wheel YAMAHA XVS125 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XVS125, Model: YAMAHA XVS125 2000Pages: 86, PDF Size: 3.07 MB

Page 61 of 86

1

2

3

4

5

6

7

8

9

6-31

PERIODIC MAINTENANCE AND MINOR REPAIR

EAU01144

Checking the wheel bearings

The front and rear wheel bearings

must be checked at the intervals

specified in the periodic maintenance

and lubrication chart. If there is play

in the wheel hub or if the wheel does

not turn smoothly, have a Yamaha

dealer check the wheel bearings.

EAU01271

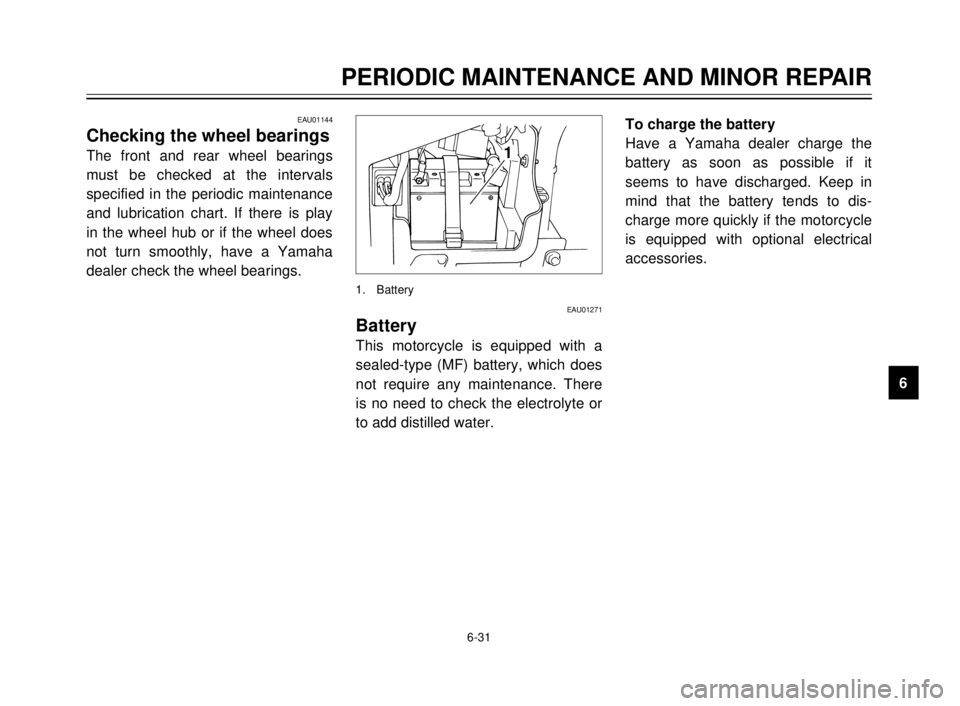

Battery

This motorcycle is equipped with a

sealed-type (MF) battery, which does

not require any maintenance. There

is no need to check the electrolyte or

to add distilled water.

1. Battery

1

To charge the battery

Have a Yamaha dealer charge the

battery as soon as possible if it

seems to have discharged. Keep in

mind that the battery tends to dis-

charge more quickly if the motorcycle

is equipped with optional electrical

accessories.

5JX-9-E0 4/9/0 4:11 AM Page 59

Page 67 of 86

1

2

3

4

5

6

7

8

9

6-37

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2. Remove the defective bulb by

pushing it in and turning it coun-

terclockwise.

3. Insert a new bulb into the socket,

push it in, and then turn it clock-

wise until it stops.

4. Install the lens by installing the

screws.

EC000108

cC

Do not overtighten the screws,

otherwise the lens may break.

1. Bulb

EAU01579

Supporting the motorcycle

Since this model is not equipped with

a centerstand, follow these precau-

tions when removing the front and

rear wheel or performing other main-

tenance requiring the motorcycle to

stand upright. Check that the motor-

cycle is in a stable and level position

before starting any maintenance. A

strong wooden box can be placed

under the engine for added stability.

To service the front wheel

1. Stabilize the rear of the motorcy-

cle by using a motorcycle stand

or, if an additional motorcycle

stand is not available, by placing

a jack under the frame in front of

the rear wheel.

2. Raise the front wheel off the

ground by using a motorcycle

stand.To service the rear wheel

Raise the rear wheel off the ground

by using a motorcycle stand or, if a

motorcycle stand is not available, by

placing a jack either under each side

of the frame in front of the rear wheel

or under each side of the swingarm.

5JX-9-E0 4/9/0 4:11 AM Page 65

Page 68 of 86

6-38

6

PERIODIC MAINTENANCE AND MINOR REPAIR

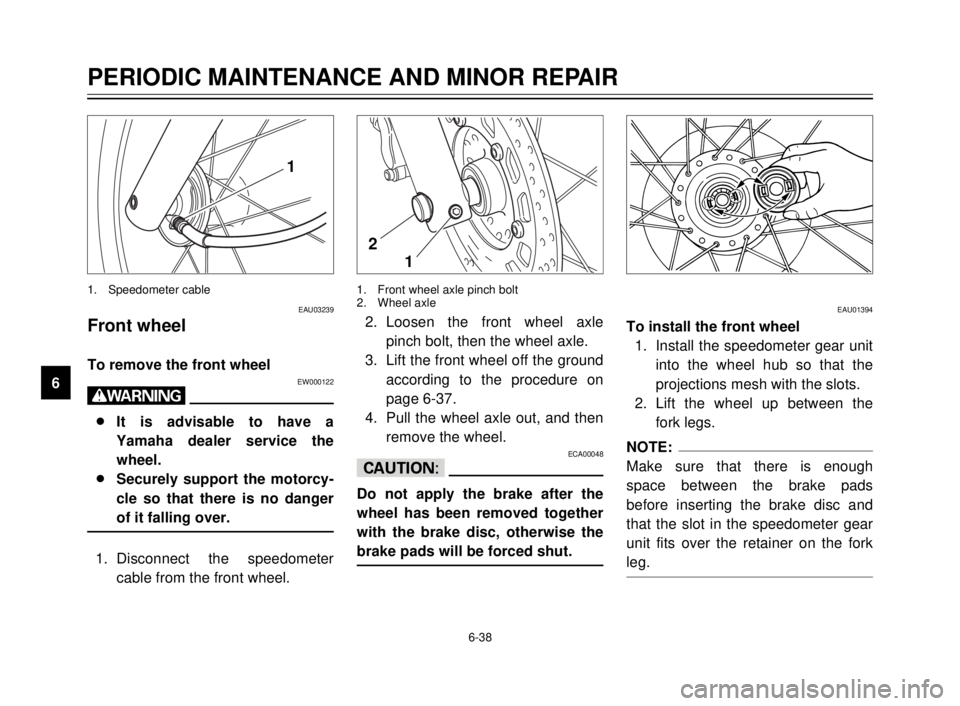

EAU03239

Front wheel

To remove the front wheelEW000122

w

8It is advisable to have a

Yamaha dealer service the

wheel.

8Securely support the motorcy-

cle so that there is no danger

of it falling over.

1. Disconnect the speedometer

cable from the front wheel.

1. Speedometer cable

1

2. Loosen the front wheel axle

pinch bolt, then the wheel axle.

3. Lift the front wheel off the ground

according to the procedure on

page 6-37.

4. Pull the wheel axle out, and then

remove the wheel.

ECA00048

cC

Do not apply the brake after the

wheel has been removed together

with the brake disc, otherwise the

brake pads will be forced shut.

1. Front wheel axle pinch bolt

2. Wheel axle

1 2

EAU01394

To install the front wheel

1. Install the speedometer gear unit

into the wheel hub so that the

projections mesh with the slots.

2. Lift the wheel up between the

fork legs.

NOTE:

Make sure that there is enough

space between the brake pads

before inserting the brake disc and

that the slot in the speedometer gear

unit fits over the retainer on the fork

leg.

5JX-9-E0 4/9/0 4:11 AM Page 66

Page 69 of 86

1

2

3

4

5

6

7

8

9

6-39

PERIODIC MAINTENANCE AND MINOR REPAIR

3. Insert the wheel axle.

4. Lower the front wheel so that it is

on the ground.

5. Push down hard on the handle-

bar several times to check for

proper fork operation.

6. Tighten the wheel axle to the

specified torque.

Tightening torque:

Wheel axle:

59 Nm (5.9 m·kg)

7. Install the front wheel axle pinch

bolt, and then tighten it to the

specified torque.

8. Connect the speedometer cable.

EAU03189

Rear wheel

To remove the rear wheelEW000122

w

8It is advisable to have a

Yamaha dealer service the

wheel.

8Securely support the motorcy-

cle so that there is no danger

of it falling over.

1. Loosen the axle nut and the

brake torque rod nut at the brake

shoe plate.

1. Axle nut

1

Tightening torque:

Front wheel axle pinch bolt:

20 Nm (2.0 m·kg)

5JX-9-E0 4/9/0 4:11 AM Page 67

Page 70 of 86

6-40

1

2

3

4

5

6

7

8

9

PERIODIC MAINTENANCE AND MINOR REPAIR

2. Lift the rear wheel off the ground

according to the procedure on

page 6-37.

3. Disconnect the brake torque rod

from the brake shoe plate by

removing the nut and the bolt.

4. Remove the brake pedal free

play adjusting nut, and then dis-

connect the brake rod at the

brake camshaft lever.

1. Brake torque rod

2. Brake torque rod nut

3. Brake rod

4. Brake pedal free play adjusting nut

1

2

34

5. Loosen the locknut and the drive

chain adjusting nut on both ends

of the swingarm.

6. Remove the axle nut, and then

pull the wheel axle out.

7. Push the wheel forward, and

then remove the drive chain from

the rear sprocket.

NOTE:

The drive chain does not need to be

disassembled in order to remove and

install the wheel.

8. Remove the wheel.

1. Wheel axle

2. Drive chain adjusting nut

3. Locknut

312

EAU03190

To install the rear wheel

1. Insert the wheel axle from the

left-hand side, and then install

the drive chain onto the rear

sprocket.

2. Install the axle nut, and then

lower the rear wheel so that it is

on the ground.

3. Install the brake rod onto the

brake camshaft lever, and then

install the brake pedal free play

adjusting nut onto the brake rod.

4. Connect the brake torque rod to

the brake shoe plate by installing

the bolt and the nut, and then

tighten the bolt to the specified

torque.

5. Adjust the drive chain slack.

(See page 6-26 for drive chain

slack adjustment procedures.) Tightening torque:

Brake torque rod bolt:

23 Nm (2.3 m·kg)

5JX-9-E0 4/9/0 4:11 AM Page 68

Page 73 of 86

1

2

3

4

5

6

7

8

9

7-1

EAU03224*

MOTORCYCLE CARE AND STORAGE

Care

While the open design of a motorcy-

cle reveals the attractiveness of the

technology, it also makes it more vul-

nerable. Rust and corrosion can

develop even if high-quality compo-

nents are used. A rusty exhaust pipe

may go unnoticed on a car, however,

it detracts from the overall appear-

ance of a motorcycle. Frequent and

proper care does not only comply

with the terms of the warranty, but it

will also keep your motorcycle looking

good, extend its life and optimize its

performance.Before cleaning

1. Cover the muffler outlets with

plastic bags after the engine has

cooled down.

2. Make sure that all caps and cov-

ers as well as all electrical cou-

plers and connectors, including

the spark plug caps, are tightly

installed.

3. Remove extremely stubborn dirt,

like oil burnt onto the crankcase,

with a degreasing agent and a

brush, but never apply such

products onto seals, gaskets,

sprockets, the drive chain and

wheel axles. Always rinse the dirt

and degreaser off with water.CleaningECA00010

cC

8Avoid using strong acidic

wheel cleaners, especially on

spoked wheels. If such prod-

ucts are used on hard-to-

remove dirt, do not leave the

cleaner on the affected area

any longer than instructed.

Also, thoroughly rinse the area

off with water, immediately dry

it, and then apply a corrosion

protection spray.

8Improper cleaning can damage

windshields, cowlings, panels

and other plastic parts. Use

only a soft, clean cloth or

sponge with mild detergent

and water to clean plastic.

5JX-9-E0 4/9/0 4:11 AM Page 71

Page 74 of 86

7-2

MOTORCYCLE CARE AND STORAGE

1

2

3

4

5

6

7

8

98Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abra-

sive cleaning products, sol-

vent or thinner, fuel (gasoline),

rust removers or inhibitors,

brake fluid, antifreeze or elec-

trolyte.

8Do not use high-pressure

washers or steam-jet cleaners

since they cause water seep-

age and deterioration in the

following areas: seals (of

wheel and swingarm bearings,

fork and brakes), electric com-

ponents (couplers, connec-

tors, instruments, switches

and lights), breather hoses

and vents.8For motorcycles equipped

with a windshield: Do not use

strong cleaners or hard

sponges as they will cause

dulling or scratching. Some

cleaning compounds for plas-

tic may leave scratches on the

windshield. Test the product

on a small hidden part of the

windshield to make sure that it

does not leave any marks. If

the windshield is scratched,

use a quality plastic polishing

compound after washing.After normal use

Remove dirt with warm water, a mild

detergent, and a soft, clean sponge,

and then rinse thoroughly with clean

water. Use a toothbrush or bottle-

brush for hard-to-reach areas.

Stubborn dirt and insects will come

off more easily if the area is covered

with a wet cloth for a few minutes

before cleaning.After riding in the rain, near the sea

or on salt-sprayed roads

Since sea salt or salt sprayed on

roads during winter are extremely

corrosive in combination with water,

carry out the following steps after

each ride in the rain, near the sea or

on salt-sprayed roads.

NOTE:

Salt sprayed on roads in the winter

may remain well into spring.

1. Clean the motorcycle with cold

water and a mild detergent, after

the engine has cooled down.

ECA00012

cC

Do not use warm water since it

increases the corrosive action of

the salt.

2. After drying the motorcycle,

apply a corrosion protection

spray on all metal, including

chrome- and nickel-plated, sur-

faces to prevent corrosion.

5JX-9-E0 4/9/0 4:11 AM Page 72

Page 77 of 86

7

MOTORCYCLE CARE AND STORAGE

7-5

7. Check and, if necessary, correct

the tire air pressure, and then lift

the motorcycle so that both of its

wheels are off the ground.

Alternatively, turn the wheels a

little every month in order to pre-

vent the tires from becoming

degraded in one spot.

8. Cover the muffler outlets with

plastic bags to prevent moisture

from entering them.

9. Remove the battery and fully

charge it. Store it in a cool, dry

place and charge it once a

month. Do not store the battery

in an excessively cold or warm

place (less than 0 °C or more

than 30 °C). For more informa-

tion on storing the battery, see

page 6-31.

NOTE:

Make any necessary repairs before

storing the motorcycle.

5JX-9-E0 4/9/0 4:11 AM Page 75

Page 78 of 86

7

EAU01038

SPECIFICATIONS

8-1

Specifications

Model XVS125

Dimensions

Overall length 2,320 mm

Overall width 910 mm

Overall height 1,075 mm

Seat height 670 mm

Wheel base 1,530 mm

Ground clearance 150 mm

Minimum turning radius 2,900 mm

Basic weight (with oil and full

fuel tank)156 kg

Engine

Engine type Air-cooled 4-stroke, SOHC,

gasoline

Cylinder arrangement V-type 2-cylinder

Displacement 124 cm

3

Bore ´Stroke 41.0 ´47.0 mm

Compression ratio 11:1

Starting system Electric starter

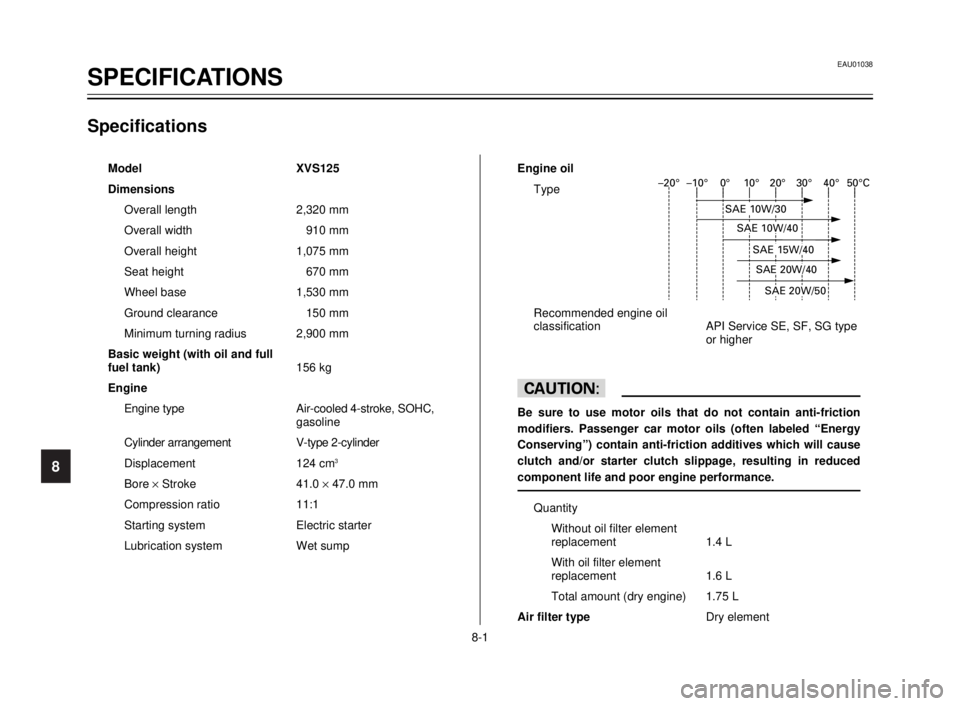

Lubrication system Wet sumpEngine oil

Type

Recommended engine oil

classification API Service SE, SF, SG type

or higher

cC

Be sure to use motor oils that do not contain anti-friction

modifiers. Passenger car motor oils (often labeled “Energy

Conserving”) contain anti-friction additives which will cause

clutch and/or starter clutch slippage, resulting in reduced

component life and poor engine performance.

Quantity

Without oil filter element

replacement 1.4 L

With oil filter element

replacement 1.6 L

Total amount (dry engine) 1.75 L

Air filter typeDry element

–10° 0° 10° 20° 30°

40°

SAE 10W/30

SAE 10W/40

SAE 20W/40

SAE 20W/50

–20°

SAE 15W/40 50°C

8

5JX-9-E0 4/9/0 4:11 AM Page 76

Page 80 of 86

8

SPECIFICATIONS

8-3

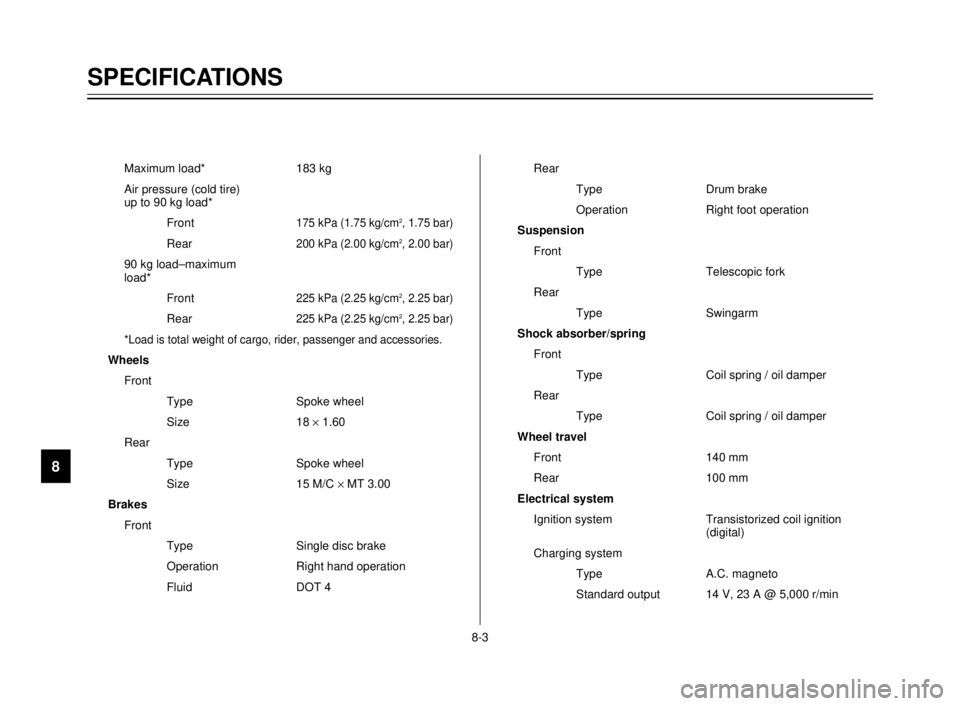

Maximum load* 183 kg

Air pressure (cold tire)

up to 90 kg load*

Front

175 kPa (1.75 kg/cm2, 1.75 bar)

Rear200 kPa (2.00 kg/cm2, 2.00 bar)

90 kg load–maximum

load*

Front

225 kPa (2.25 kg/cm2, 2.25 bar)

Rear225 kPa (2.25 kg/cm2, 2.25 bar)

*Load is total weight of cargo, rider, passenger and accessories.

Wheels

Front

Type Spoke wheel

Size 18 ´1.60

Rear

Type Spoke wheel

Size 15 M/C ´MT 3.00

Brakes

Front

Type Single disc brake

Operation Right hand operation

Fluid DOT 4Rear

Type Drum brake

Operation Right foot operation

Suspension

Front

Type Telescopic fork

Rear

Type Swingarm

Shock absorber/spring

Front

Type Coil spring / oil damper

Rear

Type Coil spring / oil damper

Wheel travel

Front 140 mm

Rear 100 mm

Electrical system

Ignition system Transistorized coil ignition

(digital)

Charging system

Type A.C. magneto

Standard output 14 V, 23 A @ 5,000 r/min

5JX-9-E0 4/9/0 4:11 AM Page 78