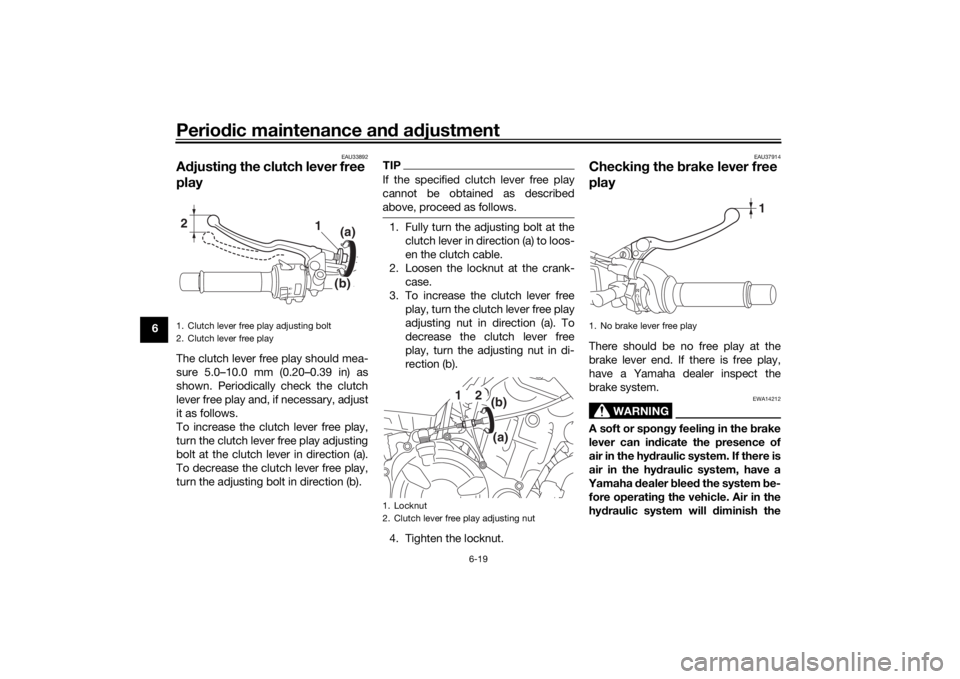

EAU33892

Adjusting the clutch lever free

playThe clutch lever free play should mea-

sure 5.0–10.0 mm (0.20–0.39 in) as

shown. Periodically check the clutch

lever free play and, if necessary, adjust

it as follows.

To increase the clutch lever free play,

turn the clutch lever free play adjusting

bolt at the clutch lever in direction (a).

To decrease the clutch lever free play,

turn the adjusting bolt in direction (b).

TIPIf the specified clutch lever free play

cannot be obtained as described

above, proceed as follows.1. Fully turn the adjusting bolt at the

clutch lever in direction (a) to loos-

en the clutch cable.

2. Loosen the locknut at the crank-

case.

3. To increase the clutch lever free

play, turn the clutch lever free play

adjusting nut in direction (a). To

decrease the clutch lever free

play, turn the adjusting nut in di-

rection (b).

4. Tighten the locknut.

EAU37914

Checking the brake lever free

playThere should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spongy feeling in the brake

lever can indicate the presence of

air in the hydraulic system. If there is

air in the hydraulic system, have a

Yamaha dealer bleed the system be-

fore operating the vehicle. Air in the

hydraulic system will diminish the

1. Clutch lever free play adjusting bolt

2. Clutch lever free play2

1

(b)(a)

1. Locknut

2. Clutch lever free play adjusting nut

1

2

(a)(b)

1. No brake lever free play

1

UB34E0E0.book Page 19 Friday, July 10, 2015 10:31 AM

Page 69 of 100

Periodic maintenance and adjustment

6-22

6 Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or dust

does not enter the brake fluid

reservoir when refilling. Water

will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock, and dirt may

clog the ABS hydraulic unit

valves.

NOTICE

ECA17641

Brake fluid may damage painted

surfaces or plastic parts. Always

clean up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brakefluid level goes down suddenly, have a

Yamaha dealer check the cause before

further riding.

EAU22733

Changing the brake fluidHave a Yamaha dealer change the

brake fluid at the intervals specified in

the periodic maintenance and lubrica-

tion chart. In addition, have the oil seals

of the master cylinders and calipers as

well as the brake hoses replaced at the

intervals listed below or whenever they

are damaged or leaking.

Oil seals: Replace every two

years.

Brake hoses: Replace every four

years.

UB34E0E0.book Page 22 Friday, July 10, 2015 10:31 AM

Page 70 of 100

Periodic maintenance and adjustment

6-23

6

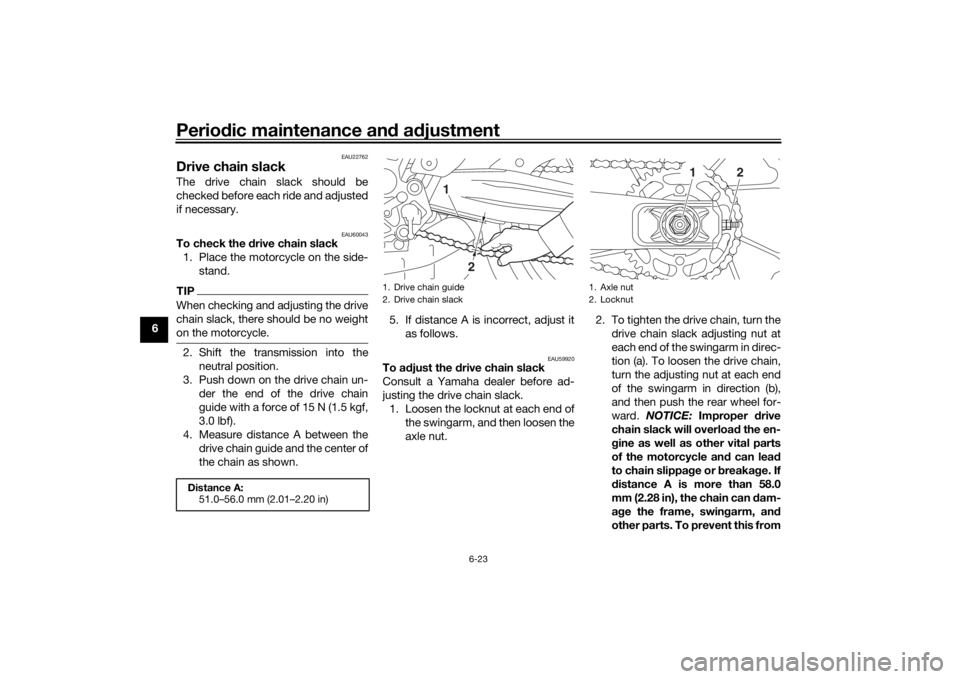

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU60043

To check the drive chain slack

1. Place the motorcycle on the side-

stand.TIPWhen checking and adjusting the drive

chain slack, there should be no weight

on the motorcycle.2. Shift the transmission into the

neutral position.

3. Push down on the drive chain un-

der the end of the drive chain

guide with a force of 15 N (1.5 kgf,

3.0 lbf).

4. Measure distance A between the

drive chain guide and the center of

the chain as shown.5. If distance A is incorrect, adjust it

as follows.

EAU59920

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack.

1. Loosen the locknut at each end of

the swingarm, and then loosen the

axle nut.2. To tighten the drive chain, turn the

drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward. NOTICE: Improper drive

chain slack will overload the en-

gine as well as other vital parts

of the motorcycle and can lead

to chain slippage or breakage. If

distance A is more than 58.0

mm (2.28 in), the chain can dam-

age the frame, swingarm, and

other parts. To prevent this from

Distance A:

51.0–56.0 mm (2.01–2.20 in)

1. Drive chain guide

2. Drive chain slack

2

1

1. Axle nut

2. Locknut

2

1

UB34E0E0.book Page 23 Friday, July 10, 2015 10:31 AM

Page 71 of 100

![YAMAHA XSR 700 2017 User Guide Periodic maintenance and adjustment

6-24

6 occurring, keep the drive chain

slack within the specified limits.

[ECA23070]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both YAMAHA XSR 700 2017 User Guide Periodic maintenance and adjustment

6-24

6 occurring, keep the drive chain

slack within the specified limits.

[ECA23070]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both](/img/51/53040/w960_53040-70.png)

Periodic maintenance and adjustment

6-24

6 occurring, keep the drive chain

slack within the specified limits.

[ECA23070]

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

3. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

4. Make sure that the drive chain

slack adjusting plates are in the

same position, the drive chain

slack is correct, and the drive

chain moves smoothly.

EAU23026

Cleaning and lubricating the

drive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lubricated

after washing the motorcycle, riding

in the rain or riding in wet areas.1. Clean the drive chain with kero-

sene and a small soft brush.

NOTICE: To prevent damaging

the O-rings, do not clean the

drive chain with steam cleaners,

high-pressure washers or inap-

propriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant. NOTICE: Do not use

engine oil or any other lubri-

cants for the drive chain, as they

1. Drive chain slack adjusting nut

1

(a)(b)

1. Alignment marks

2. Drive chain slack adjusting plate

Tightening torques:

Axle nut:

105 Nm (10.5 m·kgf, 76 ft·lbf)

Locknut:

16 Nm (1.6 m·kgf, 12 ft·lbf)

2

1

UB34E0E0.book Page 24 Friday, July 10, 2015 10:31 AM

Page 79 of 100

Periodic maintenance and adjustment

6-32

6

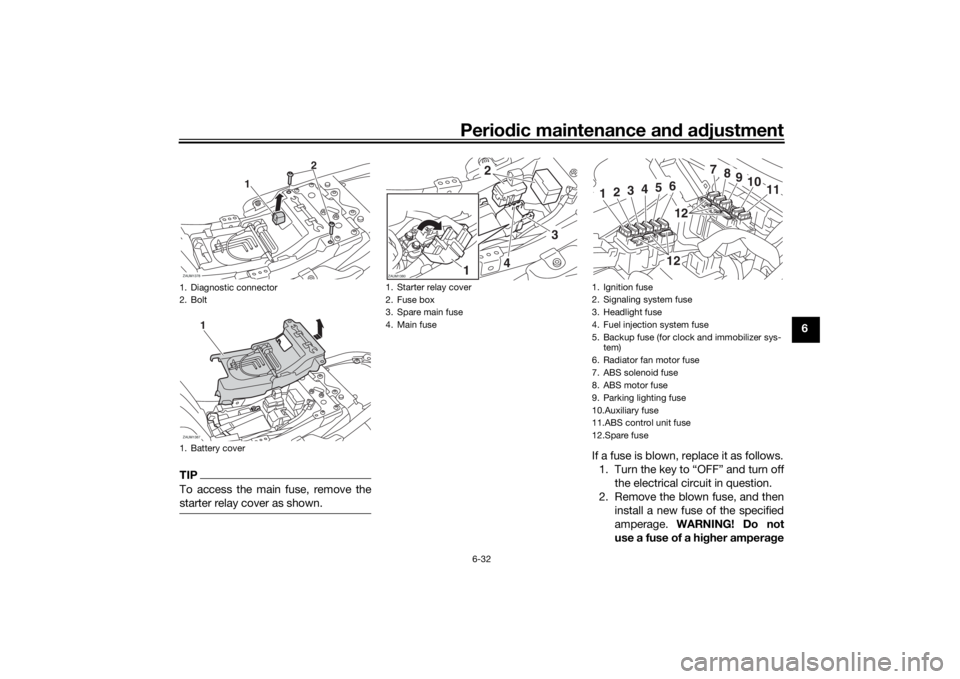

TIPTo access the main fuse, remove the

starter relay cover as shown.

If a fuse is blown, replace it as follows.

1. Turn the key to “OFF” and turn off

the electrical circuit in question.

2. Remove the blown fuse, and then

install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

1. Diagnostic connector

2. Bolt

1. Battery coverZAUM1378

2

1

ZAUM1387

1

1. Starter relay cover

2. Fuse box

3. Spare main fuse

4. Main fuseZAUM1380

2

3

4

1

1. Ignition fuse

2. Signaling system fuse

3. Headlight fuse

4. Fuel injection system fuse

5. Backup fuse (for clock and immobilizer sys-

tem)

6. Radiator fan motor fuse

7. ABS solenoid fuse

8. ABS motor fuse

9. Parking lighting fuse

10.Auxiliary fuse

11.ABS control unit fuse

12.Spare fuse

7

8

9

10

11

1

2

3

4

5

61212

UB34E0E0.book Page 32 Friday, July 10, 2015 10:31 AM