brake YAMAHA XT500E 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XT500E, Model: YAMAHA XT500E 2000Pages: 96, PDF Size: 4.23 MB

Page 59 of 96

EW000109

wA soft or spongy feeling in the

brake pedal can indicate the pres-

ence of air in the brake system.

This air must be removed by

bleeding the brake system before

the motorcycle is operated. Air in

the system will cause greatly

diminished braking capability and

can result in loss of control and an

accident. Have a Yamaha dealer

inspect and bleed the system if

necessary.

6-19

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU00712

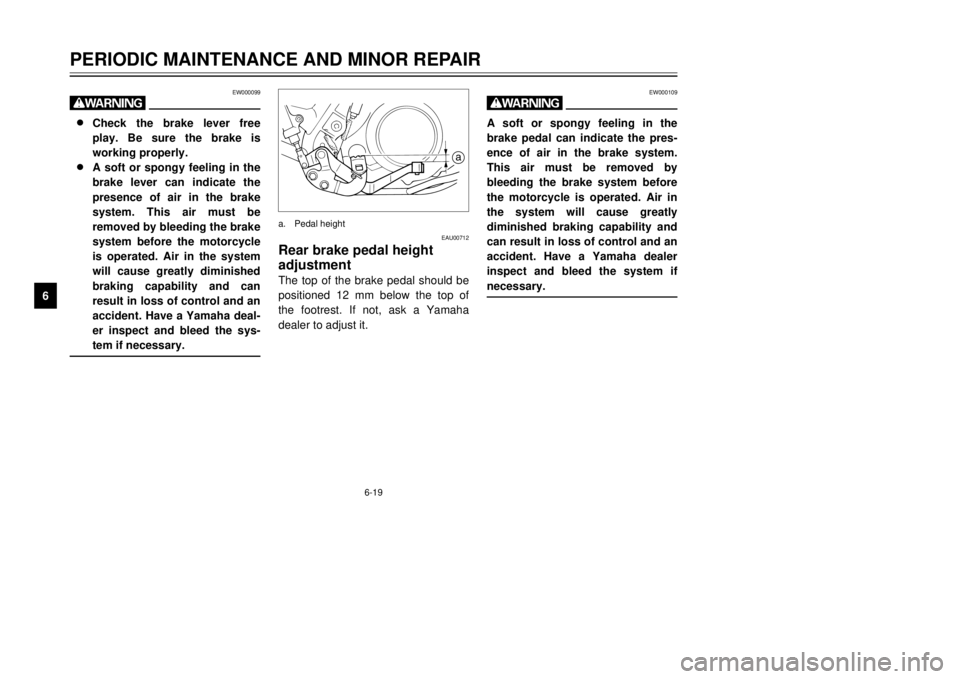

Rear brake pedal height

adjustmentThe top of the brake pedal should be

positioned 12 mm below the top of

the footrest. If not, ask a Yamaha

dealer to adjust it.

a

a.Pedal height

EW000099

w8

8

Check the brake lever free

play. Be sure the brake is

working properly.

8 8

A soft or spongy feeling in the

brake lever can indicate the

presence of air in the brake

system. This air must be

removed by bleeding the brake

system before the motorcycle

is operated. Air in the system

will cause greatly diminished

braking capability and can

result in loss of control and an

accident. Have a Yamaha deal-

er inspect and bleed the sys-

tem if necessary.

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 20

Page 60 of 96

6-20

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

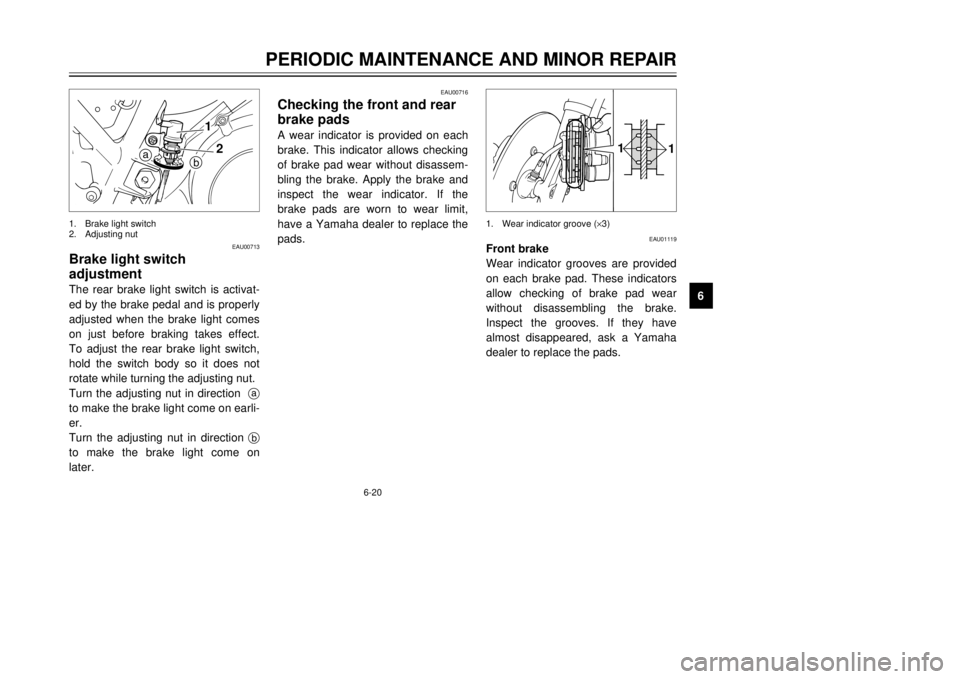

EAU00713

Brake light switch

adjustmentThe rear brake light switch is activat-

ed by the brake pedal and is properly

adjusted when the brake light comes

on just before braking takes effect.

To adjust the rear brake light switch,

hold the switch body so it does not

rotate while turning the adjusting nut.

Turn the adjusting nut in direction a

to make the brake light come on earli-

er.

Turn the adjusting nut in direction b

to make the brake light come on

later.

21

a

b

1.Brake light switch

2.Adjusting nut

EAU00716

Checking the front and rear

brake padsA wear indicator is provided on each

brake. This indicator allows checking

of brake pad wear without disassem-

bling the brake. Apply the brake and

inspect the wear indicator. If the

brake pads are worn to wear limit,

have a Yamaha dealer to replace the

pads.

EAU01119

Front brake

Wear indicator grooves are provided

on each brake pad. These indicators

allow checking of brake pad wear

without disassembling the brake.

Inspect the grooves. If they have

almost disappeared, ask a Yamaha

dealer to replace the pads.

1

1

1.Wear indicator groove (´3)

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 21

Page 61 of 96

6-21

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

1

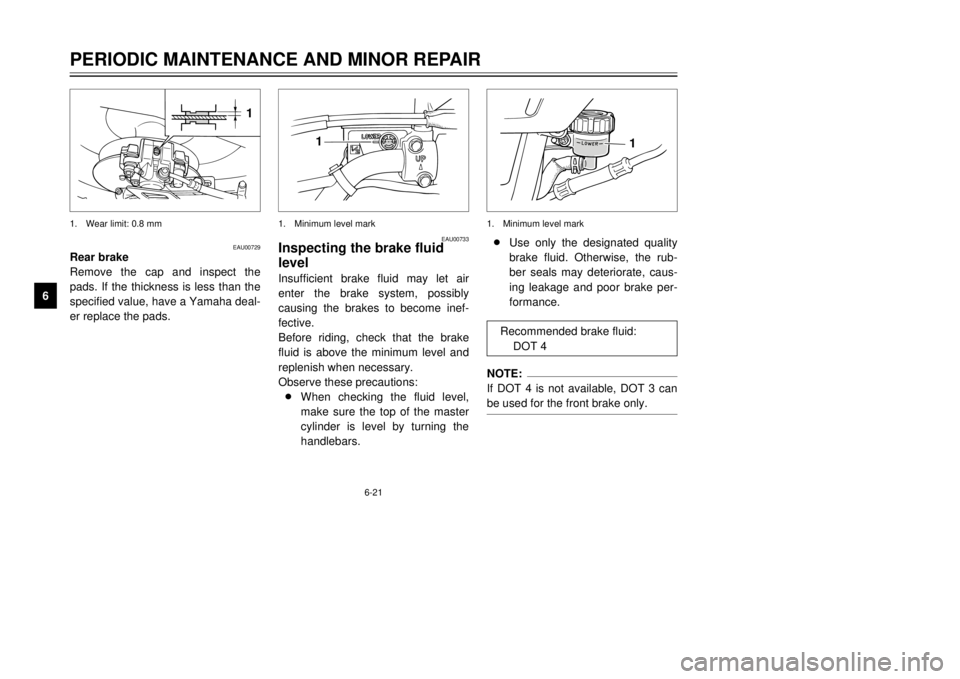

8Use only the designated quality

brake fluid. Otherwise, the rub-

ber seals may deteriorate, caus-

ing leakage and poor brake per-

formance.NOTE:

If DOT 4 is not available, DOT 3 can

be used for the front brake only.1.Minimum level mark

Recommended brake fluid:

DOT 4

1

EAU00733

Inspecting the brake fluid

levelInsufficient brake fluid may let air

enter the brake system, possibly

causing the brakes to become inef-

fective.

Before riding, check that the brake

fluid is above the minimum level and

replenish when necessary.

Observe these precautions:

8When checking the fluid level,

make sure the top of the master

cylinder is level by turning the

handlebars.1.Minimum level mark

1

EAU00729

Rear brake

Remove the cap and inspect the

pads. If the thickness is less than the

specified value, have a Yamaha deal-

er replace the pads.1.Wear limit: 0.8 mm

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 22

Page 62 of 96

6-22

8Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor brake performance.

8Be careful that water does not

enter the master cylinder when

refilling. Water will significantly

lower the boiling point of the fluid

and may result in vapor lock.

8Brake fluid may deteriorate paint-

ed surfaces or plastic parts.

Always clean up spilled fluid

immediately.

8Have a Yamaha dealer check

the cause if the brake fluid level

goes down.

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU00742

Brake fluid replacementThe brake fluid should be replaced

only by trained Yamaha service per-

sonnel. Have the Yamaha dealer

replace the following components

during periodic maintenance or when

they are damaged or leaking:

8oil seals (every two years)

8brake hoses (every four years)

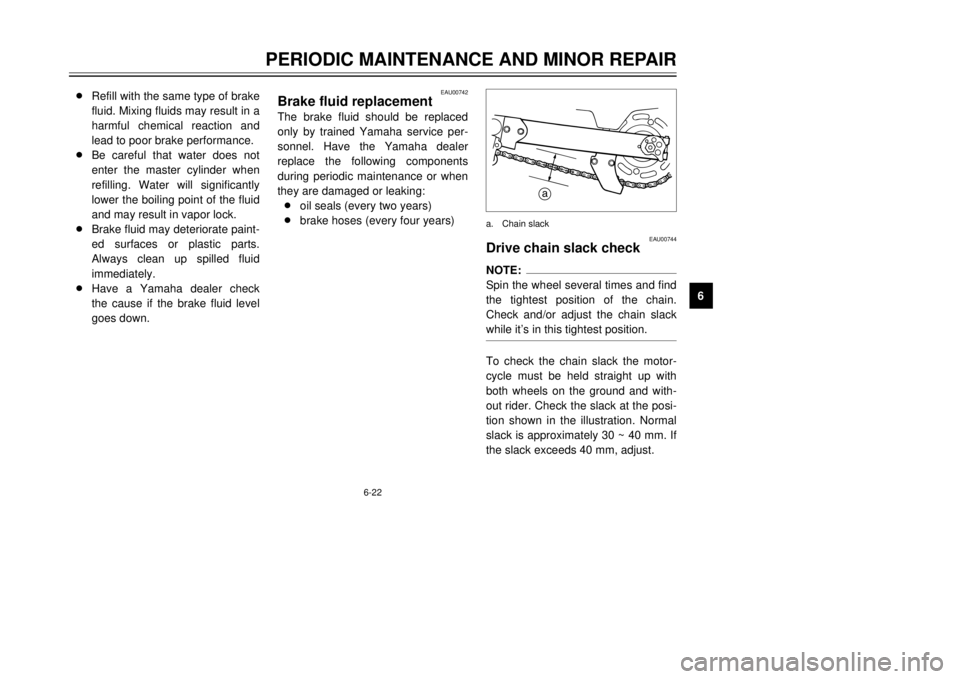

EAU00744

Drive chain slack checkNOTE:

Spin the wheel several times and find

the tightest position of the chain.

Check and/or adjust the chain slack

while itÕs in this tightest position.To check the chain slack the motor-

cycle must be held straight up with

both wheels on the ground and with-

out rider. Check the slack at the posi-

tion shown in the illustration. Normal

slack is approximately 30 ~ 40 mm. If

the slack exceeds 40 mm, adjust.

a

a.Chain slack

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 23

Page 65 of 96

6-25

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU02984

Brake and shift pedal

lubricationLubricate the pivoting parts.

Recommended lubricant:

Engine oil

EAU02986

Sidestand lubricationLubricate the sidestand pivoting point

and metal-to-metal contact surfaces.

Check that the sidestand moves up

and down smoothly.

EW000113

wIf the sidestand does not move

smoothly, consult a Yamaha deal-

er.

Recommended lubricant:

Engine oil

EAU02985

Brake and clutch lever

lubricationLubricate the pivoting parts.

Recommended lubricant:

Engine oil

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 26

Page 66 of 96

6-26

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

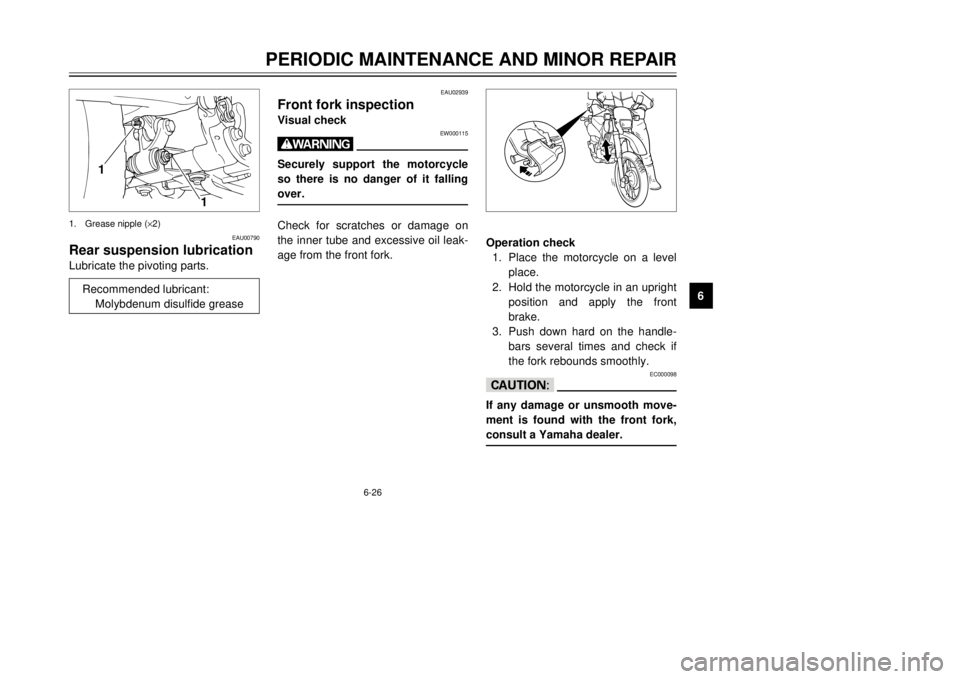

EAU00790

Rear suspension lubricationLubricate the pivoting parts.

Recommended lubricant:

Molybdenum disulfide grease

1

1

1.Grease nipple (´2)

Operation check

1.Place the motorcycle on a level

place.

2.Hold the motorcycle in an upright

position and apply the front

brake.

3.Push down hard on the handle-

bars several times and check if

the fork rebounds smoothly.

EC000098

cCIf any damage or unsmooth move-

ment is found with the front fork,

consult a Yamaha dealer.

EAU02939

Front fork inspectionVisual check

EW000115

wSecurely support the motorcycle

so there is no danger of it falling

over.Check for scratches or damage on

the inner tube and excessive oil leak-

age from the front fork.

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 27

Page 73 of 96

6-33

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

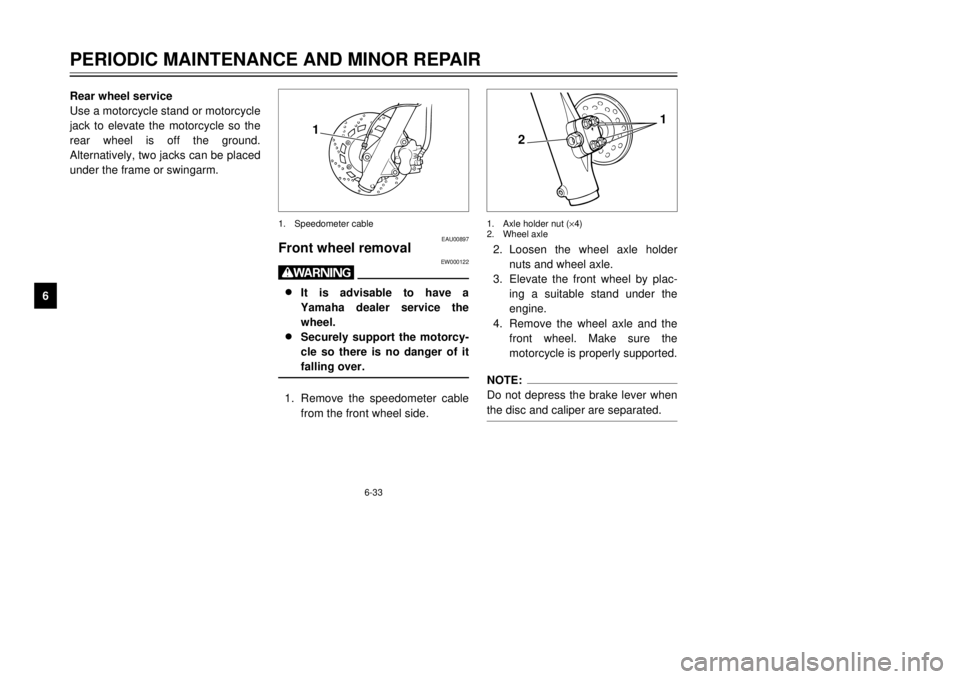

92.Loosen the wheel axle holder

nuts and wheel axle.

3.Elevate the front wheel by plac-

ing a suitable stand under the

engine.

4.Remove the wheel axle and the

front wheel. Make sure the

motorcycle is properly supported.

NOTE:

Do not depress the brake lever when

the disc and caliper are separated.

1

2

1.Axle holder nut (´4)

2.Wheel axle

EAU00897

Front wheel removal

EW000122

w8

8

It is advisable to have a

Yamaha dealer service the

wheel.

8 8

Securely support the motorcy-

cle so there is no danger of it

falling over.1.Remove the speedometer cable

from the front wheel side.

1

1.Speedometer cable

Rear wheel service

Use a motorcycle stand or motorcycle

jack to elevate the motorcycle so the

rear wheel is off the ground.

Alternatively, two jacks can be placed

under the frame or swingarm.

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 34

Page 74 of 96

6-34

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

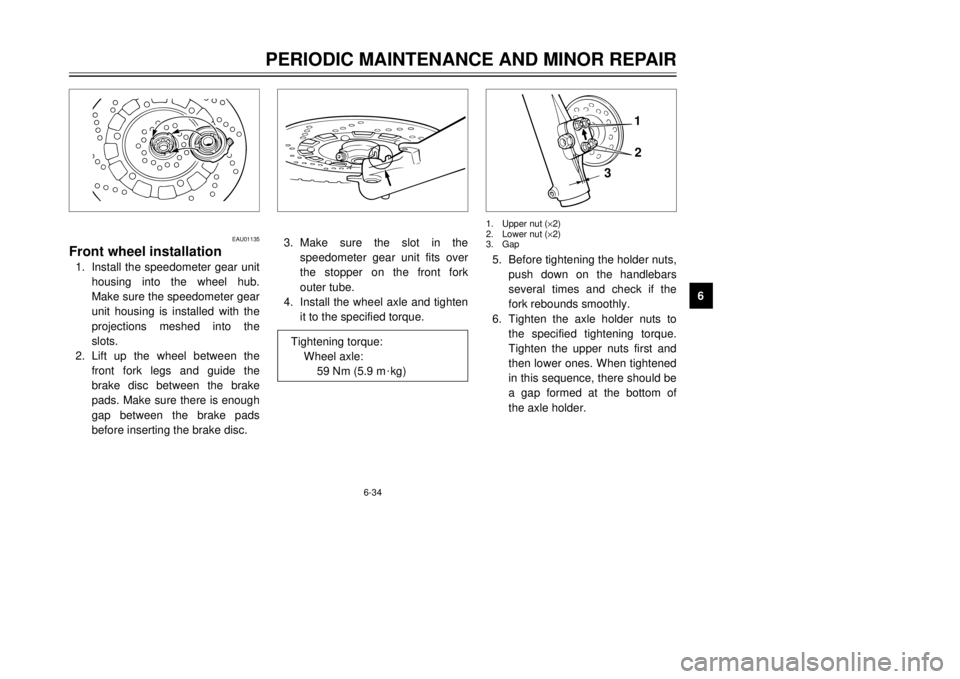

9 5.Before tightening the holder nuts,

push down on the handlebars

several times and check if the

fork rebounds smoothly.

6.Tighten the axle holder nuts to

the specified tightening torque.

Tighten the upper nuts first and

then lower ones. When tightened

in this sequence, there should be

a gap formed at the bottom of

the axle holder.

32 1

1.Upper nut (´2)

2.Lower nut (´2)

3.Gap

EAU01135

Front wheel installation1.Install the speedometer gear unit

housing into the wheel hub.

Make sure the speedometer gear

unit housing is installed with the

projections meshed into the

slots.

2.Lift up the wheel between the

front fork legs and guide the

brake disc between the brake

pads. Make sure there is enough

gap between the brake pads

before inserting the brake disc.

3.Make sure the slot in the

speedometer gear unit fits over

the stopper on the front fork

outer tube.

4.Install the wheel axle and tighten

it to the specified torque.

Tightening torque:

Wheel axle:

59 Nm (5.9 m

0kg)

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 35

Page 76 of 96

6-36

INSTRUMENT AND CONTROL FUNCTIONS

1

2

4

56

7

8

9

EAU01008

TroubleshootingAlthough Yamaha motorcycles

receive a rigid inspection before ship-

ment from the factory, trouble may

occur during operation.

Any problem in the fuel, compres-

sion, or ignition systems can cause

poor starting and loss of power. The

troubleshooting chart describes a

quick, easy procedure for making

checks.

If your motorcycle requires any

repair, bring it to a Yamaha dealer.

The skilled technicians at a Yamaha

dealership have the tools, experi-

ence, and know-how to properly ser-

vice your motorcycle. Use only gen-

uine Yamaha parts on your

motorcycle. Imitation parts may look

like Yamaha parts, but they are often

inferior. Conse-quently, they have a

shorter service life and can lead to

expensive repair bills.

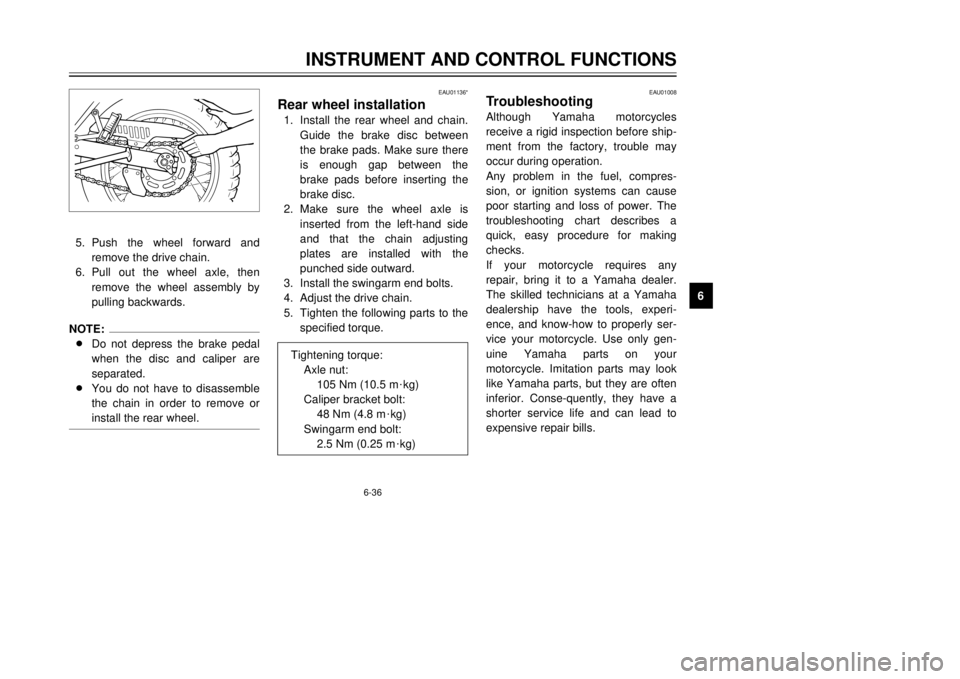

5.Push the wheel forward and

remove the drive chain.

6.Pull out the wheel axle, then

remove the wheel assembly by

pulling backwards.NOTE:

8Do not depress the brake pedal

when the disc and caliper are

separated.

8You do not have to disassemble

the chain in order to remove or

install the rear wheel.

EAU01136*

Rear wheel installation1.Install the rear wheel and chain.

Guide the brake disc between

the brake pads. Make sure there

is enough gap between the

brake pads before inserting the

brake disc.

2.Make sure the wheel axle is

inserted from the left-hand side

and that the chain adjusting

plates are installed with the

punched side outward.

3.Install the swingarm end bolts.

4.Adjust the drive chain.

5.Tighten the following parts to the

specified torque.

Tightening torque:

Axle nut:

105 Nm (10.5 m

0kg)

Caliper bracket bolt:

48 Nm (4.8 m

0kg)

Swingarm end bolt:

2.5 Nm (0.25 m0kg)

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 37

Page 80 of 96

7-2

8 8

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent

and water to clean plastic.

8 8

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, sol-

vent or thinner, fuel (gasoline),

rust removers or inhibitors,

brake fluid, antifreeze or elec-

trolyte.8 8

Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel bearings, swingarm

bearings, forks and brakes),

electric components (cou-

plers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

8 8

For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure they

do not leave any marks. If the

windshield is scratched, use a

quality plastic polishing com-

pound after washing.

After riding in the rain, near the seaor on salt-sprayed roads.Since sea salt or salt sprayed on the

roads in the winter are extremely cor-

rosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads. (Salt sprayed

in the winter may remain on the roads

well into spring.)

1.Clean your motorcycle with cold

water and soap after the engine

has cooled down.

ECA00012

cCDo not use warm water since it

increases the corrosive action of

the salt.2.Be sure to apply a corrosion pro-

tection spray on all (even

chrome- and nickel-plated) metal

surfaces to prevent corrosion.

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

67

8

9

4PT-9-E6 (ENG) 7~9 12/27/00 1:30 PM Page 3