service YAMAHA XT500E 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: XT500E, Model: YAMAHA XT500E 2002Pages: 100, PDF Size: 2.1 MB

Page 25 of 100

3-11

3. Tighten the locknut to the speci-

fied torque.

EC000018

cCAlways tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque.

EAU00315

wThis shock absorber contains

highly pressurized nitrogen gas.

For proper handling, read and

understand the following informa-

tion before handling the shock

absorber. The manufacturer can-

not be held responsible for proper-

ty damage or personal injury that

may result from improper han-

dling.

8Do not tamper with or attempt

to open the gas cylinder.

8Do not subject the shock

absorber to an open flame or

other high heat sources, other-

wise it may explode due to

excessive gas pressure.

8Do not deform or damage the

gas cylinder in any way, as

this will result in poor damp-

ing performance.

8Always have a Yamaha dealer

service the shock absorber.

EAU00330

SidestandSidestandThe sidestand is located on the left

side of the frame. Raise the side-

stand or lower it with your foot while

holding the motorcycle upright.NOTE:

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situ-

ations. (See further down for an

explanation of the ignition circuit cut-

off system.)

INSTRUMENT AND CONTROL FUNCTIONS

3Spring preload:

Minimum (soft):

Distance A = 1 mm

Standard:

Distance A = 5.5 mm

Maximum (hard):

Distance A = 12 mm

Tightening torque:

Locknut:

42 Nm (4.2 m

0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 24

Page 39 of 100

6-1

EAU00462

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01175

Owner’s tool kitTool kitThe owner’s tool kit is located behind

panel A. (See page 6-7 for panel

removal and installation procedures.)

The service information included in

this manual and the tools provided in

the owner’s tool kit are intended to

assist you in the performance of pre-

ventive maintenance and minor

repairs. However, additional tools

such as a torque wrench may be nec-

essary to perform certain mainte-

nance work correctly.

EW000060

wIf you are not familiar with motor-

cycle maintenance work, have a

Yamaha dealer do it for you.

EAU00464

Safety is an obligation of the owner.

Periodic inspection, adjustment and

lubrication will keep your vehicle in

the safest and most efficient condi-

tion possible. The most important

points of inspection, adjustment, and

lubrication are explained on the fol-

lowing pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a

general guide under normal riding

conditions. However, DEPENDING

ON THE WEATHER, TERRAIN,

GEOGRAPHICAL LOCATION, AND

INDIVIDUAL USE, THE MAINTE-

NANCE INTERVALS MAY NEED TO

BE SHORTENED.

1

1. Owner’s tool kit

4PT-E7 (English) 6/29/01 9:13 AM Page 38

Page 43 of 100

6-5

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU03884

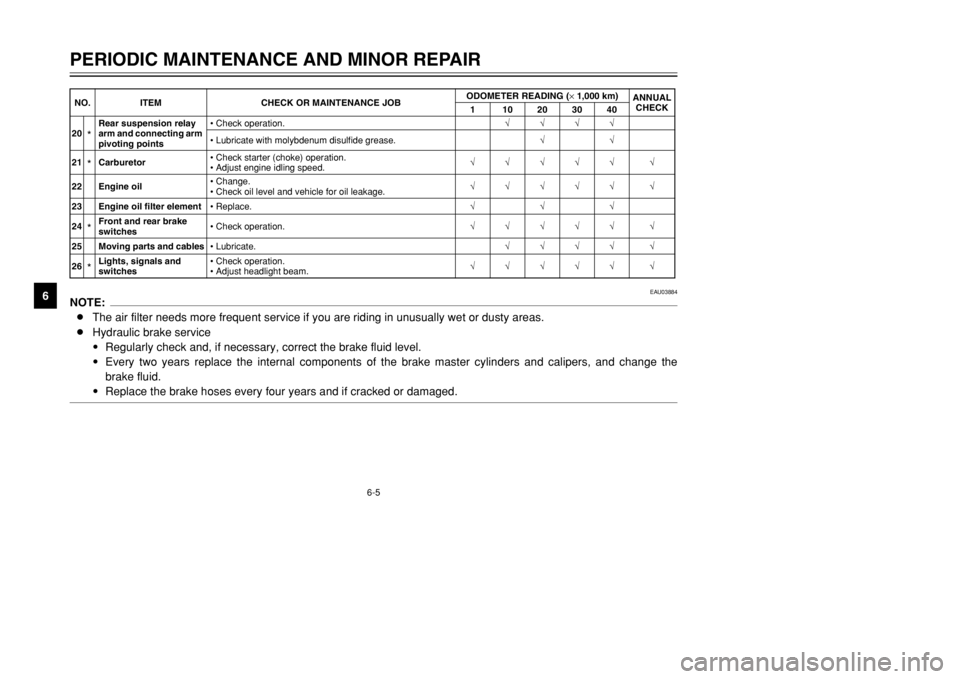

NOTE:

8The air filter needs more frequent service if you are riding in unusually wet or dusty areas.

8Hydraulic brake service

9Regularly check and, if necessary, correct the brake fluid level.

9Every two years replace the internal components of the brake master cylinders and calipers, and change the

brake fluid.

9Replace the brake hoses every four years and if cracked or damaged.20

*Rear suspension relay

arm and connecting arm

pivoting points•Check operation.√√√√

•Lubricate with molybdenum disulfide grease.√√

21*Carburetor•Check starter (choke) operation.

•Adjust engine idling speed.√√√√√ √

22 Engine oil•Change.

•Check oil level and vehicle for oil leakage.√√√√√ √

23 Engine oil filter element•Replace.√√√

24*Front and rear brake

switches•Check operation.√√√√√ √

25 Moving parts and cables•Lubricate.√√√√ √

26*Lights, signals and

switches•Check operation.

•Adjust headlight beam.√√√√√ √ NO. ITEM CHECK OR MAINTENANCE JOBODOMETER READING (× 1,000 km)

ANNUAL

CHECK

1 10203040

4PT-E7 (English) 6/29/01 9:13 AM Page 42

Page 52 of 100

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

6 3. Lightly tap the air filter element to

remove most of the dust and dirt,

and then blow the remaining dirt

out with compressed air as

shown. If the air filter element is

damaged, replace it.

4. Insert the air filter element into

the air filter case with the arrow

mark on the top pointing inward.

EAU00629

Adjusting the carburetorCarburetor, adjustingThe carburetor is an important part of

the engine and requires very sophisti-

cated adjustment. Therefore, most

carburetor adjustments should be left

to a Yamaha dealer, who has the

necessary professional knowledge

and experience. The adjustment

described in the following section,

however, may be serviced by the

owner as part of routine mainte-

nance.

EC000094

cCThe carburetor has been set and

extensively tested at the Yamaha

factory. Changing these settings

without sufficient technical knowl-

edge may result in poor perfor-

mance of or damage to the engine.

1

1. Mesh side

EC000082

cC8Make sure that the air filter ele-

ment is properly seated in the

air filter case.

8The engine should never be

operated without the air filter

element installed, otherwise

the piston and/or cylinder may

become excessively worn.5. Install the air filter case cover by

installing the screws.

6. Install the panel.

1

1. Arrow mark

4PT-E7 (English) 6/29/01 9:13 AM Page 51

Page 64 of 100

6-26

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

Make sure that both adjusting plates

are in the same position for proper

wheel alignment.

EC000096

cCImproper drive chain slack will

overload the engine as well as

other vital parts of the motorcycle

and can lead to chain slippage or

breakage. To prevent this from

occurring, keep the drive chain

slack within the specified limits.3. Tighten the axle nut and the

brake caliper bracket bolt to the

specified torques.2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

ECA00052

cCDo not use engine oil or any other

lubricants for the drive chain, as

they may contain substances that

could damage the O-rings.

EAU03006

Lubricating the drive chainDrive chain, lubricatingThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly

wear out, especially when riding in

dusty or wet areas. Service the drive

chain as follows.

EC000097

cCThe drive chain must be lubricated

after washing the motorcycle or

riding in the rain.1. Clean the drive chain with

kerosene and a small soft brush.

ECA00053

cCTo prevent damaging the O-rings,

do not clean the drive chain with

steam cleaners, high-pressure

washers or inappropriate solvents.

Tightening torques:

Axle nut:

105 Nm (10.5 m0kgf)

Brake caliper bracket bolt:

48 Nm (4.8 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 63

Page 74 of 100

6-36

PERIODIC MAINTENANCE AND MINOR REPAIR

6 2. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

EC000108

cCDo not overtighten the screws,

otherwise the lens may break.

1

1. Bulb

To service the rear wheel

Raise the rear wheel off the ground

by using a motorcycle stand or, if a

motorcycle stand is not available, by

placing a jack either under each side

of the frame in front of the rear wheel

or under each side of the swingarm.

EAU01579

Supporting the motorcycleSupporting the motorcycleSince this model is not equipped with

a centerstand, follow these precau-

tions when removing the front and

rear wheel or performing other main-

tenance requiring the motorcycle to

stand upright. Check that the motor-

cycle is in a stable and level position

before starting any maintenance. A

strong wooden box can be placed

under the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy-

cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing

a jack under the frame in front of

the rear wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.

4PT-E7 (English) 6/29/01 9:13 AM Page 73

Page 75 of 100

6-37

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU00897

Front wheel RemovingTo remove the front wheel

EW000122

w8It is advisable to have a

Yamaha dealer service the

wheel.

8Securely support the motorcy-

cle so that there is no danger

of it falling over.1. Disconnect the speedometer

cable from the front wheel.

1

1. Speedometer cable

EAU03555

To install the front wheelInstalling1. Install the speedometer gear unit

into the wheel hub so that the

projections mesh with the slots.

2. Lift the wheel up between the

fork legs.

1

1. Speedometer gear unit

2. Loosen the wheel axle holder

nuts, then the wheel axle.

3. Lift the front wheel off the ground

according to the procedure on

page 6-36.

4. Pull the wheel axle out, and then

remove the wheel.

ECA00048

cCDo not apply the brake after the

wheel has been removed together

with the brake disc, otherwise the

brake pads will be forced shut.

1

2

1. Wheel axle holder nut (×4)

2. Wheel axle

4PT-E7 (English) 6/29/01 9:13 AM Page 74

Page 77 of 100

6-39

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU04314

Rear wheelTo remove the rear wheel

EW000122

w8 8

It is advisable to have a

Yamaha dealer service the

wheel.

8Securely support the motorcy-

cle so that there is no danger

of it falling over.1. Remove the axle nut.

2. Loosen the brake caliper bracket

bolt.

2

1

1. Axle nut

2. Brake caliper bracket bolt

5. Turn the drive chain adjusting

plate on each side of the

swingarm fully in direction a.

1

a

1. Chain adjusting plate

3. Lift the rear wheel off the ground

according to the procedure on

page 6-36.

4. Remove the swingarm end bolts.

1

1

1. Swingarm end bolt (×2)

4PT-E7 (English) 6/29/01 9:13 AM Page 76

Page 79 of 100

6-41

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01008

TroubleshootingTroubleshootingAlthough Yamaha motorcycles

receive a thorough inspection before

shipment from the factory, trouble

may occur during operation. Any

problem in the fuel, compression, or

ignition systems, for example, can

cause poor starting and loss of

power.

The following troubleshooting chart

represents a quick and easy proce-

dure for checking these vital systems

yourself. However, should your

motorcycle require any repair, take it

to a Yamaha dealer, whose skilled

technicians have the necessary tools,

experience, and know-how to service

the motorcycle properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life

and can lead to expensive repair

bills. Tightening torque:

Axle nut:

105 Nm (10.5 m0kgf)

Brake caliper bracket bolt:

48 Nm (4.8 m0kgf)

Swingarm end bolt:

2.5 Nm (0.25 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 78

Page 89 of 100

8-1

EAU01038

SPECIFICATIONS

8

SpecificationsSpecifications

Model XT500E/XT600E

Dimensions

Overall length 2,220 mm

2.295 mm (N, S, CH only)

Overall width 865 mm

825 mm (CH only)

Overall height 1,205 mm

Seat height 855 mm

Wheel base 1,440 mm

Ground clearance 230 mm

Minimum turning radius 2,300 mm

Basic weight (with oil and full

fuel tank)176 kg

172 kg (CH only)

Engine

Engine type Air-cooled 4-stroke, SOHC,

gasoline

Cylinder arrangement Forward inclined single

cylinder

Displacement 499 cm

3

595 cm

3

Bore ×Stroke 87.0 ×84.0 mm (XT500E)

95.0 ×84.0 mm (XT600E)

Compression ratio 8.5:1

Starting system Electric starter

Lubrication system Dry sump

Engine oil

Type

Recommended engine oil

classification API Service SE, SF, SG type

or highercCBe sure to use motor oils that do not contain anti-friction

modifiers. Passenger car motor oils (often labeled

“ENERGY CONSERVING II”) contain anti-friction additives

which will cause clutch and/or starter clutch slippage, result-

ing in reduced component life and poor engine performance.

Capacity

Without oil filter element

replacement 2.7 L

With oil filter element

replaced 2.8 L

Total amount (dry engine) 3.3 L

–10° 0° 10° 20° 30°

40°

SAE 10W/30

SAE 10W/40

SAE 20W/40

SAE 20W/50

–20°

SAE 15W/40 50°C

4PT-E7 (English) 6/29/01 9:13 AM Page 88