light YAMAHA XT1200Z 2013 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XT1200Z, Model: YAMAHA XT1200Z 2013Pages: 108, PDF Size: 2.86 MB

Page 52 of 108

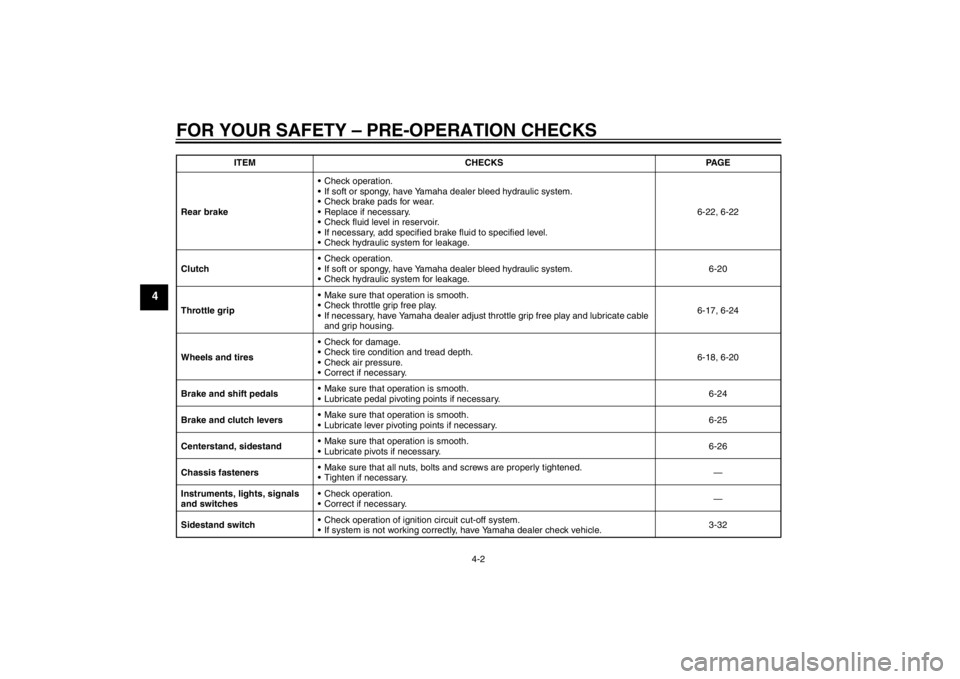

FOR YOUR SAFETY – PRE-OPERATION CHECKS

4-2

4

Rear brake Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check brake pads for wear.

Replace if necessary.

Check fluid level in reservoir.

If necessary, add specified brake fluid to specified level.

Check hydraulic system for leakage. 6-22, 6-22

Clutch Check operation.

If soft or spongy, have Yamaha dealer bleed hydraulic system.

Check hydraulic system for leakage. 6-20

Throttle grip Make sure that operation is smooth.

Check throttle grip free play.

If necessary, have Yamaha dealer adjust throttle grip free play and lubricate cable

and grip housing. 6-17, 6-24

Wheels and tires Check for damage.

Check tire condition and tread depth.

Check air pressure.

Correct if necessary. 6-18, 6-20

Brake and shift pedals Make sure that operation is smooth.

Lubricate pedal pivoting points if necessary.

6-24

Brake and clutch levers Make sure that operation is smooth.

Lubricate lever pivoting points if necessary.

6-25

Centerstand, sidestand Make sure that operation is smooth.

Lubricate pivots if necessary. 6-26

Chassis fasteners Make sure that all nuts, bolts and screws are properly tightened.

Tighten if necessary.

—

Instruments, lights, signals

and switches Check operation.

Correct if necessary.

—

Sidestand switch Check operation of ignition circuit cut-off system.

If system is not working correctly, have Yamaha dealer check vehicle. 3-32

ITEM CHECKS PAGE

U23PE3E0.book Page 2 Monday, July 30, 2012 8:44 AM

Page 53 of 108

OPERATION AND IMPORTANT RIDING POINTS

5-1

5

EAU15951

Read the Owner’s Manual carefully to

become familiar with all controls. If

there is a control or function you do not

understand, ask your Yamaha dealer.

WARNING

EWA10271

Failure to familiarize yourself with

the controls can lead to loss of con-

trol, which could cause an accident

or injury.

EAU48710

TIPThis model is equipped with:●

a lean angle sensor to stop the en-

gine in case of a turnover. In this

case, the multi-function display in-

dicates error code 30, but this is

not a malfunction. Turn the key to

“OFF” and then to “ON” to clear the

error code. Failing to do so will pre-

vent the engine from starting even

though the engine will crank when

pushing the start switch.

●

an engine auto-stop system. The

engine stops automatically if left

idling for 20 minutes. If the engine

stops, simply push the start switch

to restart the engine.

EAU54520

Starting the engine In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:●

The transmission is in the neutral

position.

●

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-33 for more informa-

tion.

1. Turn the key to “ON” and make sure that the engine stop switch is

set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off.●

Oil level warning light

●

Engine trouble warning light

●

Coolant temperature warning

light

●

Traction control system indi-

cator/warning light

●

Immobilizer system indicator

light

U23PE3E0.book Page 1 Monday, July 30, 2012 8:44 AM

Page 54 of 108

OPERATION AND IMPORTANT RIDING POINTS

5-2

5

NOTICE

ECA17670

If the above warning lights or indica-

tor light do not come on initially

when the key is turned to “ON”, or if

a warning or indicator light remains

on, see page 3-4 for the correspond-

ing warning and indicator light cir-

cuit check.

The ABS warning light should

come on when the main switch is

turned to “ON” and then go off after

traveling at a speed of 10 km/h (6

mi/h) or higher.

NOTICE

ECA17680

If the ABS warning light does not

come on and then go off as ex-

plained above, see page 3-4 for the

indicator light circuit check.2. Shift the transmission into the neu-tral position. The neutral indicator

light should come on. If not, ask a

Yamaha dealer to check the elec-

trical circuit.

3. Start the engine by pushing the start switch. If the engine fails to start, release

the start switch, wait a few sec-

onds, and then try again. Each

starting attempt should be as short

as possible to preserve the bat-

tery. Do not crank the engine more

than 10 seconds on any one at-

tempt.

NOTICE

ECA11042

For maximum engine life, never ac-

celerate hard when the engine is

cold!

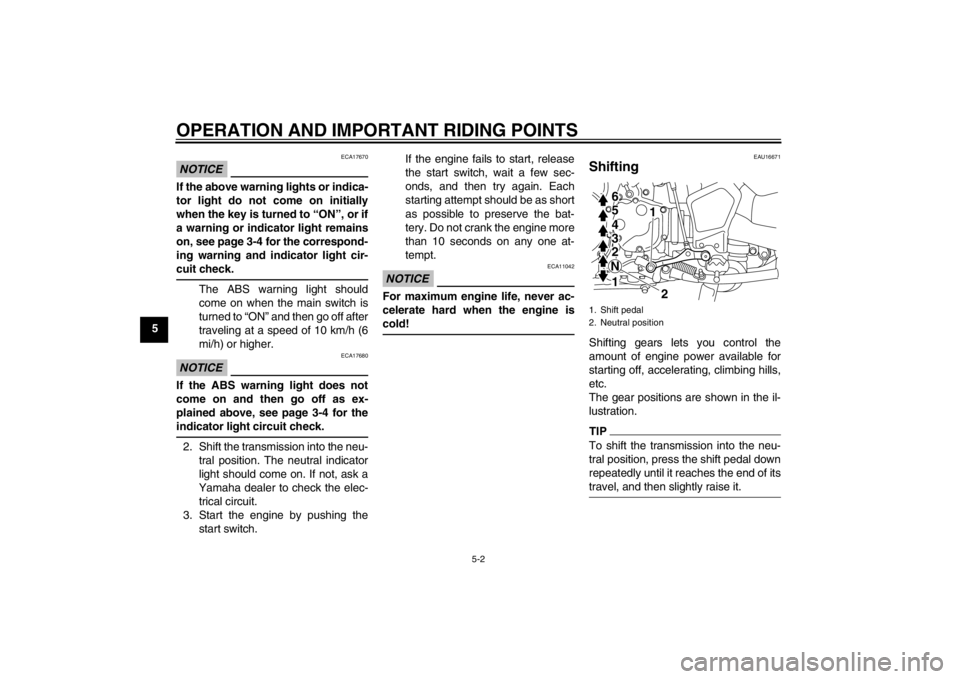

EAU16671

Shifting Shifting gears lets you control the

amount of engine power available for

starting off, accelerating, climbing hills,

etc.

The gear positions are shown in the il-

lustration.TIPTo shift the transmission into the neu-

tral position, press the shift pedal down

repeatedly until it reaches the end of its

travel, and then slightly raise it.1. Shift pedal

2. Neutral position

1

2

654321N

U23PE3E0.book Page 2 Monday, July 30, 2012 8:44 AM

Page 55 of 108

OPERATION AND IMPORTANT RIDING POINTS

5-3

5

NOTICE

ECA10260

●

Even with the transmission in

the neutral position, do not

coast for long periods of time

with the engine off, and do not

tow the motorcycle for long dis-

tances. The transmission is

properly lubricated only when

the engine is running. Inade-

quate lubrication may damage

the transmission.

●

Always use the clutch while

changing gears to avoid damag-

ing the engine, transmission,

and drive train, which are not

designed to withstand the

shock of forced shifting.

EAU16810

Tips for reducing fuel con-

sumption Fuel consumption depends largely on

your riding style. Consider the following

tips to reduce fuel consumption:●

Shift up swiftly, and avoid high en-

gine speeds during acceleration.

●

Do not rev the engine while shifting

down, and avoid high engine

speeds with no load on the engine.

●

Turn the engine off instead of let-

ting it idle for an extended length of

time (e.g., in traffic jams, at traffic

lights or at railroad crossings).

EAU16841

Engine break-in There is never a more important period

in the life of your engine than the period

between 0 and 1600 km (1000 mi). For

this reason, you should read the follow-

ing material carefully.

Since the engine is brand new, do not

put an excessive load on it for the first

1600 km (1000 mi). The various parts in

the engine wear and polish themselves

to the correct operating clearances.

During this period, prolonged full-throt-

tle operation or any condition that might

result in engine overheating must be

avoided.

EAU17123

0–1000 km (0–600 mi)

Avoid prolonged operation above 3900

r/min. NOTICE: After 1000 km (600

mi) of operation, the engine oil and

final gear oil must be changed, and

the oil filter cartridge or element re-

placed.

[ECA10332]

U23PE3E0.book Page 3 Monday, July 30, 2012 8:44 AM

Page 62 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-6

6

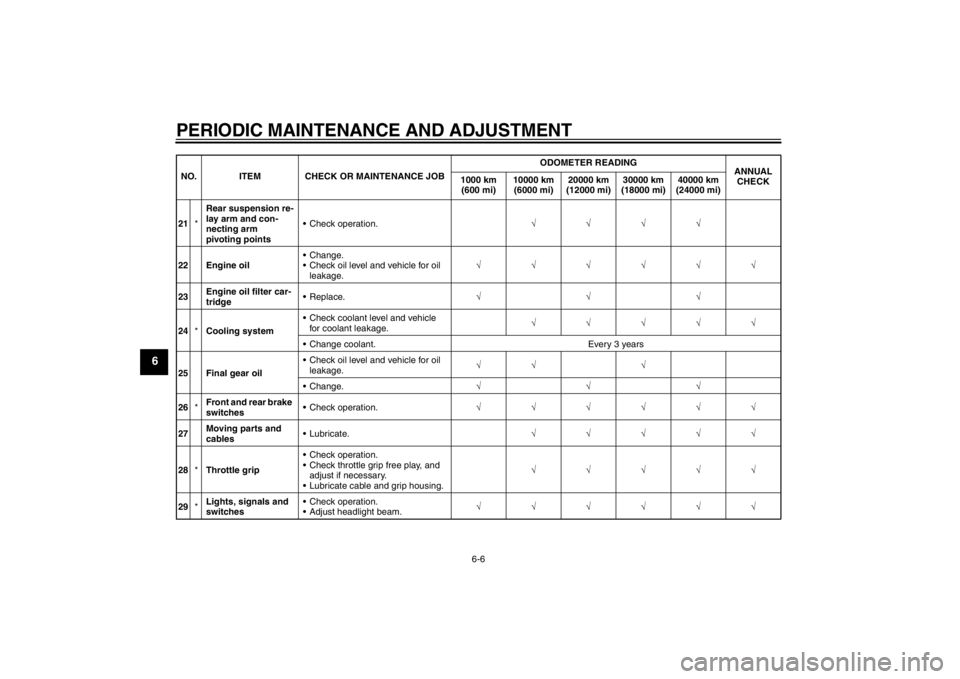

21*Rear suspension re-

lay arm and con-

necting arm

pivoting points Check operation.

√√√√

22 Engine oil Change.

Check oil level and vehicle for oil

leakage. √√√√√√

23 Engine oil filter car-

tridge Replace.

√√√

24 *Cooling system Check coolant level and vehicle

for coolant leakage. √√√√√

Change coolant. Every 3 years

25 Final gear oil Check oil level and vehicle for oil

leakage. √√ √

Change. √√√

26 *Front and rear brake

switches

Check operation.

√√√√√√

27 Moving parts and

cables

Lubricate.

√√√√√

28 *Throttle grip Check operation.

Check throttle grip free play, and

adjust if necessary.

Lubricate cable and grip housing. √√√√√

29 *Lights, signals and

switches Check operation.

Adjust headlight beam.

√√√√√√

NO. ITEM CHECK OR MAINTENANCE JOB

ODOMETER READING

ANNUAL

CHECK

1000 km

(600 mi) 10000 km

(6000 mi) 20000 km

(12000 mi) 30000 km

(18000 mi) 40000 km

(24000 mi)U23PE3E0.book Page 6 Monday, July 30, 2012 8:44 AM

Page 66 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-10

6

EAU19652

Checking the spark plugs The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal color

when the vehicle is ridden normally),

and all spark plugs installed in the en-

gine should have the same color. If any

spark plug shows a distinctly different

color, the engine could be operating im-

properly. Do not attempt to diagnose

such problems yourself. Instead, have

a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

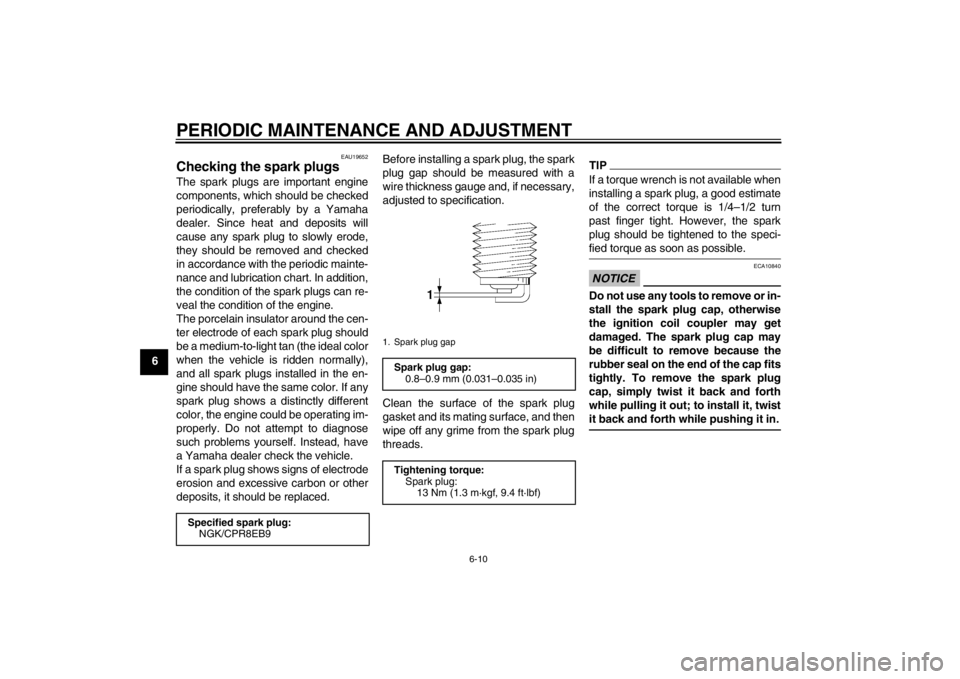

deposits, it should be replaced.Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.

Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

TIPIf a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible.NOTICE

ECA10840

Do not use any tools to remove or in-

stall the spark plug cap, otherwise

the ignition coil coupler may get

damaged. The spark plug cap may

be difficult to remove because the

rubber seal on the end of the cap fits

tightly. To remove the spark plug

cap, simply twist it back and forth

while pulling it out; to install it, twist

it back and forth while pushing it in.

Specified spark plug:

NGK/CPR8EB9

1. Spark plug gapSpark plug gap:0.8–0.9 mm (0.031–0.035 in)

Tightening torque: Spark plug:13 Nm (1.3 m·kgf, 9.4 ft·lbf)

U23PE3E0.book Page 10 Monday, July 30, 2012 8:44 AM

Page 67 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-11

6

EAU49503

Engine oil and oil filter car-

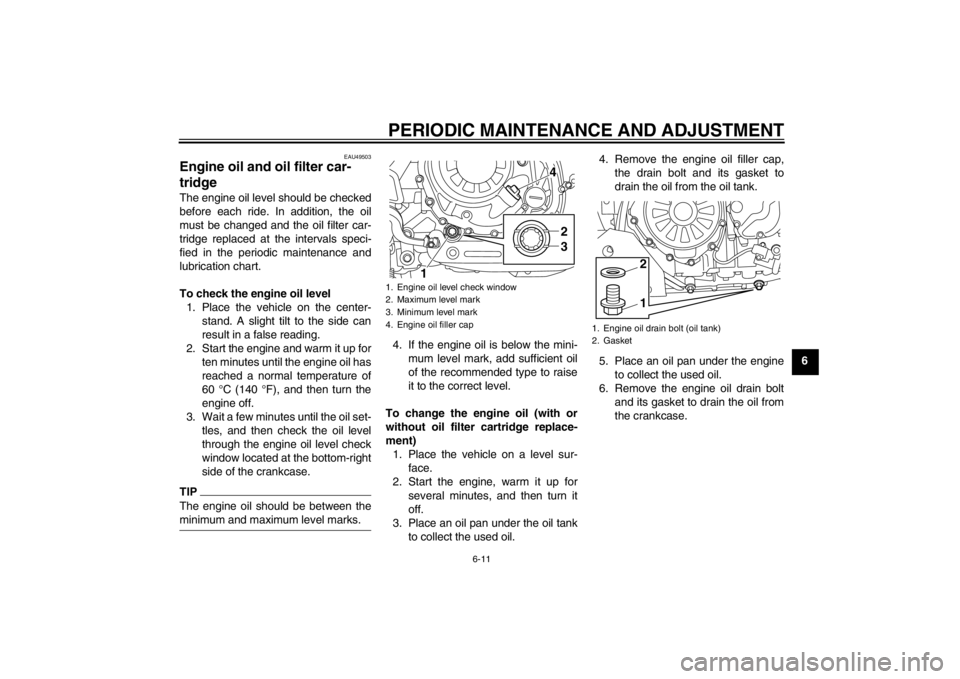

tridge The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the engine oil level1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine and warm it up for ten minutes until the engine oil has

reached a normal temperature of

60 °C (140 °F), and then turn the

engine off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the engine oil level check

window located at the bottom-right

side of the crankcase.TIPThe engine oil should be between the

minimum and maximum level marks.

4. If the engine oil is below the mini-mum level mark, add sufficient oil

of the recommended type to raise

it to the correct level.

To change the engine oil (with or

without oil filter cartridge replace-

ment) 1. Place the vehicle on a level sur- face.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Place an oil pan under the oil tank to collect the used oil. 4. Remove the engine oil filler cap,

the drain bolt and its gasket to

drain the oil from the oil tank.

5. Place an oil pan under the engine to collect the used oil.

6. Remove the engine oil drain bolt and its gasket to drain the oil from

the crankcase.1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

4. Engine oil filler cap

42

3

1

1. Engine oil drain bolt (oil tank)

2. Gasket

12

U23PE3E0.book Page 11 Monday, July 30, 2012 8:44 AM

Page 69 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-13

6

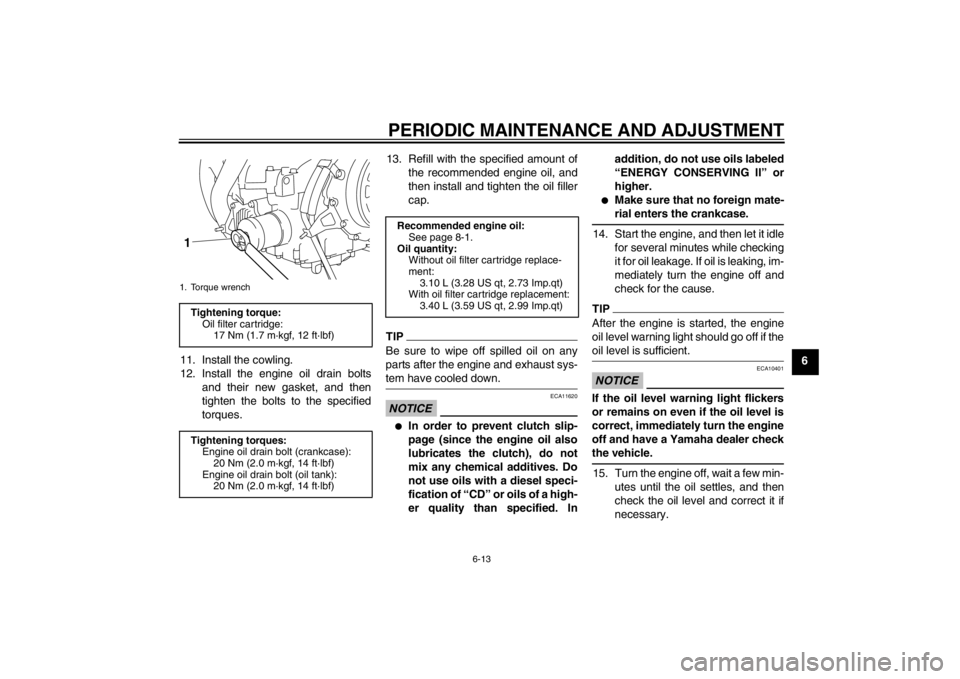

11. Install the cowling.

12. Install the engine oil drain bolts

and their new gasket, and then

tighten the bolts to the specified

torques. 13. Refill with the specified amount of

the recommended engine oil, and

then install and tighten the oil filler

cap.

TIPBe sure to wipe off spilled oil on any

parts after the engine and exhaust sys-

tem have cooled down.NOTICE

ECA11620

●

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a high-

er quality than specified. In addition, do not use oils labeled

“ENERGY CONSERVING II” or

higher.

●

Make sure that no foreign mate-

rial enters the crankcase.

14. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking, im-

mediately turn the engine off and

check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if the

oil level is sufficient.NOTICE

ECA10401

If the oil level warning light flickers

or remains on even if the oil level is

correct, immediately turn the engine

off and have a Yamaha dealer check

the vehicle.15. Turn the engine off, wait a few min-utes until the oil settles, and then

check the oil level and correct it if

necessary.

1. Torque wrenchTightening torque:Oil filter cartridge:17 Nm (1.7 m·kgf, 12 ft·lbf)

Tightening torques: Engine oil drain bolt (crankcase):

20 Nm (2.0 m·kgf, 14 ft·lbf)

Engine oil drain bolt (oil tank): 20 Nm (2.0 m·kgf, 14 ft·lbf)1

Recommended engine oil:

See page 8-1.

Oil quantity: Without oil filter cartridge replace-

ment:3.10 L (3.28 US qt, 2.73 Imp.qt)

With oil filter cartridge replacement:

3.40 L (3.59 US qt, 2.99 Imp.qt)

U23PE3E0.book Page 13 Monday, July 30, 2012 8:44 AM

Page 70 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6

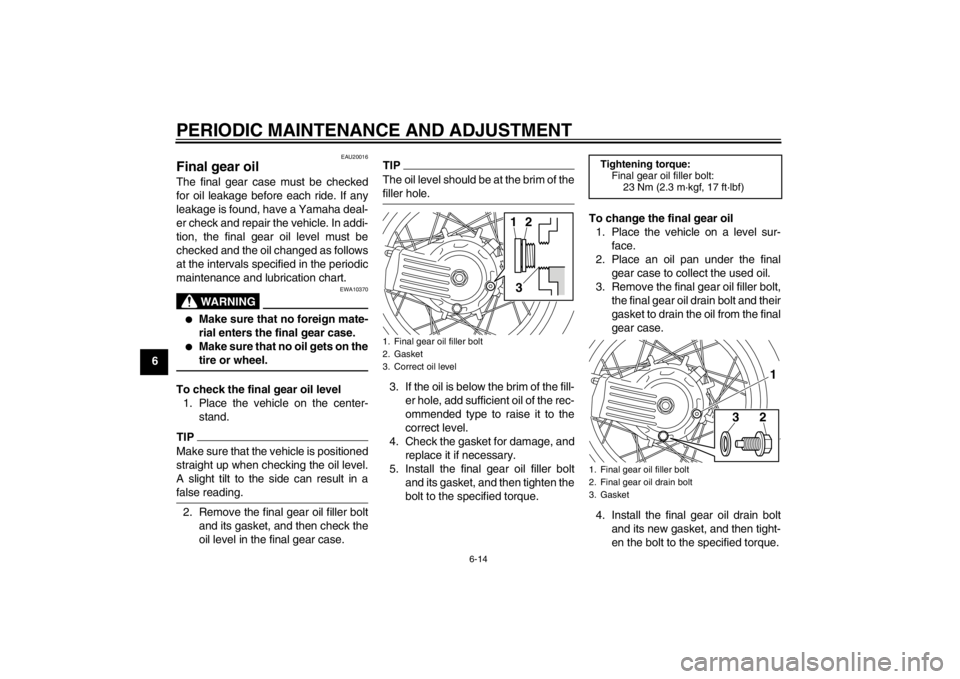

EAU20016

Final gear oil The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In addi-

tion, the final gear oil level must be

checked and the oil changed as follows

at the intervals specified in the periodic

maintenance and lubrication chart.

WARNING

EWA10370

●

Make sure that no foreign mate-

rial enters the final gear case.

●

Make sure that no oil gets on the

tire or wheel.

To check the final gear oil level1. Place the vehicle on the center- stand.TIPMake sure that the vehicle is positioned

straight up when checking the oil level.

A slight tilt to the side can result in a

false reading.2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIPThe oil level should be at the brim of the

filler hole.3. If the oil is below the brim of the fill-er hole, add sufficient oil of the rec-

ommended type to raise it to the

correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten the

bolt to the specified torque. To change the final gear oil

1. Place the vehicle on a level sur- face.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and their

gasket to drain the oil from the final

gear case.

4. Install the final gear oil drain bolt and its new gasket, and then tight-

en the bolt to the specified torque.1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

1

2

3

Tightening torque: Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)1. Final gear oil filler bolt

2. Final gear oil drain bolt

3. Gasket

2

3

1

U23PE3E0.book Page 14 Monday, July 30, 2012 8:44 AM

Page 71 of 108

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

6

5. Refill with the recommended final

gear oil to the brim of the filler hole.

6. Check the oil filler bolt gasket for damage, and replace it if neces-

sary.

7. Install the oil filler bolt and its gas- ket, and then tighten the bolt to the

specified torque.

8. Check the final gear case for oil leakage. If oil is leaking, check for

the cause.

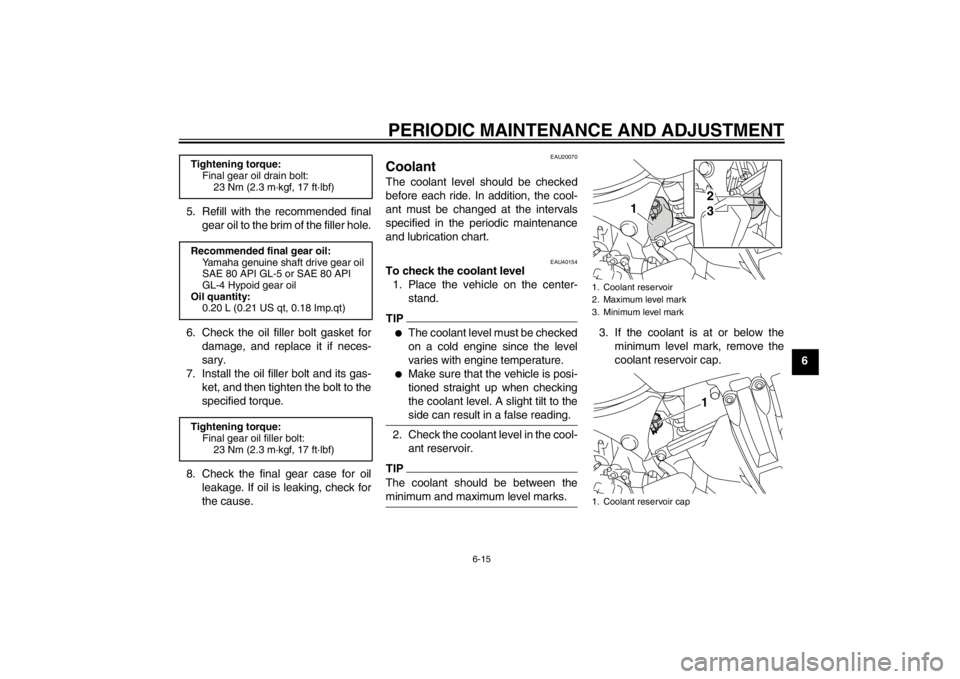

EAU20070

Coolant The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU40154

To check the coolant level1. Place the vehicle on the center- stand.TIP●

The coolant level must be checked

on a cold engine since the level

varies with engine temperature.

●

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the cool-ant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

3. If the coolant is at or below theminimum level mark, remove the

coolant reservoir cap.

Tightening torque:Final gear oil drain bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

Recommended final gear oil: Yamaha genuine shaft drive gear oil

SAE 80 API GL-5 or SAE 80 API

GL-4 Hypoid gear oil

Oil quantity: 0.20 L (0.21 US qt, 0.18 Imp.qt)

Tightening torque: Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

1. Coolant reservoir cap

2

1

31

U23PE3E0.book Page 15 Monday, July 30, 2012 8:44 AM