light YAMAHA XT500E 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XT500E, Model: YAMAHA XT500E 2000Pages: 96, PDF Size: 4.23 MB

Page 45 of 96

6-5

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU03884

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

9Replace the brake hoses every four years and if cracked or damaged.20

*Rear suspension relay

arm and connecting arm

pivoting points¥Check operation.ÖÖÖÖ

¥Lubricate with molybdenum disulfide grease.ÖÖ

21*Carburetor¥Check starter (choke) operation.

¥Adjust engine idling speed.ÖÖÖÖÖÖ

22Engine oil¥Change.ÖÖÖÖÖÖ

23Engine oil filter element¥Replace.ÖÖÖ

24*Front and rear brake

switches¥Check operation.ÖÖÖÖÖÖ

25Moving parts and cables¥Lubricate.ÖÖÖÖÖ

26*Lights, signals and

switches¥Check operation.

¥Adjust headlight beam.ÖÖÖÖÖÖ NO.ITEMCHECK OR MAINTENANCE JOBODOMETER READING (´ 1,000 km)

ANNUAL

CHECK

110203040

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 6

Page 49 of 96

Inspection

The spark plug is an important

engine component and is easy to

inspect. The condition of the spark

plug can indicate the condition of the

engine.

The ideal color on the white insulator

around the center electrode is a

medium-to-light tan color for a motor-

cycle that is being ridden normally.

Do not attempt to diagnose such

problems yourself. Instead, take the

motorcycle to a Yamaha dealer. You

should periodically remove and

inspect the spark plug because heat

and deposits will cause any spark

plug to slowly break down and erode.

If electrode erosion becomes exces-

sive, or if carbon and other deposits

are excessive, you should replace

the spark plug with the specified plug.Installation

1.Measure the electrode gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

2.Clean the gasket surface. Wipe

off any grime from the threads.

3.Install the spark plug and tighten

it to the specified torque.

NOTE:

If a torque wrench is not available

when you are installing a spark plug,

a good estimate of the correct torque

is 1/4 to 1/2 turn past finger tight.

Have the spark plug tightened to the

specified torque as soon as possible.4.Install the spark plug cap.

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

Specified spark plug:

DPR8EA-9 or

DPR9EA-9 (NGK)

Spark plug gap:

0.8 ~ 0.9 mmTightening torque:

Spark plug:

17.5 Nm (1.75 m0kg)

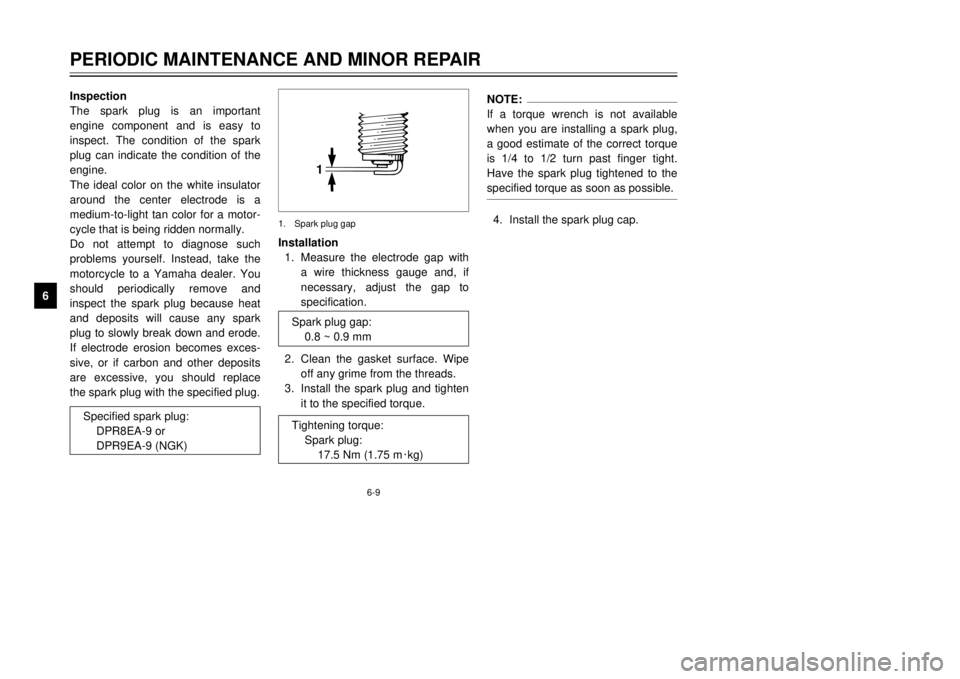

1

1.Spark plug gap

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 10

Page 53 of 96

EAU00629

Carburetor adjustmentThe carburetor is a vital part of the

engine and requires very sophisticat-

ed adjustment. Most adjustments

should be left to a Yamaha dealer

who has the professional knowledge

and experience to do so. However,

the following may be serviced by the

owner as part of routine mainte-

nance.

EC000094

cCThe carburetor was set at the

Yamaha factory after many tests. If

the settings are changed, poor

engine performance and damage

may result.

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

5.Install the air filter with the arrow

mark on the top pointing inward.

6.Install the air filter case cover

and the panel.

EC000082

cC8

8

Make sure the air filter is prop-

erly seated in the air filter

case.

8 8

The engine should never be

run without the air filter

installed. Excessive piston

and/or cylinder wear may

result.

1

3.Remove the air filter.

4.Tap the air filter lightly to remove

most of the dust and dirt and

blow out the remaining dirt with

compressed air from the mesh

side of the air filter. If it is dam-

aged, replace it.1.Mesh side

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 14

Page 60 of 96

6-20

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

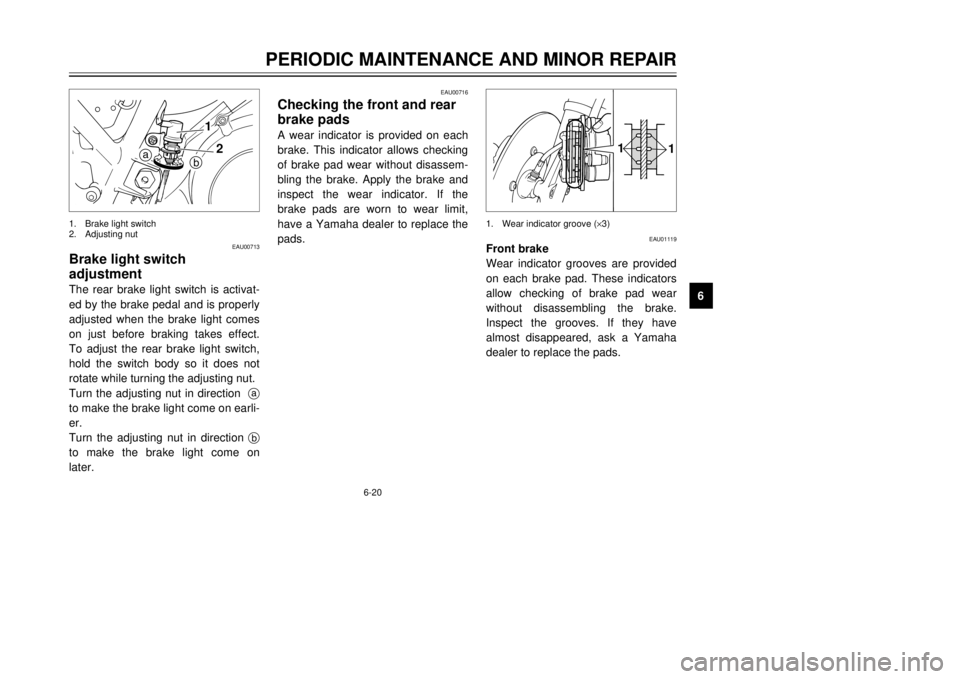

EAU00713

Brake light switch

adjustmentThe rear brake light switch is activat-

ed by the brake pedal and is properly

adjusted when the brake light comes

on just before braking takes effect.

To adjust the rear brake light switch,

hold the switch body so it does not

rotate while turning the adjusting nut.

Turn the adjusting nut in direction a

to make the brake light come on earli-

er.

Turn the adjusting nut in direction b

to make the brake light come on

later.

21

a

b

1.Brake light switch

2.Adjusting nut

EAU00716

Checking the front and rear

brake padsA wear indicator is provided on each

brake. This indicator allows checking

of brake pad wear without disassem-

bling the brake. Apply the brake and

inspect the wear indicator. If the

brake pads are worn to wear limit,

have a Yamaha dealer to replace the

pads.

EAU01119

Front brake

Wear indicator grooves are provided

on each brake pad. These indicators

allow checking of brake pad wear

without disassembling the brake.

Inspect the grooves. If they have

almost disappeared, ask a Yamaha

dealer to replace the pads.

1

1

1.Wear indicator groove (´3)

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 21

Page 69 of 96

EC000103

cCDo not use fuses of higher amper-

age rating than those recommend-

ed. Substitution of a fuse of

improper rating can cause exten-

sive electrical system damage and

possibly a fire.

EAU01146

Headlight bulb replacementThis motorcycle is equipped with a

quartz bulb headlight. If the headlight

bulb burns out, replace it as follows:

1.Remove cowling A. (See page

6-7 for cowling removal and

installation procedures.)

2.Remove the headlight unit.

6-29

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9Specified fuse:

20 A

1

1.Bolt (´3)

1

2

EAU01307

Fuse replacementThe fuse is located behind panel A.

(See page 6-7 for panel removal and

installation procedures.)

If the fuse is blown, turn off the main

switch and the switch of the circuit in

question. Install a new fuse of proper

amperage. Turn on the switches and

see if the electrical device operates.

If the fuse immediately blows again,

consult a Yamaha dealer.1.Main fuse

2.Spare fuse

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 30

Page 71 of 96

6-31

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

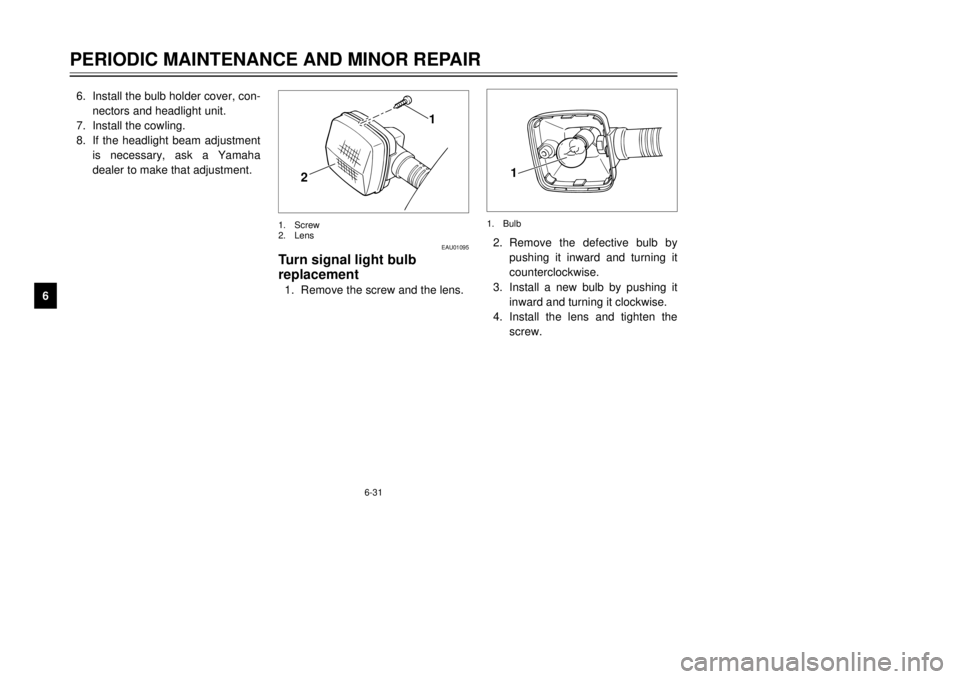

EAU01095

Turn signal light bulb

replacement1.Remove the screw and the lens.2.Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

3.Install a new bulb by pushing it

inward and turning it clockwise.

4.Install the lens and tighten the

screw.

1

2

1.Screw

2.Lens

1

1.Bulb

6.Install the bulb holder cover, con-

nectors and headlight unit.

7.Install the cowling.

8.If the headlight beam adjustment

is necessary, ask a Yamaha

dealer to make that adjustment.

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 32

Page 72 of 96

6-32

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU01579

Supporting the motorcycleSince the Yamaha XT500E/XT600E

has no centerstand, follow these pre-

cautions when removing the front and

rear wheel or performing other main-

tenance requiring the motorcycle to

stand upright. Check that the motor-

cycle is in a stable and level position

before starting any maintenance. A

strong wooden box can be placed

under the engine for added stability.

Front wheel service

To stabilize the rear of the motorcy-

cle, either use a motorcycle stand or

place a motorcycle jack under the

frame in front of the rear wheel to

prevent it from moving from side to

side. Then use a motorcycle stand to

elevate the front wheel off of the

ground.

EAU01623

Taillight bulb replacement1.Remove the screws and the

lens.

21

1.Screw (´2)

2.Lens

2.Remove the defective bulb by

pushing it inward and turning it

counterclockwise.

3.Install a new bulb by pushing it

inward and turning it clockwise.

4.Install the lens and tighten the

screws.

EC000108

cCDo not over-tighten the screws as

the lens may break.

1

1.Bulb

4PT-9-E6 (ENG) 6 12/27/00 1:29 PM Page 33

Page 80 of 96

7-2

8 8

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent

and water to clean plastic.

8 8

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, sol-

vent or thinner, fuel (gasoline),

rust removers or inhibitors,

brake fluid, antifreeze or elec-

trolyte.8 8

Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel bearings, swingarm

bearings, forks and brakes),

electric components (cou-

plers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

8 8

For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure they

do not leave any marks. If the

windshield is scratched, use a

quality plastic polishing com-

pound after washing.

After riding in the rain, near the seaor on salt-sprayed roads.Since sea salt or salt sprayed on the

roads in the winter are extremely cor-

rosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads. (Salt sprayed

in the winter may remain on the roads

well into spring.)

1.Clean your motorcycle with cold

water and soap after the engine

has cooled down.

ECA00012

cCDo not use warm water since it

increases the corrosive action of

the salt.2.Be sure to apply a corrosion pro-

tection spray on all (even

chrome- and nickel-plated) metal

surfaces to prevent corrosion.

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

67

8

9

4PT-9-E6 (ENG) 7~9 12/27/00 1:30 PM Page 3

Page 88 of 96

SPECIFICATIONS

1

2

3

4

5

6

78

9

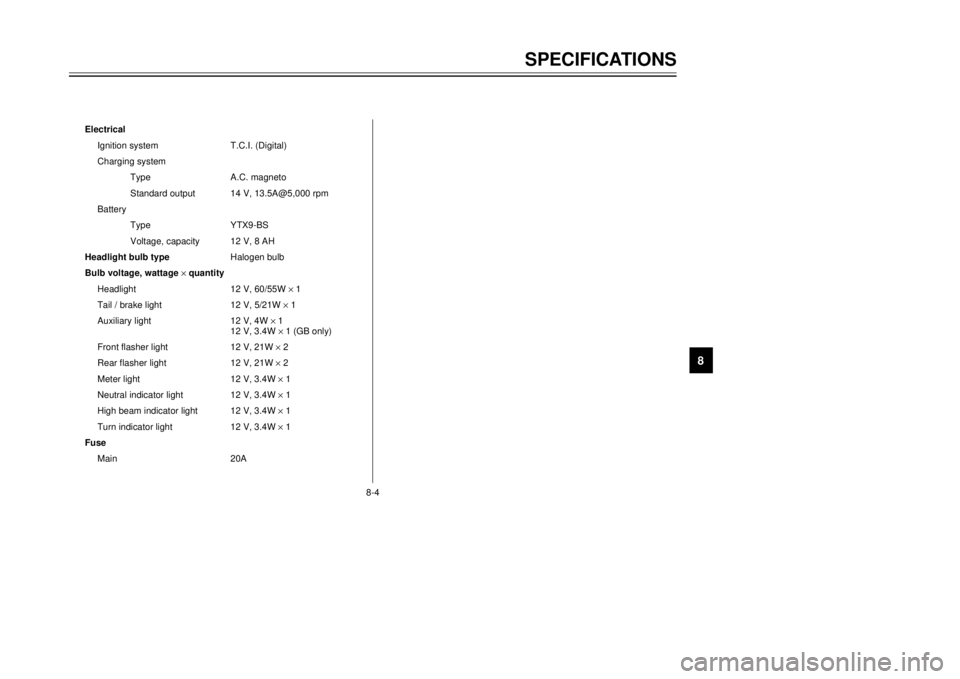

8-4 Electrical

Ignition systemT.C.I. (Digital)

Charging system

TypeA.C. magneto

Standard output14 V, 13.5A@5,000 rpm

Battery

TypeYTX9-BS

Voltage, capacity12 V, 8 AH

Headlight bulb typeHalogen bulb

Bulb voltage, wattage ´quantity

Headlight12 V, 60/55W ´1

Tail / brake light12 V, 5/21W ´1

Auxiliary light12 V, 4W ´1

12 V, 3.4W ´1 (GB only)

Front flasher light12 V, 21W ´2

Rear flasher light12 V, 21W ´2

Meter light12 V, 3.4W ´1

Neutral indicator light12 V, 3.4W ´1

High beam indicator light12 V, 3.4W ´1

Turn indicator light12 V, 3.4W ´1

Fuse

Main20A

4PT-9-E6 (ENG) 7~9 12/27/00 1:30 PM Page 11

Page 93 of 96

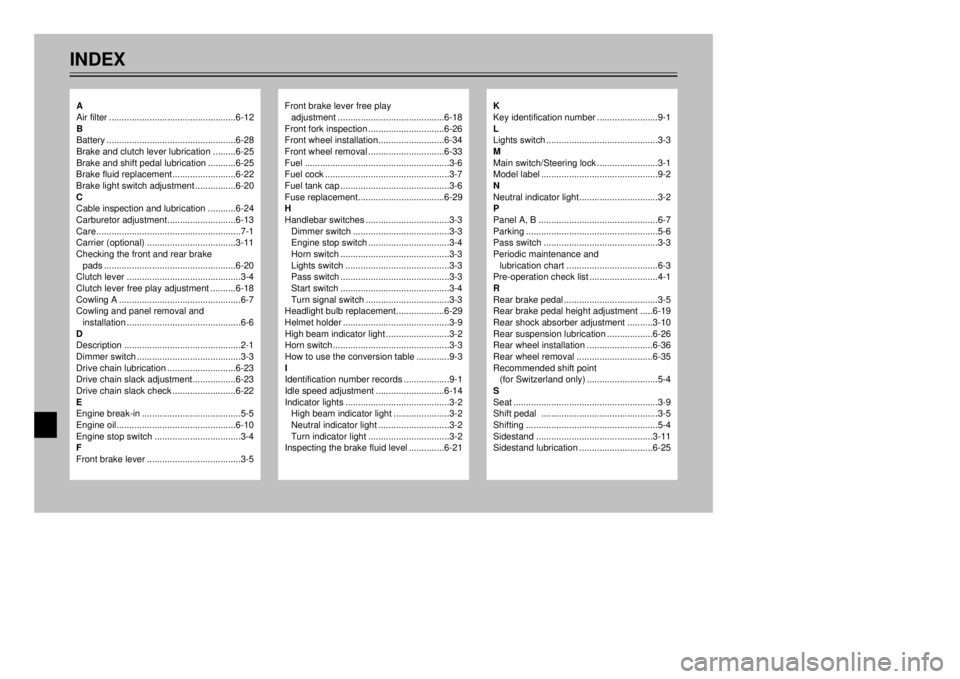

INDEX

Front brake lever free play

adjustment..........................................6-18

Front fork inspection..............................6-26

Front wheel installation..........................6-34

Front wheel removal..............................6-33

Fuel.........................................................3-6

Fuel cock.................................................3-7

Fuel tank cap...........................................3-6

Fuse replacement..................................6-29

H

Handlebar switches.................................3-3

Dimmer switch......................................3-3

Engine stop switch................................3-4

Horn switch...........................................3-3

Lights switch.........................................3-3

Pass switch...........................................3-3

Start switch...........................................3-4

Turn signal switch.................................3-3

Headlight bulb replacement...................6-29

Helmet holder..........................................3-9

High beam indicator light.........................3-2

Horn switch..............................................3-3

How to use the conversion table.............9-3

I

Identification number records..................9-1

Idle speed adjustment...........................6-14

Indicator lights.........................................3-2

High beam indicator light......................3-2

Neutral indicator light............................3-2

Turn indicator light................................3-2

Inspecting the brake fluid level..............6-21

K

Key identification number........................9-1

L

Lights switch............................................3-3

M

Main switch/Steering lock........................3-1

Model label..............................................9-2

N

Neutral indicator light...............................3-2

P

Panel A, B...............................................6-7

Parking....................................................5-6

Pass switch.............................................3-3

Periodic maintenance and

lubrication chart....................................6-3

Pre-operation check list...........................4-1

R

Rear brake pedal.....................................3-5

Rear brake pedal height adjustment.....6-19

Rear shock absorber adjustment..........3-10

Rear suspension lubrication..................6-26

Rear wheel installation..........................6-36

Rear wheel removal..............................6-35

Recommended shift point

(for Switzerland only)............................5-4

S

Seat.........................................................3-9

Shift pedal ..............................................3-5

Shifting....................................................5-4

Sidestand..............................................3-11

Sidestand lubrication.............................6-25

A

Air filter..................................................6-12

B

Battery...................................................6-28

Brake and clutch lever lubrication.........6-25

Brake and shift pedal lubrication...........6-25

Brake fluid replacement.........................6-22

Brake light switch adjustment................6-20

C

Cable inspection and lubrication...........6-24

Carburetor adjustment...........................6-13

Care.........................................................7-1

Carrier (optional)...................................3-11

Checking the front and rear brake

pads....................................................6-20

Clutch lever.............................................3-4

Clutch lever free play adjustment..........6-18

Cowling A................................................6-7

Cowling and panel removal and

installation.............................................6-6

D

Description..............................................2-1

Dimmer switch.........................................3-3

Drive chain lubrication...........................6-23

Drive chain slack adjustment.................6-23

Drive chain slack check.........................6-22

E

Engine break-in.......................................5-5

Engine oil...............................................6-10

Engine stop switch..................................3-4

F

Front brake lever.....................................3-5

4PT-9-E6 (ENG) 7~9 12/27/00 1:30 PM Page 16