fuel YAMAHA XV535 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XV535, Model: YAMAHA XV535 2000Pages: 87, PDF Size: 17.84 MB

Page 48 of 87

R

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

NOTE:

ÒGL-4Ó is a quality and additive rating.

Hypoid gear oils rated ÒGL-5Ó or ÒGL-6Ó

may also be used.

5. Install and tighten the filler bolt to

the specified torque.

6. After replacing the final gear oil, be

sure to check for oil leakage. Final gear case capacity:

0.19 L

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

If desired, an SAE 80W90 hypoid

gear oil may be used for all

conditions.

Tightening torque:

Oil filler bolt:

23 Nm (2.3 mákg)

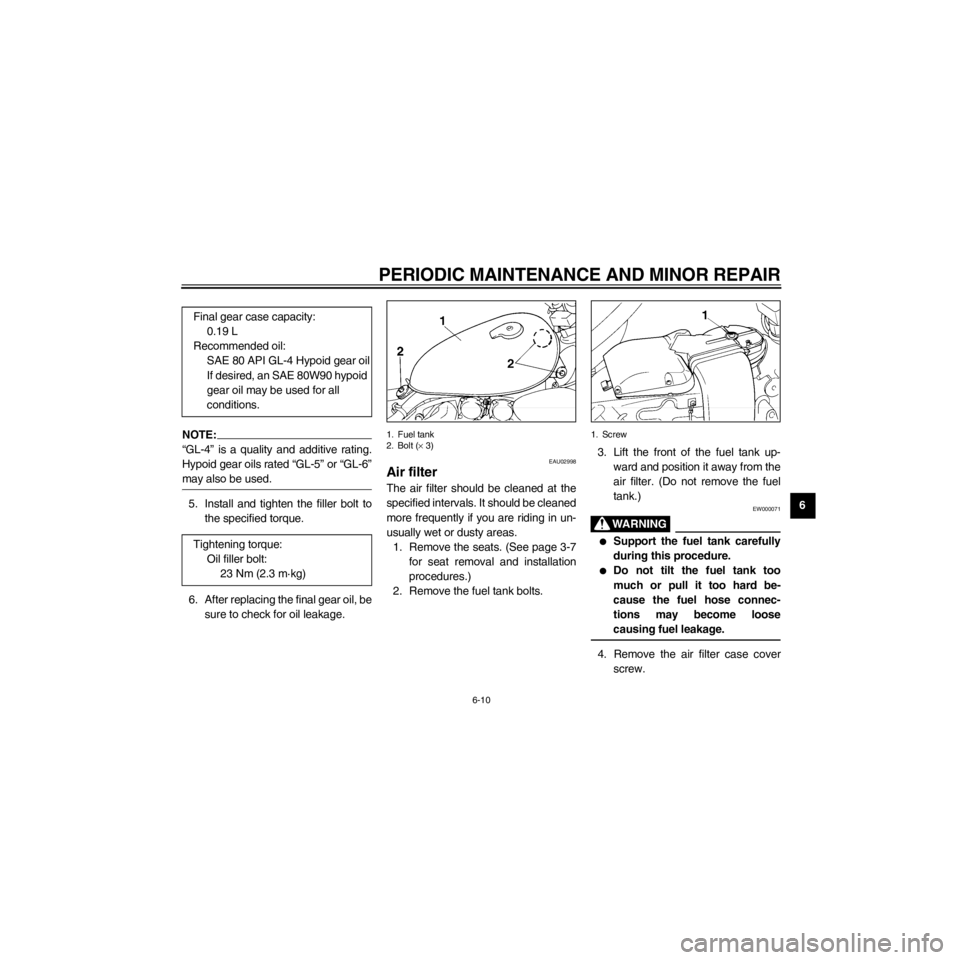

1. Fuel tank

2. Bolt (´ 3)

EAU02998

Air filter

The air filter should be cleaned at the

specified intervals. It should be cleaned

more frequently if you are riding in un-

usually wet or dusty areas.

1. Remove the seats. (See page 3-7

for seat removal and installation

procedures.)

2. Remove the fuel tank bolts.

1. Screw

3. Lift the front of the fuel tank up-

ward and position it away from the

air filter. (Do not remove the fuel

tank.)

EW000071

lSupport the fuel tank carefully

during this procedure.

lDo not tilt the fuel tank too

much or pull it too hard be-

cause the fuel hose connec-

tions may become loose

causing fuel leakage.

4. Remove the air filter case cover

screw.

Page 50 of 87

R

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

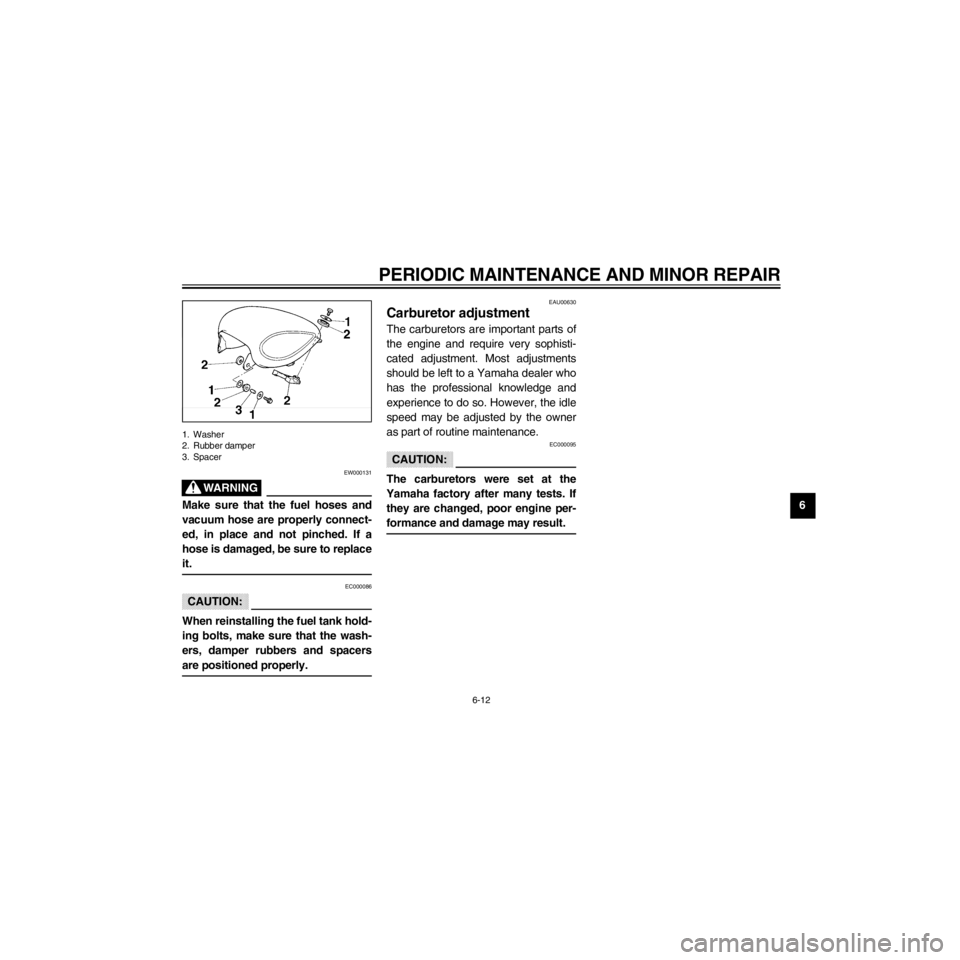

1. Washer

2. Rubber damper

3. Spacer

EW000131

Make sure that the fuel hoses and

vacuum hose are properly connect-

ed, in place and not pinched. If a

hose is damaged, be sure to replace

it.

EC000086

CAUTION:

When reinstalling the fuel tank hold-

ing bolts, make sure that the wash-

ers, damper rubbers and spacers

are positioned properly.

EAU00630

Carburetor adjustment

The carburetors are important parts of

the engine and require very sophisti-

cated adjustment. Most adjustments

should be left to a Yamaha dealer who

has the professional knowledge and

experience to do so. However, the idle

speed may be adjusted by the owner

as part of routine maintenance.

EC000095

CAUTION:

The carburetors were set at the

Yamaha factory after many tests. If

they are changed, poor engine per-

formance and damage may result.

Page 52 of 87

R

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

EAU00637

Valve clearance adjustment

The correct valve clearance changes

with use, resulting in improper fuel/air

supply or engine noise. To prevent this,

the valve clearance must be adjusted

regularly. This adjustment however,

should be left to a professional

Yamaha service technician.

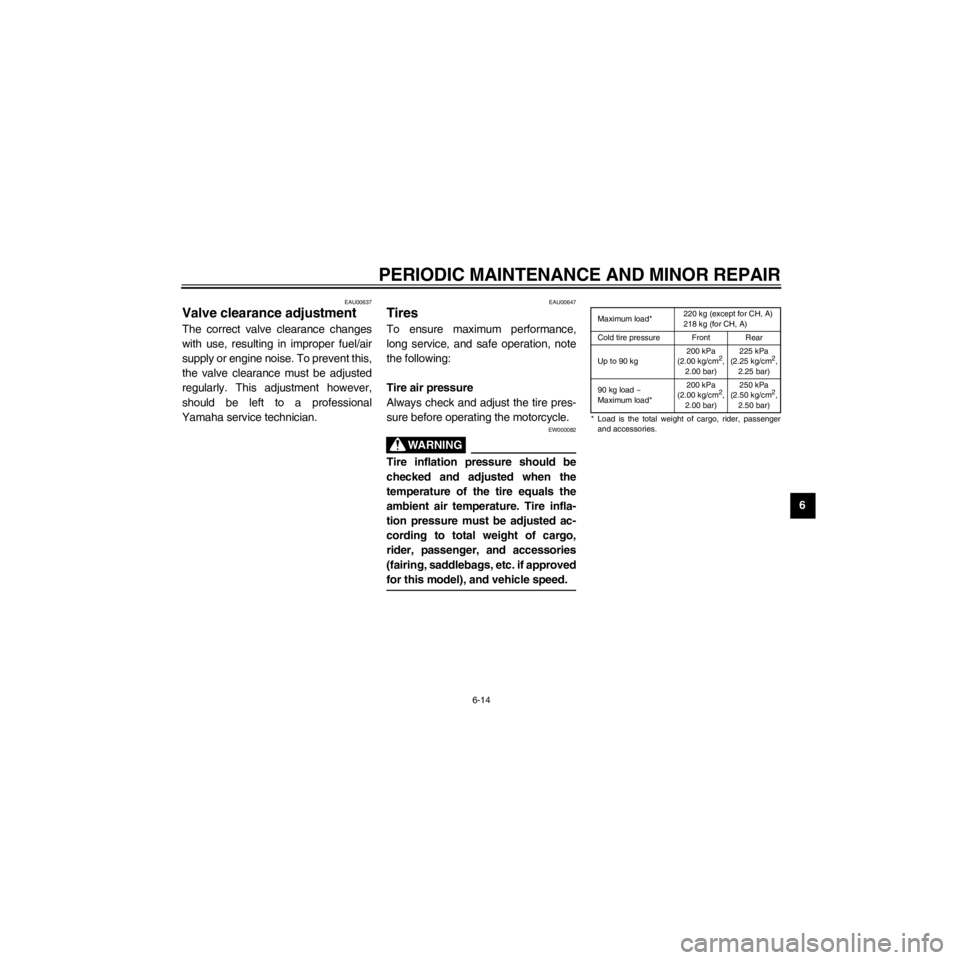

EAU00647

Tires

To ensure maximum performance,

long service, and safe operation, note

the following:

Tire air pressure

Always check and adjust the tire pres-

sure before operating the motorcycle.

EW000082

Tire inflation pressure should be

checked and adjusted when the

temperature of the tire equals the

ambient air temperature. Tire infla-

tion pressure must be adjusted ac-

cording to total weight of cargo,

rider, passenger, and accessories

(fairing, saddlebags, etc. if approved

for this model), and vehicle speed.

Maximum load*220 kg (except for CH, A)

218 kg (for CH, A)

Cold tire pressure Front Rear

Up to 90 kg200 kPa

(2.00 kg/cm

2,

2.00 bar)225 kPa

(2.25 kg/cm2,

2.25 bar)

90 kg load ~

Maximum load*200 kPa

(2.00 kg/cm

2,

2.00 bar)250 kPa

(2.50 kg/cm2,

2.50 bar)

* Load is the total weight of cargo, rider, passenger

and accessories.

Page 67 of 87

L

6-29

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

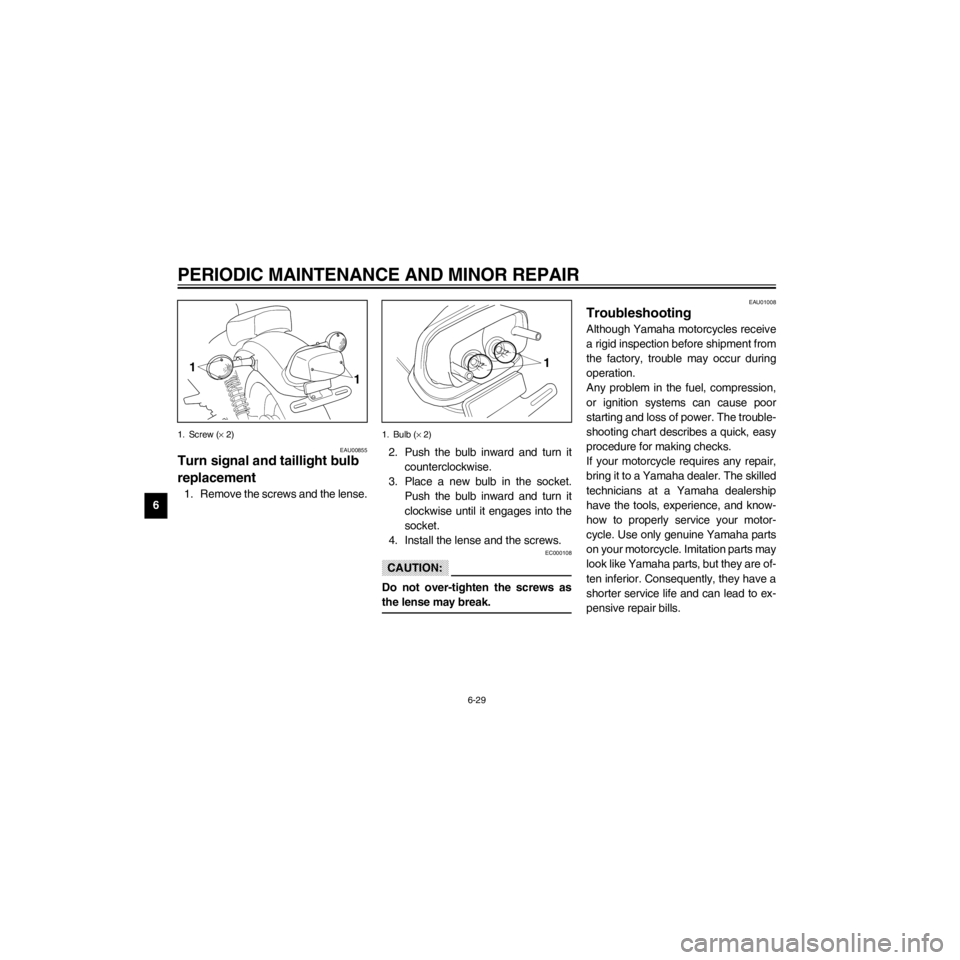

1

1

1. Screw (´ 2)

EAU00855

Turn signal and taillight bulb

replacement

1. Remove the screws and the lense.

1

1. Bulb (´ 2)

2. Push the bulb inward and turn it

counterclockwise.

3. Place a new bulb in the socket.

Push the bulb inward and turn it

clockwise until it engages into the

socket.

4. Install the lense and the screws.

EC000108

CAUTION:

Do not over-tighten the screws as

the lense may break.

EAU01008

Troubleshooting

Although Yamaha motorcycles receive

a rigid inspection before shipment from

the factory, trouble may occur during

operation.

Any problem in the fuel, compression,

or ignition systems can cause poor

starting and loss of power. The trouble-

shooting chart describes a quick, easy

procedure for making checks.

If your motorcycle requires any repair,

bring it to a Yamaha dealer. The skilled

technicians at a Yamaha dealership

have the tools, experience, and know-

how to properly service your motor-

cycle. Use only genuine Yamaha parts

on your motorcycle. Imitation parts may

look like Yamaha parts, but they are of-

ten inferior. Consequently, they have a

shorter service life and can lead to ex-

pensive repair bills.

Page 68 of 87

R

6-30

PERIODIC MAINTENANCE AND MINOR REPAIR

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-6.frame

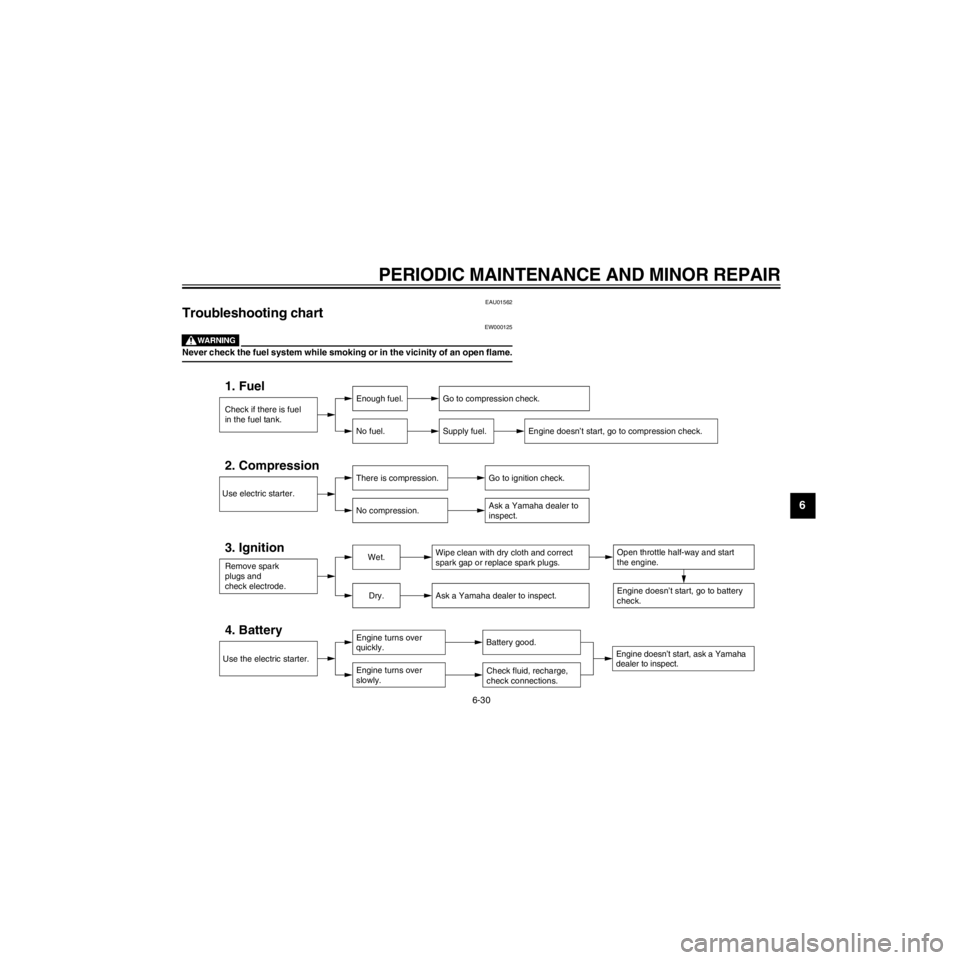

EAU01562

Troubleshooting chart

EW000125

Never check the fuel system while smoking or in the vicinity of an open flame.

Check if there is fuel

in the fuel tank.

1. FuelEnough fuel.

No fuel.Go to compression check.

Supply fuel.

Use electric starter.

2. CompressionThere is compression.

No compression.Go to ignition check.

Ask a Yamaha dealer to

inspect.

Remove spark

plugs and

check electrode.

3. IgnitionWet.

Dry.Wipe clean with dry cloth and correct

spark gap or replace spark plugs.

Ask a Yamaha dealer to inspect.

Engine doesnÕt start, go to battery

check.

Open throttle half-way and start

the engine.

Use the electric starter.

4. BatteryEngine turns over

quickly.

Engine turns over

slowly.Battery good.

Check fluid, recharge,

check connections.

Engine doesnÕt start, ask a Yamaha

dealer to inspect.

Engine doesnÕt start, go to compression check.

Page 72 of 87

R

7-2

MOTORCYCLE CARE AND STORAGE

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-7.frame

ECA00010

CAUTION:

lAvoid using strong acidic wheel

cleaners, especially on spoked

wheels. If you do use such

products for hard-to-remove

dirt, do not leave it on any long-

er than instructed, then thor-

oughly rinse it off with water,

immediately dry the area and

apply a corrosion protection

spray.

lImproper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent and

water to clean plastic.

lDo not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust re-

movers or inhibitors, brake flu-

id, antifreeze or electrolyte.

lDo not use high-pressure wash-

ers or steam-jet cleaners since

they cause water seepage and

deterioration in the following ar-

eas: seals (of wheel bearings,

swingarm bearings, forks and

brakes), electric components

(couplers, connectors, instru-

ments, switches and lights),

breather hoses and vents.

lFor motorcycles equipped with

a windshield: Do not use strong

cleaners or hard sponges as

they will cause dulling or

scratching. Some cleaning

compounds for plastic may

leave scratches on the wind-

shield. Test the product on a

small hidden part of the wind-

shield to make sure they do not

leave any marks. If the wind-

shield is scratched, use a quali-

ty plastic polishing compound

after washing.

After riding in the rain, near the sea or

on salt-sprayed roads

Since sea salt or salt sprayed on the

roads in the winter are extremely corro-

sive in combination with water, carry

out the following steps after each ride

in the rain, near the sea or on salt-

sprayed roads. (Salt sprayed in the

winter may remain on the roads well

into spring.)

Page 74 of 87

R

7-4

MOTORCYCLE CARE AND STORAGE

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-7.frame

ECA00013

CAUTION:

lApply spray oil and wax spar-

ingly and wipe off any excess.

lNever apply oil or wax on rub-

ber and plastic parts, but treat

them with a suitable care prod-

uct.

lAvoid using abrasive polishing

compounds as they wear away

the paint.

NOTE:

Consult a Yamaha dealer for advice on

what products to use.

Storage

Short-term

Always store your motorcycle in a cool,

dry place and, if necessary, protect it

against dust with a porous cover.

ECA00014

CAUTION:

lStoring the motorcycle in a

poorly ventilated room or cov-

ering it with a tarp while it is still

wet will allow water and humidi-

ty to seep in and cause rust.

lTo prevent corrosion, avoid

damp cellars, stables (because

of the presence of ammonia)

and areas where strong chemi-

cals are stored.Long-term

Before storing your motorcycle for sev-

eral months:

1. Follow all the instructions in the

ÒCareÓ section of this chapter.

2. Drain the carburetor float cham-

bers by loosening the drain bolts;

this will prevent fuel deposits from

building up. Pour the drained fuel

into the fuel tank.

3. Only for motorcycles equipped

with a fuel cock which has an

ÒOFFÓ position: Turn the fuel cock

to ÒOFFÓ.

4. Fill up the fuel tank and add fuel

stabilizer (if available) to prevent

the fuel tank from rusting and the

fuel from deteriorating.

5. Perform the following steps to pro-

tect the cylinders, piston rings, etc.

from corrosion.

Page 77 of 87

L

8-1

SPECIFICATIONS

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-8.frame

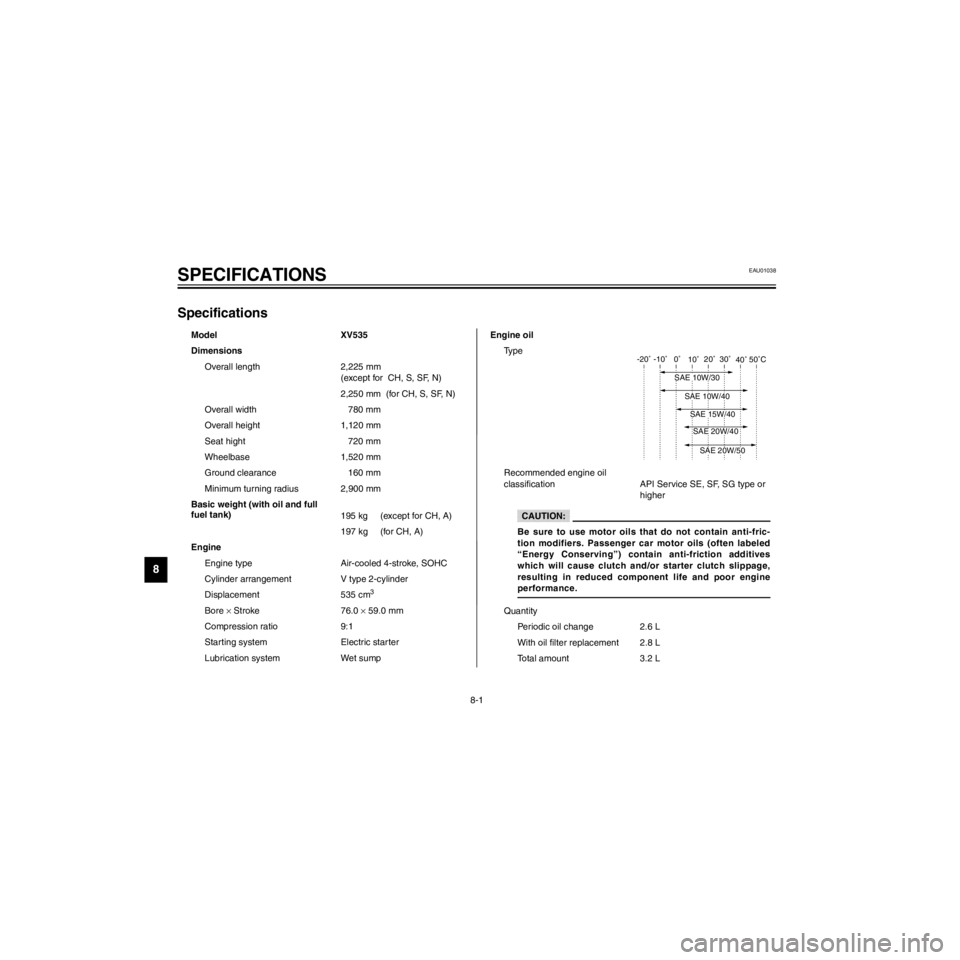

Specifications

Model XV535

Dimensions

Overall length 2,225 mm

(except for CH, S, SF, N)

2,250 mm (for CH, S, SF, N)

Overall width 780 mm

Overall height 1,120 mm

Seat hight 720 mm

Wheelbase 1,520 mm

Ground clearance 160 mm

Minimum turning radius 2,900 mm

Basic weight (with oil and full

fuel tank)

195 kg (except for CH, A)

197 kg (for CH, A)

Engine

Engine type Air-cooled 4-stroke, SOHC

Cylinder arrangement V type 2-cylinder

Displacement 535 cm

3

Bore´ Stroke 76.0 ´ 59.0 mm

Compression ratio 9:1

Starting system Electric starter

Lubrication system Wet sump

Engine oil

Ty p e

Recommended engine oil

classiÞcation API Service SE, SF, SG type or

higher

Quantity

Periodic oil change 2.6 L

With oil Þlter replacement 2.8 L

Total amount 3.2 L

-20û -10û 0û

10û20û 30û

40û50ûC

SAE 10W/30

SAE 15W/40

SAE 20W/40

SAE 20W/50

SAE 10W/40

CAUTION:

Be sure to use motor oils that do not contain anti-fric-

tion modifiers. Passenger car motor oils (often labeled

ÒEnergy ConservingÓ) contain anti-friction additives

which will cause clutch and/or starter clutch slippage,

resulting in reduced component life and poor engine

performance.

EAU01038

Page 78 of 87

R

8-2

SPECIFICATIONS

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/E-8.frame

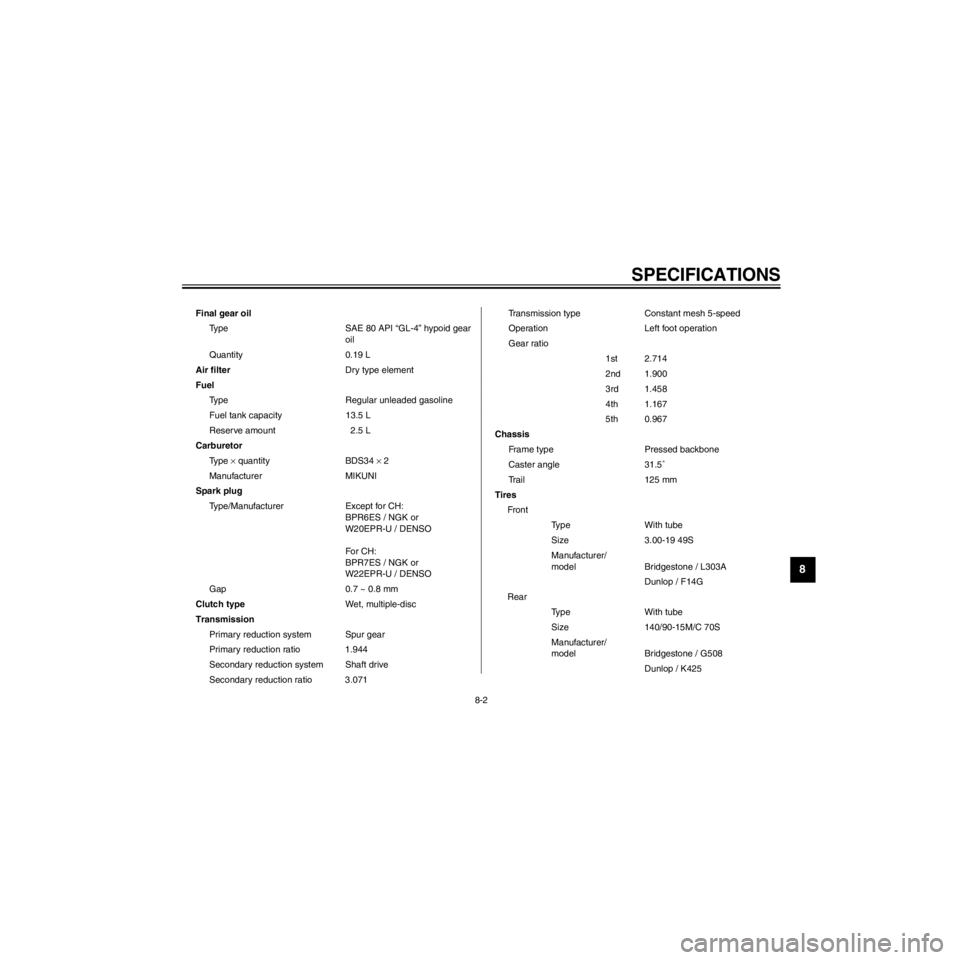

Final gear oil

Type SAE 80 API ÒGL-4Ó hypoid gear

oil

Quantity 0.19 L

Air filterDry type element

Fuel

Ty p eRegular unleaded gasoline

Fuel tank capacity 13.5 L

Reserve amount 2.5 L

Carburetor

Type ´ quantity BDS34 ´ 2

Manufacturer MIKUNI

Spark plug

Type/Manufacturer Except for CH:

BPR6ES / NGK or

W20EPR-U / DENSO

For CH:

BPR7ES / NGK or

W22EPR-U / DENSO

Gap 0.7 ~ 0.8 mm

Clutch typeWet, multiple-disc

Transmission

Primary reduction system Spur gear

Primary reduction ratio 1.944

Secondary reduction system Shaft drive

Secondary reduction ratio 3.071

Transmission type Constant mesh 5-speed

Operation Left foot operation

Gear ratio

1st 2.714

2nd 1.900

3rd 1.458

4th 1.167

5th 0.967

Chassis

Frame type Pressed backbone

Caster angle 31.5û

Tr a i l 1 2 5 m m

Tires

Front

Type With tube

Size 3.00-19 49S

Manufacturer/

model Bridgestone / L303A

Dunlop / F14G

Rear

Type With tube

Size 140/90-15M/C 70S

Manufacturer/

model Bridgestone / G508

Dunlop / K425

Page 85 of 87

L

INDEX

/Net/layout8/layout_G2/work/Imai_work/OM-PS/AA9149_XV535-E6/English/XV535IX.-

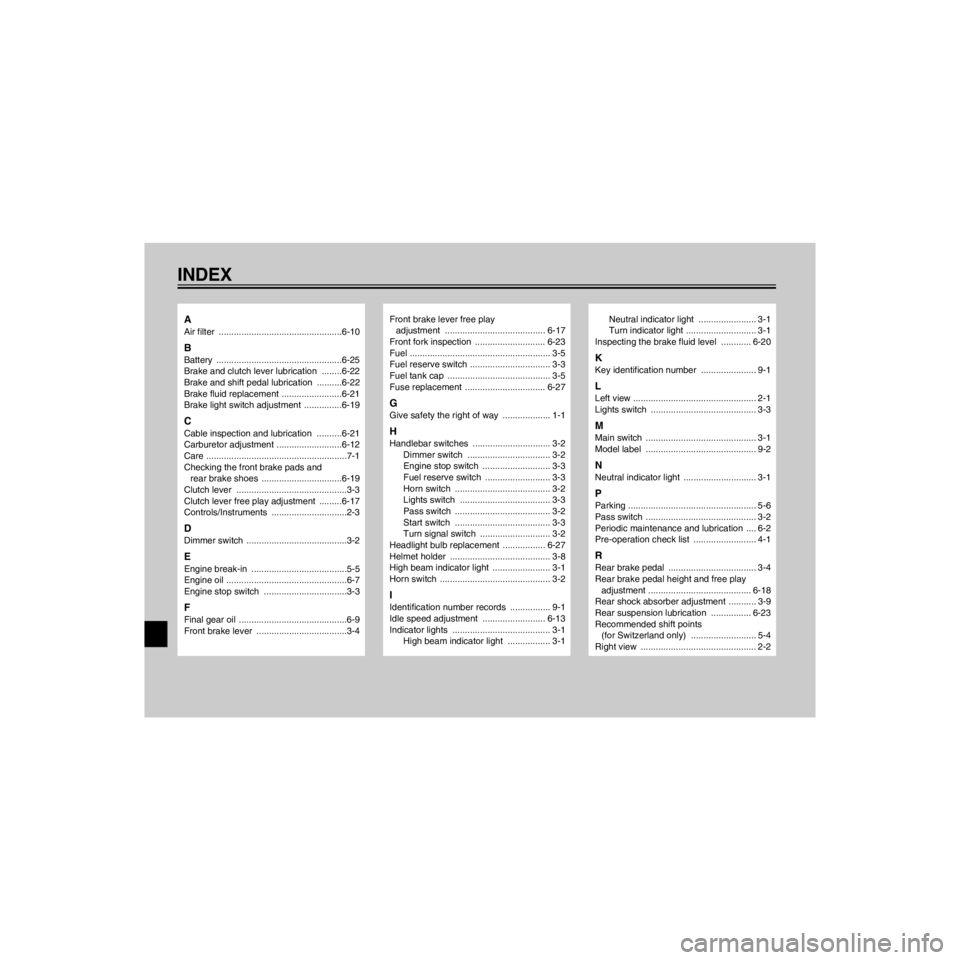

A

Air filter .................................................6-10

B

Battery ..................................................6-25

Brake and clutch lever lubrication ........6-22

Brake and shift pedal lubrication ..........6-22

Brake fluid replacement ........................6-21

Brake light switch adjustment ...............6-19

C

Cable inspection and lubrication ..........6-21

Carburetor adjustment ..........................6-12

Care ........................................................7-1

Checking the front brake pads and

rear brake shoes ................................6-19

Clutch lever ............................................3-3

Clutch lever free play adjustment .........6-17

Controls/Instruments ..............................2-3

D

Dimmer switch ........................................3-2

E

Engine break-in ......................................5-5

Engine oil ................................................6-7

Engine stop switch .................................3-3

F

Final gear oil ...........................................6-9

Front brake lever ....................................3-4

Front brake lever free play

adjustment ........................................ 6-17

Front fork inspection ............................ 6-23

Fuel ........................................................ 3-5

Fuel reserve switch ................................ 3-3

Fuel tank cap ......................................... 3-5

Fuse replacement ................................ 6-27

G

Give safety the right of way ................... 1-1

H

Handlebar switches ............................... 3-2

Dimmer switch ................................. 3-2

Engine stop switch ........................... 3-3

Fuel reserve switch .......................... 3-3

Horn switch ...................................... 3-2

Lights switch .................................... 3-3

Pass switch ...................................... 3-2

Start switch ...................................... 3-3

Turn signal switch ............................ 3-2

Headlight bulb replacement ................. 6-27

Helmet holder ........................................ 3-8

High beam indicator light ....................... 3-1

Horn switch ............................................ 3-2

I

Identification number records ................ 9-1

Idle speed adjustment ......................... 6-13

Indicator lights ....................................... 3-1

High beam indicator light ................. 3-1

Neutral indicator light ....................... 3-1

Turn indicator light ............................ 3-1

Inspecting the brake fluid level ............ 6-20

K

Key identification number ...................... 9-1

L

Left view ................................................. 2-1

Lights switch .......................................... 3-3

M

Main switch ............................................ 3-1

Model label ............................................ 9-2

N

Neutral indicator light ............................. 3-1

P

Parking ................................................... 5-6

Pass switch ............................................ 3-2

Periodic maintenance and lubrication .... 6-2

Pre-operation check list ......................... 4-1

R

Rear brake pedal ................................... 3-4

Rear brake pedal height and free play

adjustment ......................................... 6-18

Rear shock absorber adjustment ........... 3-9

Rear suspension lubrication ................ 6-23

Recommended shift points

(for Switzerland only) .......................... 5-4

Right view .............................................. 2-2