warning light YAMAHA XT1200ZE 2017 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: XT1200ZE, Model: YAMAHA XT1200ZE 2017Pages: 122, PDF Size: 3.36 MB

Page 51 of 122

Instrument and control functions

3-37

3

EAU55424

A djustin g the front an d rear

suspension

This model is equipped with an elec-

tronically adjustable suspension sys-

tem. The preload of the rear shock

absorber and the damping forces of

both the front fork and rear shock ab-

sorber can be adjusted.

WARNING

EWA12423

Be sure to stop the vehicle before

makin g any settin g chan ges to the

multi-function meter unit. Chang ing

settin gs while ri din g can d istract the

operator an d increase the risk of an

acci dent.

Preloa d

When riding with luggage or a passen-

ger, use the preload adjusting function

to adjust the suspension system to

match the load. There are 4 preload

settings.

TIP

The preload adjusting function will

appear only when the engine is

running.

Changing the preload setting will

also adjust the front and rear sus-

pension damping forces accord-

ingly. See “Damping force” on

page 3-39 for more information.

About cold temperature opera-

tion:

• When using the preload adjust- ing function, there should be no

weight on the vehicle.

• When using the preload adjust- ing function at ambient temper-

atures near or below 0 °C (32

°F), to protect the preload ad- justing function motor, the elec-

tronically adjustable suspension

system warning light may come

on.

• The suspension will still operate as normal, only the preload ad-

justing function cannot be used.

• To reset the electronically ad- justable suspension system

warning light, wait approximate-

ly 6 minutes and then turn the

key to “OFF” or immediately

turn the key to “OFF” and then

wait 6 minutes.

• If the electronically adjustable suspension system warning

light remains on, have a

Yamaha dealer check the sus- pension system.

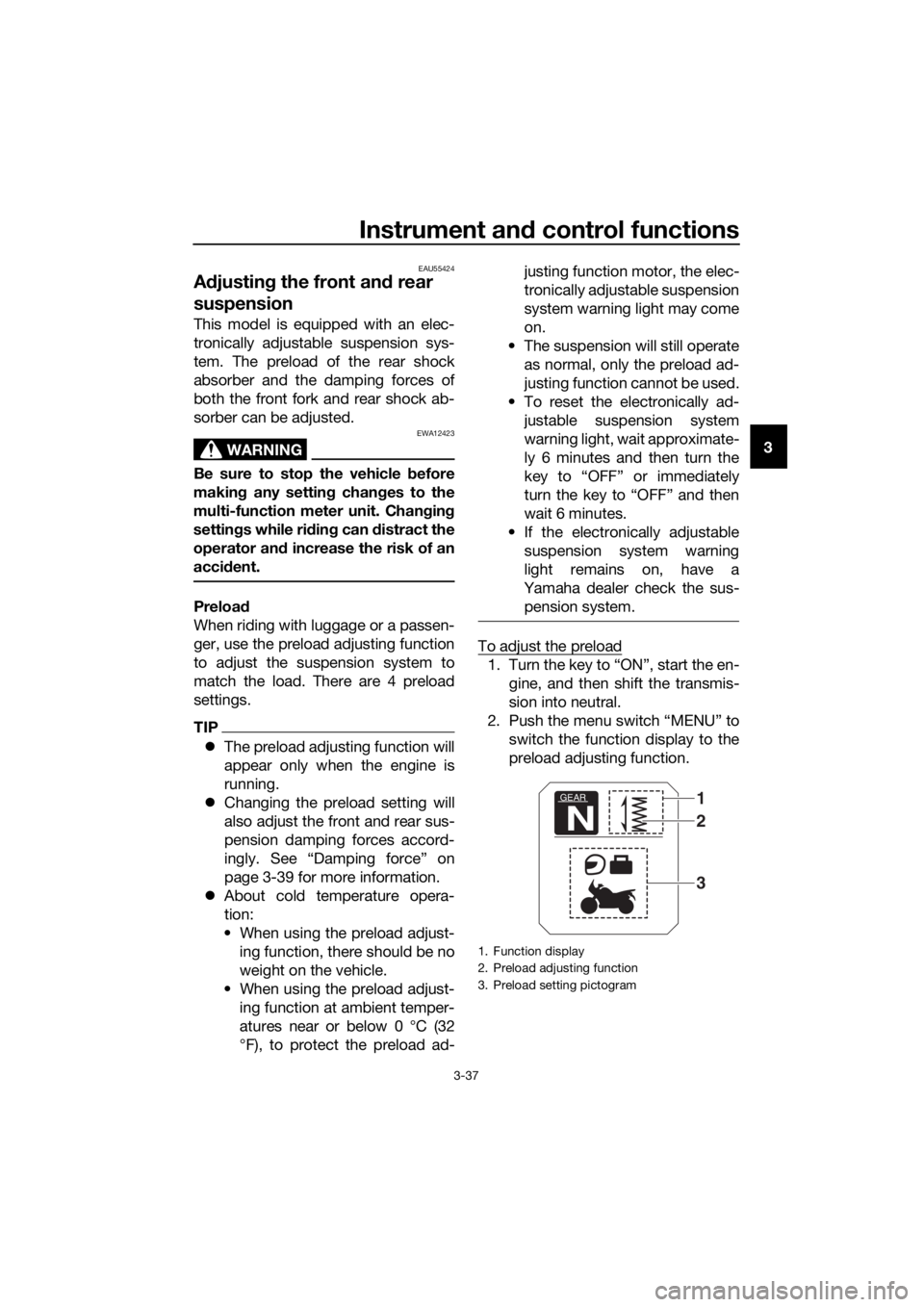

To adjust the preload

1. Turn the key to “ON”, start the en- gine, and then shift the transmis-

sion into neutral.

2. Push the menu switch “MENU” to switch the function display to the

preload adjusting function.

1. Function display

2. Preload adjusting function

3. Preload setting pictogram

GEAR

N

1

3

2

UBP9E0E0.book Page 37 Wednesday, February 8, 2017 8:34 AM

Page 63 of 122

Operation and important ri din g points

5-2

5

EAU58241

Startin g the eng ine

In order for the ignition circuit cut-off

system to enable starting, one of the

following conditions must be met:

The transmission is in the neutral

position.

The transmission is in gear with

the clutch lever pulled and the

sidestand up.

See page 3-43 for more informa-

tion.

1. Turn the key to “ON” and make sure that the start/engine stop

switch is set to “ ”.

The following warning lights and

indicator lights should come on for

a few seconds, then go off. Oil level warning light

Engine trouble warning light

Traction control system indi-

cator light

Cruise control indicator lights

Electronically adjustable sus-

pension system warning light

Immobilizer system indicator

light

NOTICE

ECA11834

If a warnin g or in dicator li ght does

not come on initially when the key is

turne d to “ON”, or if a warnin g or in-

d icator li ght remains on, see pa ge

3-4 for the correspon din g warnin g

an d in dicator li ght circuit check.

The ABS warning light should

come on when the key is turned to

“ON”, and then go off after travel-

ing at a speed of 10 km/h (6 mi/h)

or higher.

NOTICE

ECA17682

If the ABS warnin g li ght does not

come on an d then go off as ex-

plained above, see pa ge 3-4 for the

warnin g li ght circuit check.

2. Shift the transmission into the

neutral position. The neutral indi-

cator light should come on. If not,

ask a Yamaha dealer to check the

electrical circuit.

3. Start the engine by pushing the “ ” side of the start/engine

stop switch.

If the engine fails to start, release

the start/engine stop switch, wait

a few seconds, and then try again.

Each starting attempt should be

as short as possible to preserve

the battery. Do not crank the en-

gine more than 10 seconds on any

one attempt.

NOTICE

ECA11043

For maximum en gine life, never ac-

celerate har d when the en gine is

col d!

UBP9E0E0.book Page 2 Wedne sday, February 8, 2017 8:34 AM

Page 79 of 122

Periodic maintenance an d a djustment

6-13

6

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical add itives. Do

not use oils with a d iesel speci-

fication of “CD” or oils of a hi gh-

er quality than specified . In

a ddition, do not use oils la bele d

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

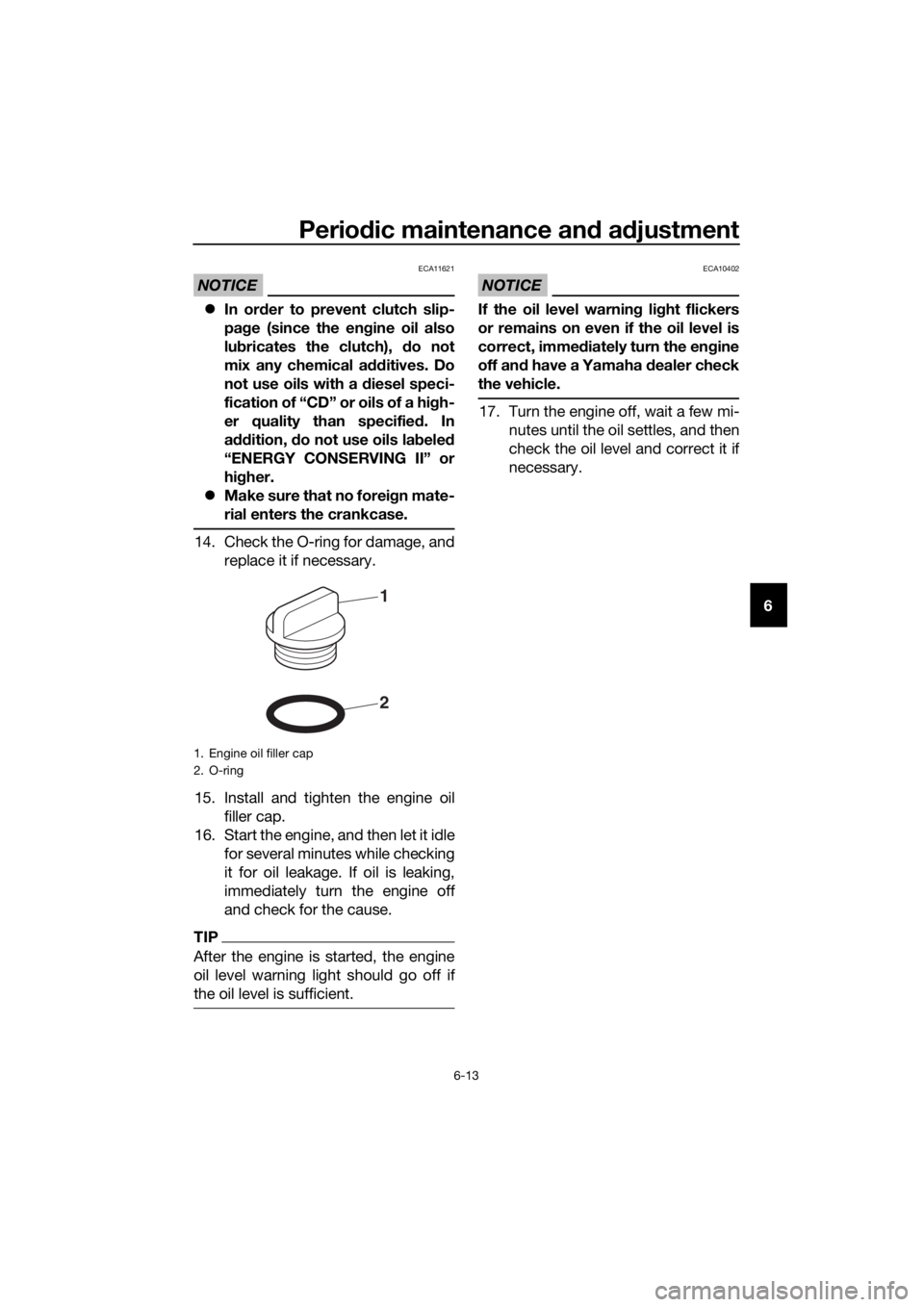

14. Check the O-ring for damage, and replace it if necessary.

15. Install and tighten the engine oil filler cap.

16. Start the engine, and then let it idle for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

TIP

After the engine is started, the engine

oil level warning light should go off if

the oil level is sufficient.

NOTICE

ECA10402

If the oil level warnin g li ght flickers

or remains on even if the oil level is

correct, imme diately turn the en gine

off an d have a Yamaha d ealer check

the vehicle.

17. Turn the engine off, wait a few mi- nutes until the oil settles, and then

check the oil level and correct it if

necessary.

1. Engine oil filler cap

2. O-ring

2

1

UBP9E0E0.book Page 13 Wednesday, February 8, 2017 8:34 AM

Page 80 of 122

Periodic maintenance an d a djustment

6-14

6

EAU20017

Final g ear oil

The final gear case must be checked

for oil leakage before each ride. If any

leakage is found, have a Yamaha deal-

er check and repair the vehicle. In ad-

dition, the final gear oil level must be

checked and the oil changed as fol-

lows at the intervals specified in the

periodic maintenance and lubrication

chart.

WARNING

EWA10371

Make sure that no forei gn mate-

rial enters the final g ear case.

Make sure that no oil g ets on

the tire or wheel.

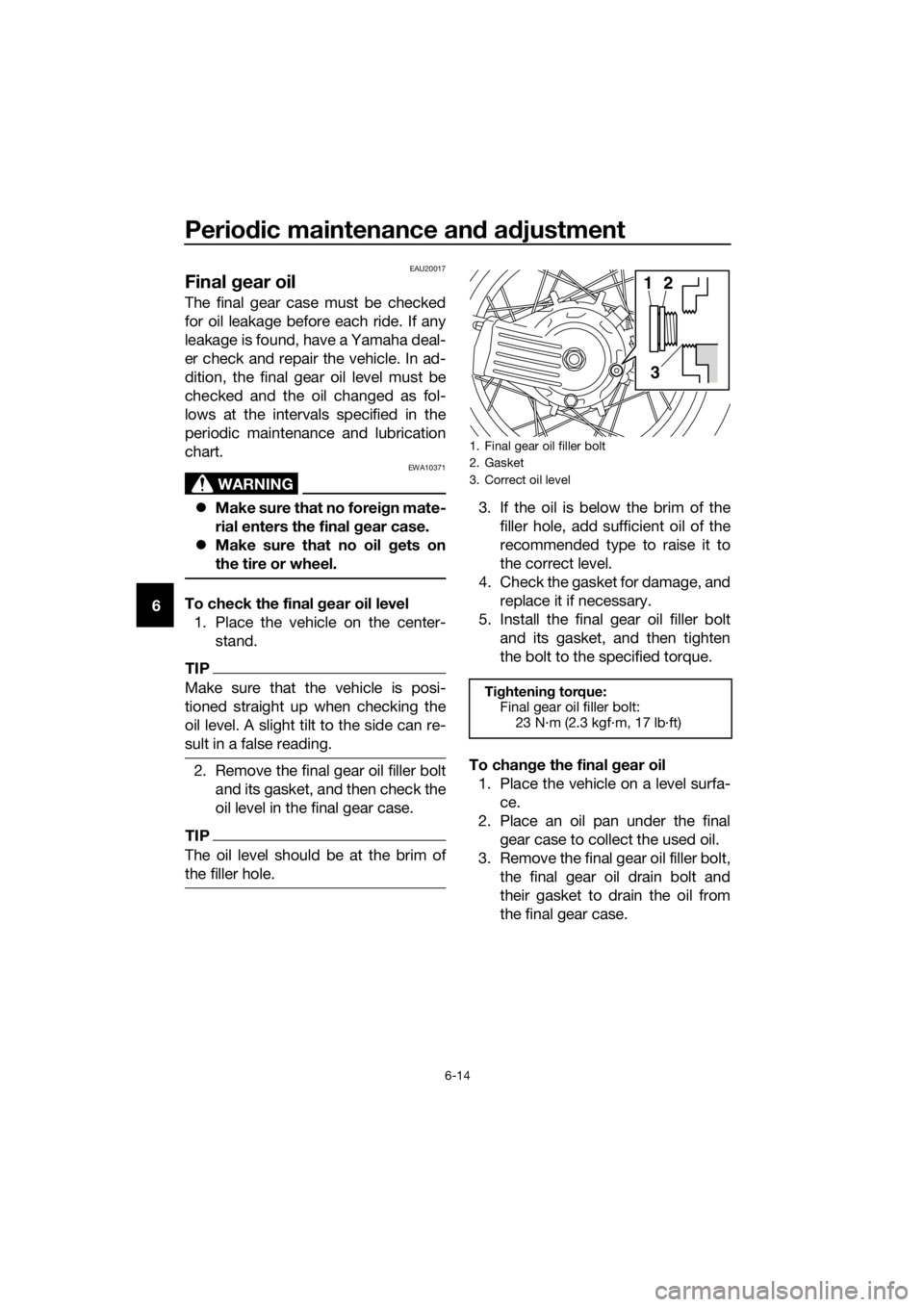

To check the final gear oil level

1. Place the vehicle on the center- stand.

TIP

Make sure that the vehicle is posi-

tioned straight up when checking the

oil level. A slight tilt to the side can re-

sult in a false reading.

2. Remove the final gear oil filler boltand its gasket, and then check the

oil level in the final gear case.

TIP

The oil level should be at the brim of

the filler hole.

3. If the oil is below the brim of thefiller hole, add sufficient oil of the

recommended type to raise it to

the correct level.

4. Check the gasket for damage, and replace it if necessary.

5. Install the final gear oil filler bolt and its gasket, and then tighten

the bolt to the specified torque.

To chan ge the final gear oil

1. Place the vehicle on a level surfa- ce.

2. Place an oil pan under the final gear case to collect the used oil.

3. Remove the final gear oil filler bolt, the final gear oil drain bolt and

their gasket to drain the oil from

the final gear case.

1. Final gear oil filler bolt

2. Gasket

3. Correct oil level

Tightening torque:

Final gear oil filler bolt:

23 N·m (2.3 kgf·m, 17 lb·ft)

12

3

UBP9E0E0.book Page 14 Wednesday, February 8, 2017 8:34 AM

Page 82 of 122

Periodic maintenance an d a djustment

6-16

6

EAU20071

Coolant

The coolant level should be checked

before each ride. In addition, the cool-

ant must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

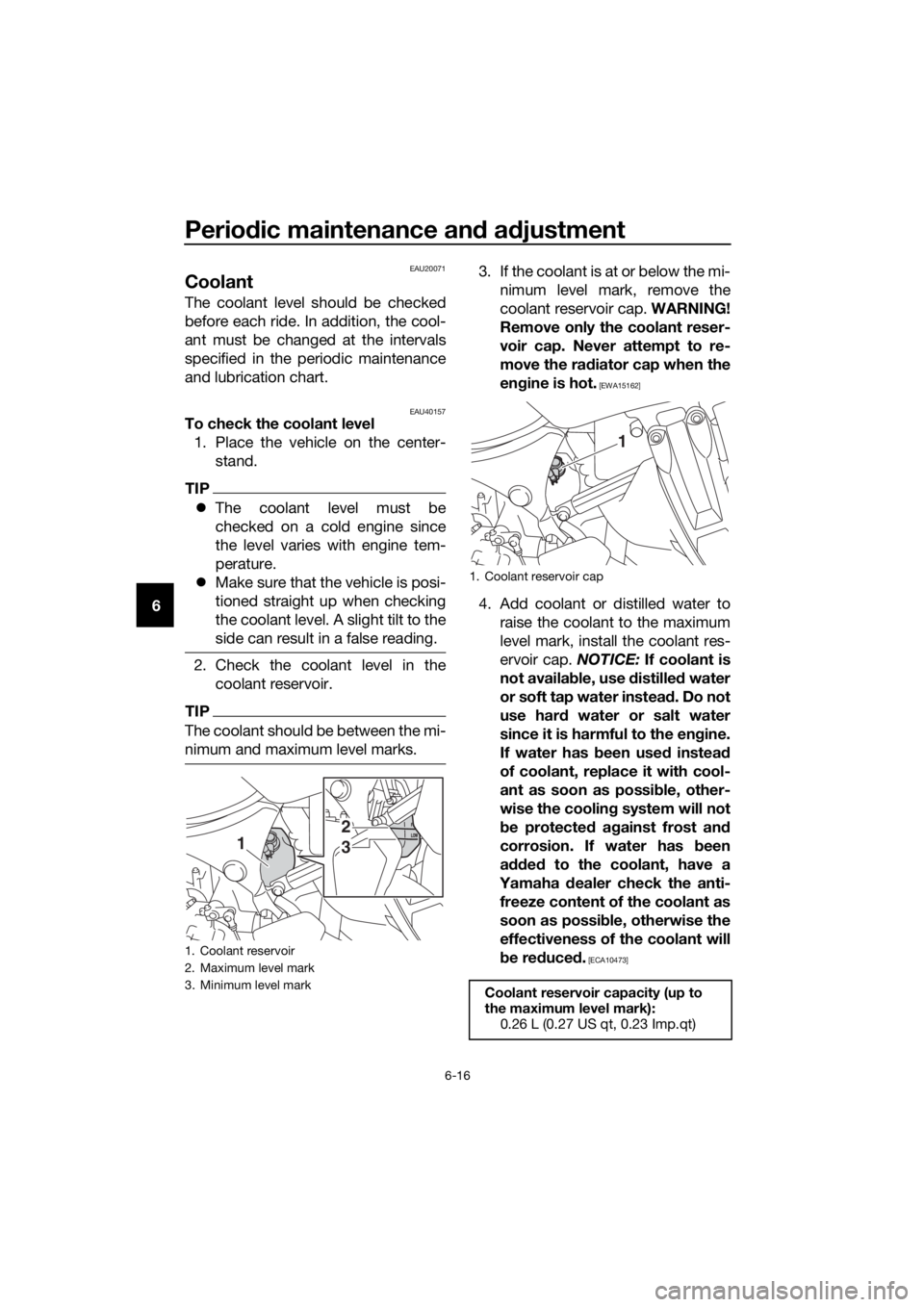

EAU40157To check the coolant level

1. Place the vehicle on the center- stand.

TIP

The coolant level must be

checked on a cold engine since

the level varies with engine tem-

perature.

Make sure that the vehicle is posi-

tioned straight up when checking

the coolant level. A slight tilt to the

side can result in a false reading.

2. Check the coolant level in the

coolant reservoir.

TIP

The coolant should be between the mi-

nimum and maximum level marks.

3. If the coolant is at or below the mi-nimum level mark, remove the

coolant reservoir cap. WARNING!

Remove only the coolant reser-

voir cap. Never attempt to re-

move the ra diator cap when the

en gine is hot.

[EWA15162]

4. Add coolant or distilled water to

raise the coolant to the maximum

level mark, install the coolant res-

ervoir cap. NOTICE: If coolant is

not availa ble, use d istilled water

or soft tap water instea d. Do not

use har d water or salt water

since it is harmful to the en gine.

If water has been used instead

of coolant, replace it with cool-

ant as soon as possi ble, other-

wise the coolin g system will not

b e protecte d a gainst frost an d

corrosion. If water has b een

a dde d to the coolant, have a

Yamaha dealer check the anti-

freeze content of the coolant as

soon as possi ble, otherwise the

effectiveness of the coolant will

b e red uced.

[ECA10473]1. Coolant reservoir

2. Maximum level mark

3. Minimum level mark

2

13

1. Coolant reservoir cap

Coolant reservoir capacity (up to

the maximum level mark):

0.26 L (0.27 US qt, 0.23 Imp.qt)

1

UBP9E0E0.book Page 16 Wednesday, February 8, 2017 8:34 AM

Page 89 of 122

Periodic maintenance an d a djustment

6-23

6

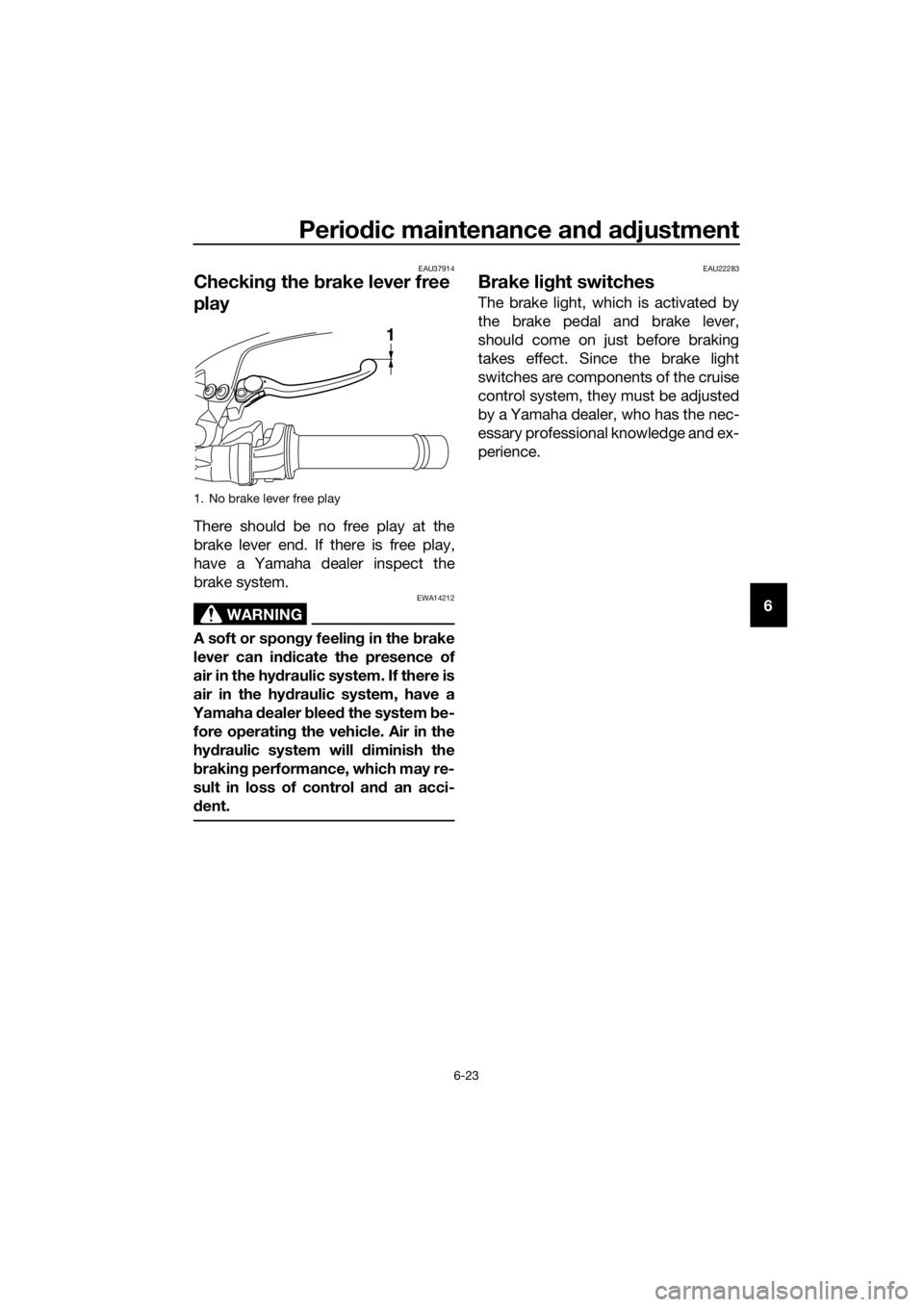

EAU37914

Checkin g the brake lever free

play

There should be no free play at the

brake lever end. If there is free play,

have a Yamaha dealer inspect the

brake system.

WARNING

EWA14212

A soft or spon gy feelin g in the b rake

lever can in dicate the presence of

air in the hy draulic system. If there is

air in the hy draulic system, have a

Yamaha dealer blee d the system be-

fore operatin g the vehicle. Air in the

hy draulic system will diminish the

b rakin g performance, which may re-

sult in loss of control an d an acci-

d ent.

EAU22283

Brake li ght switches

The brake light, which is activated by

the brake pedal and brake lever,

should come on just before braking

takes effect. Since the brake light

switches are components of the cruise

control system, they must be adjusted

by a Yamaha dealer, who has the nec-

essary professional knowledge and ex-

perience.

1. No brake lever free play

1

UBP9E0E0.book Page 23 Wednesday, February 8, 2017 8:34 AM

Page 98 of 122

Periodic maintenance an d a djustment

6-32

6

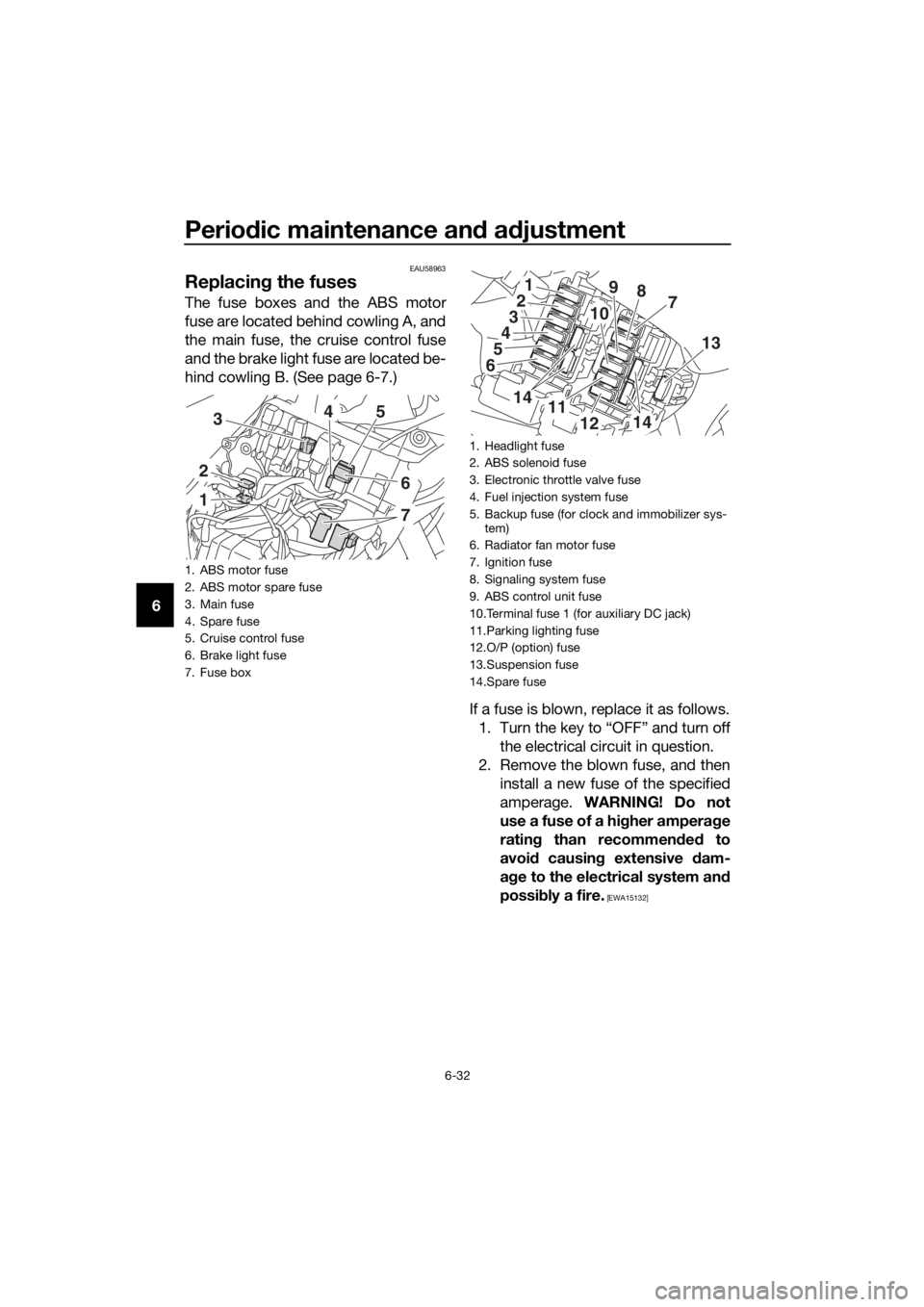

EAU58963

Replacin g the fuses

The fuse boxes and the ABS motor

fuse are located behind cowling A, and

the main fuse, the cruise control fuse

and the brake light fuse are located be-

hind cowling B. (See page 6-7.)

If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a hi gher ampera ge

ratin g than recommen ded to

avoi d causin g extensive dam-

a g e to the electrical system an d

possi bly a fire.

[EWA15132]

1. ABS motor fuse

2. ABS motor spare fuse

3. Main fuse

4. Spare fuse

5. Cruise control fuse

6. Brake light fuse

7. Fuse box

1

2

35

6

7

4

1. Headlight fuse

2. ABS solenoid fuse

3. Electronic throttle valve fuse

4. Fuel injection system fuse

5. Backup fuse (for clock and immobilizer sys-

tem)

6. Radiator fan motor fuse

7. Ignition fuse

8. Signaling system fuse

9. ABS control unit fuse

10.Terminal fuse 1 (for auxiliary DC jack)

11.Parking lighting fuse

12.O/P (option) fuse

13.Suspension fuse

14.Spare fuse

1

3

4

5

6

2789

10

14

13

11

1214

UBP9E0E0.book Page 32 Wednesday, February 8, 2017 8:34 AM

Page 102 of 122

Periodic maintenance an d a djustment

6-36

6

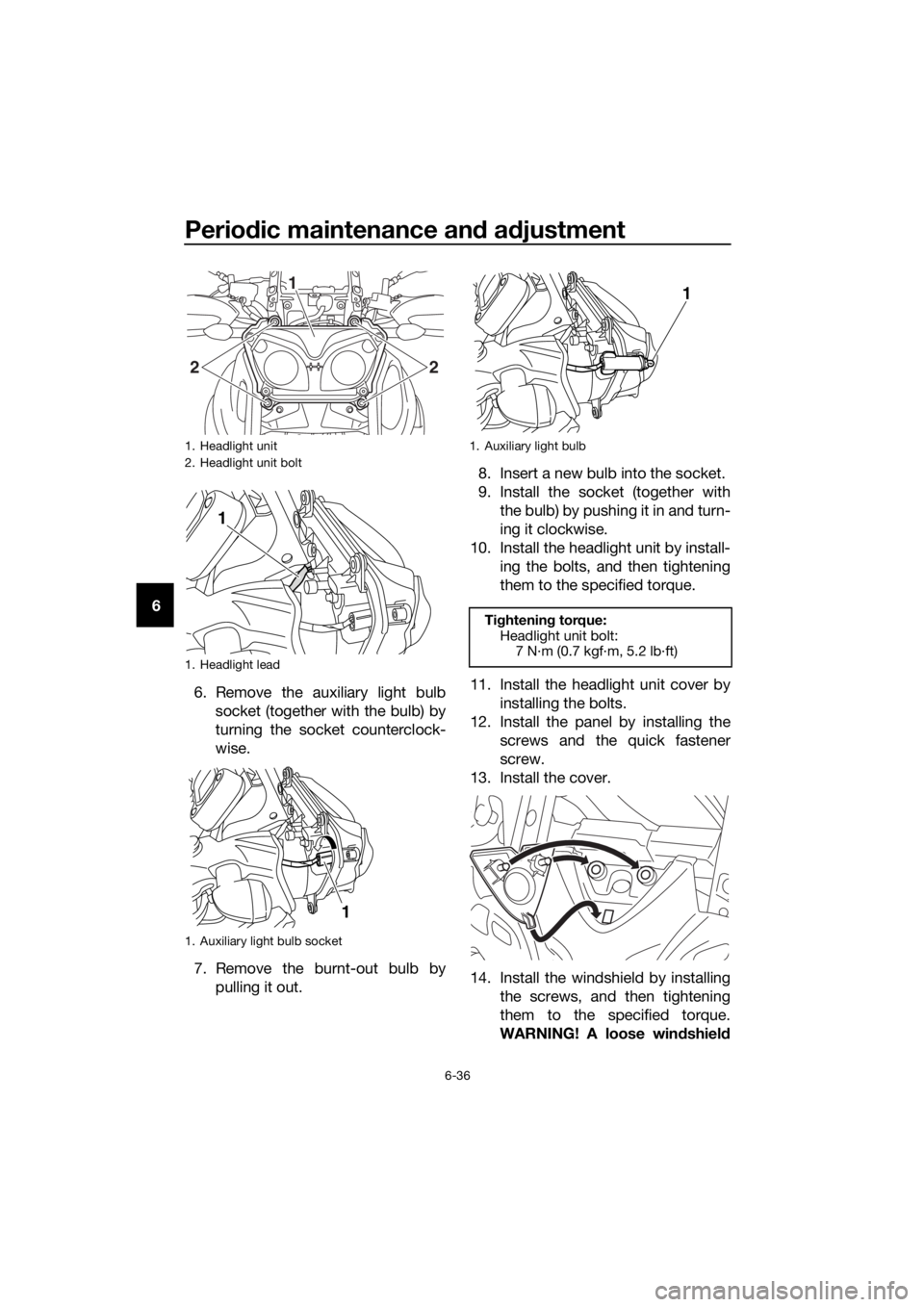

6. Remove the auxiliary light bulbsocket (together with the bulb) by

turning the socket counterclock-

wise.

7. Remove the burnt-out bulb by pulling it out. 8. Insert a new bulb into the socket.

9. Install the socket (together with

the bulb) by pushing it in and turn-

ing it clockwise.

10. Install the headlight unit by install- ing the bolts, and then tightening

them to the specified torque.

11. Install the headlight unit cover by installing the bolts.

12. Install the panel by installing the screws and the quick fastener

screw.

13. Install the cover.

14. Install the windshield by installing the screws, and then tightening

them to the specified torque.

WARNING! A loose win dshield

1. Headlight unit

2. Headlight unit bolt

1. Headlight lead

1. Auxiliary light bulb socket

1

2

2

1

1

1. Auxiliary light bulb

Tightening torque:

Headlight unit bolt: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

1

UBP9E0E0.book Page 36 Wednesday, February 8, 2017 8:34 AM

Page 110 of 122

Motorcycle care and stora ge

7-3

7 2. After drying the motorcycle, apply

a corrosion protection spray on all

metal, including chrome- and

nickel-plated, surfaces to prevent

corrosion.

Windshield cleaning

Avoid using any alkaline or strong acid

cleaner, gasoline, brake fluid, or any

other solvent. Clean the windshield

with a cloth or sponge dampened with

a neutral detergent, and after cleaning,

thoroughly wash it off with water. For

additional cleaning, use Yamaha Wind-

shield Cleaner or other quality cleaner.

Some cleaning compounds for plastics

may leave scratches on surfaces of the

windshield. Before using them, make a

test by polishing an area which does

not affect your visibility.

After cleanin g

1. Dry the motorcycle with a chamois or an absorbing cloth.

2. Use a chrome polish to shine chrome, aluminum and stainless-

steel parts, including the exhaust

system. (Even the thermally in-

duced discoloring of stainless-

steel exhaust systems can be re-

moved through polishing.)

3. To prevent corrosion, it is recom- mended to apply a corrosion pro-

tection spray on all metal,

including chrome- and nickel-plat-

ed, surfaces.

4. Use spray oil as a universal clean- er to remove any remaining dirt.

5. Touch up minor paint damage caused by stones, etc.

6. Wax all painted surfaces. 7. Let the motorcycle dry completely

before storing or covering it.

WARNING

EWA11132

Contaminants on the brakes or tires

can cause loss of control. Make sure that there is no oil or

wax on the brakes or tires.

If necessary, clean the b rake

d iscs an d b rake linin gs with a

re gular brake disc cleaner or

acetone, an d wash the tires with

warm water an d a mil d d eter-

g ent. Before ri din g at hi gher

speed s, test the motorcycle’s

b rakin g performance an d cor-

nering b ehavior.

NOTICE

ECA10801

Apply spray oil an d wax spar-

in gly an d make sure to wipe off

any excess.

Never apply oil or wax to any

rubber an d plastic parts, but

treat them with a suitab le care

prod uct.

Avoi d using abrasive polishin g

compoun ds as they will wear

away the paint.

TIP

Consult a Yamaha dealer for ad-

vice on what products to use.

Washing, rainy weather or humid

climates can cause the headlight

lens to fog. Turning the headlight

on for a short period of time will

help remove the moisture from the

lens.

UBP9E0E0.book Page 3 Wedne sday, February 8, 2017 8:34 AM

Page 115 of 122

Specifications

8-3

8

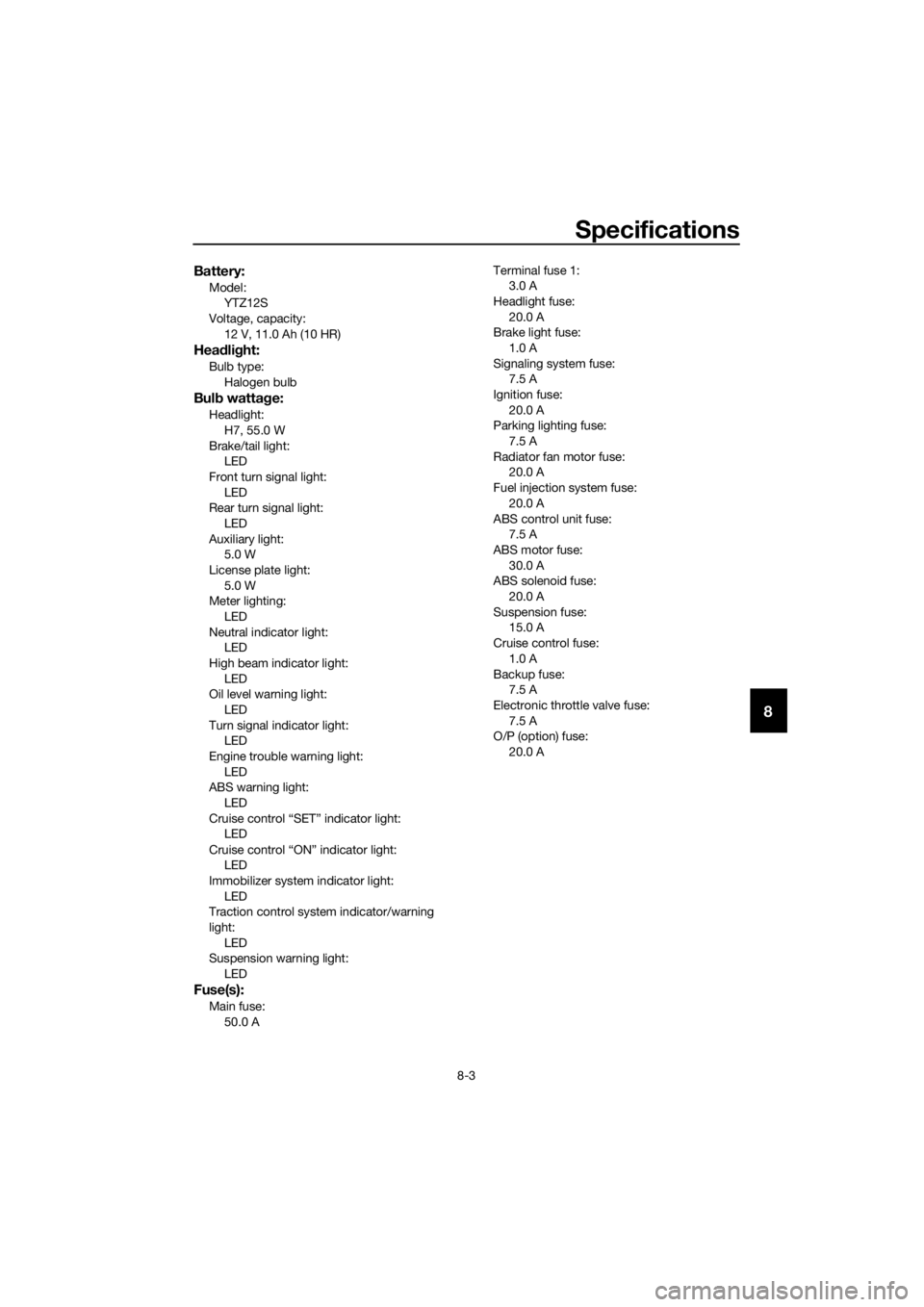

Battery:

Model:YTZ12S

Voltage, capacity:

12 V, 11.0 Ah (10 HR)

Hea dlig ht:

Bulb type:

Halogen bulb

Bul b watta ge:

Headlight:

H7, 55.0 W

Brake/tail light: LED

Front turn signal light:

LED

Rear turn signal light:

LED

Auxiliary light: 5.0 W

License plate light: 5.0 W

Meter lighting:

LED

Neutral indicator light: LED

High beam indicator light: LED

Oil level warning light:

LED

Turn signal indicator light: LED

Engine trouble warning light: LED

ABS warning light:

LED

Cruise control “SET” indicator light: LED

Cruise control “ON” indicator light: LED

Immobilizer system indicator light:

LED

Traction control system indicator/warning

light:

LED

Suspension warning light: LED

Fuse(s):

Main fuse:

50.0 A Terminal fuse 1:

3.0 A

Headlight fuse: 20.0 A

Brake light fuse:

1.0 A

Signaling system fuse: 7.5 A

Ignition fuse: 20.0 A

Parking lighting fuse:

7.5 A

Radiator fan motor fuse: 20.0 A

Fuel injection system fuse: 20.0 A

ABS control unit fuse: 7.5 A

ABS motor fuse:

30.0 A

ABS solenoid fuse: 20.0 A

Suspension fuse: 15.0 A

Cruise control fuse:

1.0 A

Backup fuse: 7.5 A

Electronic throttle valve fuse: 7.5 A

O/P (option) fuse:

20.0 A

UBP9E0E0.book Page 3 Wedne sday, February 8, 2017 8:34 AM