warning light YAMAHA XT1200Z 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XT1200Z, Model: YAMAHA XT1200Z 2013Pages: 108, PDF Size: 2.86 MB

Page 35 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-20

3

EAU49481

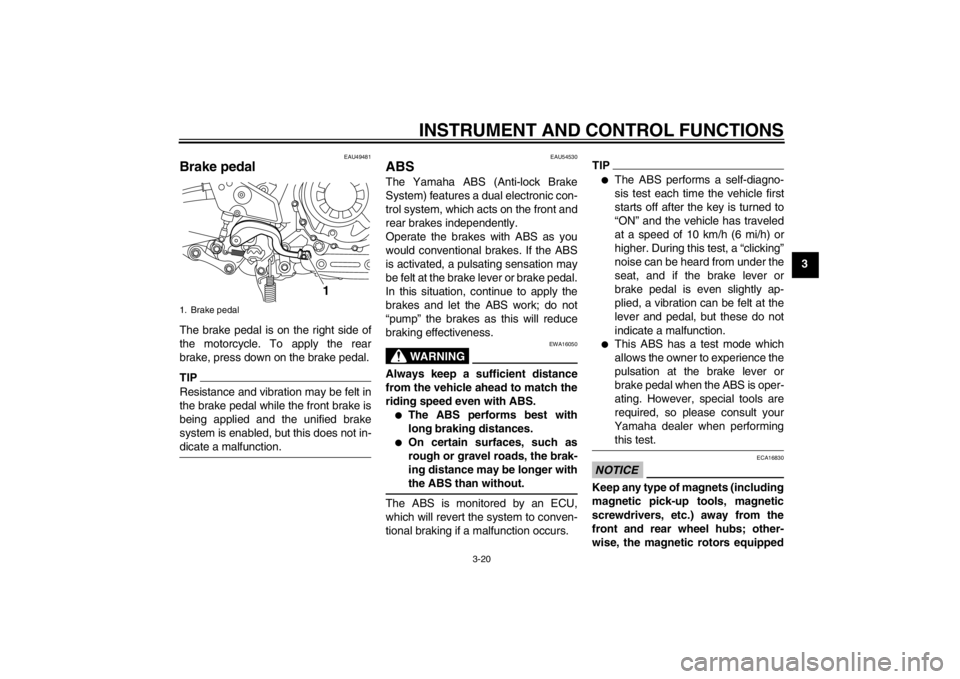

Brake pedal The brake pedal is on the right side of

the motorcycle. To apply the rear

brake, press down on the brake pedal.TIPResistance and vibration may be felt in

the brake pedal while the front brake is

being applied and the unified brake

system is enabled, but this does not in-

dicate a malfunction.

EAU54530

ABS The Yamaha ABS (Anti-lock Brake

System) features a dual electronic con-

trol system, which acts on the front and

rear brakes independently.

Operate the brakes with ABS as you

would conventional brakes. If the ABS

is activated, a pulsating sensation may

be felt at the brake lever or brake pedal.

In this situation, continue to apply the

brakes and let the ABS work; do not

“pump” the brakes as this will reduce

braking effectiveness.

WARNING

EWA16050

Always keep a sufficient distance

from the vehicle ahead to match the

riding speed even with ABS.●

The ABS performs best with

long braking distances.

●

On certain surfaces, such as

rough or gravel roads, the brak-

ing distance may be longer with

the ABS than without.

The ABS is monitored by an ECU,

which will revert the system to conven-

tional braking if a malfunction occurs.

TIP●

The ABS performs a self-diagno-

sis test each time the vehicle first

starts off after the key is turned to

“ON” and the vehicle has traveled

at a speed of 10 km/h (6 mi/h) or

higher. During this test, a “clicking”

noise can be heard from under the

seat, and if the brake lever or

brake pedal is even slightly ap-

plied, a vibration can be felt at the

lever and pedal, but these do not

indicate a malfunction.

●

This ABS has a test mode which

allows the owner to experience the

pulsation at the brake lever or

brake pedal when the ABS is oper-

ating. However, special tools are

required, so please consult your

Yamaha dealer when performing this test.

NOTICE

ECA16830

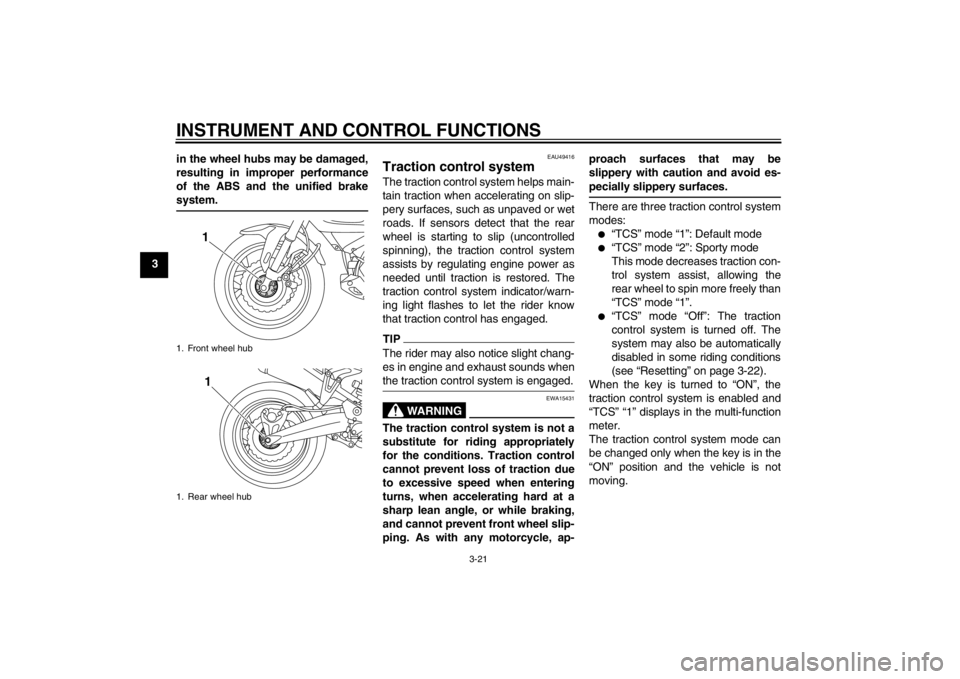

Keep any type of magnets (including

magnetic pick-up tools, magnetic

screwdrivers, etc.) away from the

front and rear wheel hubs; other-

wise, the magnetic rotors equipped

1. Brake pedal

1

U23PE3E0.book Page 20 Monday, July 30, 2012 8:44 AM

Page 36 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-21

3in the wheel hubs may be damaged,

resulting in improper performance

of the ABS and the unified brake

system.

EAU49416

Traction control system The traction control system helps main-

tain traction when accelerating on slip-

pery surfaces, such as unpaved or wet

roads. If sensors detect that the rear

wheel is starting to slip (uncontrolled

spinning), the traction control system

assists by regulating engine power as

needed until traction is restored. The

traction control system indicator/warn-

ing light flashes to let the rider know

that traction control has engaged.TIPThe rider may also notice slight chang-

es in engine and exhaust sounds when

the traction control system is engaged.

WARNING

EWA15431

The traction control system is not a

substitute for riding appropriately

for the conditions. Traction control

cannot prevent loss of traction due

to excessive speed when entering

turns, when accelerating hard at a

sharp lean angle, or while braking,

and cannot prevent front wheel slip-

ping. As with any motorcycle, ap- proach surfaces that may be

slippery with caution and avoid es-

pecially slippery surfaces.

There are three traction control system

modes:●

“TCS” mode “1”: Default mode

●

“TCS” mode “2”: Sporty mode

This mode decreases traction con-

trol system assist, allowing the

rear wheel to spin more freely than

“TCS” mode “1”.

●

“TCS” mode “Off”: The traction

control system is turned off. The

system may also be automatically

disabled in some riding conditions

(see “Resetting” on page 3-22).

When the key is turned to “ON”, the

traction control system is enabled and

“TCS” “1” displays in the multi-function

meter.

The traction control system mode can

be changed only when the key is in the

“ON” position and the vehicle is not

moving.

1. Front wheel hub

1. Rear wheel hub

11

U23PE3E0.book Page 21 Monday, July 30, 2012 8:44 AM

Page 37 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-22

3

TIPUse “TCS” mode “Off” to help free the

rear wheel if the motorcycle gets stuck

in mud, sand, or other soft surfaces.NOTICE

ECA16800

Use only the specified tires. (See

page 6-18.) Using different sized

tires will prevent the traction control

system from controlling tire rotation

accurately.Setting the traction control system

WARNING

EWA15440

Be sure to stop the vehicle before

making any setting changes to the

traction control system. Changing

settings while riding can distract the

operator and increase the risk of an

accident.Push the traction control system switch

on the multi-function meter for less than

one second to change between “TCS”

modes “1” and “2”. Push the switch for

at least two seconds to select “TCS”

mode “Off” and turn the traction controlsystem off. Push the switch again to re-

turn to the previously selected mode “1”

or “2”.

Resetting

The traction control system will be dis-

abled in the following conditions:

●

The rear wheel is rotated with the

centerstand down and the key in

the “ON” position.

●

Either the front wheel or rear wheel

comes off the ground while riding.

●

Excessive rear wheel spinning

If the traction control system has been

disabled, both the traction control sys-

tem indicator/warning light and the en-

gine trouble warning light come on. To reset the traction control system:

Turn the key to “OFF”. Wait at least one

second, then turn the key back to “ON”.

The traction control system indica-

tor/warning light should go off and the

system will be enabled. The engine

trouble warning light should go off after

the motorcycle reaches at least 20

km/h (12 mi/h). If the traction control

system indicator light/warning light

and/or engine trouble warning light still

remain on after resetting, the motorcy-

cle may still be ridden; however, have a

Yamaha dealer check the motorcycle

as soon as possible.

1. Traction control system switch

2. Traction control system mode display

2

1

U23PE3E0.book Page 22 Monday, July 30, 2012 8:44 AM

Page 38 of 108

INSTRUMENT AND CONTROL FUNCTIONS

3-23

3

EAU13074

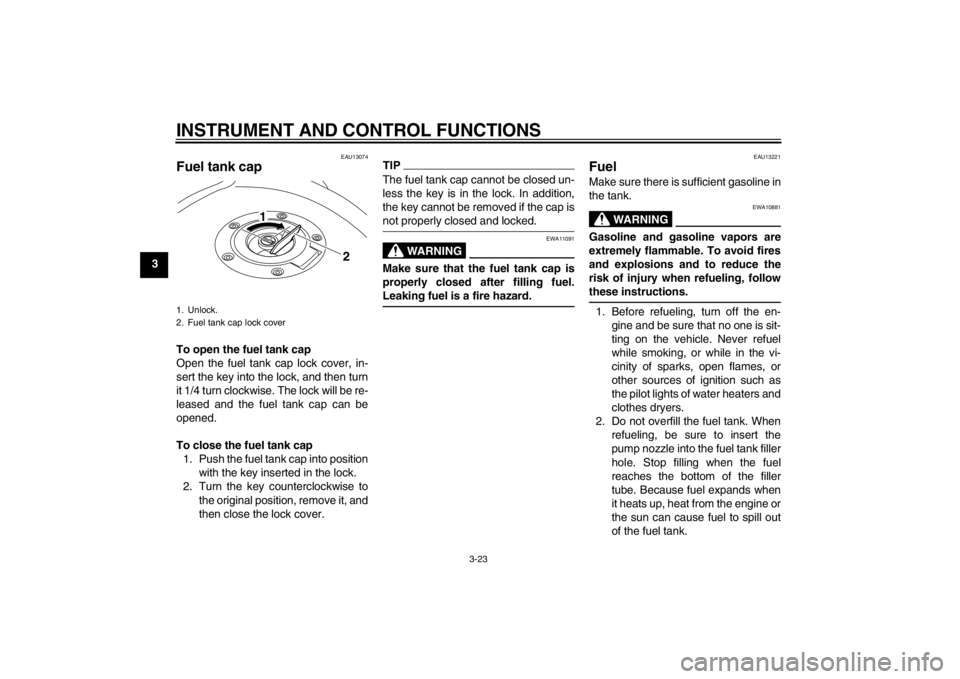

Fuel tank cap To open the fuel tank cap

Open the fuel tank cap lock cover, in-

sert the key into the lock, and then turn

it 1/4 turn clockwise. The lock will be re-

leased and the fuel tank cap can be

opened.

To close the fuel tank cap1. Push the fuel tank cap into position with the key inserted in the lock.

2. Turn the key counterclockwise to the original position, remove it, and

then close the lock cover.

TIPThe fuel tank cap cannot be closed un-

less the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly closed and locked.

WARNING

EWA11091

Make sure that the fuel tank cap is

properly closed after filling fuel.

Leaking fuel is a fire hazard.

EAU13221

Fuel Make sure there is sufficient gasoline in

the tank.

WARNING

EWA10881

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, follow

these instructions.1. Before refueling, turn off the en-gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters and

clothes dryers.

2. Do not overfill the fuel tank. When refueling, be sure to insert the

pump nozzle into the fuel tank filler

hole. Stop filling when the fuel

reaches the bottom of the filler

tube. Because fuel expands when

it heats up, heat from the engine or

the sun can cause fuel to spill out

of the fuel tank.

1. Unlock.

2. Fuel tank cap lock cover

2

1

U23PE3E0.book Page 23 Monday, July 30, 2012 8:44 AM

Page 53 of 108

OPERATION AND IMPORTANT RIDING POINTS

5-1

5

EAU15951

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10271

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which could cause an accident

or injury.

EAU48710

TIPThis model is equipped with:●

a lean angle sensor to stop the en-

gine in case of a turnover. In this

case, the multi-function display in-

dicates error code 30, but this is

not a malfunction. Turn the key to

“OFF” and then to “ON” to clear the

error code. Failing to do so will pre-

vent the engine from starting even

though the engine will crank when

pushing the start switch.

●

an engine auto-stop system. The

engine stops automatically if left

idling for 20 minutes. If the engine

stops, simply push the start switch

to restart the engine.

EAU54520

Starting the engine In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:●

The transmission is in the neutral

position.

●

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-33 for more informa-

tion.

1. Turn the key to “ON” and make sure that the engine stop switch is

set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off.●

Oil level warning light

●

Engine trouble warning light

●

Coolant temperature warning

light

●

Traction control system indi-

cator/warning light

●

Immobilizer system indicator

light

U23PE3E0.book Page 1 Monday, July 30, 2012 8:44 AM

Page 54 of 108

OPERATION AND IMPORTANT RIDING POINTS

5-2

5

NOTICE

ECA17670

If the above warning lights or indica-

tor light do not come on initially

when the key is turned to “ON”, or if

a warning or indicator light remains

on, see page 3-4 for the correspond-

ing warning and indicator light cir-

cuit check.

The ABS warning light should

come on when the main switch is

turned to “ON” and then go off after

traveling at a speed of 10 km/h (6

mi/h) or higher.

NOTICE

ECA17680

If the ABS warning light does not

come on and then go off as ex-

plained above, see page 3-4 for the

indicator light circuit check.2. Shift the transmission into the neu-tral position. The neutral indicator

light should come on. If not, ask a

Yamaha dealer to check the elec-

trical circuit.

3. Start the engine by pushing the start switch. If the engine fails to start, release

the start switch, wait a few sec-

onds, and then try again. Each

starting attempt should be as short

as possible to preserve the bat-

tery. Do not crank the engine more

than 10 seconds on any one at-

tempt.

NOTICE

ECA11042

For maximum engine life, never ac-

celerate hard when the engine is

cold!

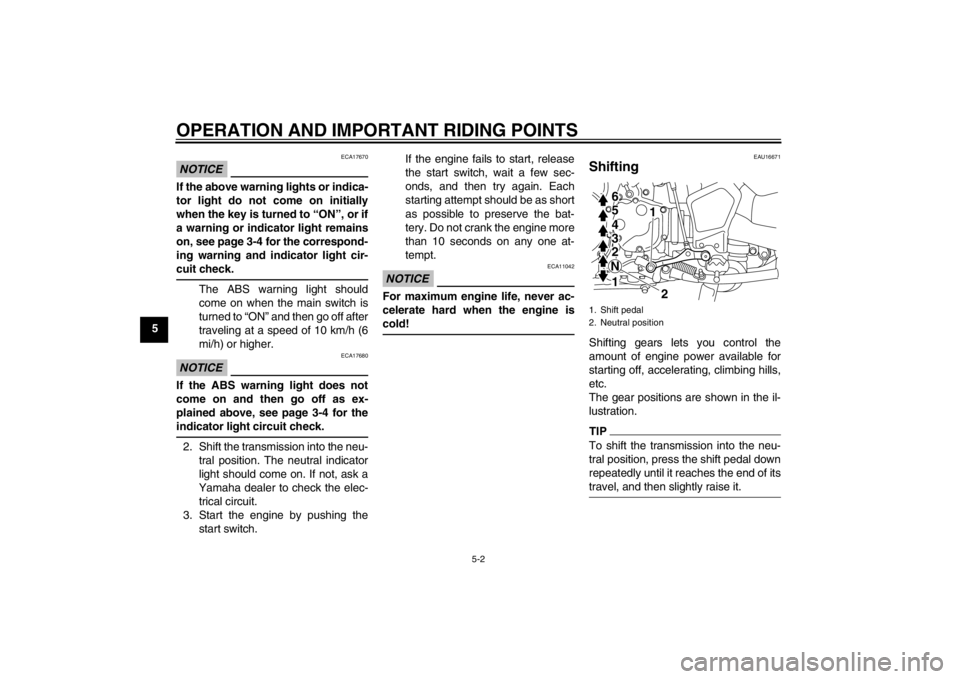

EAU16671

Shifting Shifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.TIPTo shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.1. Shift pedal

2. Neutral position

1

2

654321N

U23PE3E0.book Page 2 Monday, July 30, 2012 8:44 AM

Page 69 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

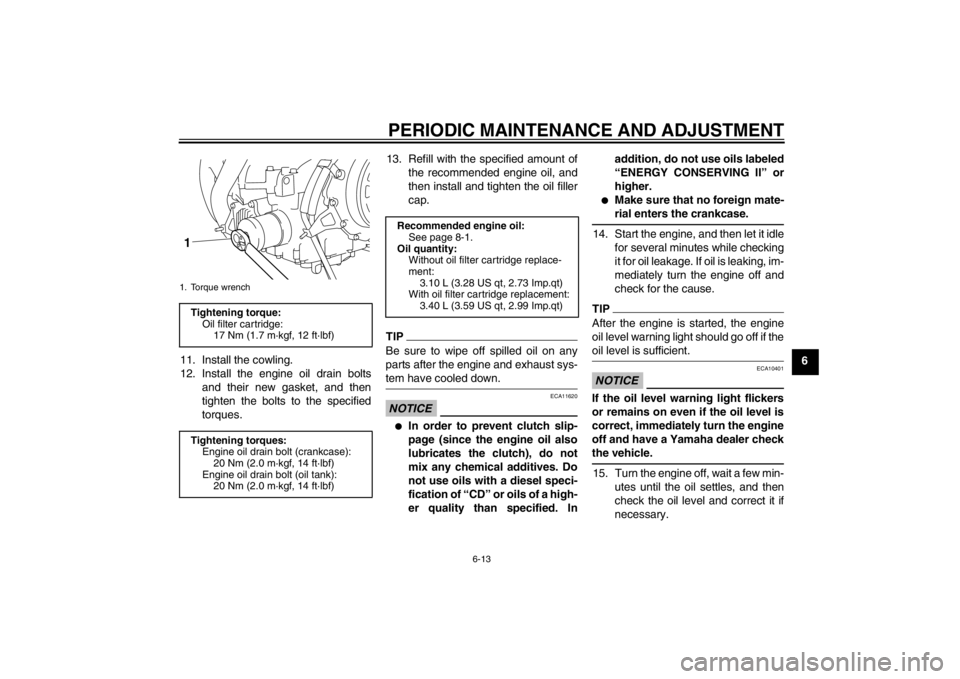

11. Install the cowling.

12. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques. 13. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11620

●

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

●

Make sure that no foreign mate-

rial enters the crankcase.

14. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if the

oil level is sufficient.NOTICE

ECA10401

If the oil level warning light flickers

or remains on even if the oil level is

correct, immediately turn the engine

off and have a Yamaha dealer check

the vehicle.15. Turn the engine off, wait a few min-utes until the oil settles, and then

check the oil level and correct it if

necessary.

1. Torque wrenchTightening torque:Oil filter cartridge:17 Nm (1.7 m·kgf, 12 ft·lbf)

Tightening torques: Engine oil drain bolt (crankcase):

20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil drain bolt (oil tank): 20 Nm (2.0 m·kgf, 14 ft·lbf)1

Recommended engine oil:

See page 8-1.

Oil quantity: Without oil filter cartridge replace-

ment:3.10 L (3.28 US qt, 2.73 Imp.qt)

With oil filter cartridge replacement:

3.40 L (3.59 US qt, 2.99 Imp.qt)

U23PE3E0.book Page 13 Monday, July 30, 2012 8:44 AM

Page 70 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6

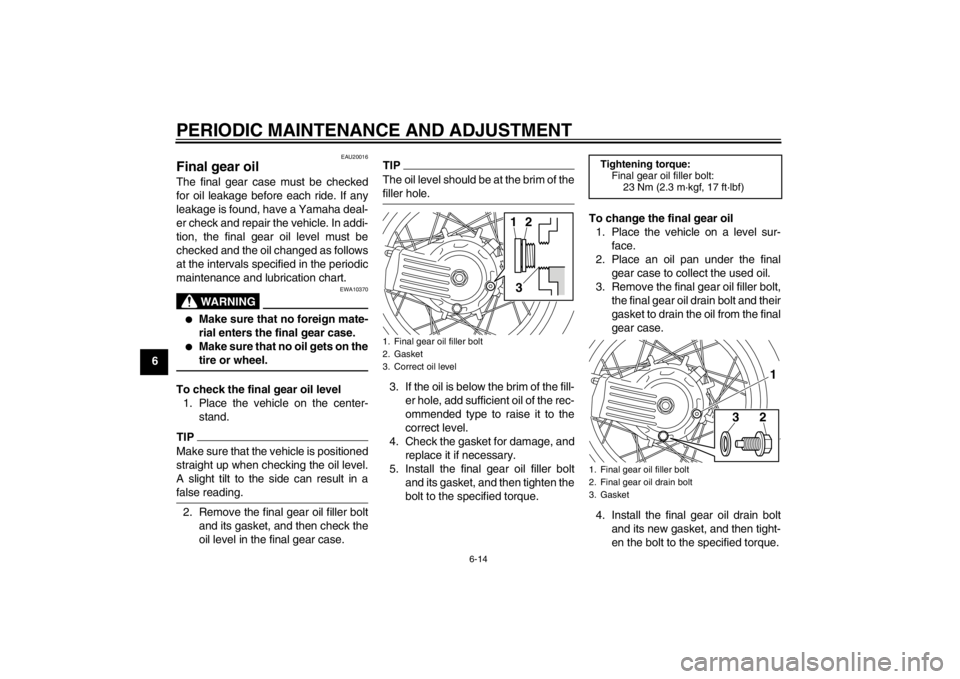

EAU20016

Final gear oil The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In addi-

tion, the final gear oil level must be

checked and the oil changed as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

WARNING

EWA10370

●

Make sure that no foreign mate-

rial enters the final gear case.

●

Make sure that no oil gets on the

tire or wheel.

To check the final gear oil level1. Place the vehicle on the center- stand.TIPMake sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIPThe oil level should be at the brim of the

filler hole.3. If the oil is below the brim of the fill-er hole, add sufficient oil of the rec-

ommended type to raise it to the

correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten the

bolt to the specified torque. To change the final gear oil

1. Place the vehicle on a level sur- face.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and their

gasket to drain the oil from the final

gear case.

4. Install the final gear oil drain bolt and its new gasket, and then tight-

en the bolt to the specified torque.1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

1

2

3

Tightening torque: Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)1. Final gear oil filler bolt

2. Final gear oil drain bolt

3. Gasket

2

3

1

U23PE3E0.book Page 14 Monday, July 30, 2012 8:44 AM

Page 77 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-21

6

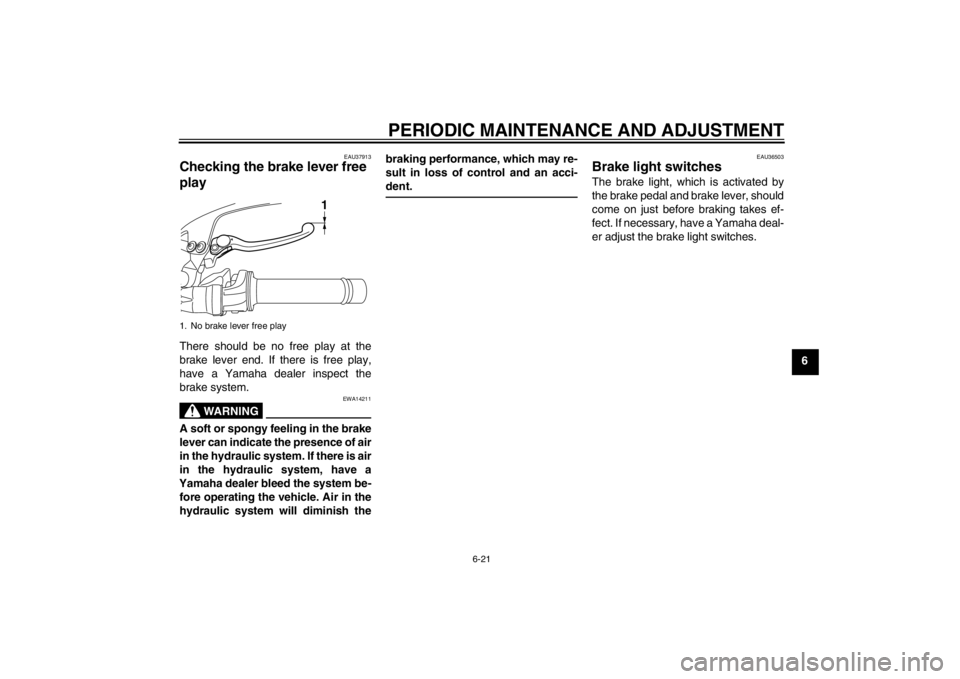

EAU37913

Checking the brake lever free

play There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14211

A soft or spongy feeling in the brake

lever can indicate the presence of air

in the hydraulic system. If there is air

in the hydraulic system, have a

Yamaha dealer bleed the system be- fore operating the vehicle. Air in the

hydraulic system will diminish the braking performance, which may re-

sult in loss of control and an acci-

dent.

EAU36503

Brake light switches The brake light, which is activated by

the brake pedal and brake lever, should

come on just before braking takes ef-

fect. If necessary, have a Yamaha deal-

er adjust the brake light switches.

1. No brake lever free play

1

U23PE3E0.book Page 21 Monday, July 30, 2012 8:44 AM

Page 86 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15131]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

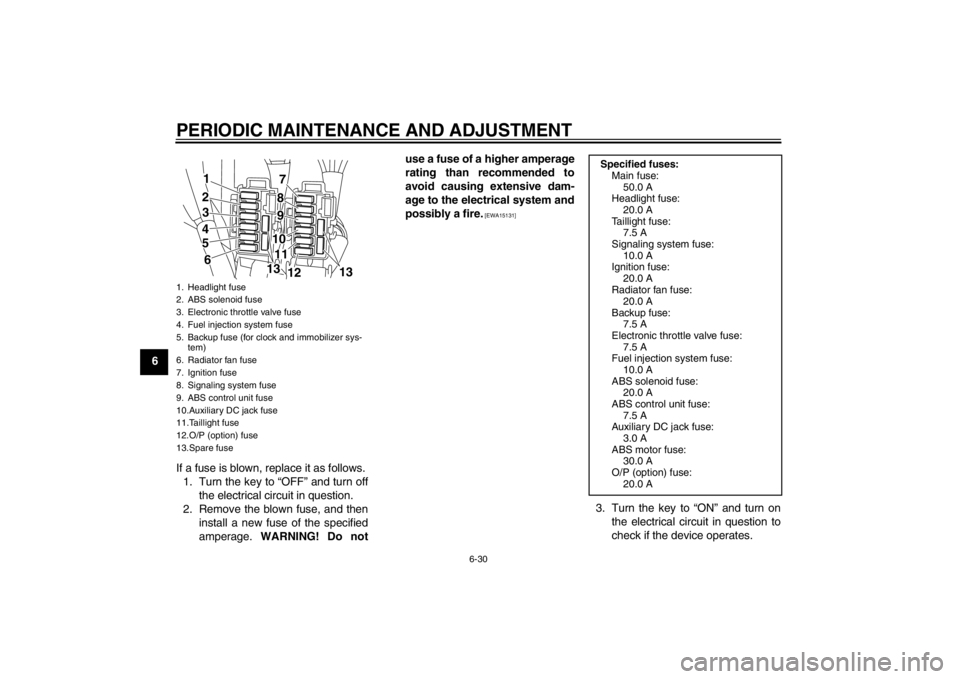

1. Headlight fuse

2. ABS solenoid fuse

3. Electronic throttle valve fuse

4. Fuel injection system fuse

5. Backup fuse (for clock and immobilizer sys-tem)

6. Radiator fan fuse

7. Ignition fuse

8. Signaling system fuse

9. ABS control unit fuse

10.Auxiliary DC jack fuse

11.Taillight fuse

12.O/P (option) fuse

13.Spare fuse

78912

13

13

1110

124563

Specified fuses: Main fuse:

50.0 A

Headlight fuse:

20.0 A

Taillight fuse: 7.5 A

Signaling system fuse: 10.0 A

Ignition fuse:

20.0 A

Radiator fan fuse: 20.0 A

Backup fuse: 7.5 A

Electronic throttle valve fuse:

7.5 A

Fuel injection system fuse: 10.0 A

ABS solenoid fuse: 20.0 A

ABS control unit fuse:

7.5 A

Auxiliary DC jack fuse: 3.0 A

ABS motor fuse: 30.0 A

O/P (option) fuse:

20.0 A

U23PE3E0.book Page 30 Monday, July 30, 2012 8:44 AM