oil YAMAHA XSR 700 2021 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2021, Model line: XSR 700, Model: YAMAHA XSR 700 2021Pages: 98, PDF Size: 3.85 MB

Page 56 of 98

Periodic maintenance an d a djustment

6-10

6

EAU36113

CanisterThis model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather is not blocked, and if

necessary, clean it.

EAU60474

Engine oil an d oil filter car-

tri dgeThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

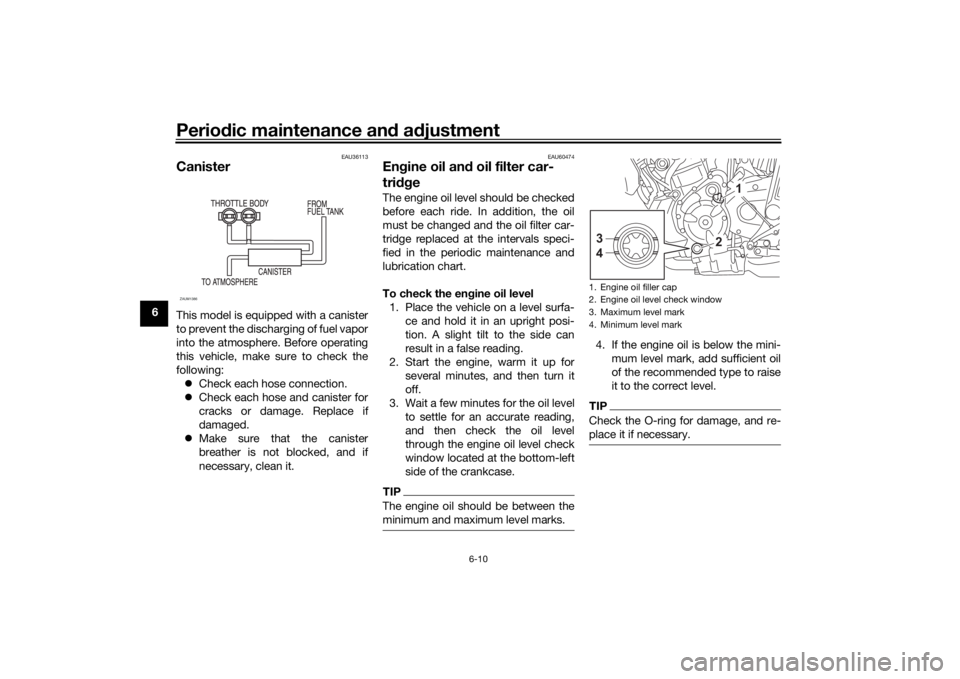

To check the en gine oil level

1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes for the oil level to settle for an accurate reading,

and then check the oil level

through the engine oil level check

window located at the bottom-left

side of the crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.TIPCheck the O-ring for damage, and re-

place it if necessary.

ZAUM1386

1. Engine oil filler cap

2. Engine oil level check window

3. Maximum level mark

4. Minimum level mark

1

2

3

4

UBJVE0E0.book Page 10 Wednesday, December 23, 2020 8:59 AM

Page 57 of 98

Periodic maintenance an d a djustment

6-11

6

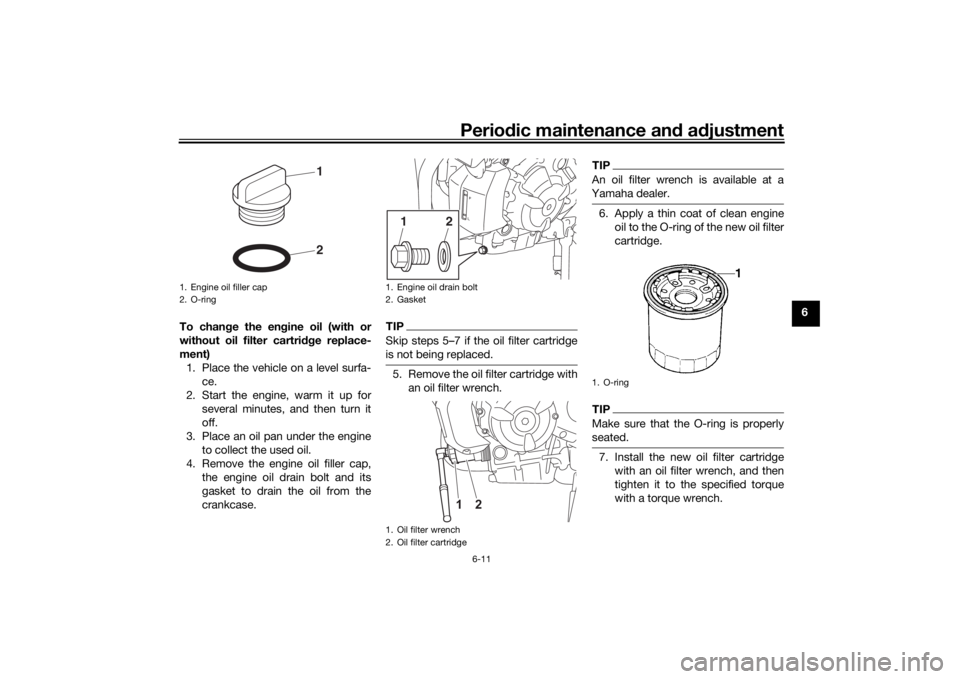

To chan ge the en gine oil (with or

without oil filter cartri dge replace-

ment) 1. Place the vehicle on a level surfa- ce.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the engine to collect the used oil.

4. Remove the engine oil filler cap, the engine oil drain bolt and its

gasket to drain the oil from the

crankcase.

TIPSkip steps 5–7 if the oil filter cartridge

is not being replaced.5. Remove the oil filter cartridge withan oil filter wrench.

TIPAn oil filter wrench is available at a

Yamaha dealer.6. Apply a thin coat of clean engineoil to the O-ring of the new oil filter

cartridge.TIPMake sure that the O-ring is properly

seated.7. Install the new oil filter cartridgewith an oil filter wrench, and then

tighten it to the specified torque

with a torque wrench.

1. Engine oil filler cap

2. O-ring

21

1. Engine oil drain bolt

2. Gasket

1. Oil filter wrench

2. Oil filter cartridge

2

1

2

1

1. O-ring

UBJVE0E0.book Page 11 Wednesday, December 23, 2020 8:59 AM

Page 58 of 98

Periodic maintenance an d a djustment

6-12

6

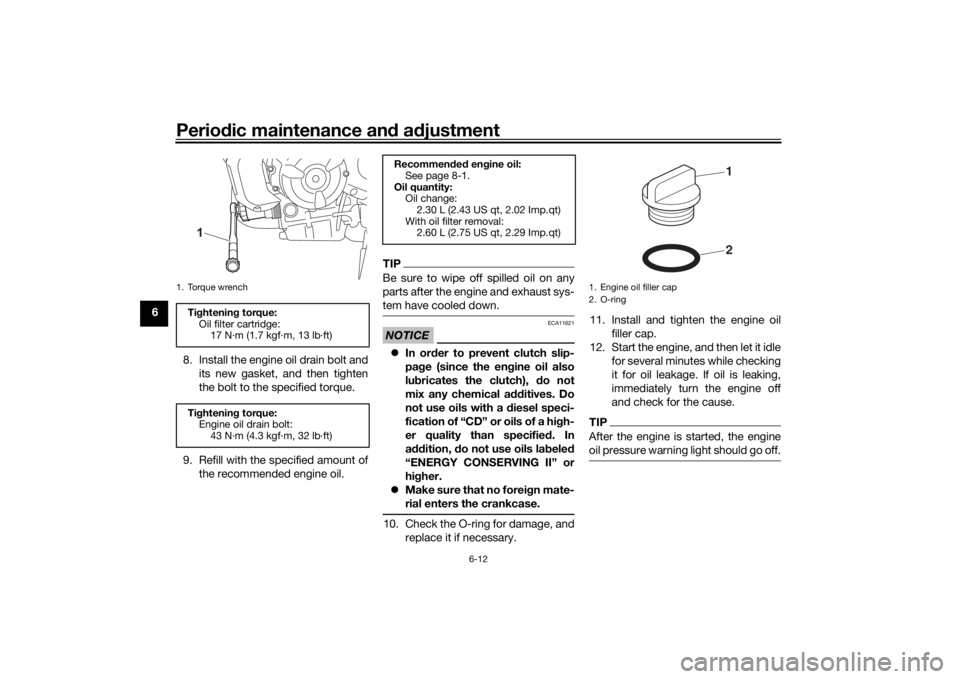

8. Install the engine oil drain bolt andits new gasket, and then tighten

the bolt to the specified torque.

9. Refill with the specified amount of the recommended engine oil.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.10. Check the O-ring for damage, and replace it if necessary. 11. Install and tighten the engine oil

filler cap.

12. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIPAfter the engine is started, the engine

oil pressure warning light should go off.

1. Torque wrenchTightenin g torque:

Oil filter cartridge: 17 N·m (1.7 kgf·m, 13 lb·ft)

Ti ghtenin g torque:

Engine oil drain bolt:

43 N·m (4.3 kgf·m, 32 lb·ft)1

Recommen ded en gine oil:

See page 8-1.

Oil quantity: Oil change:

2.30 L (2.43 US qt, 2.02 Imp.qt)

With oil filter removal: 2.60 L (2.75 US qt, 2.29 Imp.qt)

1. Engine oil filler cap

2. O-ring

21

UBJVE0E0.book Page 12 Wednesday, December 23, 2020 8:59 AM

Page 59 of 98

Periodic maintenance an d a djustment

6-13

6

NOTICE

ECA20860

If the oil pressure warnin g li ght flick-

ers or remains on even if the oil level

is correct, immed iately turn the en-

g ine off an d have a Yamaha d ealer

check the vehicle.13. Turn the engine off, wait a few mi- nutes for the oil level to settle for

an accurate reading, and then

check the oil level and correct it if

necessary.

EAU85450

Why Yamalu beYAMALUBE oil is a Genuine YAMAHA

Part born of the engineers’ passion

and belief that engine oil is an impor-

tant liquid engine component. We form

teams of specialists in the fields of me-

chanical engineering, chemistry, elec-

tronics and track testing, and have

them develop the engine together with

the oil it will use. Yamalube oils take full

advantage of the base oil’s qualities

and blend in the ideal balance of addi-

tives to make sure the final oil clears

our performance standards. Thus,

Yamalube mineral, semisynthetic and

synthetic oils have their own distinct

characters and value. Yamaha’s expe-

rience gained over many years of re-

search and development into oil since

the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

EAUS1203

CoolantThe coolant level should be checked

regularly. In addition, the coolant must

be changed at the intervals specified in

the periodic maintenance chart.TIPIf genuine Yamaha coolant is not avail-

able, use an ethylene glycol antifreeze

containing corrosion inhibitors for alu-

minum engines and mix with distilled

water at a 1:1 ratio.

EAU20097

To check the coolant level

Since the coolant level varies with en-

gine temperature, check when the en-

gine is cold.

1. Park the vehicle on a level surface.

Recommen ded coolant:

YAMALUBE coolant

Coolant quantity: Coolant reservoir (max level mark): 0.25 L (0.26 US qt, 0.22 Imp.qt)

Radiator (including all routes): 1.60 L (1.69 US qt, 1.41 Imp.qt)

UBJVE0E0.book Page 13 Wednesday, December 23, 2020 8:59 AM

Page 68 of 98

Periodic maintenance an d a djustment

6-22

6

Use only the specified b rake flu-

i d ; otherwise, the ru bber seals

may deteriorate, causin g leak-

a g e.

Refill with the same type of

brake flui d. A ddin g a brake flui d

other than DOT 4 may result in a

harmful chemical reaction.

Be careful that water or d ust

d oes not enter the brake flui d

reservoir when refillin g. Water

will si gnificantly lower the boil-

in g point of the flui d an d may re-

sult in vapor lock, an d d irt may

clo g the ABS hy draulic unit

valves.

NOTICE

ECA17641

Brake flui d may damag e painted

surfaces or plastic parts. Always

clean up spille d flui d imme diately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake

system leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. If the brake fluid level goes down suddenly, have a

Yamaha dealer check the cause before further riding.

EAU22734

Chan gin g the brake flui dHave a Yamaha dealer change the

brake fluid every 2 years. In addition,

have the seals of the master cylinders

and brake calipers, as well as the brake

hoses replaced at the intervals listed

below or sooner if they are damaged or

leaking.

Brake seals: every 2 years

Brake hoses: every 4 years

UBJVE0E0.book Page 22 Wednesday, December 23, 2020 8:59 AM

Page 70 of 98

Periodic maintenance an d a djustment

6-24

6

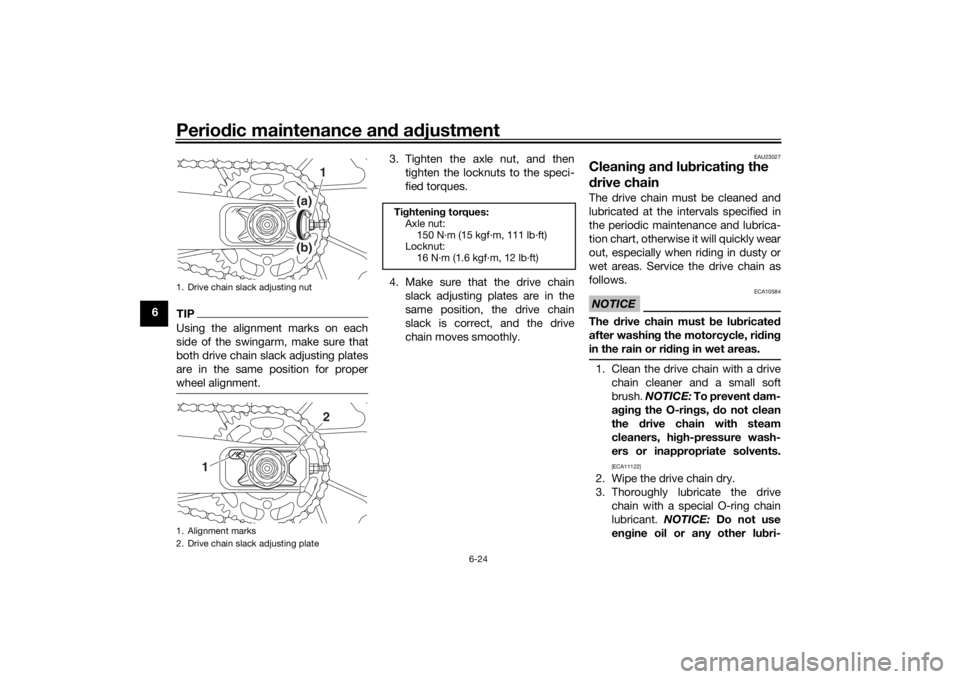

TIPUsing the alignment marks on each

side of the swingarm, make sure that

both drive chain slack adjusting plates

are in the same position for proper

wheel alignment.

3. Tighten the axle nut, and then

tighten the locknuts to the speci-

fied torques.

4. Make sure that the drive chain slack adjusting plates are in the

same position, the drive chain

slack is correct, and the drive

chain moves smoothly.

EAU23027

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Clean the drive chain with a drive

chain cleaner and a small soft

brush. NOTICE: To prevent dam-

a g in g the O-rin gs, do not clean

the drive chain with steam

cleaners, hi gh-pressure wash-

ers or inappropriate solvents.

[ECA11122]

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a special O-ring chain

lubricant. NOTICE: Do not use

en gine oil or any other lu bri-

1. Drive chain slack adjusting nut

1. Alignment marks

2. Drive chain slack adjusting plate

1

(a)(b)

2

1

Ti ghtenin g torques:

Axle nut: 150 N·m (15 kgf·m, 111 lb·ft)

Locknut:

16 N·m (1.6 kgf·m, 12 lb·ft)

UBJVE0E0.book Page 24 Wednesday, December 23, 2020 8:59 AM

Page 74 of 98

Periodic maintenance an d a djustment

6-28

6

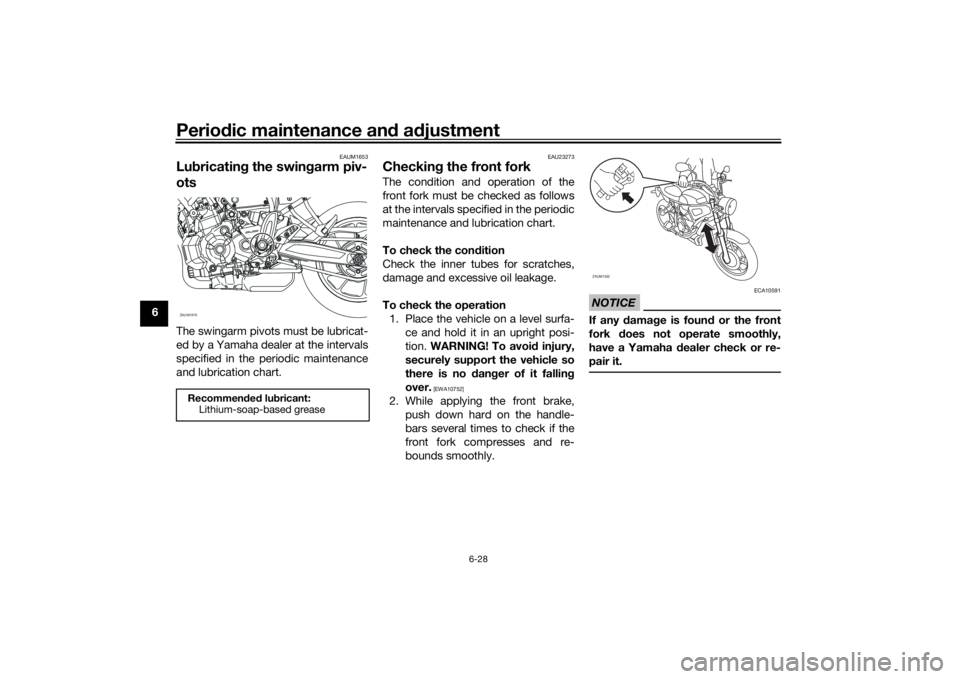

EAUM1653

Lub ricatin g the swin garm piv-

otsThe swingarm pivots must be lubricat-

ed by a Yamaha dealer at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU23273

Checkin g the front forkThe condition and operation of the

front fork must be checked as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

To check the con dition

Check the inner tubes for scratches,

damage and excessive oil leakage.

To check the operation 1. Place the vehicle on a level surfa- ce and hold it in an upright posi-

tion. WARNING! To avoi d injury,

securely support the vehicle so

there is no dan ger of it fallin g

over.

[EWA10752]

2. While applying the front brake, push down hard on the handle-

bars several times to check if the

front fork compresses and re-

bounds smoothly.

NOTICE

ECA10591

If any d amage is foun d or the front

fork does not operate smoothly,

have a Yamaha dealer check or re-

pair it.

Recommen ded lu bricant:

Lithium-soap-based greaseZAUM1978

ZAUM1352

UBJVE0E0.book Page 28 Wednesday, December 23, 2020 8:59 AM

Page 79 of 98

Periodic maintenance an d a djustment

6-33

6

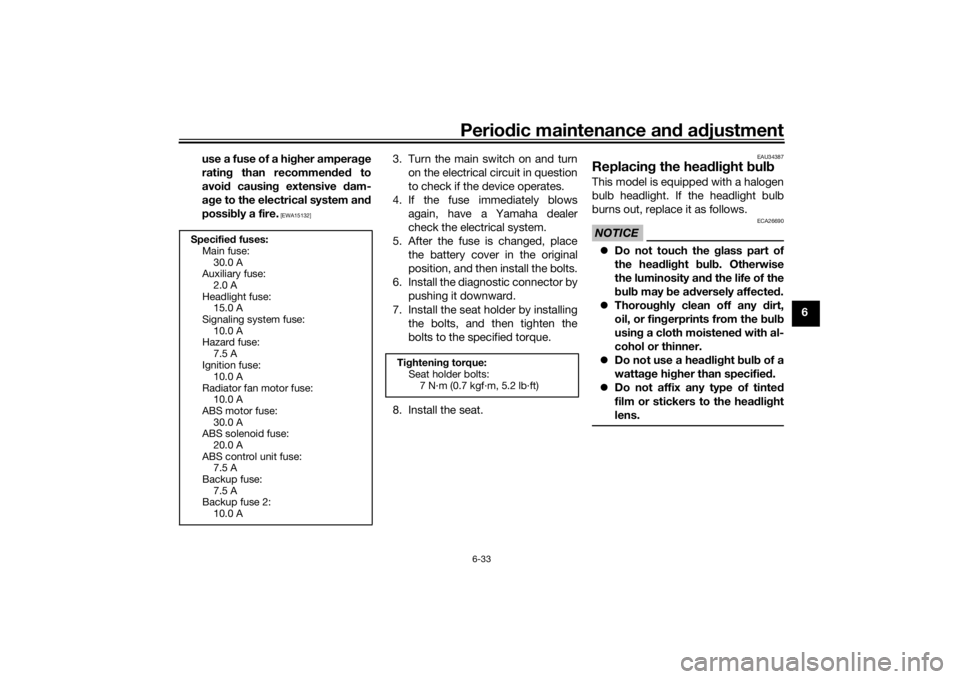

use a fuse of a hi

gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the main switch on and turn

on the electrical circuit in question

to check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

5. After the fuse is changed, place the battery cover in the original

position, and then install the bolts.

6. Install the diagnostic connector by pushing it downward.

7. Install the seat holder by installing the bolts, and then tighten the

bolts to the specified torque.

8. Install the seat.

EAU34387

Replacin g the hea dlig ht bul bThis model is equipped with a halogen

bulb headlight. If the headlight bulb

burns out, replace it as follows.NOTICE

ECA26690

Do not touch the glass part of

the hea dlig ht bul b. Otherwise

the luminosity an d the life of the

b ul b may b e adversely affected .

Thorou ghly clean off any d irt,

oil, or fin gerprints from the bul b

usin g a cloth moistene d with al-

cohol or thinner.

Do not use a hea dlig ht bul b of a

watta ge hi gher than specified .

Do not affix any type of tinted

film or stickers to the hea dlig ht

lens.

Specifie d fuses:

Main fuse: 30.0 A

Auxiliary fuse:

2.0 A

Headlight fuse: 15.0 A

Signaling system fuse: 10.0 A

Hazard fuse:

7.5 A

Ignition fuse: 10.0 A

Radiator fan motor fuse: 10.0 A

ABS motor fuse:

30.0 A

ABS solenoid fuse: 20.0 A

ABS control unit fuse: 7.5 A

Backup fuse:

7.5 A

Backup fuse 2: 10.0 A

Tightenin g torque:

Seat holder bolts: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

UBJVE0E0.book Page 33 Wednesday, December 23, 2020 8:59 AM

Page 87 of 98

Motorcycle care and stora ge

7-2

7

chemicals such as, solvents,

g

asoline, rust removers, b rake

flui d, or antifreeze, etc.

Before washin g

1. Park the vehicle out of direct sun- light and allow it to cool. This will

help avoid water spots.

2. Make sure all caps, covers, elec- trical couplers and connectors are

tightly installed.

3. Cover the muffler end with a plas- tic bag and a strong rubber band.

4. Pre-soak stubborn stains like in- sects or bird droppings with a wet

towel for a few minutes.

5. Remove road grime and oil stains with a quality degreasing agent

and a plastic-bristle brush or

sponge. NOTICE: Do not use

d eg reasin g a gent on areas re-

quirin g lu brication such as

seals, gaskets, an d wheel axles.

Follow pro duct instructions.

[ECA26290]

Washin g

1. Rinse off any degreaser and spray down the vehicle with a garden

hose. Use only enough pressure

to do the job. Avoid spraying wa-

ter directly into the muffler, instru-

ment panel, air inlet, or other inner

areas such as underseat storage

compartments.

2. Wash the vehicle with a quality au- tomotive-type detergent mixed

with cool water and a soft, clean

towel or sponge. Use an old tooth-

brush or plastic-bristle brush for

hard-to-reach places. NOTICE:

Use col d water if the vehicle has

b een exposed to salt. Warm wa-

ter will increase salt’s corrosive

properties.

[ECA26301]

3. For windshield-equipped vehicles: Clean the windshield with a soft

towel or sponge dampened with

water and a pH neutral detergent.

If necessary, use a high-quality

windshield cleaner or polish for

motorcycles. NOTICE: Never use

any stron g chemicals to clean

the wind shield. Additionally,

some cleanin g compoun ds for plastic may scratch the win

d-

shiel d, so b e sure to test all

cleanin g pro ducts before gen-

eral application.

[ECA26310]

4. Rinse off thoroughly with clean water. Be sure to remove all deter-

gent residues, as they can be

harmful to plastic parts.

After washin g

1. Dry the vehicle with a chamois or absorbent towel, preferably mi-

crofiber terrycloth.

2. For drive chain-equipped models: Dry and then lubricate the drive

chain to prevent rust.

3. Use a chrome polish to shine chrome, aluminum, and stainless

steel parts. Often the thermally in-

duced discoloring of stainless

steel exhaust systems can be re-

moved through polishing.

4. Apply a corrosion protection spray on all metal parts including

chrome or nickel-plated surfaces.

WARNING! Do not apply sili- cone or oil spray to seats, han d

g rips, ru bber foot pe gs or tire

trea ds. Otherwise these parts

UBJVE0E0.book Page 2 Wednesday, December 23, 2020 8:59 AM

Page 89 of 98

Motorcycle care and stora ge

7-4

7

1. Make all necessary repairs and

perform any outstanding mainte-

nance.

2. Follow all instructions in the Care section of this chapter.

3. Fill up the fuel tank, adding fuel stabilizer according to product in-

structions. Run the engine for 5

minutes to distribute treated fuel

through the fuel system.

4. For vehicles equipped with a fuel cock: Turn the fuel cock lever to

the off position.

5. For vehicles with a carburetor: To prevent fuel deposits from build-

ing up, drain the fuel in the carbu-

retor float chamber into a clean

container. Retighten the drain bolt

and pour the fuel back into the fuel

tank.

6. Use a quality engine fogging oil according to product instructions

to protect internal engine compo-

nents from corrosion. If engine

fogging oil is not available, per-

form the following steps for each

cylinder:a. Remove the spark plug cap and spark plug. b. Pour a teaspoonful of engine

oil into the spark plug bore.

c. Install the spark plug cap onto the spark plug, and then place

the spark plug on the cylinder

head so that the electrodes are

grounded. (This will limit spark-

ing during the next step.)

d. Turn the engine over several times with the starter. (This will

coat the cylinder wall with oil.)

WARNING! To prevent dam-

a g e or injury from sparkin g,

make sure to groun d the

spark plu g electro des while

turnin g the en gine over.

[EWA10952]

e. Remove the spark plug cap

from the spark plug, and then

install the spark plug and the

spark plug cap.

7. Lubricate all control cables, piv- ots, levers and pedals, as well as

the sidestand and centerstand (if

equipped).

8. Check and correct the tire air pressure, and then lift the vehicle

so that all wheels are off the

ground. Otherwise, turn the wheels a little once a month in or-

der to prevent the tires from be-

coming degraded in one spot.

9. Cover the muffler outlet with a plastic bag to prevent moisture

from entering it.

10. Remove the battery and fully char- ge it, or attach a maintenance

charger to keep the battery opti-

mally charged. NOTICE: Confirm

that the battery an d its char ger

are compati ble. Do not char ge a

VRLA battery with a convention-

al char ger.

[ECA26330]

TIP If the battery will be removed,

charge it once a month and store

it in a temperate location between

0-30 °C (32-90 °F).

See page 6-29 for more informa-

tion on charging and storing the

battery.

UBJVE0E0.book Page 4 Wednesday, December 23, 2020 8:59 AM