lock YAMAHA XV1600A 2001 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: XV1600A, Model: YAMAHA XV1600A 2001Pages: 104, PDF Size: 20.37 MB

Page 29 of 104

INSTRUMENT AND CONTROL FUNCTIONS

3-14

3

EAU01694*

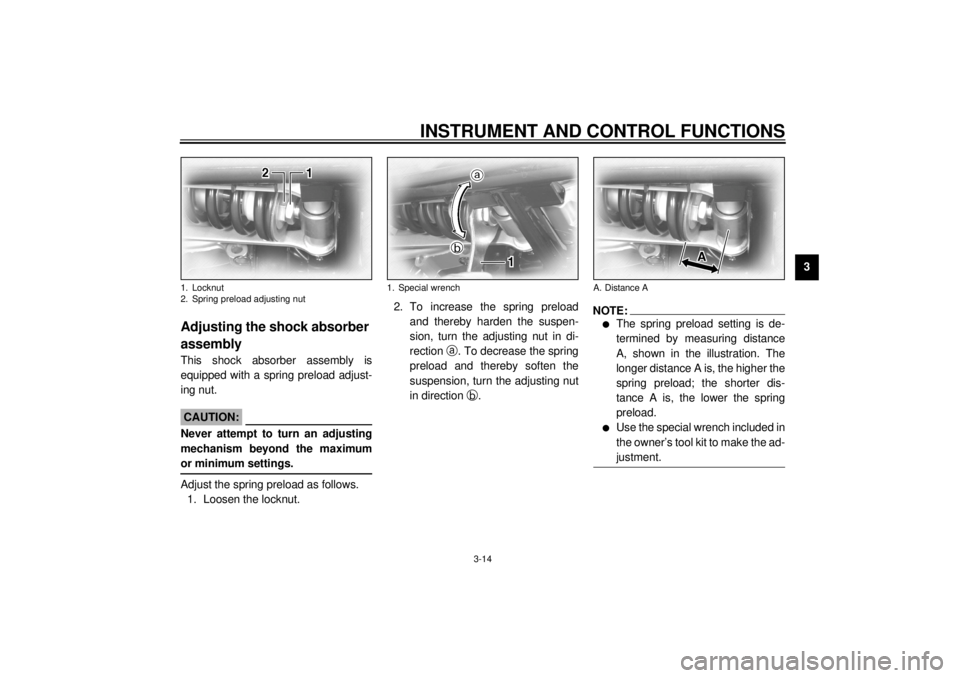

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing nut.

EC000015

CAUTION:@ Never attempt to turn an adjusting

mechanism beyond the maximum

or minimum settings. @Adjust the spring preload as follows.

1. Loosen the locknut.2. To increase the spring preload

and thereby harden the suspen-

sion, turn the adjusting nut in di-

rection

a. To decrease the spring

preload and thereby soften the

suspension, turn the adjusting nut

in direction

b.

NOTE:@ l

The spring preload setting is de-

termined by measuring distance

A, shown in the illustration. The

longer distance A is, the higher the

spring preload; the shorter dis-

tance A is, the lower the spring

preload.

l

Use the special wrench included in

the owner’s tool kit to make the ad-

justment.

@

1. Locknut

2. Spring preload adjusting nut

1. Special wrench

A. Distance A

E_5JA.book Page 14 Wednesday, September 13, 2000 6:06 PM

Page 30 of 104

INSTRUMENT AND CONTROL FUNCTIONS

3-15

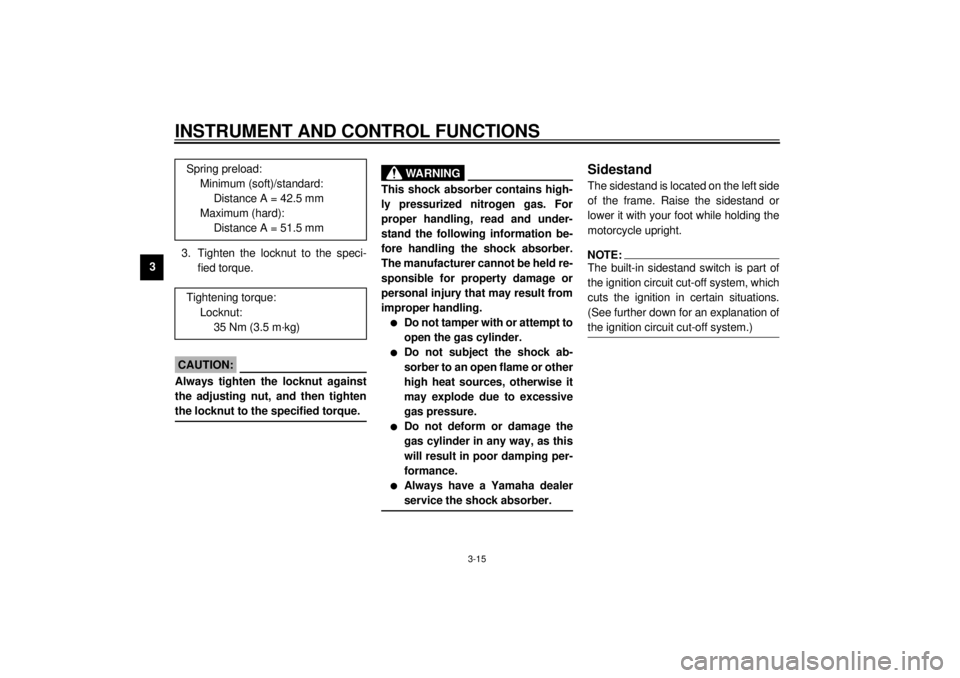

33. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:@ Always tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque. @

EAU00315

WARNING

@ This shock absorber contains high-

ly pressurized nitrogen gas. For

proper handling, read and under-

stand the following information be-

fore handling the shock absorber.

The manufacturer cannot be held re-

sponsible for property damage or

personal injury that may result from

improper handling.l

Do not tamper with or attempt to

open the gas cylinder.

l

Do not subject the shock ab-

sorber to an open flame or other

high heat sources, otherwise it

may explode due to excessive

gas pressure.

l

Do not deform or damage the

gas cylinder in any way, as this

will result in poor damping per-

formance.

l

Always have a Yamaha dealer

service the shock absorber.

@

EAU00330

Sidestand The sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

motorcycle upright.NOTE:@ The built-in sidestand switch is part of

the ignition circuit cut-off system, which

cuts the ignition in certain situations.

(See further down for an explanation of

the ignition circuit cut-off system.) @

Spring preload:

Minimum (soft)/standard:

Distance A = 42.5 mm

Maximum (hard):

Distance A = 51.5 mm

Tightening torque:

Locknut:

35 Nm (3.5 m·kg)

E_5JA.book Page 15 Wednesday, September 13, 2000 6:06 PM

Page 66 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-21

6

EAU00694

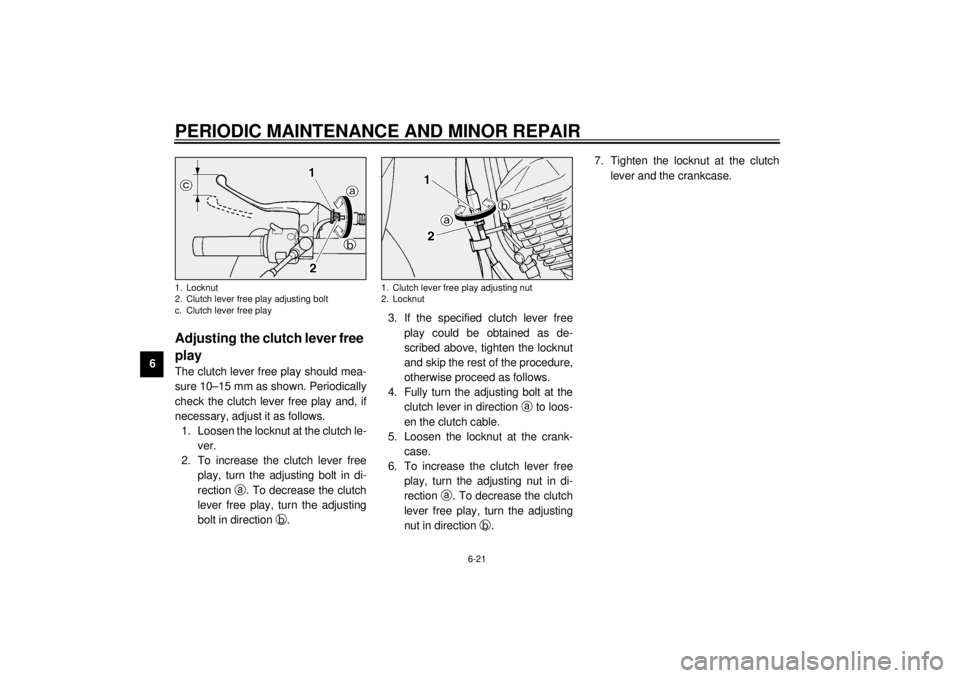

Adjusting the clutch lever free

play The clutch lever free play should mea-

sure 10–15 mm as shown. Periodically

check the clutch lever free play and, if

necessary, adjust it as follows.

1. Loosen the locknut at the clutch le-

ver.

2. To increase the clutch lever free

play, turn the adjusting bolt in di-

rection

a. To decrease the clutch

lever free play, turn the adjusting

bolt in direction

b.3. If the specified clutch lever free

play could be obtained as de-

scribed above, tighten the locknut

and skip the rest of the procedure,

otherwise proceed as follows.

4. Fully turn the adjusting bolt at the

clutch lever in direction

a to loos-

en the clutch cable.

5. Loosen the locknut at the crank-

case.

6. To increase the clutch lever free

play, turn the adjusting nut in di-

rection

a. To decrease the clutch

lever free play, turn the adjusting

nut in direction

b.7. Tighten the locknut at the clutch

lever and the crankcase.1. Locknut

2. Clutch lever free play adjusting bolt

c. Clutch lever free play

1. Clutch lever free play adjusting nut

2. Locknut

E_5JA.book Page 21 Wednesday, September 13, 2000 6:06 PM

Page 67 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-22

6

EAU00696

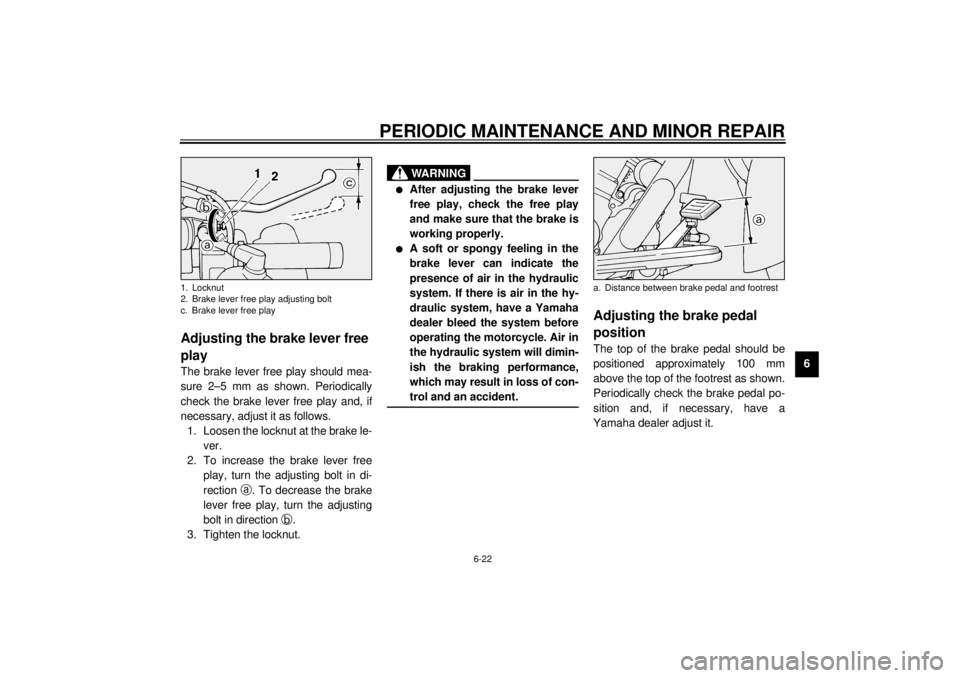

Adjusting the brake lever free

play The brake lever free play should mea-

sure 2–5 mm as shown. Periodically

check the brake lever free play and, if

necessary, adjust it as follows.

1. Loosen the locknut at the brake le-

ver.

2. To increase the brake lever free

play, turn the adjusting bolt in di-

rection

a. To decrease the brake

lever free play, turn the adjusting

bolt in direction

b.

3. Tighten the locknut.

EW000099

WARNING

@ l

After adjusting the brake lever

free play, check the free play

and make sure that the brake is

working properly.

l

A soft or spongy feeling in the

brake lever can indicate the

presence of air in the hydraulic

system. If there is air in the hy-

draulic system, have a Yamaha

dealer bleed the system before

operating the motorcycle. Air in

the hydraulic system will dimin-

ish the braking performance,

which may result in loss of con-

trol and an accident.

@

EAU01746

Adjusting the brake pedal

position The top of the brake pedal should be

positioned approximately 100 mm

above the top of the footrest as shown.

Periodically check the brake pedal po-

sition and, if necessary, have a

Yamaha dealer adjust it.

1. Locknut

2. Brake lever free play adjusting bolt

c. Brake lever free play

a. Distance between brake pedal and footrest

E_5JA.book Page 22 Wednesday, September 13, 2000 6:06 PM

Page 70 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-25

6

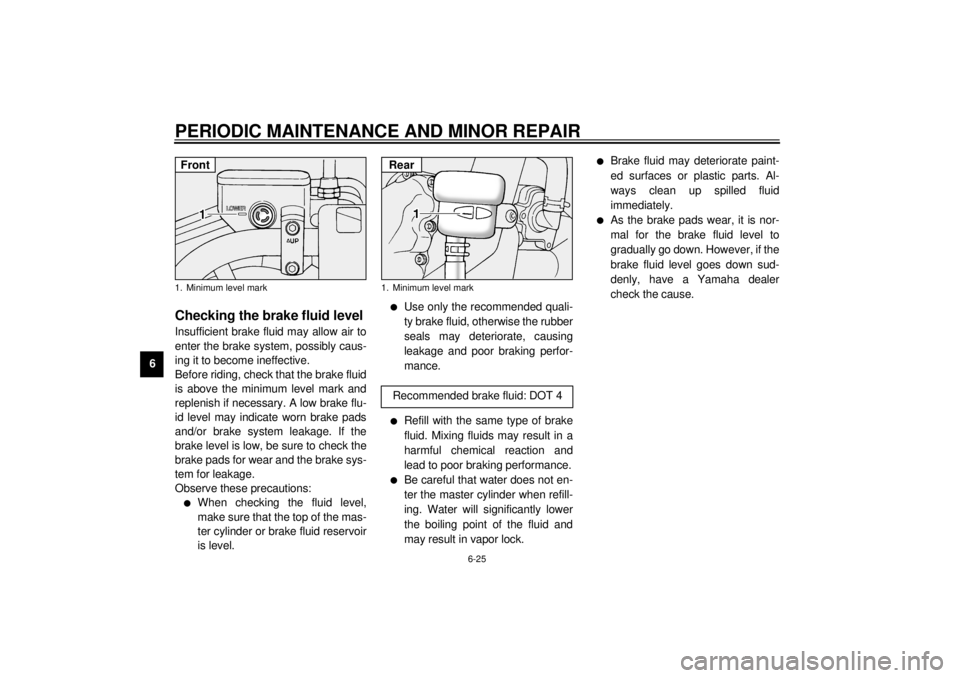

EAU03196

Checking the brake fluid level Insufficient brake fluid may allow air to

enter the brake system, possibly caus-

ing it to become ineffective.

Before riding, check that the brake fluid

is above the minimum level mark and

replenish if necessary. A low brake flu-

id level may indicate worn brake pads

and/or brake system leakage. If the

brake level is low, be sure to check the

brake pads for wear and the brake sys-

tem for leakage.

Observe these precautions:l

When checking the fluid level,

make sure that the top of the mas-

ter cylinder or brake fluid reservoir

is level.

l

Use only the recommended quali-

ty brake fluid, otherwise the rubber

seals may deteriorate, causing

leakage and poor braking perfor-

mance.

l

Refill with the same type of brake

fluid. Mixing fluids may result in a

harmful chemical reaction and

lead to poor braking performance.

l

Be careful that water does not en-

ter the master cylinder when refill-

ing. Water will significantly lower

the boiling point of the fluid and

may result in vapor lock.

l

Brake fluid may deteriorate paint-

ed surfaces or plastic parts. Al-

ways clean up spilled fluid

immediately.

l

As the brake pads wear, it is nor-

mal for the brake fluid level to

gradually go down. However, if the

brake fluid level goes down sud-

denly, have a Yamaha dealer

check the cause.

1. Minimum level markFront

1. Minimum level mark

Recommended brake fluid: DOT 4Rear

E_5JA.book Page 25 Wednesday, September 13, 2000 6:06 PM

Page 72 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-27

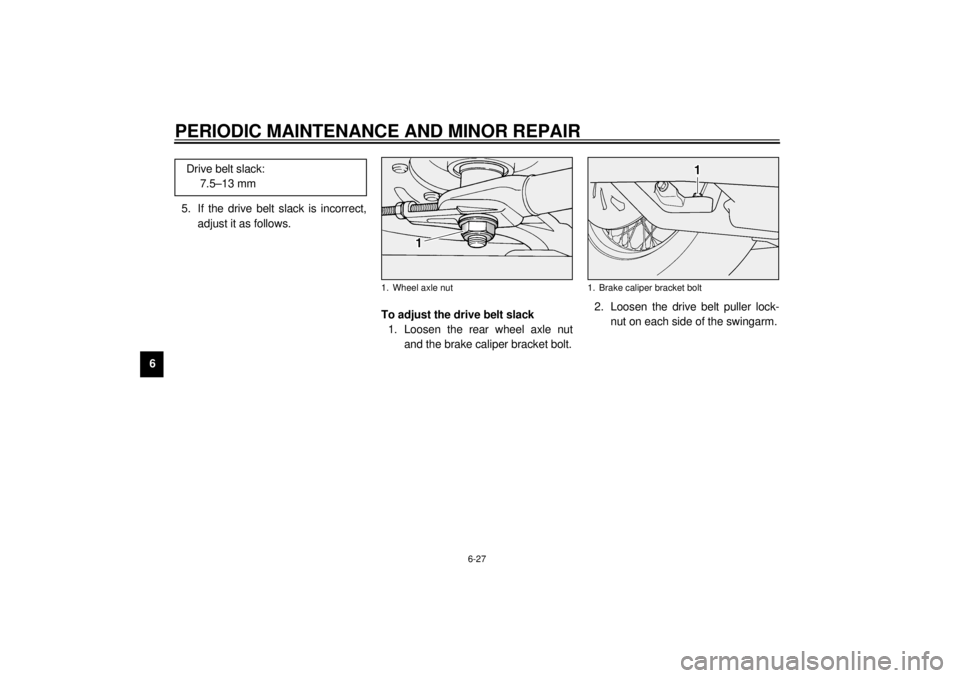

65. If the drive belt slack is incorrect,

adjust it as follows.

EAU01748

To adjust the drive belt slack

1. Loosen the rear wheel axle nut

and the brake caliper bracket bolt.2. Loosen the drive belt puller lock-

nut on each side of the swingarm. Drive belt slack:

7.5–13 mm1. Wheel axle nut

1. Brake caliper bracket bolt

E_5JA.book Page 27 Wednesday, September 13, 2000 6:06 PM

Page 73 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

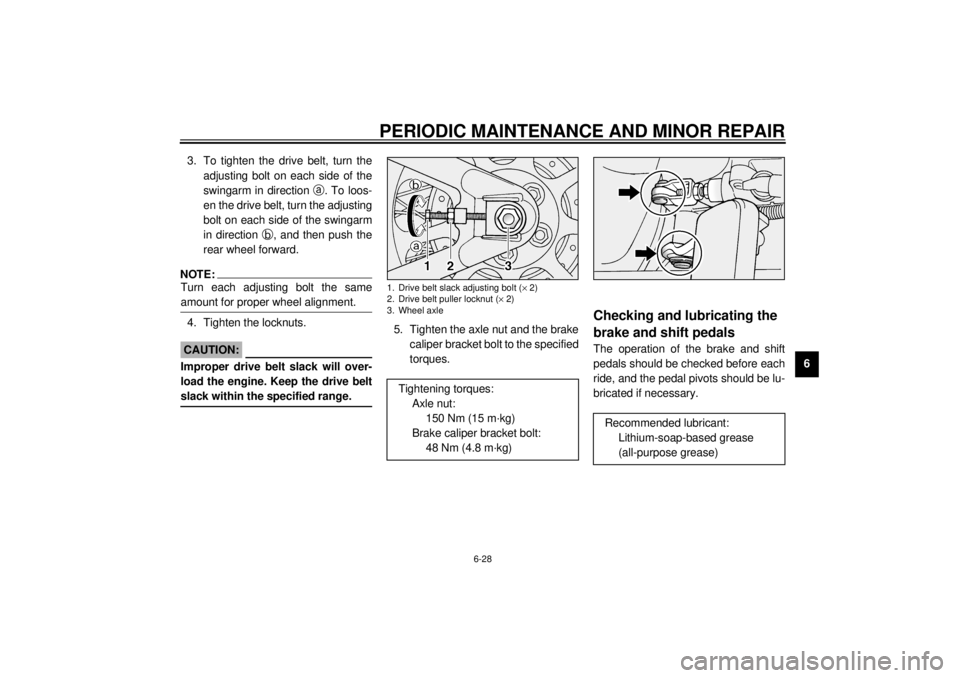

6 3. To tighten the drive belt, turn the

adjusting bolt on each side of the

swingarm in direction

a. To loos-

en the drive belt, turn the adjusting

bolt on each side of the swingarm

in direction

b, and then push the

rear wheel forward.

NOTE:@ Turn each adjusting bolt the same

amount for proper wheel alignment. @4. Tighten the locknuts.

ECA00025

CAUTION:@ Improper drive belt slack will over-

load the engine. Keep the drive belt

slack within the specified range. @

5. Tighten the axle nut and the brake

caliper bracket bolt to the specified

torques.

EAU03370

Checking and lubricating the

brake and shift pedals The operation of the brake and shift

pedals should be checked before each

ride, and the pedal pivots should be lu-

bricated if necessary.

1. Drive belt slack adjusting bolt (´ 2)

2. Drive belt puller locknut (´ 2)

3. Wheel axleTightening torques:

Axle nut:

150 Nm (15 m·kg)

Brake caliper bracket bolt:

48 Nm (4.8 m·kg)

Recommended lubricant:

Lithium-soap-based grease

(all-purpose grease)

E_5JA.book Page 28 Wednesday, September 13, 2000 6:06 PM

Page 82 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-37

6

EAU00855

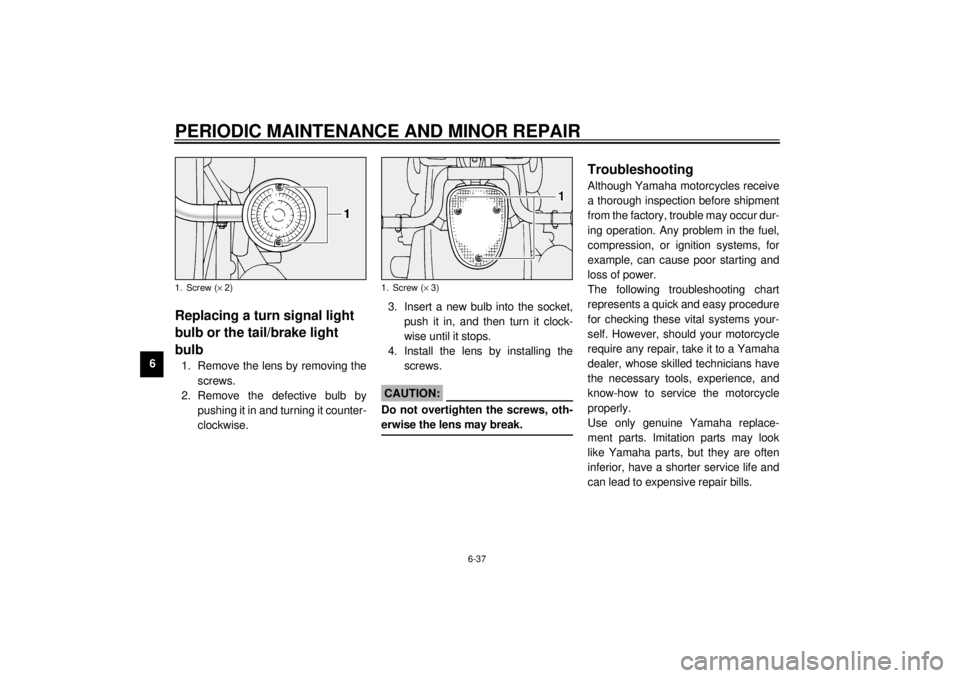

Replacing a turn signal light

bulb or the tail/brake light

bulb 1. Remove the lens by removing the

screws.

2. Remove the defective bulb by

pushing it in and turning it counter-

clockwise.3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

EC000108

CAUTION:@ Do not overtighten the screws, oth-

erwise the lens may break. @

EAU01008

Troubleshooting Although Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur dur-

ing operation. Any problem in the fuel,

compression, or ignition systems, for

example, can cause poor starting and

loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

1. Screw (´ 2)

1. Screw (´ 3)

E_5JA.book Page 37 Wednesday, September 13, 2000 6:06 PM

Page 100 of 104

10-INDEXAAir filter element, cleaning ...................... 6-13

Anti-theft alarm ........................................3-4BBattery ................................................... 6-32

Brake and clutch levers, checking and

lubricating ............................................ 6-29

Brake and shift pedals, checking and

lubricating ............................................ 6-28

Brake fluid, changing ............................. 6-26

Brake fluid level, checking...................... 6-25

Brake lever...............................................3-8

Brake lever free play, adjusting .............. 6-22

Brake light switch (rear), adjusting ......... 6-23

Brake pads, checking............................. 6-23

Brake pedal..............................................3-8

Brake pedal position, adjusting .............. 6-22CCarburetor, adjusting ............................. 6-16

Care.........................................................7-1

Clock .......................................................3-5

Clutch lever ..............................................3-7

Clutch lever free play, adjusting ............. 6-21

Conversion table ......................................8-5DDimmer switch .........................................3-6

Drive belt slack ...................................... 6-26

Adjusting .......................................... 6-27

Checking .......................................... 6-26

EEngine break-in ....................................... 5-5

Engine oil and oil filter cartridge ............... 6-8

Engine stop switch................................... 3-6

Engine trouble warning light .................... 3-2FFront fork, checking ............................... 6-30

Fuel ......................................................... 3-9

Fuel cock ............................................... 3-11

Fuel consumption, tips for reducing ......... 5-4

Fuel gauge .............................................. 3-4

Fuel level warning light ............................ 3-2

Fuel tank breather hose ......................... 3-10

Fuel tank cap ........................................... 3-9

Fuses, replacing .................................... 6-33HHandlebar switches ................................. 3-6

Headlight bulb, replacing ....................... 6-35

Helmet holder ........................................ 3-13

High beam indicator light ......................... 3-2

Horn switch ............................................. 3-6IIdentification numbers ............................. 9-1

Idling speed, adjusting ........................... 6-16

Ignition circuit cut-off system.................. 3-16

Indicator and warning lights ..................... 3-2KKey identification number ........................ 9-1

LLight switch ..............................................3-6MMain switch/steering lock .........................3-1

Model label ..............................................9-2NNeutral indicator light ...............................3-2PPanel, removing and installing..................6-6

Parking.....................................................5-6

Part locations ...........................................2-1

Pass switch ..............................................3-6

Periodic maintenance and

lubrication chart ....................................... 6-3

Pre-operation check list ............................4-1RRider seat ..............................................3-12SSafety information ....................................1-1

Self-diagnosis device ...............................3-4

Shifting .....................................................5-3

Shift pedal ................................................3-7

Shift points (for Switzerland only) .............5-4

Shock absorber assembly, adjusting ......3-14

Sidestand ...............................................3-15

Sidestand, checking and lubricating .......6-30

Spark plugs, checking ..............................6-7

Specifications ...........................................8-1

Speedometer unit.....................................3-3

E_5JA.book Page 1 Wednesday, September 13, 2000 6:06 PM

Page 101 of 104

INDEX

Starter (choke) knob .............................. 3-12

Starting a warm engine ............................ 5-3

Starting the engine .................................. 5-1

Start switch .............................................. 3-7

Steering, checking ................................. 6-31

Steering, locking with a padlock............. 3-12

Storage.................................................... 7-4TThrottle cable free play, adjusting .......... 6-17

Tires ...................................................... 6-17

Tool kit..................................................... 6-1

Transfer case oil .................................... 6-12

Troubleshooting..................................... 6-37

Troubleshooting chart ............................ 6-38

Turn signal indicator light ......................... 3-2

Turn signal light or tail/brake light bulb,

replacing ............................................. 6-37

Turn signal switch .................................... 3-6VValve clearance, adjusting ..................... 6-17

Vehicle identification number ................... 9-1WWheel bearings, checking...................... 6-31

Wheels .................................................. 6-20

E_5JA.book Page 2 Wednesday, September 13, 2000 6:06 PM