light YAMAHA XT1200Z 2014 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: XT1200Z, Model: YAMAHA XT1200Z 2014Pages: 116, PDF Size: 3.11 MB

Page 77 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-14

6

a

ddition, do not use oils lab eled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

14. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.TIPAfter the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.NOTICE

ECA10402

If the oil level warnin g li ght flickers

or remains on even if the oil level is

correct, imme diately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.15. Turn the engine off, wait a few minutes until the oil settles, and

then check the oil level and cor-

rect it if necessary.

EAU20028

Final gear oilThe final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In ad-

dition, the final gear oil level must be

checked and the oil changed as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

WARNING

EWA10371

Make sure that no forei gn mate-

rial enters the final gear case.

Make sure that no oil gets on

the tire or wheel.To check the final g ear oil level

1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIPMake sure that the vehicle is posi-

tioned straight up when checking the

oil level. A slight tilt to the side can re-

sult in a false reading.

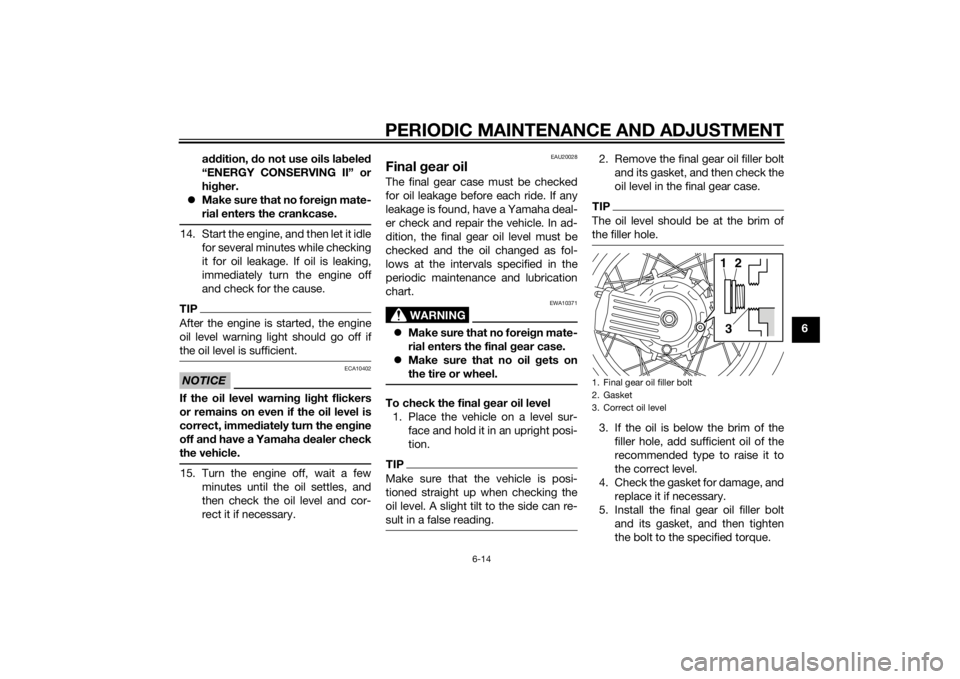

2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.TIPThe oil level should be at the brim of

the filler hole.3. If the oil is below the brim of thefiller hole, add sufficient oil of the

recommended type to raise it to

the correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten

the bolt to the specified torque.1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

1

2

3

U2BSE0E0.book Page 14 Tuesday, September 17, 2013 8:55 AM

Page 78 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-15

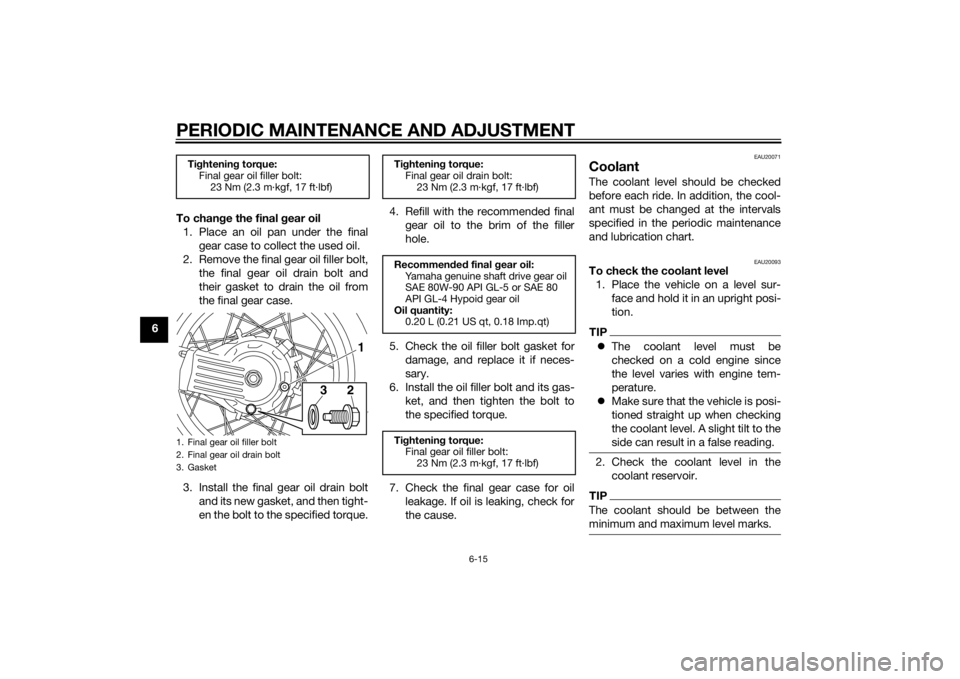

6To chan

ge the final gear oil

1. Place an oil pan under the final gear case to collect the used oil.

2. Remove the final gear oil filler bolt, the final gear oil drain bolt and

their gasket to drain the oil from

the final gear case.

3. Install the final gear oil drain bolt and its new gasket, and then tight-

en the bolt to the specified torque. 4. Refill with the recommended final

gear oil to the brim of the filler

hole.

5. Check the oil filler bolt gasket for damage, and replace it if neces-

sary.

6. Install the oil filler bolt and its gas- ket, and then tighten the bolt to

the specified torque.

7. Check the final gear case for oil leakage. If oil is leaking, check for

the cause.

EAU20071

CoolantThe coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

EAU20093

To check the coolant level1. Place the vehicle on a level sur- face and hold it in an upright posi-

tion.TIPThe coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.2. Check the coolant level in the

coolant reservoir.TIPThe coolant should be between the

minimum and maximum level marks.

Tightenin g torque:

Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)1. Final gear oil filler bolt

2. Final gear oil drain bolt

3. Gasket

2

3

1

Tightenin g torque:

Final gear oil drain bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

Recommen ded final gear oil:

Yamaha genuine shaft drive gear oil

SAE 80W-90 API GL-5 or SAE 80

API GL-4 Hypoid gear oil

Oil quantity: 0.20 L (0.21 US qt, 0.18 Imp.qt)

Ti ghtenin g torque:

Final gear oil filler bolt:

23 Nm (2.3 m·kgf, 17 ft·lbf)

U2BSE0E0.book Page 15 Tuesday, September 17, 2013 8:55 AM

Page 85 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-22

6

b

rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

EAU22283

Brake li ght switchesThe brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. Since the brake light

switches are components of the cruise

control system, they must be adjusted

by a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience.

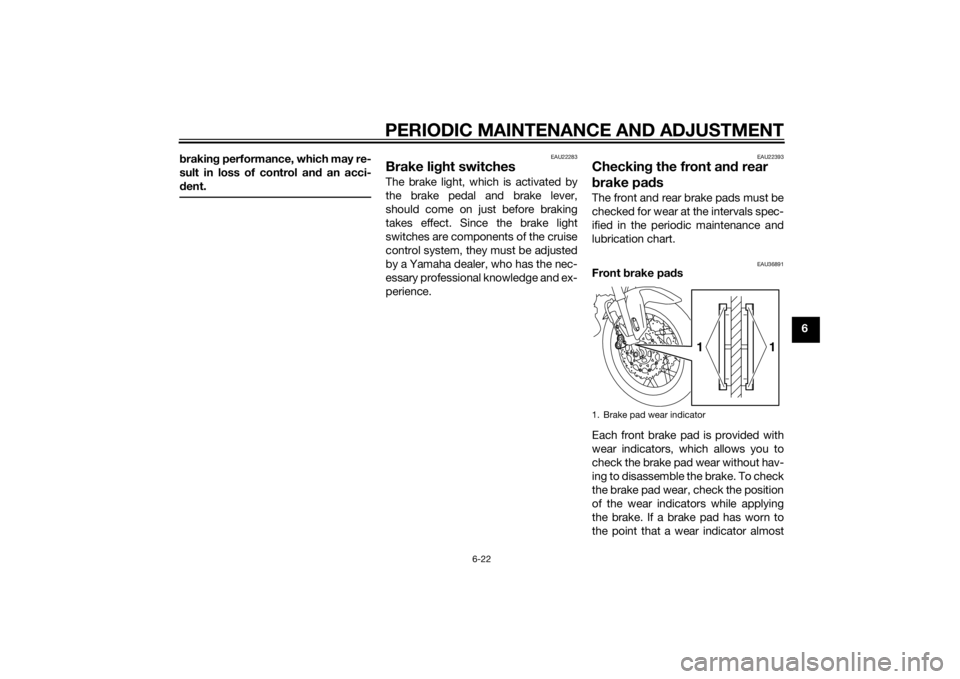

EAU22393

Checkin g the front an d rear

b rake pa dsThe front and rear brake pads must be

checked for wear at the intervals spec-

ified in the periodic maintenance and

lubrication chart.

EAU36891

Front brake pad s

Each front brake pad is provided with

wear indicators, which allows you to

check the brake pad wear without hav-

ing to disassemble the brake. To check

the brake pad wear, check the position

of the wear indicators while applying

the brake. If a brake pad has worn to

the point that a wear indicator almost1. Brake pad wear indicator

1

1

U2BSE0E0.book Page 22 Tuesday, September 17, 2013 8:55 AM

Page 93 of 116

![YAMAHA XT1200Z 2014 Owners Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

is turne

d to “OFF”, then connect

the positive lea d before con-

nectin g the ne gative lead .

[ECA16841]

4. After installation, make sure that

the bat YAMAHA XT1200Z 2014 Owners Guide PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

is turne

d to “OFF”, then connect

the positive lea d before con-

nectin g the ne gative lead .

[ECA16841]

4. After installation, make sure that

the bat](/img/51/53126/w960_53126-92.png)

PERIODIC MAINTENANCE AND ADJUSTMENT

6-30

6

is turne

d to “OFF”, then connect

the positive lea d before con-

nectin g the ne gative lead .

[ECA16841]

4. After installation, make sure that

the battery leads are properly con-

nected to the battery terminals.NOTICE

ECA16531

Always keep the b attery charged .

Storin g a dischar ged battery can

cause permanent battery damag e.

EAU58960

Replacin g the fusesThe fuse boxes and the ABS motor

fuse are located behind cowling A, and

the main fuse, the cruise control fuse

and the brake light fuse are located be-

hind cowling B. (See page 6-8.)

If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not1. ABS motor fuse

2. ABS motor spare fuse

3. Main fuse

4. Spare fuse

5. Cruise control fuse

6. Brake light fuse

7. Fuse box123

5

4

67

1. Headlight fuse

2. ABS solenoid fuse

3. Electronic throttle valve fuse

4. Fuel injection system fuse

5. Backup fuse (for clock and immobilizer sys-

tem)

6. Radiator fan fuse

7. Ignition fuse

8. Signaling system fuse

9. ABS control unit fuse

10.Auxiliary DC jack fuse

11.Parking lighting fuse

12.O/P (option) fuse

13.Spare fuse

13456

2

7

8

9

10

13

11

12

13

U2BSE0E0.book Page 30 Tuesday, September 17, 2013 8:55 AM

Page 94 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-31

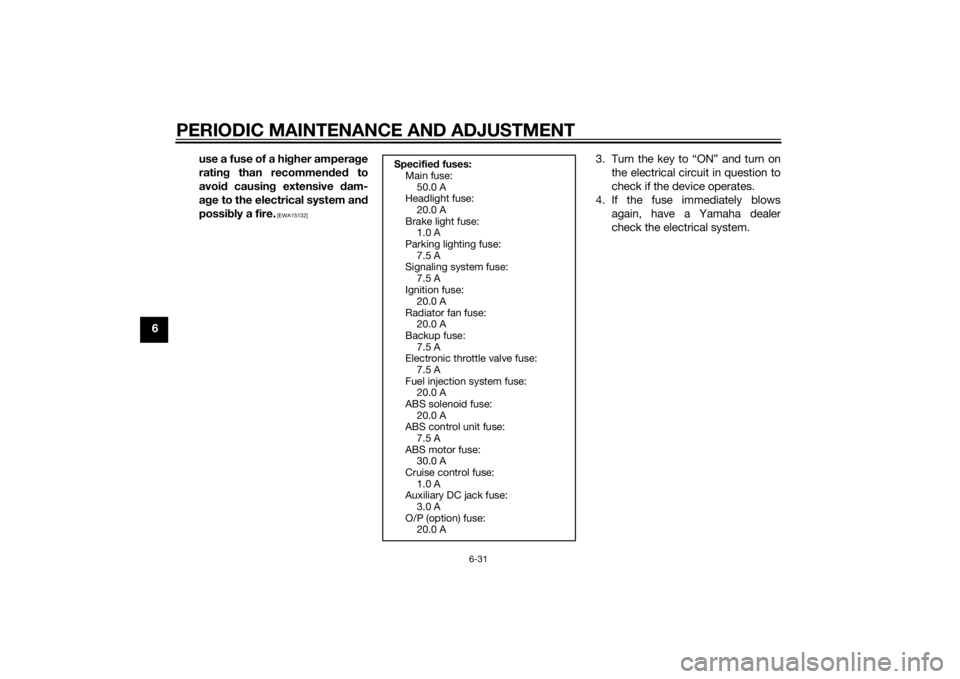

6use a fuse of a hi

gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive d am-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

3. Turn the key to “ON” and turn on

the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

Specifie d fuses:

Main fuse:

50.0 A

Headlight fuse:

20.0 A

Brake light fuse: 1.0 A

Parking lighting fuse: 7.5 A

Signaling system fuse:

7.5 A

Ignition fuse: 20.0 A

Radiator fan fuse: 20.0 A

Backup fuse:

7.5 A

Electronic throttle valve fuse: 7.5 A

Fuel injection system fuse: 20.0 A

ABS solenoid fuse:

20.0 A

ABS control unit fuse: 7.5 A

ABS motor fuse: 30.0 A

Cruise control fuse:

1.0 A

Auxiliary DC jack fuse: 3.0 A

O/P (option) fuse: 20.0 A

U2BSE0E0.book Page 31 Tuesday, September 17, 2013 8:55 AM

Page 95 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-32

6

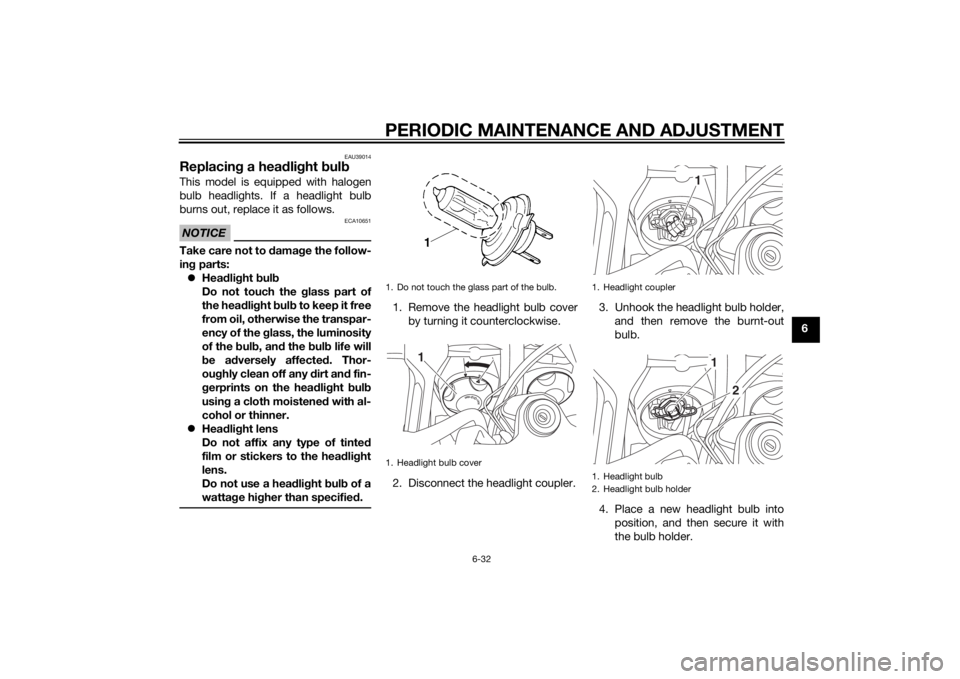

EAU39014

Replacing a hea dlig ht bul bThis model is equipped with halogen

bulb headlights. If a headlight bulb

burns out, replace it as follows.NOTICE

ECA10651

Take care not to damag e the follow-

in g parts:

Hea dlig ht bul b

Do not touch the glass part of

the hea dlig ht bul b to keep it free

from oil, otherwise the transpar-

ency of the g lass, the luminosity

of the b ulb, an d the b ulb life will

b e ad versely affected . Thor-

ou ghly clean off any d irt and fin-

g erprints on the head light bul b

using a cloth moistene d with al-

cohol or thinner.

Hea dlig ht lens

Do not affix any type of tinted

film or stickers to the head light

lens.

Do not use a hea dlig ht bul b of a

watta ge hi gher than specified .

1. Remove the headlight bulb cover

by turning it counterclockwise.

2. Disconnect the headlight coupler. 3. Unhook the headlight bulb holder,

and then remove the burnt-out

bulb.

4. Place a new headlight bulb into position, and then secure it with

the bulb holder.1. Do not touch the glass part of the bulb.

1. Headlight bulb cover

1

1. Headlight coupler

1. Headlight bulb

2. Headlight bulb holder

1

1

2

U2BSE0E0.book Page 32 Tuesday, September 17, 2013 8:55 AM

Page 96 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-33

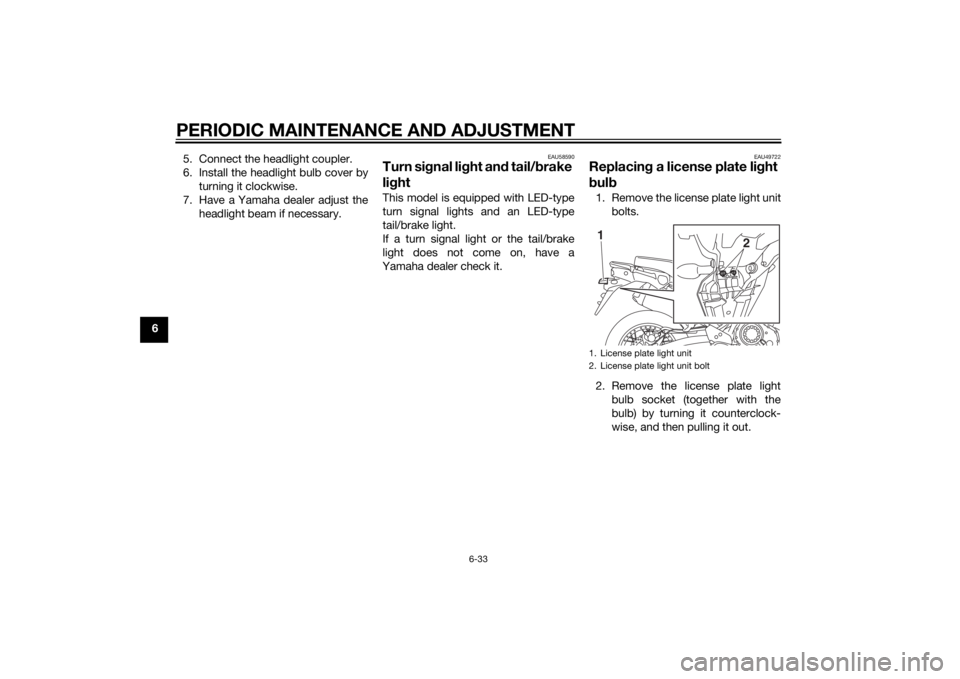

65. Connect the headlight coupler.

6. Install the headlight bulb cover by

turning it clockwise.

7. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU58590

Turn si gnal li ght an d tail/ brake

li g htThis model is equipped with LED-type

turn signal lights and an LED-type

tail/brake light.

If a turn signal light or the tail/brake

light does not come on, have a

Yamaha dealer check it.

EAU49722

Replacin g a license plate li ght

b ul b1. Remove the license plate light unit

bolts.

2. Remove the license plate light bulb socket (together with the

bulb) by turning it counterclock-

wise, and then pulling it out.1. License plate light unit

2. License plate light unit bolt

2

1

U2BSE0E0.book Page 33 Tuesday, September 17, 2013 8:55 AM

Page 97 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-34

6

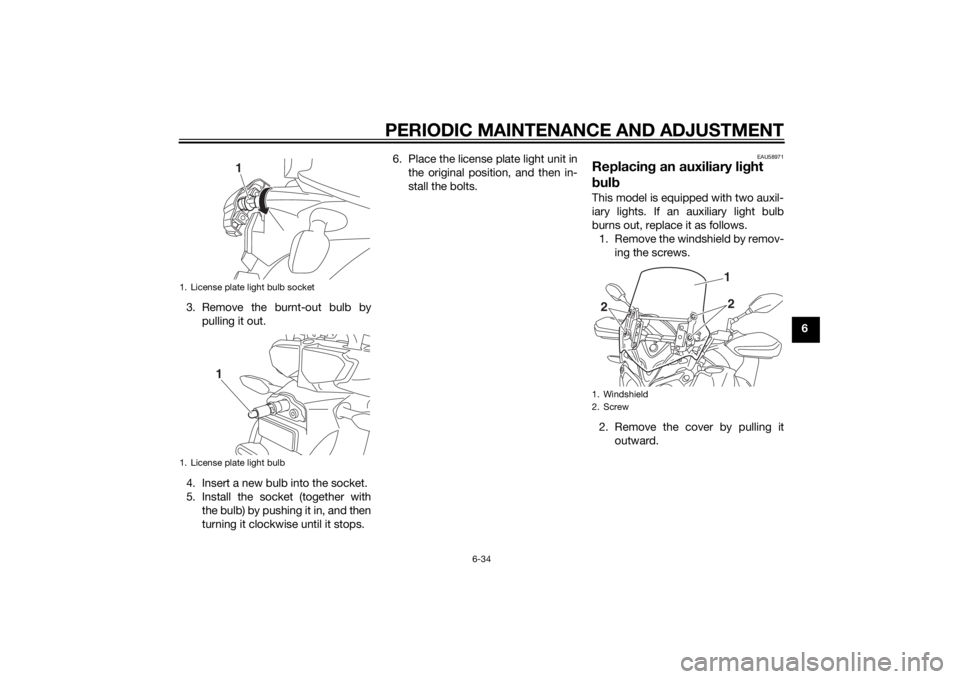

3. Remove the burnt-out bulb by

pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in, and then

turning it clockwise until it stops. 6. Place the license plate light unit in

the original position, and then in-

stall the bolts.

EAU58971

Replacin g an auxiliary lig ht

b ul bThis model is equipped with two auxil-

iary lights. If an auxiliary light bulb

burns out, replace it as follows.

1. Remove the windshield by remov- ing the screws.

2. Remove the cover by pulling it outward.

1. License plate light bulb socket

1. License plate light bulb

1

1

1. Windshield

2. Screw

12

2

U2BSE0E0.book Page 34 Tuesday, September 17, 2013 8:55 AM

Page 98 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-35

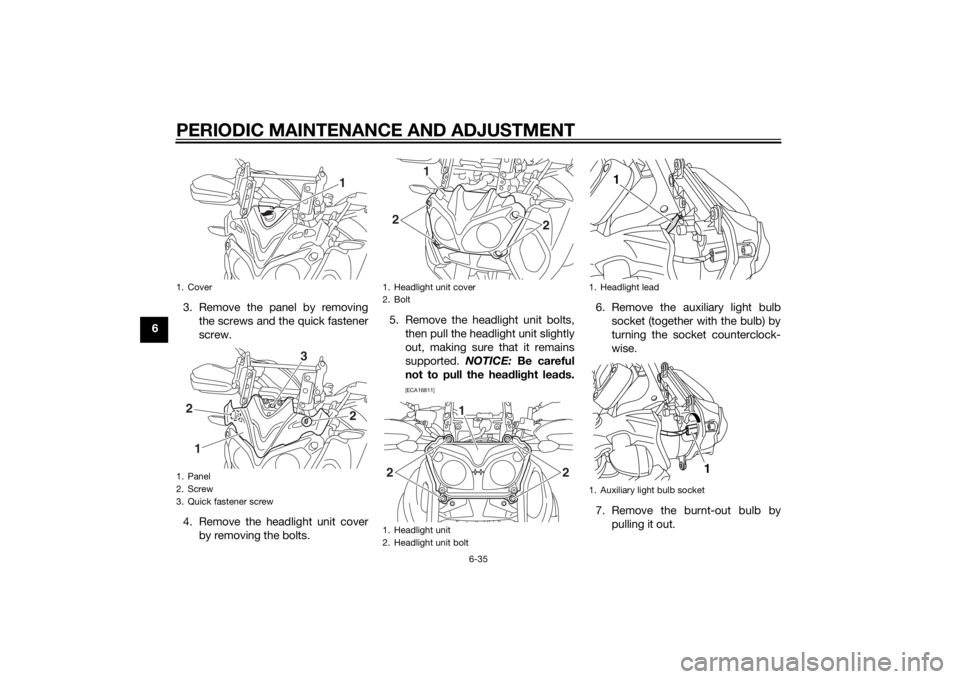

63. Remove the panel by removing

the screws and the quick fastener

screw.

4. Remove the headlight unit cover by removing the bolts. 5. Remove the headlight unit bolts,

then pull the headlight unit slightly

out, making sure that it remains

supported. NOTICE: Be careful

not to pull the hea dlig ht lea ds.

[ECA16811]

6. Remove the auxiliary light bulb

socket (together with the bulb) by

turning the socket counterclock-

wise.

7. Remove the burnt-out bulb by pulling it out.

1. Cover

1. Panel

2. Screw

3. Quick fastener screw

1

3

2

21

1. Headlight unit cover

2. Bolt

1. Headlight unit

2. Headlight unit bolt

1

2

2

1

2

2

1. Headlight lead

1. Auxiliary light bulb socket

1

1

U2BSE0E0.book Page 35 Tuesday, September 17, 2013 8:55 AM

Page 99 of 116

PERIODIC MAINTENANCE AND ADJUSTMENT

6-36

6

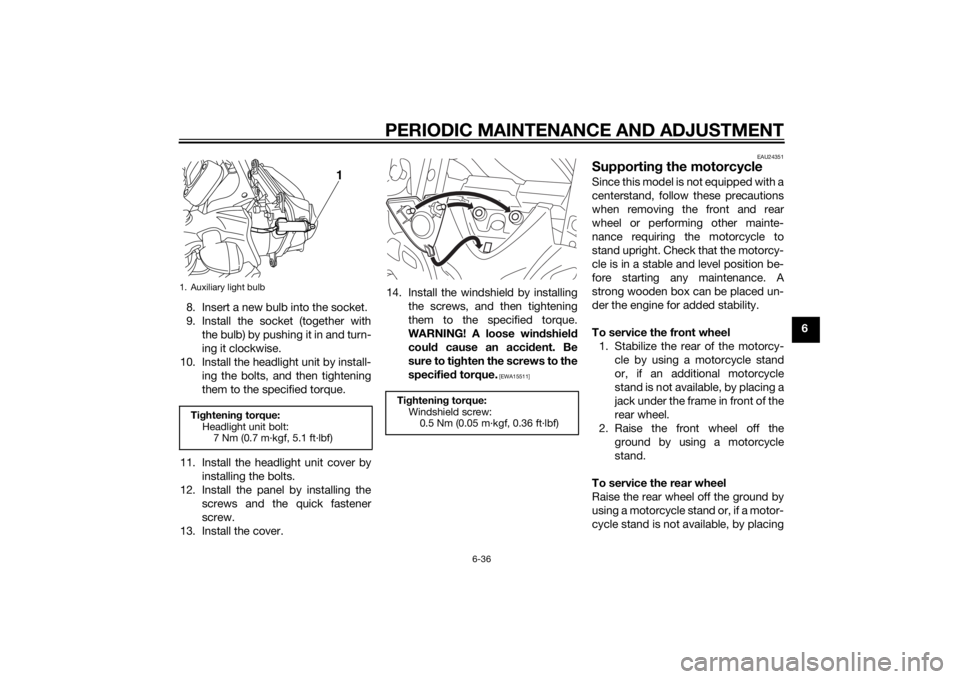

8. Insert a new bulb into the socket.

9. Install the socket (together with

the bulb) by pushing it in and turn-

ing it clockwise.

10. Install the headlight unit by install- ing the bolts, and then tightening

them to the specified torque.

11. Install the headlight unit cover by installing the bolts.

12. Install the panel by installing the screws and the quick fastener

screw.

13. Install the cover. 14. Install the windshield by installing

the screws, and then tightening

them to the specified torque.

WARNING! A loose win dshiel d

coul d cause an acci dent. Be

sure to tig hten the screws to the

specifie d torque.

[EWA15511] EAU24351

Supportin

g the motorcycleSince this model is not equipped with a

centerstand, follow these precautions

when removing the front and rear

wheel or performing other mainte-

nance requiring the motorcycle to

stand upright. Check that the motorcy-

cle is in a stable and level position be-

fore starting any maintenance. A

strong wooden box can be placed un-

der the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy- cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing a

jack under the frame in front of the

rear wheel.

2. Raise the front wheel off the ground by using a motorcycle

stand.

To service the rear wheel

Raise the rear wheel off the ground by

using a motorcycle stand or, if a motor-

cycle stand is not available, by placing

1. Auxiliary light bulbTi ghtenin g torque:

Headlight unit bolt: 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

1

Tightenin g torque:

Windshield screw: 0.5 Nm (0.05 m·kgf, 0.36 ft·lbf)

U2BSE0E0.book Page 36 Tuesday, September 17, 2013 8:55 AM