check engine YAMAHA XT1200ZE 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: XT1200ZE, Model: YAMAHA XT1200ZE 2017Pages: 122, PDF Size: 3.36 MB

Page 51 of 122

Instrument and control functions

3-37

3

EAU55424

A djustin g the front an d rear

suspension

This model is equipped with an elec-

tronically adjustable suspension sys-

tem. The preload of the rear shock

absorber and the damping forces of

both the front fork and rear shock ab-

sorber can be adjusted.

WARNING

EWA12423

Be sure to stop the vehicle before

makin g any settin g chan ges to the

multi-function meter unit. Chang ing

settin gs while ri din g can d istract the

operator an d increase the risk of an

acci dent.

Preloa d

When riding with luggage or a passen-

ger, use the preload adjusting function

to adjust the suspension system to

match the load. There are 4 preload

settings.

TIP

The preload adjusting function will

appear only when the engine is

running.

Changing the preload setting will

also adjust the front and rear sus-

pension damping forces accord-

ingly. See “Damping force” on

page 3-39 for more information.

About cold temperature opera-

tion:

• When using the preload adjust- ing function, there should be no

weight on the vehicle.

• When using the preload adjust- ing function at ambient temper-

atures near or below 0 °C (32

°F), to protect the preload ad- justing function motor, the elec-

tronically adjustable suspension

system warning light may come

on.

• The suspension will still operate as normal, only the preload ad-

justing function cannot be used.

• To reset the electronically ad- justable suspension system

warning light, wait approximate-

ly 6 minutes and then turn the

key to “OFF” or immediately

turn the key to “OFF” and then

wait 6 minutes.

• If the electronically adjustable suspension system warning

light remains on, have a

Yamaha dealer check the sus- pension system.

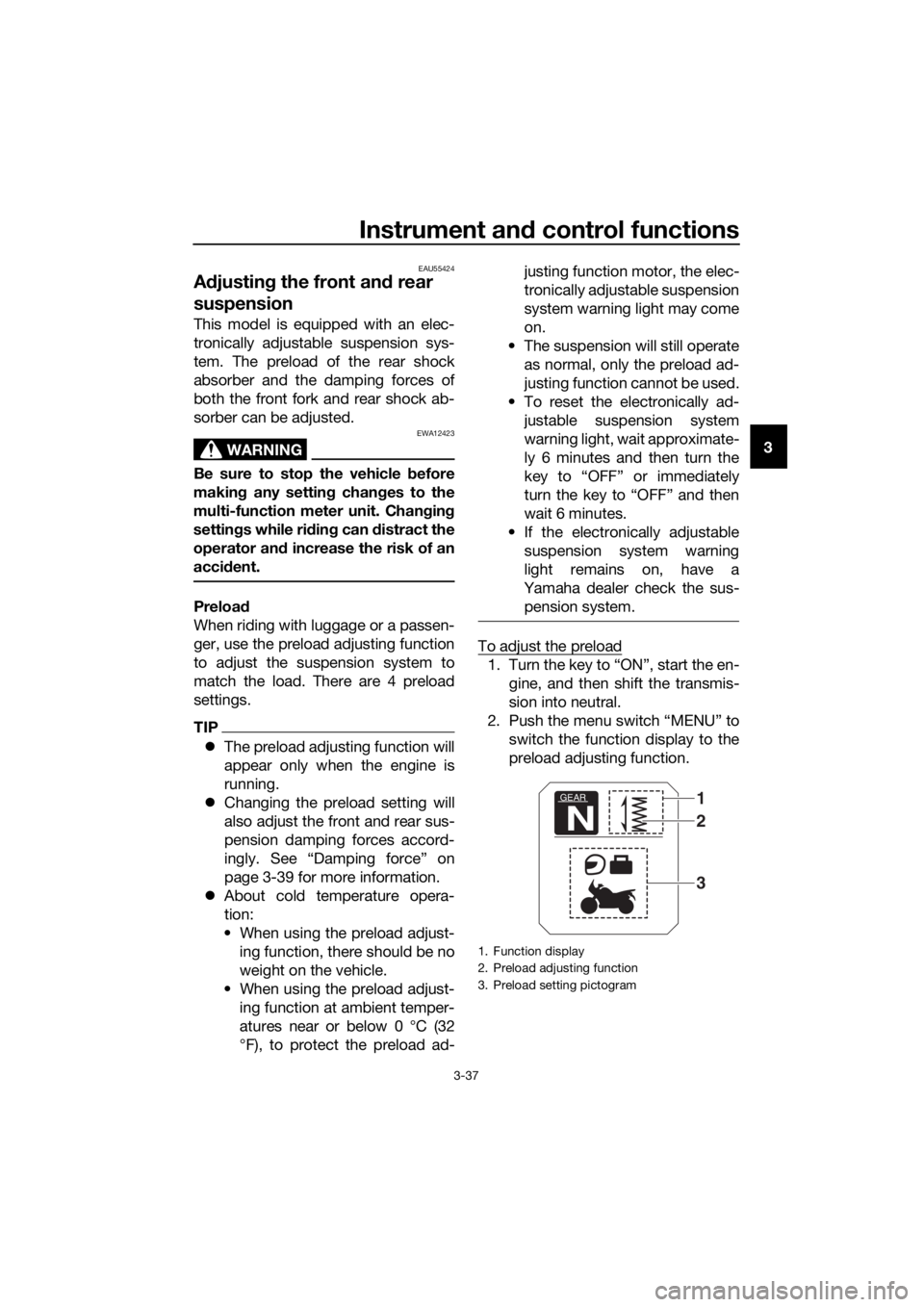

To adjust the preload

1. Turn the key to “ON”, start the en- gine, and then shift the transmis-

sion into neutral.

2. Push the menu switch “MENU” to switch the function display to the

preload adjusting function.

1. Function display

2. Preload adjusting function

3. Preload setting pictogram

GEAR

N

1

3

2

UBP9E0E0.book Page 37 Wednesday, February 8, 2017 8:34 AM

Page 57 of 122

Instrument and control functions

3-43

3

EAU15306

Si destan d

The sidestand is located on the left

side of the frame. Raise the sidestand

or lower it with your foot while holding

the vehicle upright.

TIP

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situa-

tions. (See the following section for an

explanation of the ignition circuit cut-

off system.)

WARNING

EWA10242

The vehicle must not be ri dden with

the si destan d d own, or if the si de-

stan d cannot b e properly move d up

(or does not stay up), otherwise the

si destan d coul d contact the g round

an d d istract the operator, resultin g

in a possib le loss of control.

Yamaha’s ig nition circuit cut-off

system has been desi gne d to assist

the operator in fulfillin g the respon-

si bility of raising the sidestan d b e-

fore startin g off. Therefore, check

this system re gularly an d have a

Yamaha dealer repair it if it does not

function properly.

EAU63430

I g nition circuit cut-off system

The ignition circuit cut-off system

(comprising the sidestand switch,

clutch switch and neutral switch) has

the following functions.

It prevents starting when the

transmission is in gear and the

sidestand is up, but the clutch le-

ver is not pulled.

It prevents starting when the

transmission is in gear and the

clutch lever is pulled, but the side-

stand is still down.

It cuts the running engine when

the transmission is in gear and the

sidestand is moved down.

Periodically check the operation of the

ignition circuit cut-off system accord-

ing to the following procedure.

UBP9E0E0.book Page 43 Wednesday, February 8, 2017 8:34 AM

Page 58 of 122

Instrument and control functions

3-44

3

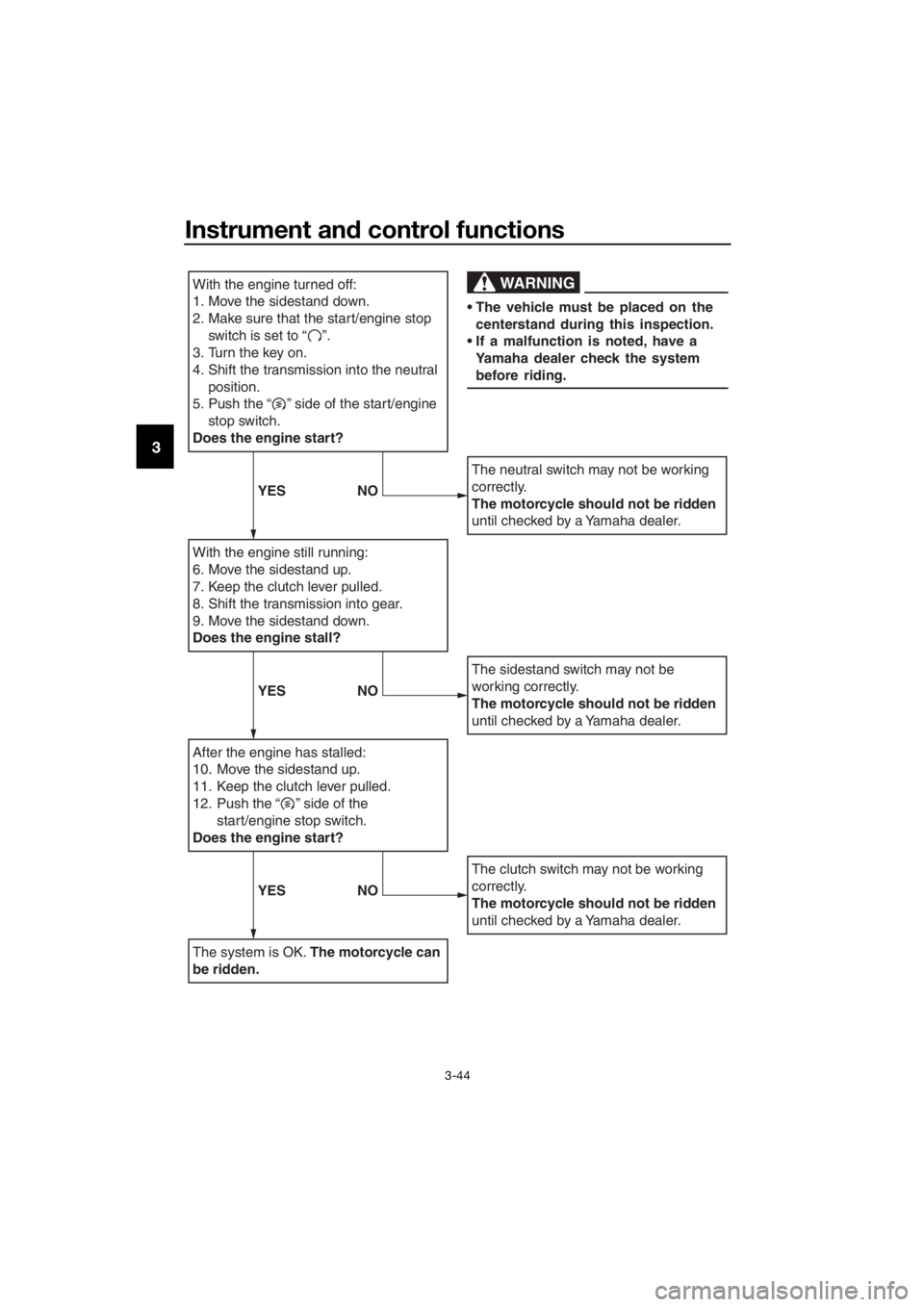

With the engine turned off:

1. Move the sidestand down.

2.

Make sure that the start/engine stop

switch is set to “ ”.

3. Turn the key on.

4. Shift the transmission into the neutral position.

5.

Push the “ ” side of the start/engine

stop switch.

Does the engine start?

With the engine still running:

6. Move the sidestand up.

7. Keep the clutch lever pulled.

8. Shift the transmission into gear.

9. Move the sidestand down.

Does the engine stall?

After the engine has stalled:

10. Move the sidestand up.

11. Keep the clutch lever pulled.

12.

Push the “ ” side of the

start/engine stop switch.

Does the engine start?

The system is OK. The motorcycle can

be ridden.

The neutral switch may not be working

correctly.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

The sidestand switch may not be

working correctly.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

The clutch switch may not be working

correctly.

The motorcycle should not be ridden

until checked by a Yamaha dealer.

WARNING

The vehicle must be placed on the centerstand during this inspection.

If a malfunction is noted, have a Yamaha dealer check the system

before riding.

YES NO

YESNO

YESNO

UBP9E0E0.book Page 44 Wednesday, February 8, 2017 8:34 AM

Page 60 of 122

For your safety – pre-operation checks

4-1

4

EAU63440

Inspect your vehicle each time you use it to make sure the vehicle is in safe oper-

ating condition. Always follow the inspection and maintenance procedures and

schedules described in the Owner’s Manual.

WARNING

EWA11152

Failure to inspect or maintain the vehicle properly increases the possibility

of an acci dent or equipment d amage. Do not operate the vehicle if you fin d

any pro blem. If a pro blem cannot be correcte d b y the proce dures provi ded

in this manual, have the vehicle inspecte d b y a Yamaha dealer.

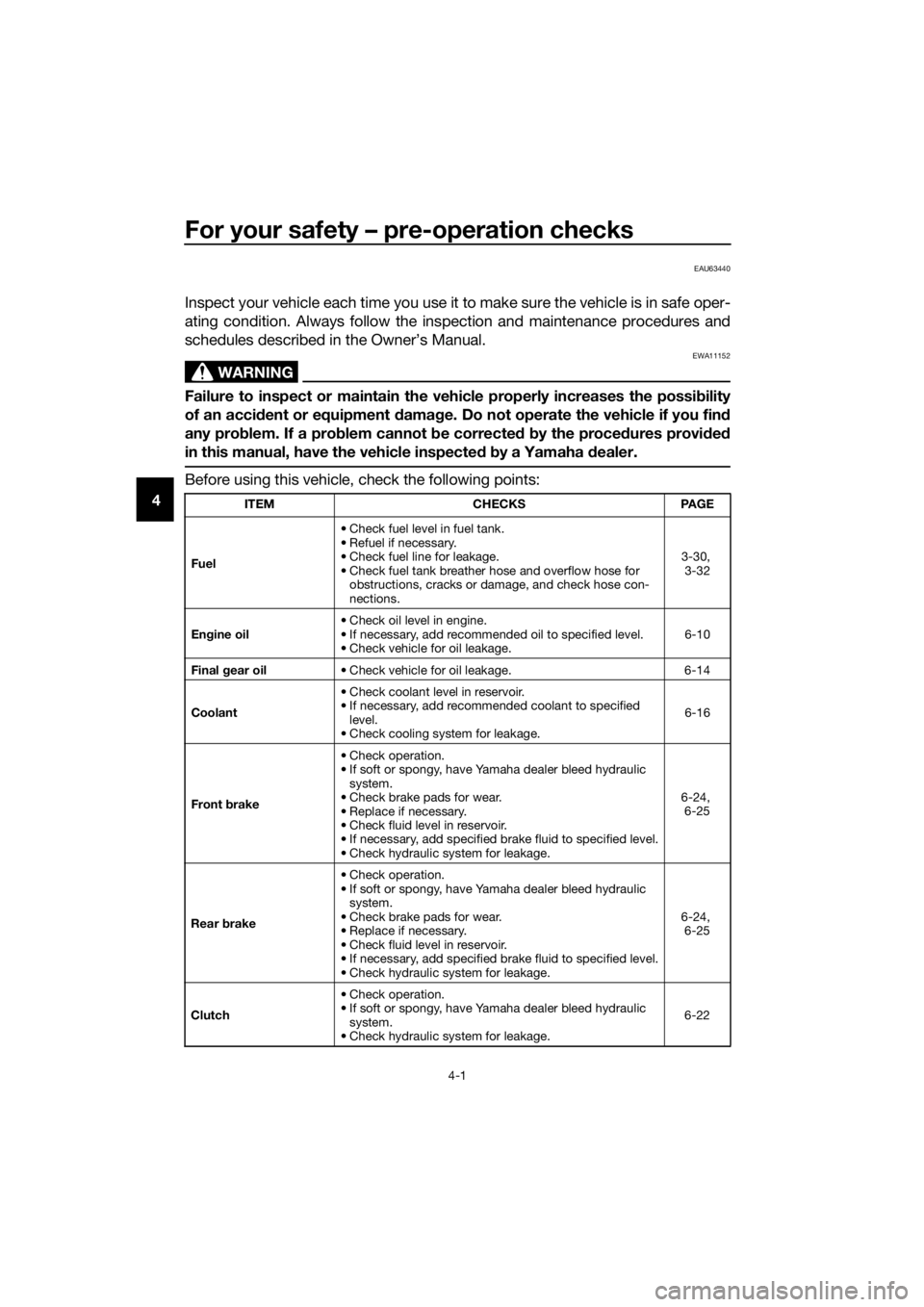

Before using this vehicle, check the following points:

ITEM CHECKSPAGE

Fuel • Check fuel level in fuel tank.

• Refuel if necessary.

• Check fuel line for leakage.

• Check fuel tank breather hose and overflow hose for

obstructions, cracks or damage, and check hose con-

nections. 3-30,

3-32

En gine oil • Check oil level in engine.

• If necessary, add recommended oil to specified level.

• Check vehicle for oil leakage. 6-10

Final gear oil • Check vehicle for oil leakage. 6-14

Coolant • Check coolant level in reservoir.

• If necessary, add recommended coolant to specified

level.

• Check cooling system for leakage. 6-16

Front brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-24,

6-25

Rear brake • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check brake pads for wear.

• Replace if necessary.

• Check fluid level in reservoir.

• If necessary, add specified brake fluid to specified level.

• Check hydraulic system for leakage. 6-24,

6-25

Clutch • Check operation.

• If soft or spongy, have Yamaha dealer bleed hydraulic

system.

• Check hydraulic system for leakage. 6-22

UBP9E0E0.book Page 1 Wedne

sday, February 8, 2017 8:34 AM

Page 63 of 122

Operation and important ri din g points

5-2

5

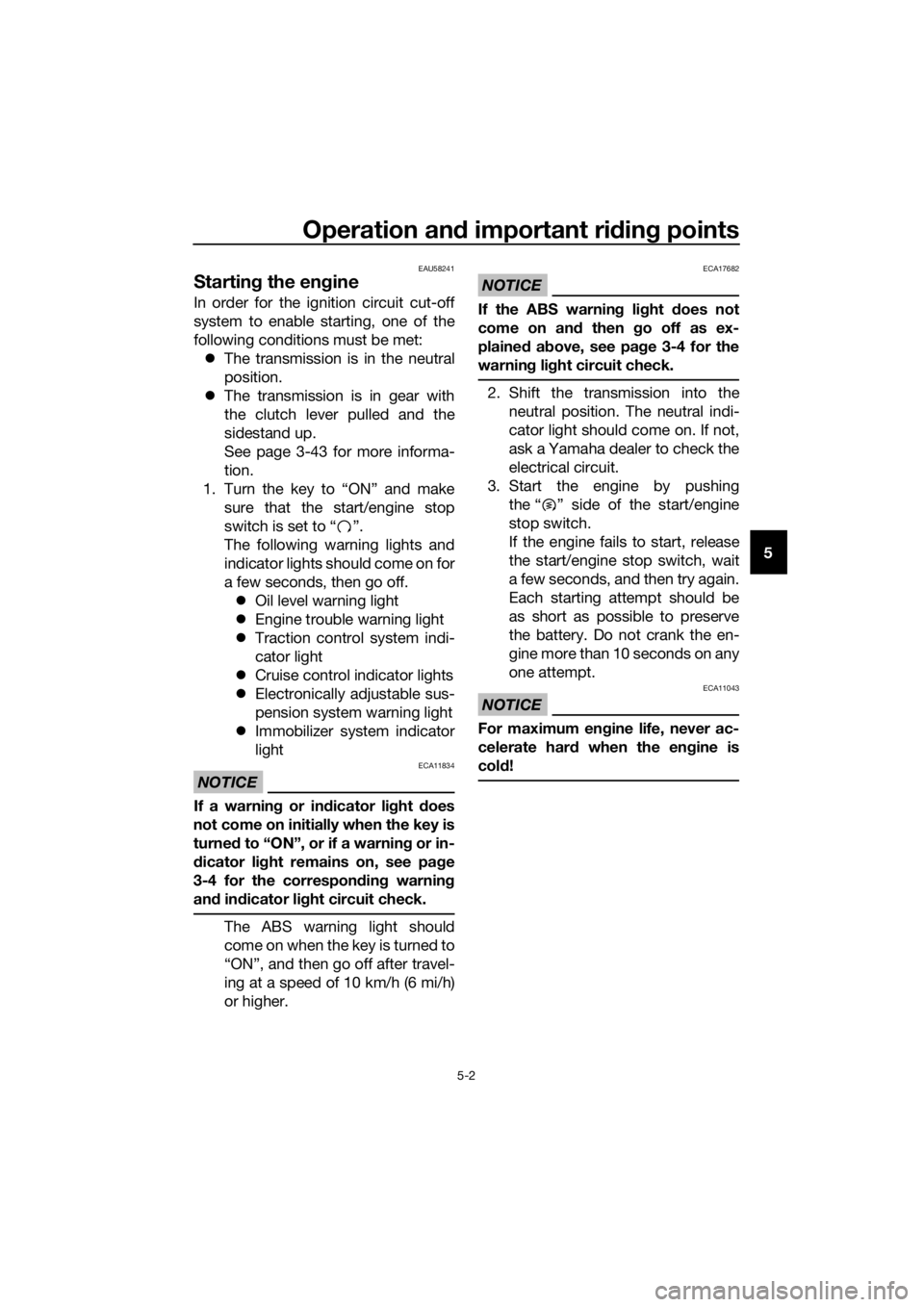

EAU58241

Startin g the eng ine

In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

The transmission is in the neutral

position.

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-43 for more informa-

tion.

1. Turn the key to “ON” and make sure that the start/engine stop

switch is set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off. Oil level warning light

Engine trouble warning light

Traction control system indi-

cator light

Cruise control indicator lights

Electronically adjustable sus-

pension system warning light

Immobilizer system indicator

light

NOTICE

ECA11834

If a warnin g or in dicator li ght does

not come on initially when the key is

turne d to “ON”, or if a warnin g or in-

d icator li ght remains on, see pa ge

3-4 for the correspon din g warnin g

an d in dicator li ght circuit check.

The ABS warning light should

come on when the key is turned to

“ON”, and then go off after travel-

ing at a speed of 10 km/h (6 mi/h)

or higher.

NOTICE

ECA17682

If the ABS warnin g li ght does not

come on an d then go off as ex-

plained above, see pa ge 3-4 for the

warnin g li ght circuit check.

2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the “ ” side of the start/engine

stop switch.

If the engine fails to start, release

the start/engine stop switch, wait

a few seconds, and then try again.

Each starting attempt should be

as short as possible to preserve

the battery. Do not crank the en-

gine more than 10 seconds on any

one attempt.

NOTICE

ECA11043

For maximum en gine life, never ac-

celerate har d when the en gine is

col d!

UBP9E0E0.book Page 2 Wedne sday, February 8, 2017 8:34 AM

Page 66 of 122

Operation and important rid ing points

5-5

5

If any en gine trou ble shoul d oc-

cur during the en gine break-in

period , imme diately have a

Yamaha dealer check the vehi-

cle.

EAU17214

Parkin g

When parking, stop the engine, and

then remove the key from the main

switch.

WARNING

EWA10312

Since the en gine an d exhaust

system can become very hot,

park in a place where ped estri-

ans or chil dren are not likely to

touch them and b e burne d.

Do not park on a slope or on soft

groun d, otherwise the vehicle

may overturn, increasin g the

risk of a fuel leak an d fire.

Do not park near g rass or other

flammab le materials which

mi ght catch fire.

UBP9E0E0.book Page 5 Wedne sday, February 8, 2017 8:34 AM

Page 69 of 122

Periodic maintenance an d a djustment

6-3

6

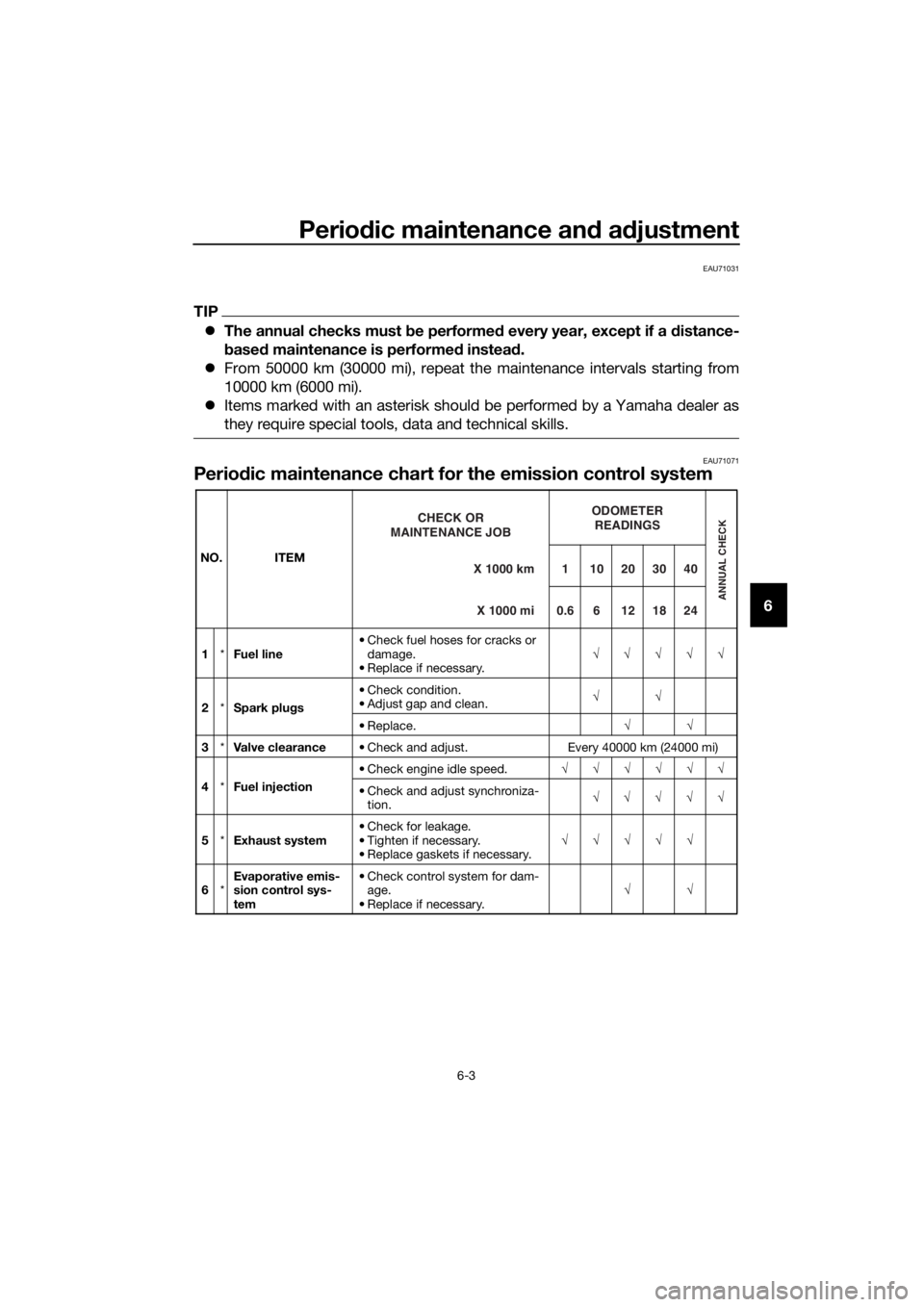

EAU71031

TIP

The annual checks must b e performed every year, except if a distance-

b ased maintenance is performed instead.

From 50000 km (30000 mi), repeat the maintenance intervals starting from

10000 km (6000 mi).

Items marked with an asterisk should be performed by a Yamaha dealer as

they require special tools, data and technical skills.

EAU71071

Perio dic maintenance chart for the emission control system

NO. ITEM

1 *Fuel line • Check fuel hoses for cracks or

damage.

• Replace if necessary. √√√√√

2 *Spark plu gs • Check condition.

• Adjust gap and clean.

√√

• Replace. √√

3 *Valve clearance • Check and adjust. Every 40000 km (24000 mi)

4 *Fuel injection • Check engine idle speed.

√√√√√√

• Check and adjust synchroniza- tion. √√√√√

5 *Exhaust system • Check for leakage.

• Tighten if necessary.

• Replace gaskets if necessary. √√√√√

6 *Evaporative emis-

sion control sys-

tem • Check control system for dam-

age.

• Replace if necessary. √√X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER READINGS

ANNUAL CHECK

110203040

0.66121824

UBP9E0E0.book Page 3 Wedne sday, February 8, 2017 8:34 AM

Page 71 of 122

Periodic maintenance an d a djustment

6-5

6

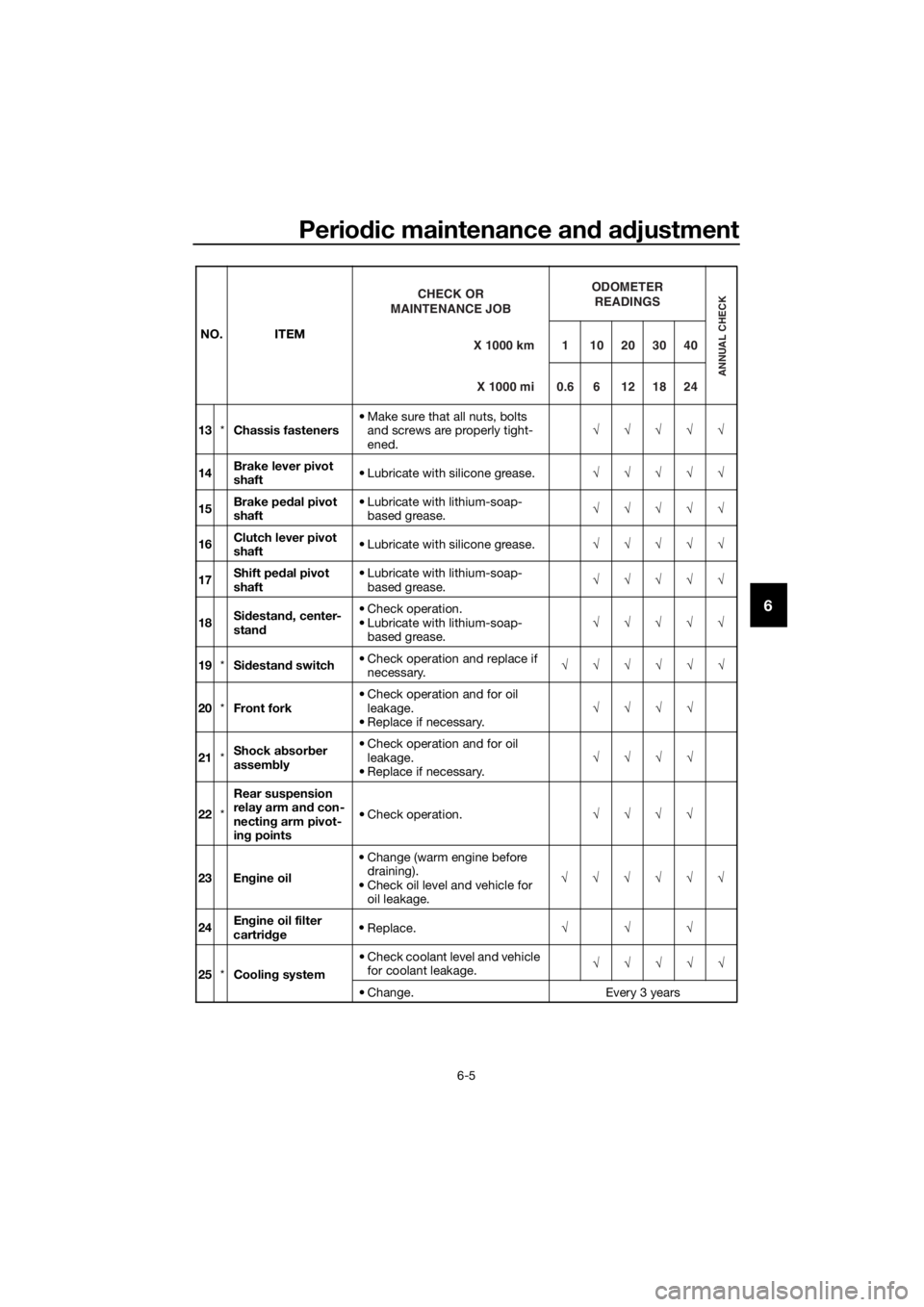

13 *Chassis fasteners • Make sure that all nuts, bolts

and screws are properly tight-

ened. √√√√√

14 Brake lever pivot

shaft

• Lubricate with silicone grease.

√√√√√

15 Brake ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

16 Clutch lever pivot

shaft • Lubricate with silicone grease.

√√√√√

17 Shift ped

al pivot

shaft • Lubricate with lithium-soap-

based grease. √√√√√

18 Si

destan d, center-

stan d • Check operation.

• Lubricate with lithium-soap-

based grease. √√√√√

19 *Sidestan d switch • Check operation and replace if

necessary. √√√√√√

20 *Front fork • Check operation and for oil

leakage.

• Replace if necessary. √√√√

21 *Shock a

bsor ber

assem bly • Check operation and for oil

leakage.

• Replace if necessary. √√√√

22 *Rear suspension

relay arm an

d con-

nectin g arm pivot-

in g points • Check operation.

√√√√

23 En gine oil • Change (warm engine before

draining).

• Check oil level and vehicle for oil leakage. √√√√√√

24 En

gine oil filter

cartri dge •

R

eplace.

√√√

25 *Coolin g system • Check coolant level and vehicle

for coolant leakage. √√√√√

• Change. Every 3 years

NO. ITEM

X 1000 km

CHECK OR

MAINTENANCE JOB

X 1000 mi

ODOMETER READINGS

ANNUAL CHECK

110203040

0.66121824

UBP9E0E0.book Page 5 Wedne sday, February 8, 2017 8:34 AM

Page 75 of 122

Periodic maintenance an d a djustment

6-9

6

EAU19653

Checkin g the spark plu gs

The spark plugs are important engine

components, which should be

checked periodically, preferably by a

Yamaha dealer. Since heat and depos- its will cause any spark plug to slowly

erode, they should be removed and

checked in accordance with the peri-

odic maintenance and lubrication

chart. In addition, the condition of the

spark plugs can reveal the condition of

the engine.

The porcelain insulator around the

center electrode of each spark plug

should be a medium-to-light tan (the

ideal color when the vehicle is ridden

normally), and all spark plugs installed

in the engine should have the same

color. If any spark plug shows a dis-

tinctly different color, the engine could

be operating improperly. Do not at-

tempt to diagnose such problems

yourself. Instead, have a Yamaha deal-

er check the vehicle.

If a spark plug shows signs of elec-

trode erosion and excessive carbon or

other deposits, it should be replaced.

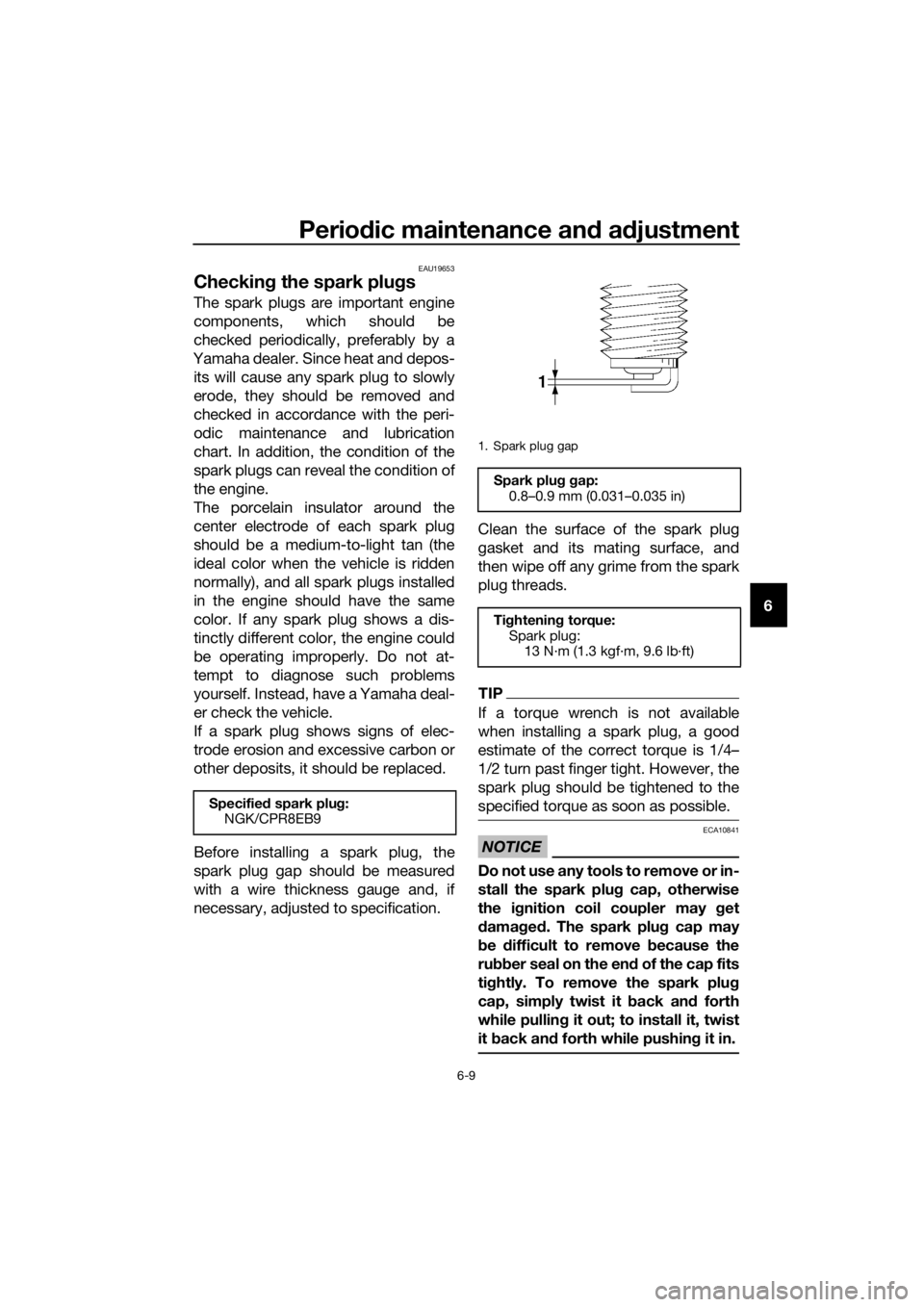

Before installing a spark plug, the

spark plug gap should be measured

with a wire thickness gauge and, if

necessary, adjusted to specification. Clean the surface of the spark plug

gasket and its mating surface, and

then wipe off any grime from the spark

plug threads.

TIP

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.

NOTICE

ECA10841

Do not use any tools to remove or in-

stall the spark plu

g cap, otherwise

the i gnition coil coupler may get

d amag ed . The spark plu g cap may

b e difficult to remove because the

ru bber seal on the en d of the cap fits

ti g htly. To remove the spark plu g

cap, simply twist it b ack and forth

while pullin g it out; to install it, twist

it back an d forth while pushin g it in.

Specified spark plu g:

NGK/CPR8EB9

1. Spark plug gap

Spark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.6 lb·ft)

UBP9E0E0.book Page 9 Wedne sday, February 8, 2017 8:34 AM

Page 76 of 122

Periodic maintenance an d a djustment

6-10

6

EAU79401

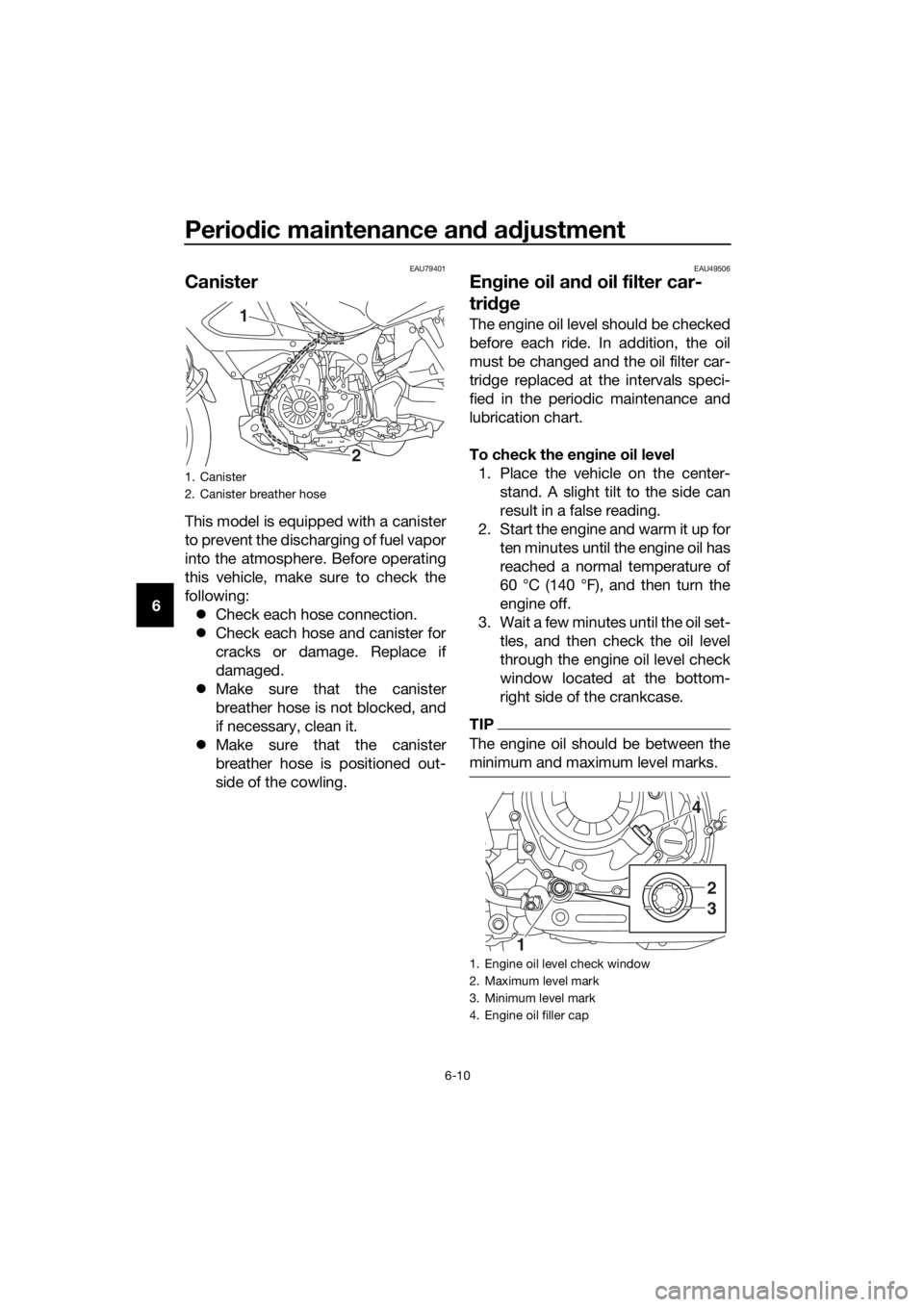

Canister

This model is equipped with a canister

to prevent the discharging of fuel vapor

into the atmosphere. Before operating

this vehicle, make sure to check the

following:

Check each hose connection.

Check each hose and canister for

cracks or damage. Replace if

damaged.

Make sure that the canister

breather hose is not blocked, and

if necessary, clean it.

Make sure that the canister

breather hose is positioned out-

side of the cowling.

EAU49506

Engine oil an d oil filter car-

tri dge

The engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter car-

tridge replaced at the intervals speci-

fied in the periodic maintenance and

lubrication chart.

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine and warm it up for ten minutes until the engine oil has

reached a normal temperature of

60 °C (140 °F), and then turn the

engine off.

3. Wait a few minutes until the oil set- tles, and then check the oil level

through the engine oil level check

window located at the bottom-

right side of the crankcase.

TIP

The engine oil should be between the

minimum and maximum level marks.

1. Canister

2. Canister breather hose

2

1

1. Engine oil level check window

2. Maximum level mark

3. Minimum level mark

4. Engine oil filler cap

4

2

3

1

UBP9E0E0.book Page 10 Wednesday, February 8, 2017 8:34 AM