ESP YAMAHA XT500E 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: XT500E, Model: YAMAHA XT500E 2002Pages: 100, PDF Size: 2.1 MB

Page 25 of 100

3-11

3. Tighten the locknut to the speci-

fied torque.

EC000018

cCAlways tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque.

EAU00315

wThis shock absorber contains

highly pressurized nitrogen gas.

For proper handling, read and

understand the following informa-

tion before handling the shock

absorber. The manufacturer can-

not be held responsible for proper-

ty damage or personal injury that

may result from improper han-

dling.

8Do not tamper with or attempt

to open the gas cylinder.

8Do not subject the shock

absorber to an open flame or

other high heat sources, other-

wise it may explode due to

excessive gas pressure.

8Do not deform or damage the

gas cylinder in any way, as

this will result in poor damp-

ing performance.

8Always have a Yamaha dealer

service the shock absorber.

EAU00330

SidestandSidestandThe sidestand is located on the left

side of the frame. Raise the side-

stand or lower it with your foot while

holding the motorcycle upright.NOTE:

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situ-

ations. (See further down for an

explanation of the ignition circuit cut-

off system.)

INSTRUMENT AND CONTROL FUNCTIONS

3Spring preload:

Minimum (soft):

Distance A = 1 mm

Standard:

Distance A = 5.5 mm

Maximum (hard):

Distance A = 12 mm

Tightening torque:

Locknut:

42 Nm (4.2 m

0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 24

Page 26 of 100

3-12

INSTRUMENT AND CONTROL FUNCTIONS

3

EW000044

wThe motorcycle must not be ridden

with the sidestand down, or if the

sidestand cannot be properly

moved up (or does not stay up),

otherwise the sidestand could con-

tact the ground and distract the

operator, resulting in a possible

loss of control. Yamaha’s ignition

circuit cut-off system has been

designed to assist the operator in

fulfilling the responsibility of rais-

ing the sidestand before starting

off. Therefore, check this system

regularly as described below and

have a Yamaha dealer repair it if it

does not function properly.

EAU03720

Ignition circuit cut-off

systemIgnition circuit cut-off systemThe ignition circuit cut-off system

(comprising the sidestand switch,

clutch switch and neutral switch) has

the following functions.

8It prevents starting when the

transmission is in gear and the

sidestand is up, but the clutch

lever is not pulled.

8It prevents starting when the

transmission is in gear and the

clutch lever is pulled, but the

sidestand is still down.

8It cuts the running engine when

the transmission is in gear and

the sidestand is moved down.

Periodically check the operation of

the ignition circuit cut-off system

according to the following procedure.

EW000045

wIf a malfunction is noted, have a

Yamaha dealer check the system

before riding.

4PT-E7 (English) 6/29/01 9:13 AM Page 25

Page 29 of 100

4-1

EAU01114

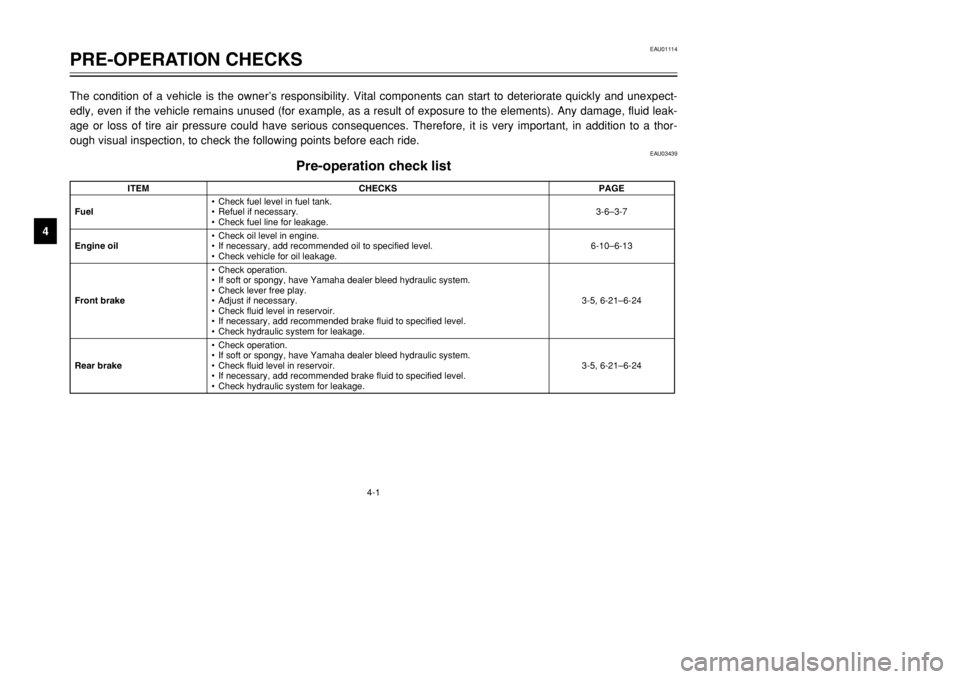

PRE-OPERATION CHECKS

4The condition of a vehicle is the owner’s responsibility. Vital components can start to deteriorate quickly and unexpect-

edly, even if the vehicle remains unused (for example, as a result of exposure to the elements). Any damage, fluid leak-

age or loss of tire air pressure could have serious consequences. Therefore, it is very important, in addition to a thor-

ough visual inspection, to check the following points before each ride.

EAU03439

Pre-operation check list

Pre-operation check list

ITEM CHECKS PAGE

Fuel•Check fuel level in fuel tank.

•Refuel if necessary.

•Check fuel line for leakage.3-6–3-7

Engine oil•Check oil level in engine.

•If necessary, add recommended oil to specified level.

•Check vehicle for oil leakage.6-10–6-13

Front brake•Check operation.

•If soft or spongy, have Yamaha dealer bleed hydraulic system.

•Check lever free play.

•Adjust if necessary.

•Check fluid level in reservoir.

•If necessary, add recommended brake fluid to specified level.

•Check hydraulic system for leakage.3-5, 6-21–6-24

Rear brake•Check operation.

•If soft or spongy, have Yamaha dealer bleed hydraulic system.

•Check fluid level in reservoir.

•If necessary, add recommended brake fluid to specified level.

•Check hydraulic system for leakage.3-5, 6-21–6-24

4PT-E7 (English) 6/29/01 9:13 AM Page 28

Page 34 of 100

5-2

OPERATION AND IMPORTANT RIDING POINTS

5 7. When the engine is warm, turn

the starter (choke) off.

NOTE:

The engine is warm when it responds

normally to the throttle with the starter

(choke) turned off.

EAU01258

Starting a warm engineEngine, starting a warmFollow the same procedure as for

starting a cold engine with the excep-

tion that the starter (choke) is not

required when the engine is warm.

NOTE:

If the engine fails to start, release the

start switch, wait a few seconds, and

then try again. Each starting attempt

should be as short as possible to pre-

serve the battery. Do not crank the

engine more than 10 seconds on any

one attempt.6. After starting the engine, move

the starter (choke) knob back

halfway.

ECA00055

cCFor maximum engine life, always

warm the engine up before starting

off. Never accelerate hard when

the engine is cold!

4PT-E7 (English) 6/29/01 9:13 AM Page 33

Page 53 of 100

6-15

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU00632

Adjusting the engine idling

speedEngine idling speedThe engine idling speed must be

checked and, if necessary, adjusted

as follows at the intervals specified in

the periodic maintenance and lubrica-

tion chart.

1. Start the engine and warm it up

for several minutes at 1,000–

2,000 r/min while occasionally

revving it to 4,000–5,000 r/min.NOTE:

The engine is warm when it quickly

responds to the throttle.

NOTE:

If the specified idling speed cannot

be obtained as described above,

have a Yamaha dealer make the

adjustment.

2. Check the engine idling speed

and, if necessary, adjust it to

specification by turning the throt-

tle stop screw. To increase the

engine idling speed, turn the

screw in direction a. To

decrease the engine idling

speed, turn the screw in direction

b.

1

b

a

1. Throttle stop screw

Engine idling speed:

1,200–1,400 r/min

(Except for CH)

1,300–1,400 r/min

(For CH)

4PT-E7 (English) 6/29/01 9:13 AM Page 52

Page 64 of 100

6-26

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

Make sure that both adjusting plates

are in the same position for proper

wheel alignment.

EC000096

cCImproper drive chain slack will

overload the engine as well as

other vital parts of the motorcycle

and can lead to chain slippage or

breakage. To prevent this from

occurring, keep the drive chain

slack within the specified limits.3. Tighten the axle nut and the

brake caliper bracket bolt to the

specified torques.2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

ECA00052

cCDo not use engine oil or any other

lubricants for the drive chain, as

they may contain substances that

could damage the O-rings.

EAU03006

Lubricating the drive chainDrive chain, lubricatingThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly

wear out, especially when riding in

dusty or wet areas. Service the drive

chain as follows.

EC000097

cCThe drive chain must be lubricated

after washing the motorcycle or

riding in the rain.1. Clean the drive chain with

kerosene and a small soft brush.

ECA00053

cCTo prevent damaging the O-rings,

do not clean the drive chain with

steam cleaners, high-pressure

washers or inappropriate solvents.

Tightening torques:

Axle nut:

105 Nm (10.5 m0kgf)

Brake caliper bracket bolt:

48 Nm (4.8 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 63

Page 83 of 100

7-1

EAU03521

MOTORCYCLE CARE AND STORAGE

7

CareCareWhile the open design of a motorcy-

cle reveals the attractiveness of the

technology, it also makes it more vul-

nerable. Rust and corrosion can

develop even if high-quality compo-

nents are used. A rusty exhaust pipe

may go unnoticed on a car, however,

it detracts from the overall appear-

ance of a motorcycle. Frequent and

proper care does not only comply

with the terms of the warranty, but it

will also keep your motorcycle looking

good, extend its life and optimize its

performance.Before cleaning

1. Cover the muffler outlet with a

plastic bag after the engine has

cooled down.

2. Make sure that all caps and cov-

ers as well as all electrical cou-

plers and connectors, including

the spark plug cap, are tightly

installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets,

sprockets, the drive chain and

wheel axles. Always rinse the dirt

and degreaser off with water.Cleaning

ECA00010

cC8

8

Avoid using strong acidic

wheel cleaners, especially on

spoked wheels. If such prod-

ucts are used on hard-to-

remove dirt, do not leave the

cleaner on the affected area

any longer than instructed.

Also, thoroughly rinse the area

off with water, immediately dry

it, and then apply a corrosion

protection spray.

8 8

Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent

and water to clean plastic.

4PT-E7 (English) 6/29/01 9:13 AM Page 82