maintenance YAMAHA XVS650 2000 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2000, Model line: XVS650, Model: YAMAHA XVS650 2000Pages: 101, PDF Size: 6.77 MB

Page 54 of 101

6-8

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

1. Spark plug wrench

Inspection

The spark plug is an important engine

component and is easy to inspect. The

condition of the spark plug can indicate

the condition of the engine. Normally,

all spark plugs from the same engine

should have the same color on the

white insulator around the center elec-

trode. The ideal color at this point is a

medium-to-light tan color for a motor-

cycle that is being ridden normally. If

one spark plug shows a distinctly dif-

ferent color, there could be something

wrong with the engine. Do not attempt

to diagnose such problems yourself.

Instead, take the motorcycle to a

Yamaha dealer. You should periodi-cally remove and inspect the spark

plugs because heat and deposits will

cause any spark plug to slowly break

down and erode. If electrode erosion

becomes excessive, or if carbon and

other deposits are excessive, you

should replace the spark plug with the

specified plug.

Specified spark plug:

DPR7EA-9 (NGK)

X22EPR-U9 (DENSO)

a. Spark plug gap

Installation

1. Measure the electrode gap with a

wire thickness gauge and, if nec-

essary, adjust the gap to specifi-

cation.

2. Clean the gasket surface. Wipe

off any grime from the threads.

3. Install the spark plug and tighten it

to the specified torque. Spark plug gap:

0.8 ~ 0.9 mm

Page 55 of 101

6-9

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

NOTE:

If a torque wrench is not available

when you are installing a spark plug, a

good estimate of the correct torque is

1/4 to 1/2 turn past finger tight. Have

the spark plug tightened to the speci-

fied torque as soon as possible.Tightening torque:

Spark plug:

20 Nm (2.0 m·kg)

1. Maximum level mark

2. Minimum level mark

EAU01326*

Engine oil

Oil level inspection

1. Place the motorcycle on a level

place and hold it in an upright po-

sition. Warm up the engine for

several minutes.

NOTE:

Be sure the motorcycle is positioned

straight up when checking the oil level.

A slight tilt toward the side can result in

false readings.

1. Engine oil drain bolt

2. With the engine stopped, check

the oil level through the level win-

dow located at the lower part of

the left side crankcase cover.

NOTE:

Wait a few minutes until the oil level

settles before checking.

3. The oil level should be between

the maximum and minimum

marks. If the level is low, fill the

engine with sufficient oil to the

specified level.

Page 56 of 101

6-10

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

1. Engine oil filler cap

Engine oil and oil filter element re-

placement

1. Warm up the engine for a few

minutes.

2. Stop the engine. Place an oil pan

under the engine and remove the

oil filler cap.

3. Remove the drain bolt and drain

the oil.

1. Cover

2. Bolt (

´

3)

4. Remove the cover and the oil filter

cover by removing the bolts.

5. Remove the oil filter and O-ring.

6. Reinstall the drain bolt and tighten

it to the specified torque.

7. Install a new oil filter and O-ring.Tightening torque:

Drain bolt:

43 Nm (4.3 m·kg)

1. Bolt (

´

5)

2. Oil filter cover

8. Install oil filter cover and cover,

then tighten the bolts.

9. Fill the engine with oil. Install the

oil filler cap and tighten it.

Recommended oil:

See page 8-1.

Oil quantity:

Total amount:

3.2 L

Periodic oil change:

2.6 L

With oil filter replacement:

2.8 L

Page 57 of 101

6-11

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

1. O-ring

2. Oil filter element

EC000066

CAUTION:

l

Do not put in any chemical ad-

ditives. Engine oil also lubri-

cates the clutch and additives

could cause clutch slippage.

l

Be sure no foreign material en-

ters the crankcase.

10. Start the engine and warm it up

for a few minutes. While warming

up, check for oil leakage. If oil

leakage is found, stop the engine

immediately and check for the

cause.

1. Final gear oil drain bolt

2. Final gear oil filler bolt

3. Proper level

EAU02943*

Final gear oil

EW000066

WARNING

Do not let foreign material enter the

final gear case. Be sure oil does not

get on the tire or wheel.

Oil level inspection

1. Place the motorcycle on a level

place and hold it in an upright po-

sition. The engine should be cool

at ambient temperature.2. Remove the oil filler bolt and

check the oil level. The oil level

should be at the brim of the filler

hole. Add the recommended oil if

necessary.

Oil replacement

1. Place an oil pan under the final

gear case.

2. Remove the oil filler bolt and drain

bolt to drain the oil.

3. Install and tighten the drain bolt to

the specified torque.

4. Fill the gear case to the brim of the

filler hole with the recommended

oil. Tightening torque:

Drain bolt:

23 Nm (2.3 m·kg)

Page 58 of 101

6-12

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

NOTE:“GL-4” is a quality and additive rating.

Hypoid gear oils rated “GL-5” or “GL-6”may also be used.

5. Install and tighten the filler bolt to

the specified torque.

6. After replacing the final gear oil,

be sure to check for oil leakage. Final gear oil quantity:

0.19 L

Recommended oil:

SAE 80 API GL-4 Hypoid gear oil

If desired, an SAE 80W90 hypoid

gear oil may be used for all

conditions.

Tightening torque:

Oil filler bolt:

23 Nm (2.3 m·kg)

1. Air filter case cover

2. Screw (´ 3)

EAU00586*

Air filterThe air filter should be cleaned at the

specified intervals. It should be

cleaned more frequently if you are

riding in unusually wet or dusty areas.

1. Remove the air filter case cover

by removing the screws.

2. Remove the air filter.

3. Tap the air filter lightly to remove

most of the dust and dirt. Blow out

the remaining dirt with com-

pressed air as shown. If the air fil-

ter is damaged, replace it.

Page 59 of 101

6-13

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

1. Holder

2. Projection

3. Slot4. Install the air filter into the air filter

case as shown.

1. Match marks5. Align the match marks and install

the air filter case cover.

EC000082

CAUTION:l

Make sure the air filter is prop-

erly seated in the air filter case.

l

The engine should never be run

without the air filter installed.

Excessive piston and/or cylin-der wear may result.

EAU00630

Carburetor adjustmentThe carburetors are important parts of

the engine and require very sophisti-

cated adjustment. Most adjustments

should be left to a Yamaha dealer who

has the professional knowledge and

experience to do so. However, the idle

speed may be adjusted by the owner

as part of routine maintenance.

EC000095

CAUTION:

The carburetors were set at the

Yamaha factory after many tests. If

they are changed, poor engine per-formance and damage may result.

Page 60 of 101

6-14

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EAU01168

Idle speed adjustmentNOTE:A diagnostic tachometer must be usedfor this procedure.

1. Attach the tachometer. Start the

engine and warm it up for a few

minutes at approximately 1,000 to

2,000 r/min. Occasionally rev the

engine to 4,000 to 5,000 r/min.

The engine is warm when it quick-

ly responds to the throttle.

1. Throttle stop screw2. Set the idle to the specified en-

gine speed by adjusting the throt-

tle stop screw. Turn the screw in

direction a to increase engine

speed and in direction b to de-

crease engine speed.NOTE:If the specified idle speed cannot be

obtained by performing the above ad-justment, consult a Yamaha dealer.Standard idle speed:

1,150 ~ 1,250 r/min

Page 61 of 101

6-15

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

a. Free play

EAU00635

Throttle cable free play

inspectionThere should be a free play of 4 ~

6 mm at the throttle grip. If the free play

is incorrect, ask a Yamaha dealer to

make this adjustment.

EAU00637

Valve clearance adjustmentThe correct valve clearance changes

with use, resulting in improper fuel/air

supply or engine noise. To prevent

this, the valve clearance must be ad-

justed regularly. This adjustment how-

ever, should be left to a professional

Yamaha service technician.

a. Tread depth

1. Side wall

EAU00647*

TiresTo ensure maximum performance,

long service, and safe operation, note

the following:

Tire air pressure

Always check and adjust the tire pres-

sure before operating the motorcycle.

Page 62 of 101

6-16

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

9

EW000082

WARNING

Tire inflation pressure should be

checked and adjusted when the

temperature of the tire equals the

ambient air temperature. Tire infla-

tion pressure must be adjusted ac-

cording to total weight of cargo,

rider, passenger, and accessories

(fairing, saddlebags, etc. if ap-

proved for this model), and vehiclespeed.COPY CE-32ECE-32EXVS650

Maximum load* 180 kg

Cold tire pressure Front Rear

Up to 90 kg*200 kPa

(2.00 kg/cm

2,

2.00 bar)225 kPa

(2.25 kg/cm

2,

2.25 bar)

90 kg load ~

Maximum load*200 kPa

(2.00 kg/cm

2,

2.00 bar)250 kPa

(2.50 kg/cm

2,

2.50 bar)

* Load is the total weight of cargo, rider, passenger

and accessories.

COPY CE-32ECE-32EXVS650A

Maximum load*201 kg (except for D, A)

200 kg (for D, A)

Cold tire pressure Front Rear

Up to 90 kg*225 kPa

(2.25 kg/cm

2,

2.25 bar)225 kPa

(2.25 kg/cm

2,

2.25 bar)

90 kg load ~

Maximum load*225 kPa

(2.25 kg/cm

2,

2.25 bar)250 kPa

(2.50 kg/cm

2,

2.50 bar)

* Load is the total weight of cargo, rider, passenger

and accessories.

EW000083

WARNING

Proper loading of your motorcycle

is important for several characteris-

tics of your motorcycle, such as

handling, braking, performance and

safety. Do not carry loosely packed

items that can shift. Securely pack

your heaviest items close to the

center of the motorcycle, and dis-

tribute the weight evenly from side

to side. Properly adjust the suspen-

sion for your load, and check the

condition and pressure of your

tires. NEVER OVERLOAD YOUR

MOTORCYCLE. Make sure the total

weight of the cargo, rider, passen-

ger, and accessories (fairing, sad-

dlebags, etc. if approved for this

model) does not exceed the maxi-

mum load of the motorcycle. Opera-

tion of an overloaded motorcycle

could cause tire damage, an acci-dent, or even injury.

Page 63 of 101

6-17

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

56

7

8

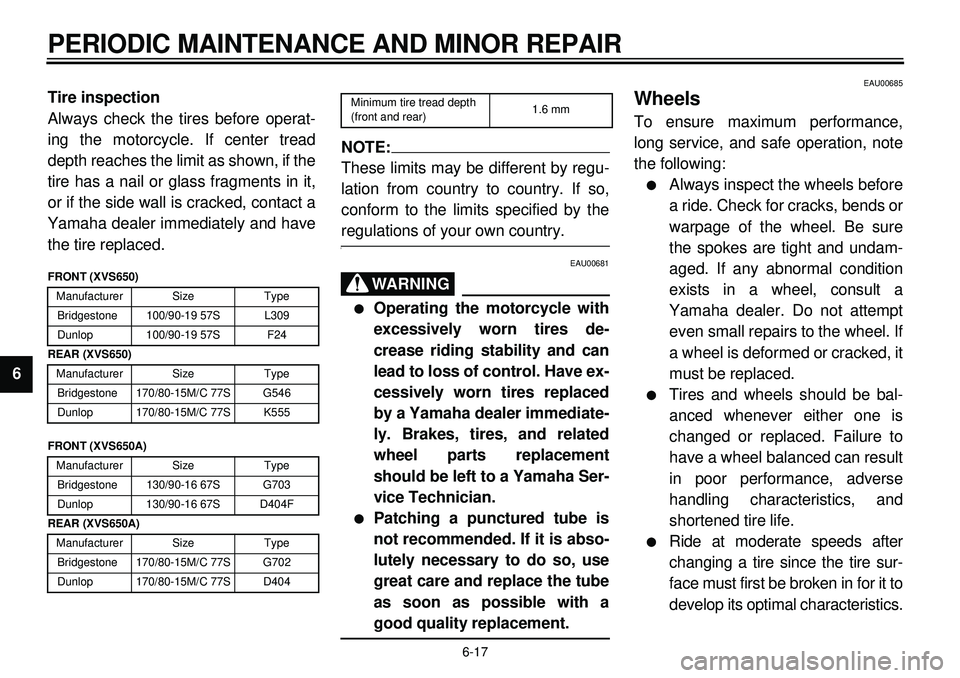

9Tire inspection

Always check the tires before operat-

ing the motorcycle. If center tread

depth reaches the limit as shown, if the

tire has a nail or glass fragments in it,

or if the side wall is cracked, contact a

Yamaha dealer immediately and have

the tire replaced.

COPY CE-10ECE-10E

CE-10EFRONT (XVS650)

Manufacturer Size Type

Bridgestone 100/90-19 57S L309

Dunlop 100/90-19 57S F24

REAR (XVS650)

Manufacturer Size Type

Bridgestone 170/80-15M/C 77S G546

Dunlop 170/80-15M/C 77S K555

FRONT (XVS650A)

Manufacturer Size Type

Bridgestone 130/90-16 67S G703

Dunlop 130/90-16 67S D404F

REAR (XVS650A)

Manufacturer Size Type

Bridgestone 170/80-15M/C 77S G702

Dunlop 170/80-15M/C 77S D404

CE-26ECE-26ENOTE:These limits may be different by regu-

lation from country to country. If so,

conform to the limits specified by theregulations of your own country.

EAU00681

WARNING

l

Operating the motorcycle with

excessively worn tires de-

crease riding stability and can

lead to loss of control. Have ex-

cessively worn tires replaced

by a Yamaha dealer immediate-

ly. Brakes, tires, and related

wheel parts replacement

should be left to a Yamaha Ser-

vice Technician.

l

Patching a punctured tube is

not recommended. If it is abso-

lutely necessary to do so, use

great care and replace the tube

as soon as possible with agood quality replacement.

Minimum tire tread depth

(front and rear)1.6 mm

EAU00685

WheelsTo ensure maximum performance,

long service, and safe operation, note

the following:l

Always inspect the wheels before

a ride. Check for cracks, bends or

warpage of the wheel. Be sure

the spokes are tight and undam-

aged. If any abnormal condition

exists in a wheel, consult a

Yamaha dealer. Do not attempt

even small repairs to the wheel. If

a wheel is deformed or cracked, it

must be replaced.

l

Tires and wheels should be bal-

anced whenever either one is

changed or replaced. Failure to

have a wheel balanced can result

in poor performance, adverse

handling characteristics, and

shortened tire life.

l

Ride at moderate speeds after

changing a tire since the tire sur-

face must first be broken in for it to

develop its optimal characteristics.