torque YAMAHA XV1600A 2001 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: XV1600A, Model: YAMAHA XV1600A 2001Pages: 104, PDF Size: 20.37 MB

Page 30 of 104

INSTRUMENT AND CONTROL FUNCTIONS

3-15

33. Tighten the locknut to the speci-

fied torque.

EC000018

CAUTION:@ Always tighten the locknut against

the adjusting nut, and then tighten

the locknut to the specified torque. @

EAU00315

WARNING

@ This shock absorber contains high-

ly pressurized nitrogen gas. For

proper handling, read and under-

stand the following information be-

fore handling the shock absorber.

The manufacturer cannot be held re-

sponsible for property damage or

personal injury that may result from

improper handling.l

Do not tamper with or attempt to

open the gas cylinder.

l

Do not subject the shock ab-

sorber to an open flame or other

high heat sources, otherwise it

may explode due to excessive

gas pressure.

l

Do not deform or damage the

gas cylinder in any way, as this

will result in poor damping per-

formance.

l

Always have a Yamaha dealer

service the shock absorber.

@

EAU00330

Sidestand The sidestand is located on the left side

of the frame. Raise the sidestand or

lower it with your foot while holding the

motorcycle upright.NOTE:@ The built-in sidestand switch is part of

the ignition circuit cut-off system, which

cuts the ignition in certain situations.

(See further down for an explanation of

the ignition circuit cut-off system.) @

Spring preload:

Minimum (soft)/standard:

Distance A = 42.5 mm

Maximum (hard):

Distance A = 51.5 mm

Tightening torque:

Locknut:

35 Nm (3.5 m·kg)

E_5JA.book Page 15 Wednesday, September 13, 2000 6:06 PM

Page 46 of 104

6-1

6

EAU00462

6-PERIODIC MAINTENANCE AND MINOR REPAIR

EAU00464

Safety is an obligation of the owner.

Periodic inspection, adjustment and lu-

brication will keep your vehicle in the

safest and most efficient condition pos-

sible. The most important points of in-

spection, adjustment, and lubrication

are explained on the following pages.

The intervals given in the periodic

maintenance and lubrication chart

should be simply considered as a gen-

eral guide under normal riding condi-

tions. However, DEPENDING ON THE

WEATHER, TERRAIN, GEOGRAPHI-

CAL LOCATION, AND INDIVIDUAL

USE, THE MAINTENANCE INTER-VALS MAY NEED TO BE SHORT-

ENED.

EW000060

WARNING

@ If you are not familiar with motor-

cycle maintenance work, have a

Yamaha dealer do it for you. @

EAU03394

Owner’s tool kit The owner’s tool kit is located under

the rider seat. (See page 3-12 for rider

seat removal and installation proce-

dures.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.1. Owner’s tool kit

E_5JA.book Page 1 Wednesday, September 13, 2000 6:06 PM

Page 52 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-7

6

EAU01639

Checking the spark plugs The spark plugs are important engine

components, which should be checked

periodically, preferably by a Yamaha

dealer. Since heat and deposits will

cause any spark plug to slowly erode,

they should be removed and checked

in accordance with the periodic mainte-

nance and lubrication chart. In addition,

the condition of the spark plugs can re-

veal the condition of the engine.

The porcelain insulator around the cen-

ter electrode of each spark plug should

be a medium-to-light tan (the ideal col-

or when the motorcycle is ridden nor-

mally), and all spark plugs installed inthe engine should have the same color.

If any spark plug shows a distinctly dif-

ferent color, the engine could be defec-

tive. Do not attempt to diagnose such

problems yourself. Instead, have a

Yamaha dealer check the motorcycle.

If a spark plug shows signs of electrode

erosion and excessive carbon or other

deposits, it should be replaced.

Before installing a spark plug, the spark

plug gap should be measured with a

wire thickness gauge and, if necessary,

adjusted to specification.Clean the surface of the spark plug

gasket and its mating surface, and then

wipe off any grime from the spark plug

threads.

NOTE:@ If a torque wrench is not available when

installing a spark plug, a good estimate

of the correct torque is 1/4–1/2 turn

past finger tight. However, the spark

plug should be tightened to the speci-

fied torque as soon as possible. @

a. Spark plug gap

Specified spark plug:

DPR7EA-9/NGK or

X22EPR-U9/DENSO

Spark plug gap:

0.8–0.9 mm

Tightening torque:

Spark plug:

17.5 Nm (1.75 m·kg)

E_5JA.book Page 7 Wednesday, September 13, 2000 6:06 PM

Page 55 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-10

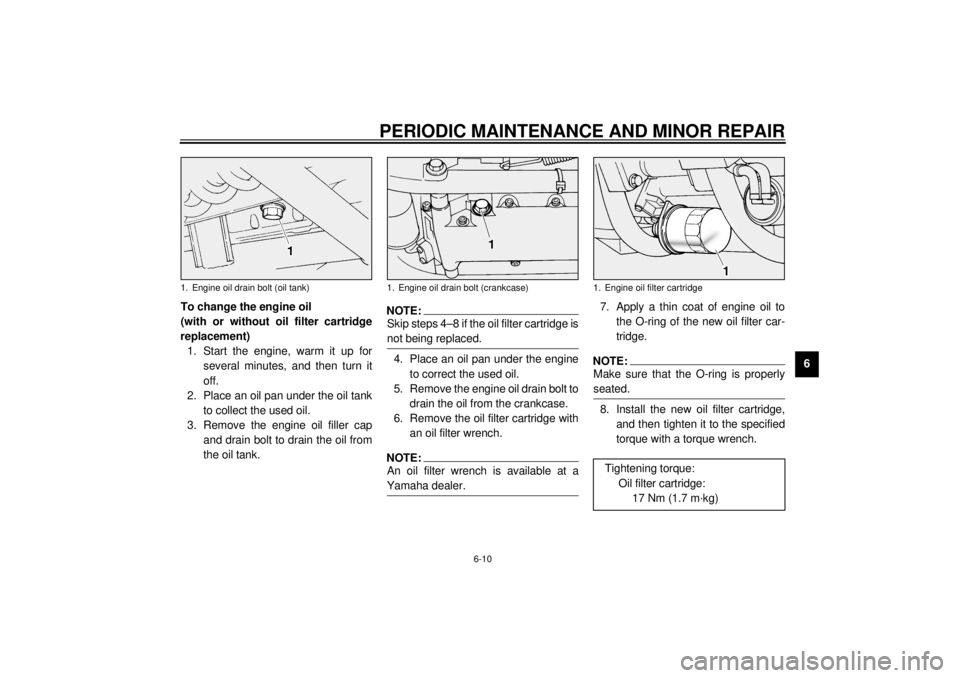

6 To change the engine oil

(with or without oil filter cartridge

replacement)

1. Start the engine, warm it up for

several minutes, and then turn it

off.

2. Place an oil pan under the oil tank

to collect the used oil.

3. Remove the engine oil filler cap

and drain bolt to drain the oil from

the oil tank.

NOTE:@ Skip steps 4–8 if the oil filter cartridge is

not being replaced. @4. Place an oil pan under the engine

to correct the used oil.

5. Remove the engine oil drain bolt to

drain the oil from the crankcase.

6. Remove the oil filter cartridge with

an oil filter wrench.NOTE:@ An oil filter wrench is available at a

Yamaha dealer. @

7. Apply a thin coat of engine oil to

the O-ring of the new oil filter car-

tridge.NOTE:@ Make sure that the O-ring is properly

seated. @8. Install the new oil filter cartridge,

and then tighten it to the specified

torque with a torque wrench.

1. Engine oil drain bolt (oil tank)

1. Engine oil drain bolt (crankcase)

1. Engine oil filter cartridgeTightening torque:

Oil filter cartridge:

17 Nm (1.7 m·kg)

E_5JA.book Page 10 Wednesday, September 13, 2000 6:06 PM

Page 56 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-11

69. Install the engine oil drain bolts,

and then tighten them to the spec-

ified torque.

10. Pour only 2.5 L of the specified

amount of recommended engine

oil through the filler hole, insert the

dipstick, and then tighten the oil

filler cap.

11. Start the engine, rev it several

times, and then turn it off.

12. Remove the engine oil filler cap,

and then gradually fill the oil tank

with the remaining oil quantity

while regularly checking the oil

level on the dipstick.

EC000072

CAUTION:@ l

In order to prevent clutch slip-

page (since the engine oil also

lubricates the clutch), do not

mix any chemical additives with

the oil or use oils of a higher

grade than “CD”. In addition, do

not use oils labeled “ENERGY

CONSERVING II” or higher.

l

Make sure that no foreign mate-

rial enters the crankcase.

@

13. Install the engine oil filler cap.

14. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

15. Turn the engine off, and then

check the oil level and correct it if

necessary. Tightening torque:

Engine oil drain bolt:

43 Nm (4.3 m·kg)

Recommended engine oil:

See page 8-1.

Oil quantity:

Without oil filter cartridge

replacement:

3.7 L

With oil filter cartridge

replacement:

4.1 L

Total amount (dry engine):

5.0 L

E_5JA.book Page 11 Wednesday, September 13, 2000 6:06 PM

Page 57 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-12

6

EAU03395

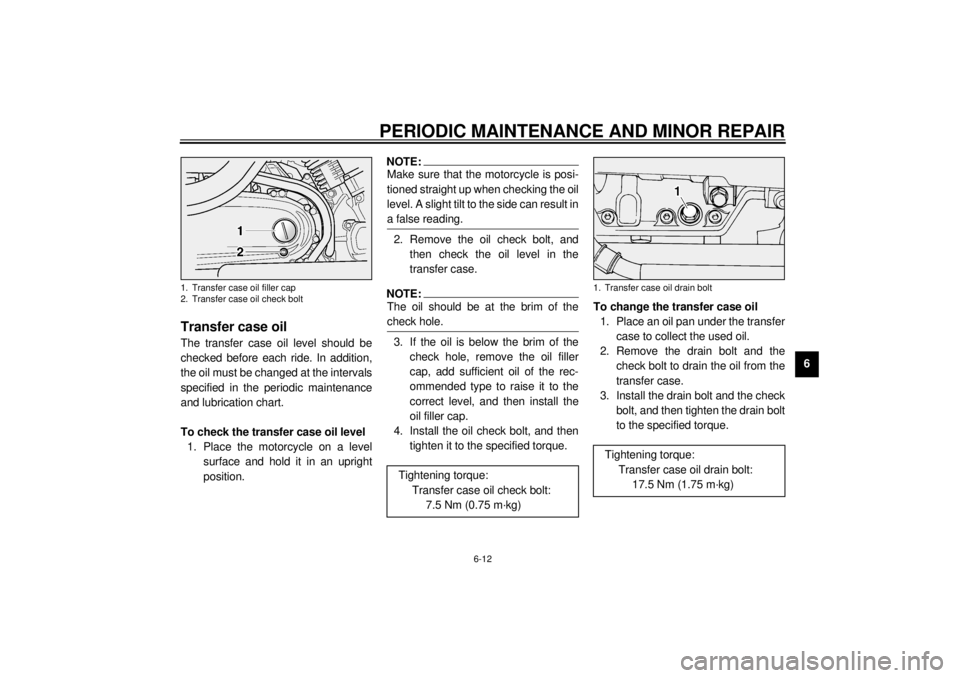

Transfer case oil The transfer case oil level should be

checked before each ride. In addition,

the oil must be changed at the intervals

specified in the periodic maintenance

and lubrication chart.

To check the transfer case oil level

1. Place the motorcycle on a level

surface and hold it in an upright

position.

NOTE:@ Make sure that the motorcycle is posi-

tioned straight up when checking the oil

level. A slight tilt to the side can result in

a false reading. @2. Remove the oil check bolt, and

then check the oil level in the

transfer case.NOTE:@ The oil should be at the brim of the

check hole. @3. If the oil is below the brim of the

check hole, remove the oil filler

cap, add sufficient oil of the rec-

ommended type to raise it to the

correct level, and then install the

oil filler cap.

4. Install the oil check bolt, and then

tighten it to the specified torque.To change the transfer case oil

1. Place an oil pan under the transfer

case to collect the used oil.

2. Remove the drain bolt and the

check bolt to drain the oil from the

transfer case.

3. Install the drain bolt and the check

bolt, and then tighten the drain bolt

to the specified torque.

1. Transfer case oil filler cap

2. Transfer case oil check bolt

Tightening torque:

Transfer case oil check bolt:

7.5 Nm (0.75 m·kg)

1. Transfer case oil drain boltTightening torque:

Transfer case oil drain bolt:

17.5 Nm (1.75 m·kg)

E_5JA.book Page 12 Wednesday, September 13, 2000 6:06 PM

Page 73 of 104

PERIODIC MAINTENANCE AND MINOR REPAIR

6-28

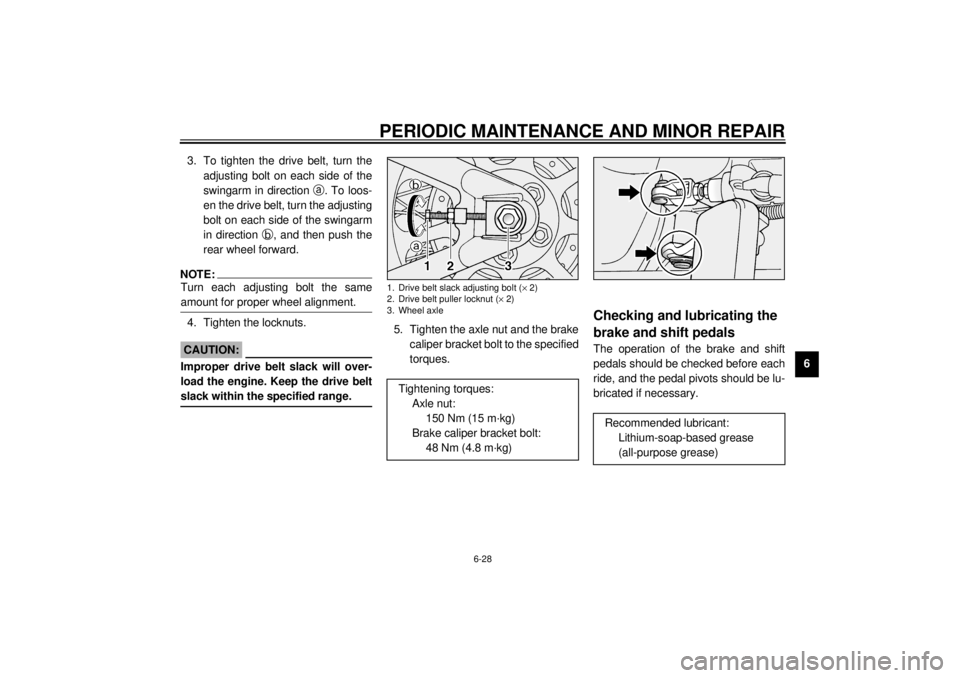

6 3. To tighten the drive belt, turn the

adjusting bolt on each side of the

swingarm in direction

a. To loos-

en the drive belt, turn the adjusting

bolt on each side of the swingarm

in direction

b, and then push the

rear wheel forward.

NOTE:@ Turn each adjusting bolt the same

amount for proper wheel alignment. @4. Tighten the locknuts.

ECA00025

CAUTION:@ Improper drive belt slack will over-

load the engine. Keep the drive belt

slack within the specified range. @

5. Tighten the axle nut and the brake

caliper bracket bolt to the specified

torques.

EAU03370

Checking and lubricating the

brake and shift pedals The operation of the brake and shift

pedals should be checked before each

ride, and the pedal pivots should be lu-

bricated if necessary.

1. Drive belt slack adjusting bolt (´ 2)

2. Drive belt puller locknut (´ 2)

3. Wheel axleTightening torques:

Axle nut:

150 Nm (15 m·kg)

Brake caliper bracket bolt:

48 Nm (4.8 m·kg)

Recommended lubricant:

Lithium-soap-based grease

(all-purpose grease)

E_5JA.book Page 28 Wednesday, September 13, 2000 6:06 PM

Page 96 of 104

SPECIFICATIONS

8-5

8

EAU01064

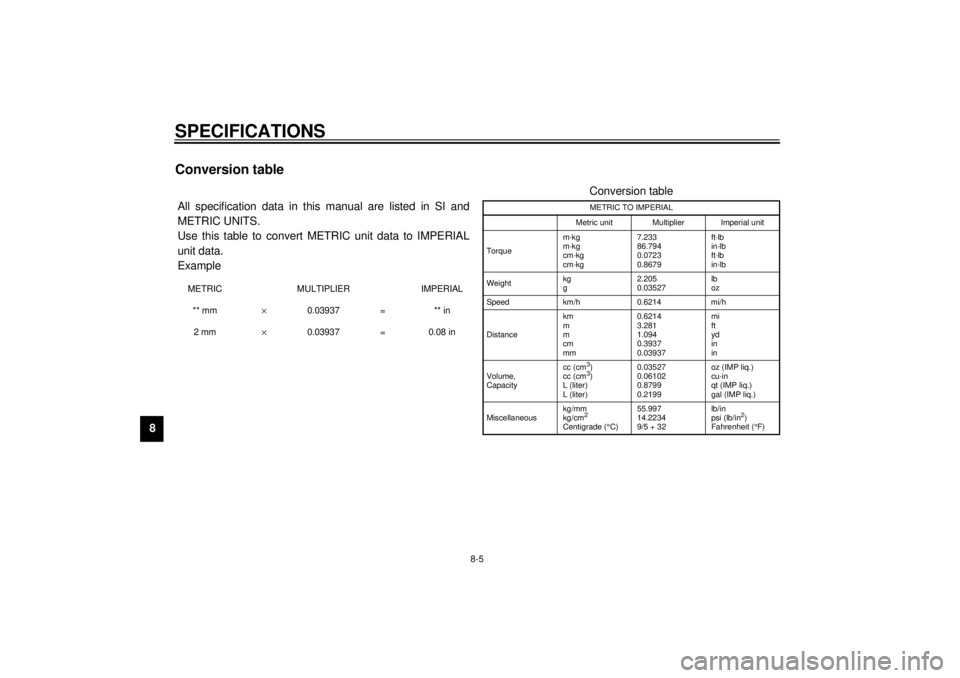

Conversion table CS-02EAll specification data in this manual are listed in SI and

METRIC UNITS.

Use this table to convert METRIC unit data to IMPERIAL

unit data.

ExampleMETRIC MULTIPLIER IMPERIAL

** mm´ 0.03937 = ** in

2 mm´ 0.03937 = 0.08 in

Conversion tableMETRIC TO IMPERIAL

Metric unit Multiplier Imperial unit

Torquem·kg

m·kg

cm·kg

cm·kg7.233

86.794

0.0723

0.8679ft·lb

in·lb

ft·lb

in·lb

Weightkg

g2.205

0.03527lb

oz

Speed km/h 0.6214 mi/h

Distancekm

m

m

cm

mm0.6214

3.281

1.094

0.3937

0.03937mi

ft

yd

in

in

Volume,

Capacitycc (cm3)

cc (cm3)

L (liter)

L (liter)0.03527

0.06102

0.8799

0.2199oz (IMP liq.)

cu·in

qt (IMP liq.)

gal (IMP liq.)

Miscellaneouskg/mm

kg/cm2

Centigrade (°

C)55.997

14.2234

9/5 + 32 lb/in

psi (lb/in

2)

Fahrenheit (°

F)

E_5JA.book Page 5 Wednesday, September 13, 2000 6:06 PM