lock YAMAHA XV1900A 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: XV1900A, Model: YAMAHA XV1900A 2013Pages: 88, PDF Size: 1.75 MB

Page 28 of 88

INSTRUMENT AND CONTROL FUNCTIONS

3-13

3

EAU13122

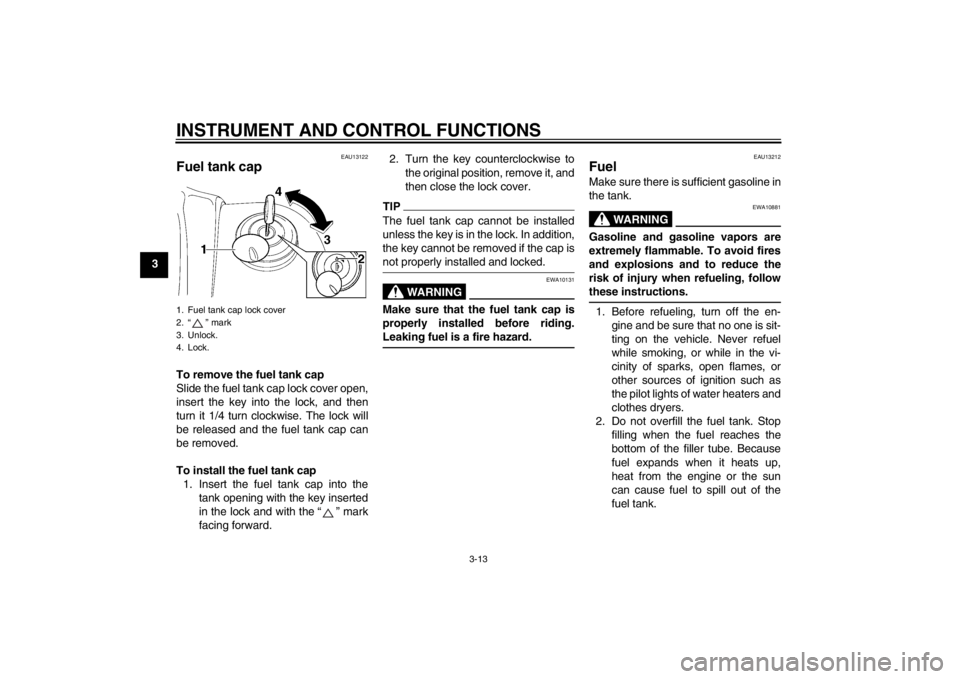

Fuel tank cap To remove the fuel tank cap

Slide the fuel tank cap lock cover open,

insert the key into the lock, and then

turn it 1/4 turn clockwise. The lock will

be released and the fuel tank cap can

be removed.

To install the fuel tank cap1. Insert the fuel tank cap into the tank opening with the key inserted

in the lock and with the “ ” mark

facing forward. 2. Turn the key counterclockwise to

the original position, remove it, and

then close the lock cover.

TIPThe fuel tank cap cannot be installed

unless the key is in the lock. In addition,

the key cannot be removed if the cap is

not properly installed and locked.

WARNING

EWA10131

Make sure that the fuel tank cap is

properly installed before riding.

Leaking fuel is a fire hazard.

EAU13212

Fuel Make sure there is sufficient gasoline in

the tank.

WARNING

EWA10881

Gasoline and gasoline vapors are

extremely flammable. To avoid fires

and explosions and to reduce the

risk of injury when refueling, follow

these instructions.1. Before refueling, turn off the en-gine and be sure that no one is sit-

ting on the vehicle. Never refuel

while smoking, or while in the vi-

cinity of sparks, open flames, or

other sources of ignition such as

the pilot lights of water heaters and

clothes dryers.

2. Do not overfill the fuel tank. Stop filling when the fuel reaches the

bottom of the filler tube. Because

fuel expands when it heats up,

heat from the engine or the sun

can cause fuel to spill out of the

fuel tank.

1. Fuel tank cap lock cover

2. “ ” mark

3. Unlock.

4. Lock.U1CRE2E0.book Page 13 Monday, September 17, 2012 9:05 AM

Page 30 of 88

INSTRUMENT AND CONTROL FUNCTIONS

3-15

3

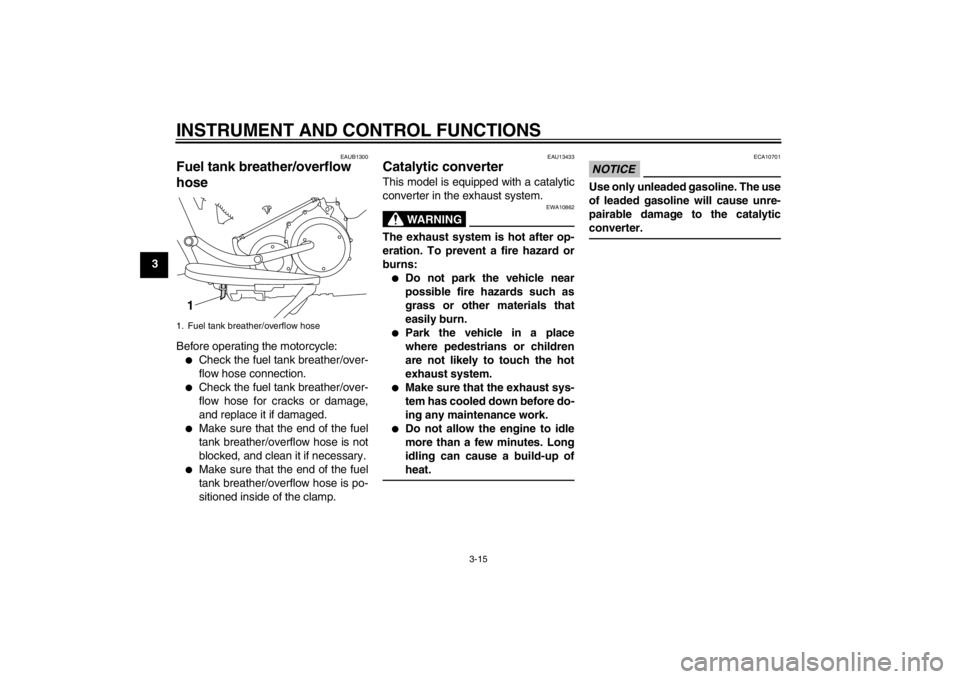

EAUB1300

Fuel tank breather/overflow

hose Before operating the motorcycle:●

Check the fuel tank breather/over-

flow hose connection.

●

Check the fuel tank breather/over-

flow hose for cracks or damage,

and replace it if damaged.

●

Make sure that the end of the fuel

tank breather/overflow hose is not

blocked, and clean it if necessary.

●

Make sure that the end of the fuel

tank breather/overflow hose is po-

sitioned inside of the clamp.

EAU13433

Catalytic converter This model is equipped with a catalytic

converter in the exhaust system.

WARNING

EWA10862

The exhaust system is hot after op-

eration. To prevent a fire hazard or

burns:●

Do not park the vehicle near

possible fire hazards such as

grass or other materials that

easily burn.

●

Park the vehicle in a place

where pedestrians or children

are not likely to touch the hot

exhaust system.

●

Make sure that the exhaust sys-

tem has cooled down before do-

ing any maintenance work.

●

Do not allow the engine to idle

more than a few minutes. Long

idling can cause a build-up of

heat.

NOTICE

ECA10701

Use only unleaded gasoline. The use

of leaded gasoline will cause unre-

pairable damage to the catalytic

converter.

1. Fuel tank breather/overflow hose1

U1CRE2E0.book Page 15 Monday, September 17, 2012 9:05 AM

Page 31 of 88

INSTRUMENT AND CONTROL FUNCTIONS

3-16

3

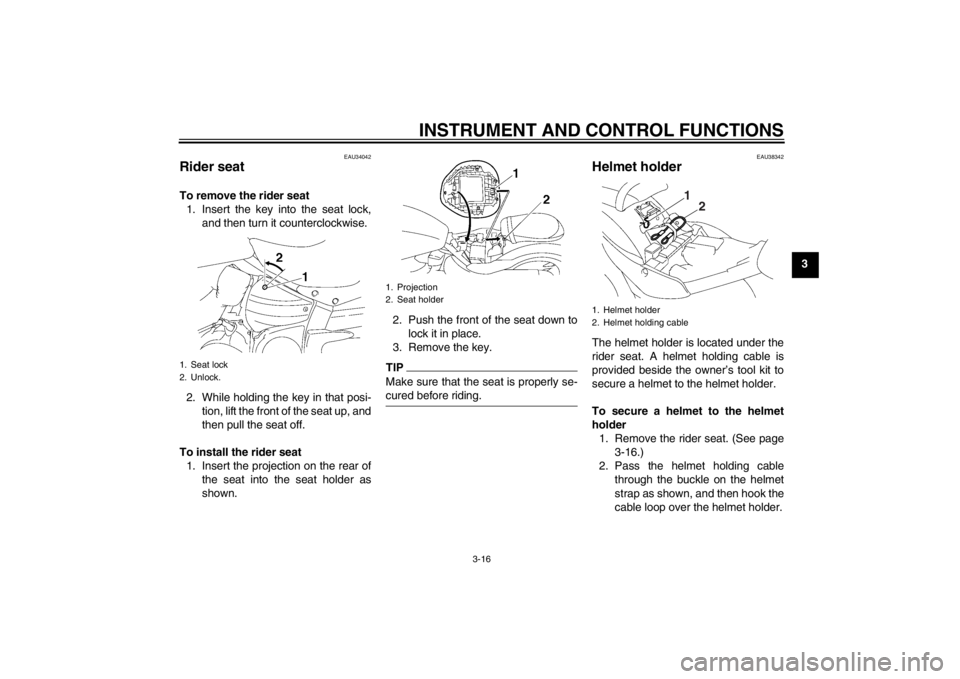

EAU34042

Rider seat To remove the rider seat1. Insert the key into the seat lock, and then turn it counterclockwise.

2. While holding the key in that posi- tion, lift the front of the seat up, and

then pull the seat off.

To install the rider seat 1. Insert the projection on the rear of the seat into the seat holder as

shown. 2. Push the front of the seat down to

lock it in place.

3. Remove the key.

TIPMake sure that the seat is properly se-

cured before riding.

EAU38342

Helmet holder The helmet holder is located under the

rider seat. A helmet holding cable is

provided beside the owner’s tool kit to

secure a helmet to the helmet holder.

To secure a helmet to the helmet

holder 1. Remove the rider seat. (See page 3-16.)

2. Pass the helmet holding cable through the buckle on the helmet

strap as shown, and then hook the

cable loop over the helmet holder.

1. Seat lock

2. Unlock.

1. Projection

2. Seat holder

1. Helmet holder

2. Helmet holding cable

1

2

U1CRE2E0.book Page 16 Monday, September 17, 2012 9:05 AM

Page 32 of 88

INSTRUMENT AND CONTROL FUNCTIONS

3-17

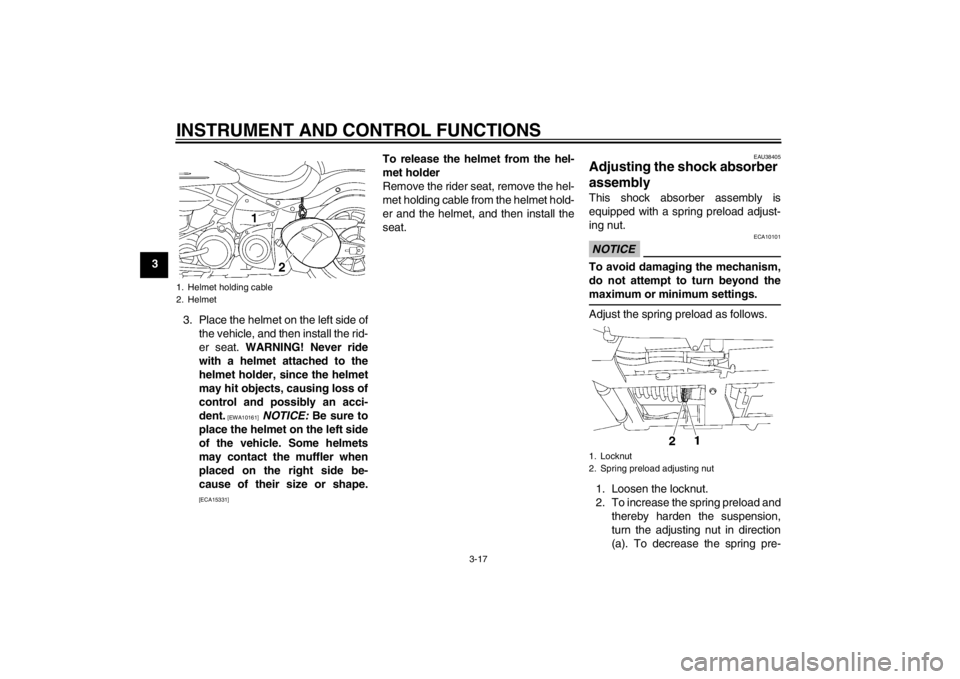

33. Place the helmet on the left side ofthe vehicle, and then install the rid-

er seat. WARNING! Never ride

with a helmet attached to the

helmet holder, since the helmet

may hit objects, causing loss of

control and possibly an acci-

dent.

[EWA10161]

NOTICE: Be sure to

place the helmet on the left side

of the vehicle. Some helmets

may contact the muffler when

placed on the right side be-

cause of their size or shape.

[ECA15331]

To release the helmet from the hel-

met holder

Remove the rider seat, remove the hel-

met holding cable from the helmet hold-

er and the helmet, and then install the

seat.

EAU38405

Adjusting the shock absorber

assembly This shock absorber assembly is

equipped with a spring preload adjust-

ing nut.NOTICE

ECA10101

To avoid damaging the mechanism,

do not attempt to turn beyond the

maximum or minimum settings.Adjust the spring preload as follows.

1. Loosen the locknut.

2. To increase the spring preload and thereby harden the suspension,

turn the adjusting nut in direction

(a). To decrease the spring pre-

1. Helmet holding cable

2. Helmet

1. Locknut

2. Spring preload adjusting nut

U1CRE2E0.book Page 17 Monday, September 17, 2012 9:05 AM

Page 33 of 88

INSTRUMENT AND CONTROL FUNCTIONS

3-18

3

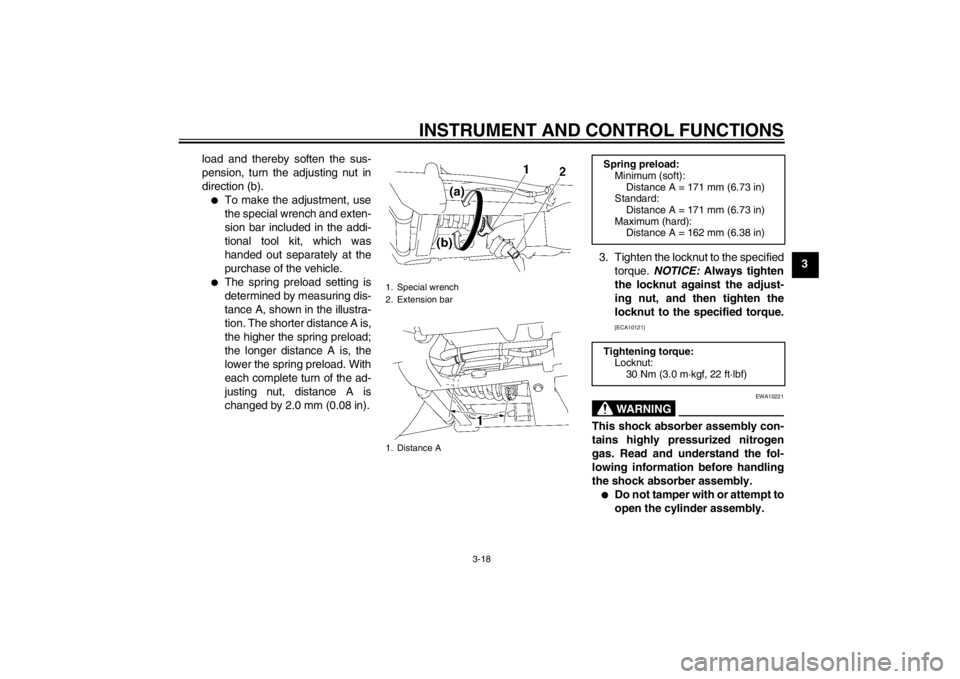

load and thereby soften the sus-

pension, turn the adjusting nut in

direction (b).

●

To make the adjustment, use

the special wrench and exten-

sion bar included in the addi-

tional tool kit, which was

handed out separately at the

purchase of the vehicle.

●

The spring preload setting is

determined by measuring dis-

tance A, shown in the illustra-

tion. The shorter distance A is,

the higher the spring preload;

the longer distance A is, the

lower the spring preload. With

each complete turn of the ad-

justing nut, distance A is

changed by 2.0 mm (0.08 in). 3. Tighten the locknut to the specified

torque. NOTICE: Always tighten

the locknut against the adjust-

ing nut, and then tighten the

locknut to the specified torque.

[ECA10121]WARNING

EWA10221

This shock absorber assembly con-

tains highly pressurized nitrogen

gas. Read and understand the fol-

lowing information before handling

the shock absorber assembly.●

Do not tamper with or attempt to

open the cylinder assembly.

1. Special wrench

2. Extension bar

1. Distance A

Spring preload: Minimum (soft):

Distance A = 171 mm (6.73 in)

Standard:

Distance A = 171 mm (6.73 in)

Maximum (hard): Distance A = 162 mm (6.38 in)

Tightening torque: Locknut:

30 Nm (3.0 m·kgf, 22 ft·lbf)

U1CRE2E0.book Page 18 Monday, September 17, 2012 9:05 AM

Page 62 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-18

6Rear brake

Clutch

TIPThe rear brake fluid reservoir is located

under the rider seat. (See page 3-16.)

WARNING

EWA16000

Improper maintenance can result in

loss of braking ability or clutch oper-

ation. Observe these precautions:●

Insufficient brake or clutch fluid

may allow air to enter the brake

or clutch system, reducing

braking or clutch performance.

●

Clean the filler caps before re-

moving. Use only DOT 4 brake

fluid from a sealed container.

●

Use only the specified brake flu-

id; otherwise, the rubber seals

may deteriorate, causing leak-

age.

●

Refill with the same type of

brake fluid. Adding a brake fluid

other than DOT 4 may result in a

harmful chemical reaction.

●

Be careful that water does not

enter the brake or clutch fluid

reservoir when refilling. Water will significantly lower the boil-

ing point of the fluid and may re-

sult in vapor lock.

NOTICE

ECA17640

Brake fluid may damage painted sur-

faces or plastic parts. Always clean

up spilled fluid immediately.As the brake pads wear, it is normal for

the brake fluid level to gradually go

down. A low brake fluid level may indi-

cate worn brake pads and/or brake sys-

tem leakage; therefore, be sure to

check the brake pads for wear and the

brake system for leakage. A low clutch

fluid level may indicate clutch system

leakage; therefore, be sure to check the

clutch system for leakage. If the brake

or clutch fluid level goes down sudden-

ly, have a Yamaha dealer check the

cause before further riding.

1. Minimum level mark

1. Minimum level mark

Specified brake and clutch fluid:

DOT 4 brake fluid

U1CRE2E0.book Page 18 Monday, September 17, 2012 9:05 AM

Page 70 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-26

6If a fuse is blown, replace it as follows.1. Turn the key to “OFF” and turn off the electrical circuit in question.

2. Remove the blown fuse, and then install a new fuse of the specified

amperage. WARNING! Do not

use a fuse of a higher amperage

rating than recommended to

avoid causing extensive dam-

age to the electrical system and

possibly a fire.

[EWA15131]

3. Turn the key to “ON” and turn on the electrical circuit in question to

check if the device operates.

4. If the fuse immediately blows again, have a Yamaha dealer

check the electrical system.

EAU38455

Replacing a headlight bulb This model features a headlight

equipped with two halogen bulbs. If the

high beam or the low beam bulb burns

out, replace it as follows.NOTICE

ECA10650

Take care not to damage the follow-

ing parts:●

Headlight bulb

Do not touch the glass part of

the headlight bulb to keep it free

from oil, otherwise the transpar-

ency of the glass, the luminosity

of the bulb, and the bulb life will

be adversely affected. Thor-

1. Fuse box

2. Auxiliary DC connector fuse

3. Signaling system fuse

4. Ignition fuse

5. Parking lighting fuse

6. Backup fuse (for clock and immobilizer sys-tem)

7. Headlight fuse

8. Spare fuse

Specified fuses: Main fuse:

50.0 A

Headlight fuse:

25.0 A

Signaling system fuse: 10.0 A

Ignition fuse: 25.0 A

Fuel injection system fuse:

15.0 A

Auxiliary DC connector fuse: 3.0 A

Parking lighting fuse: 10.0 A

Backup fuse:

3.0 A

1. Low beam headlight bulb

2. High beam headlight bulb

U1CRE2E0.book Page 26 Monday, September 17, 2012 9:05 AM

Page 71 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-27

6

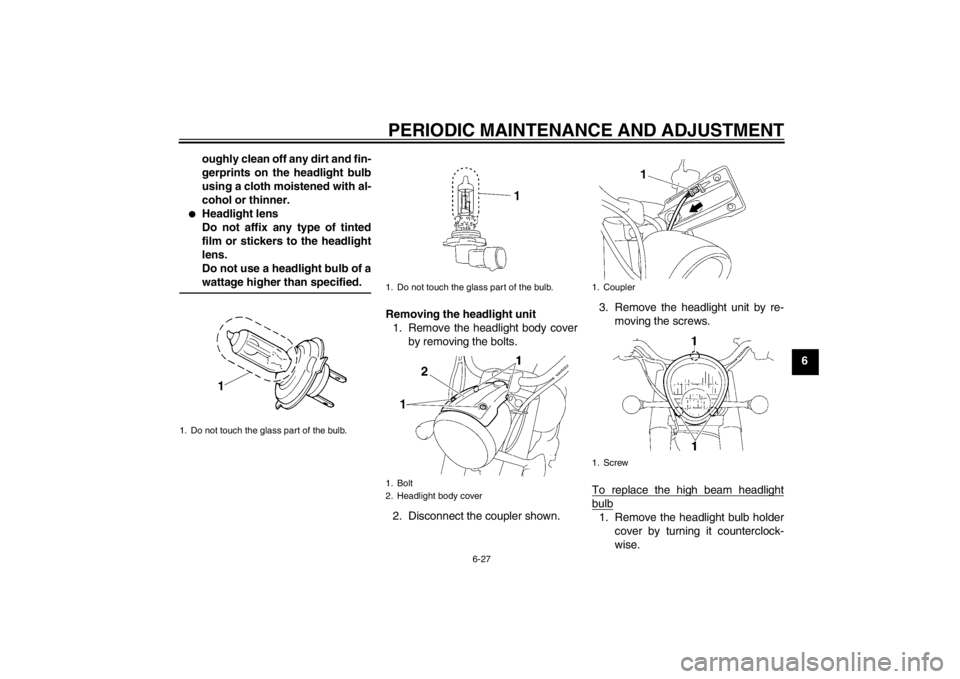

oughly clean off any dirt and fin-

gerprints on the headlight bulb

using a cloth moistened with al-

cohol or thinner.

●

Headlight lens

Do not affix any type of tinted

film or stickers to the headlight

lens.

Do not use a headlight bulb of a

wattage higher than specified.

Removing the headlight unit

1. Remove the headlight body cover by removing the bolts.

2. Disconnect the coupler shown. 3. Remove the headlight unit by re-

moving the screws.

To replace the high beam headlight

bulb1. Remove the headlight bulb holder cover by turning it counterclock-

wise.

1. Do not touch the glass part of the bulb.

1. Do not touch the glass part of the bulb.

1. Bolt

2. Headlight body cover

1. Coupler

1. Screw

U1CRE2E0.book Page 27 Monday, September 17, 2012 9:05 AM

Page 72 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-28

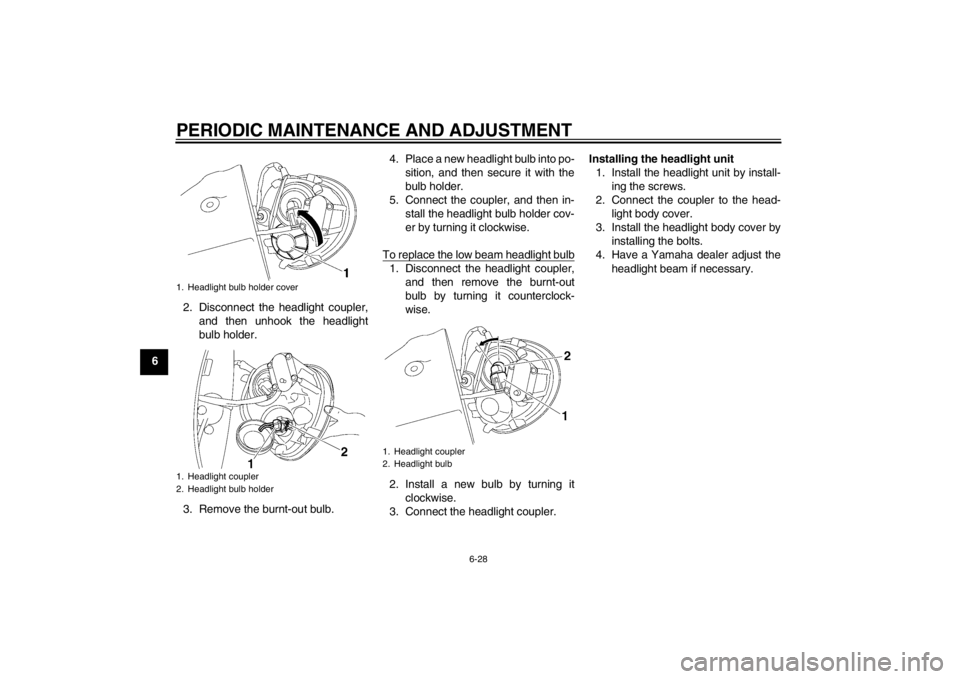

62. Disconnect the headlight coupler,

and then unhook the headlight

bulb holder.

3. Remove the burnt-out bulb. 4. Place a new headlight bulb into po-

sition, and then secure it with the

bulb holder.

5. Connect the coupler, and then in- stall the headlight bulb holder cov-

er by turning it clockwise.

To replace the low beam headlight bulb

1. Disconnect the headlight coupler, and then remove the burnt-out

bulb by turning it counterclock-

wise.

2. Install a new bulb by turning it clockwise.

3. Connect the headlight coupler. Installing the headlight unit

1. Install the headlight unit by install- ing the screws.

2. Connect the coupler to the head- light body cover.

3. Install the headlight body cover by installing the bolts.

4. Have a Yamaha dealer adjust the headlight beam if necessary.

1. Headlight bulb holder cover

1. Headlight coupler

2. Headlight bulb holder

1. Headlight coupler

2. Headlight bulb

U1CRE2E0.book Page 28 Monday, September 17, 2012 9:05 AM

Page 73 of 88

PERIODIC MAINTENANCE AND ADJUSTMENT

6-29

6

EAU24181

Tail/brake light This model is equipped with an LED-

type tail/brake light.

If the tail/brake light does not come on,

have a Yamaha dealer check it.

EAU38382

Replacing a turn signal light

bulb 1. Remove the turn signal light lensby removing the screw, and then

turning the lens counterclockwise.

2. Remove the burnt-out bulb by pushing it in and turning it counter-

clockwise.

3. Insert a new bulb into the socket, push it in, and then turn it clock-

wise until it stops.

4. Install the lens by turning it clock- wise, and then installing the screw.

NOTICE: Do not overtighten the

screw, otherwise the lens may

break.

[ECA11191] EAU24330

License plate light If the license plate light does not come

on, have a Yamaha dealer check the

electrical circuit or replace the bulb.

1. Turn signal light lens

2. Screw

21

U1CRE2E0.book Page 29 Monday, September 17, 2012 9:05 AM