torque YAMAHA XT500E 2002 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: XT500E, Model: YAMAHA XT500E 2002Pages: 100, PDF Size: 2.1 MB

Page 25 of 100

3-11

3. Tighten the locknut to the speci-

fied torque.

EC000018

cCAlways tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque.

EAU00315

wThis shock absorber contains

highly pressurized nitrogen gas.

For proper handling, read and

understand the following informa-

tion before handling the shock

absorber. The manufacturer can-

not be held responsible for proper-

ty damage or personal injury that

may result from improper han-

dling.

8Do not tamper with or attempt

to open the gas cylinder.

8Do not subject the shock

absorber to an open flame or

other high heat sources, other-

wise it may explode due to

excessive gas pressure.

8Do not deform or damage the

gas cylinder in any way, as

this will result in poor damp-

ing performance.

8Always have a Yamaha dealer

service the shock absorber.

EAU00330

SidestandSidestandThe sidestand is located on the left

side of the frame. Raise the side-

stand or lower it with your foot while

holding the motorcycle upright.NOTE:

The built-in sidestand switch is part of

the ignition circuit cut-off system,

which cuts the ignition in certain situ-

ations. (See further down for an

explanation of the ignition circuit cut-

off system.)

INSTRUMENT AND CONTROL FUNCTIONS

3Spring preload:

Minimum (soft):

Distance A = 1 mm

Standard:

Distance A = 5.5 mm

Maximum (hard):

Distance A = 12 mm

Tightening torque:

Locknut:

42 Nm (4.2 m

0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 24

Page 39 of 100

6-1

EAU00462

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01175

Owner’s tool kitTool kitThe owner’s tool kit is located behind

panel A. (See page 6-7 for panel

removal and installation procedures.)

The service information included in

this manual and the tools provided in

the owner’s tool kit are intended to

assist you in the performance of pre-

ventive maintenance and minor

repairs. However, additional tools

such as a torque wrench may be nec-

essary to perform certain mainte-

nance work correctly.

EW000060

wIf you are not familiar with motor-

cycle maintenance work, have a

Yamaha dealer do it for you.

EAU00464

Safety is an obligation of the owner.

Periodic inspection, adjustment and

lubrication will keep your vehicle in

the safest and most efficient condi-

tion possible. The most important

points of inspection, adjustment, and

lubrication are explained on the fol-

lowing pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a

general guide under normal riding

conditions. However, DEPENDING

ON THE WEATHER, TERRAIN,

GEOGRAPHICAL LOCATION, AND

INDIVIDUAL USE, THE MAINTE-

NANCE INTERVALS MAY NEED TO

BE SHORTENED.

1

1. Owner’s tool kit

4PT-E7 (English) 6/29/01 9:13 AM Page 38

Page 47 of 100

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

6To check the spark plug

1. Check that the porcelain insula-

tor around the center electrode

of the spark plug is a medium-to-

light tan (the ideal color when the

motorcycle is ridden normally).

NOTE:

If the spark plug shows a distinctly

different color, the engine could be

defective. Do not attempt to diagnose

such problems yourself. Instead,

have a Yamaha dealer check the

motorcycle.2. Check the spark plug for elec-

trode erosion and excessive car-

bon or other deposits, and

replace it if necessary.3. Install the spark plug with the

spark plug wrench, and then

tighten it to the specified torque.

NOTE:

If a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4-

1/2 turn past finger tight. However,

the spark plug should be tightened to

the specified torque as soon as pos-

sible.4. Install the spark plug cap. To install the spark plug

1. Measure the spark plug gap with

a wire thickness gauge and, if

necessary, adjust the gap to

specification.

2. Clean the surface of the spark

plug gasket and its mating sur-

face, and then wipe off any grime

from the spark plug threads.

a

a. Spark plug gap

Specified spark plug:

DPR8EA-9 or

DPR9EA-9 (NGK)

Spark plug gap:

0.8–0.9 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 46

Page 50 of 100

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

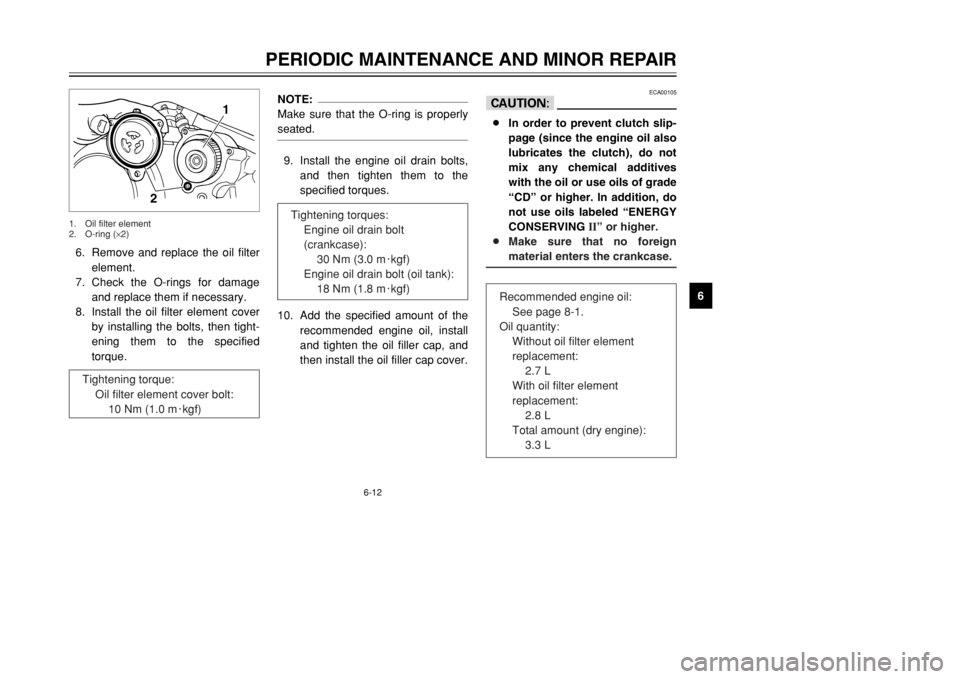

6 6. Remove and replace the oil filter

element.

7. Check the O-rings for damage

and replace them if necessary.

8. Install the oil filter element cover

by installing the bolts, then tight-

ening them to the specified

torque.

NOTE:

Make sure that the O-ring is properly

seated.9. Install the engine oil drain bolts,

and then tighten them to the

specified torques.

10. Add the specified amount of the

recommended engine oil, install

and tighten the oil filler cap, and

then install the oil filler cap cover.

ECA00105

cC8In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives

with the oil or use oils of grade

“CD” or higher. In addition, do

not use oils labeled “ENERGY

CONSERVING II” or higher.

8Make sure that no foreign

material enters the crankcase.

1

2

1. Oil filter element

2. O-ring (×2)

Tightening torque:

Oil filter element cover bolt:

10 Nm (1.0 m0kgf)

Tightening torques:

Engine oil drain bolt

(crankcase):

30 Nm (3.0 m0kgf)

Engine oil drain bolt (oil tank):

18 Nm (1.8 m0kgf)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter element

replacement:

2.7 L

With oil filter element

replacement:

2.8 L

Total amount (dry engine):

3.3 L

4PT-E7 (English) 6/29/01 9:13 AM Page 49

Page 64 of 100

6-26

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

Make sure that both adjusting plates

are in the same position for proper

wheel alignment.

EC000096

cCImproper drive chain slack will

overload the engine as well as

other vital parts of the motorcycle

and can lead to chain slippage or

breakage. To prevent this from

occurring, keep the drive chain

slack within the specified limits.3. Tighten the axle nut and the

brake caliper bracket bolt to the

specified torques.2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive

chain with a special O-ring chain

lubricant.

ECA00052

cCDo not use engine oil or any other

lubricants for the drive chain, as

they may contain substances that

could damage the O-rings.

EAU03006

Lubricating the drive chainDrive chain, lubricatingThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly

wear out, especially when riding in

dusty or wet areas. Service the drive

chain as follows.

EC000097

cCThe drive chain must be lubricated

after washing the motorcycle or

riding in the rain.1. Clean the drive chain with

kerosene and a small soft brush.

ECA00053

cCTo prevent damaging the O-rings,

do not clean the drive chain with

steam cleaners, high-pressure

washers or inappropriate solvents.

Tightening torques:

Axle nut:

105 Nm (10.5 m0kgf)

Brake caliper bracket bolt:

48 Nm (4.8 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 63

Page 76 of 100

6-38

PERIODIC MAINTENANCE AND MINOR REPAIR

6

NOTE:

Make sure that there is enough

space between the brake pads

before inserting the brake disc and

that the slot in the speedometer gear

unit fits over the retainer on the fork

leg.3. Install the wheel axle.

4. Lower the front wheel so that it is

on the ground.

5. Tighten the wheel axle to the

specified torque.7. After tightening the holder nuts,

while applying the front brake,

push down on the handlebars

several times to check if the front

fork compresses and rebounds

smoothly.

8. Connect the speedometer cable.

1

1. Retainer

6. Tighten the axle holder nuts to

the specified tightening torque.

Tighten the upper nuts first and

then lower ones. When tightened

in this sequence, there should be

a gap formed at the bottom of

the axle holder.

2 1

a

1. Upper nut (×2)

2. Lower nut (×2)

a. Gap

Tightening torque:

Wheel axle:

59 Nm (5.9 m0kgf)

Tightening torque:

Axle holder nut:

9 Nm (0.9 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 75

Page 78 of 100

6-40

PERIODIC MAINTENANCE AND MINOR REPAIR

6 6. Push the wheel forward, and

then remove the drive chain from

the rear sprocket.

NOTE:

The drive chain does not need to be

disassembled in order to remove and

install the wheel.7. Pull the wheel axle out, and then

remove the wheel.

ECA00048

cCDo not apply the brake after the

wheel has been removed together

with the brake disc, otherwise the

brake pads will be forced shut.

EAU01136

To install the rear wheelInstall1. Install the drive chain onto the

rear sprocket, and then insert the

wheel axle from the left-hand

side.NOTE:

8Make sure that there is enough

space between the brake pads

before inserting the brake disc

between the brake pads.

8Make sure that the drive chain

adjusting plates are installed with

the punched sides facing to the

outside.2. Install the swingarm end bolts.

3. Adjust the drive chain slack.

(See page 6-25 for drive chain

slack adjustment procedures.)

4. Tighten the axle nut, brake

caliper bracket bolt and

swingarm end bolts to the speci-

fied torques.

4PT-E7 (English) 6/29/01 9:13 AM Page 77

Page 79 of 100

6-41

PERIODIC MAINTENANCE AND MINOR REPAIR

6

EAU01008

TroubleshootingTroubleshootingAlthough Yamaha motorcycles

receive a thorough inspection before

shipment from the factory, trouble

may occur during operation. Any

problem in the fuel, compression, or

ignition systems, for example, can

cause poor starting and loss of

power.

The following troubleshooting chart

represents a quick and easy proce-

dure for checking these vital systems

yourself. However, should your

motorcycle require any repair, take it

to a Yamaha dealer, whose skilled

technicians have the necessary tools,

experience, and know-how to service

the motorcycle properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life

and can lead to expensive repair

bills. Tightening torque:

Axle nut:

105 Nm (10.5 m0kgf)

Brake caliper bracket bolt:

48 Nm (4.8 m0kgf)

Swingarm end bolt:

2.5 Nm (0.25 m0kgf)

4PT-E7 (English) 6/29/01 9:13 AM Page 78

Page 93 of 100

8-5

SPECIFICATIONS

8

EAU03941

Conversion tableConversion table

Conversion tableAll specification data in this manual are listed in SI and

METRIC UNITS.

Use this table to convert METRIC unit data to

IMPERIAL unit data.

Ex.

METRIC MULTIPLIER IMPERIAL

** mm×0.03937 = ** in

2 mm×0.03937 = 0.08 in

METRIC TO IMPERIAL

Metric unit Multiplier Imperial unit

m•kgf 7.233 ft•lb

Torquem•kgf 86.794 in•lb

cm•kgf 0.0723 ft•lb

cm•kgf 0.8679 in•lb

Weightkg 2.205 lbg 0.03527 oz

Speed km/hr 0.6214 mph

km 0.6214 mi

m 3.281 ft

Distance m 1.094 yd

cm 0.3937 in

mm 0.03937 in

cc (cm

3) 0.03527 oz (IMP liq.)

Volume, cc (cm3) 0.06102 cu•in

capacity L (liter) 0.8799 qt (IMP liq.)

L (liter) 0.2199 gal (IMP liq.)

kgf/mm 55.997 lb/in

Misc. kgf/cm

2

14.2234 psi (lb/in

2)

Centigrade (°C)

9/5 + 32

Fahrenheit (°F)

CONVERSION TABLE

4PT-E7 (English) 6/29/01 9:13 AM Page 92