engine YAMAHA YBR125 2004 Owner's Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2004, Model line: YBR125, Model: YAMAHA YBR125 2004Pages: 83, PDF Size: 3.16 MB

Page 53 of 83

NOTE:

A diagnostic tachometer must be used for this procedure.

1. Attach the tachometer. Start the engine and warm it up

for a few minutes (normally, 1 or 2 minutes) at

approximately 1,000 to 2,000 r/min. Occasionally rev

the engine to 4,000 to 5,000 r/min. The engine is warm

when it quickly responds to the throttle.

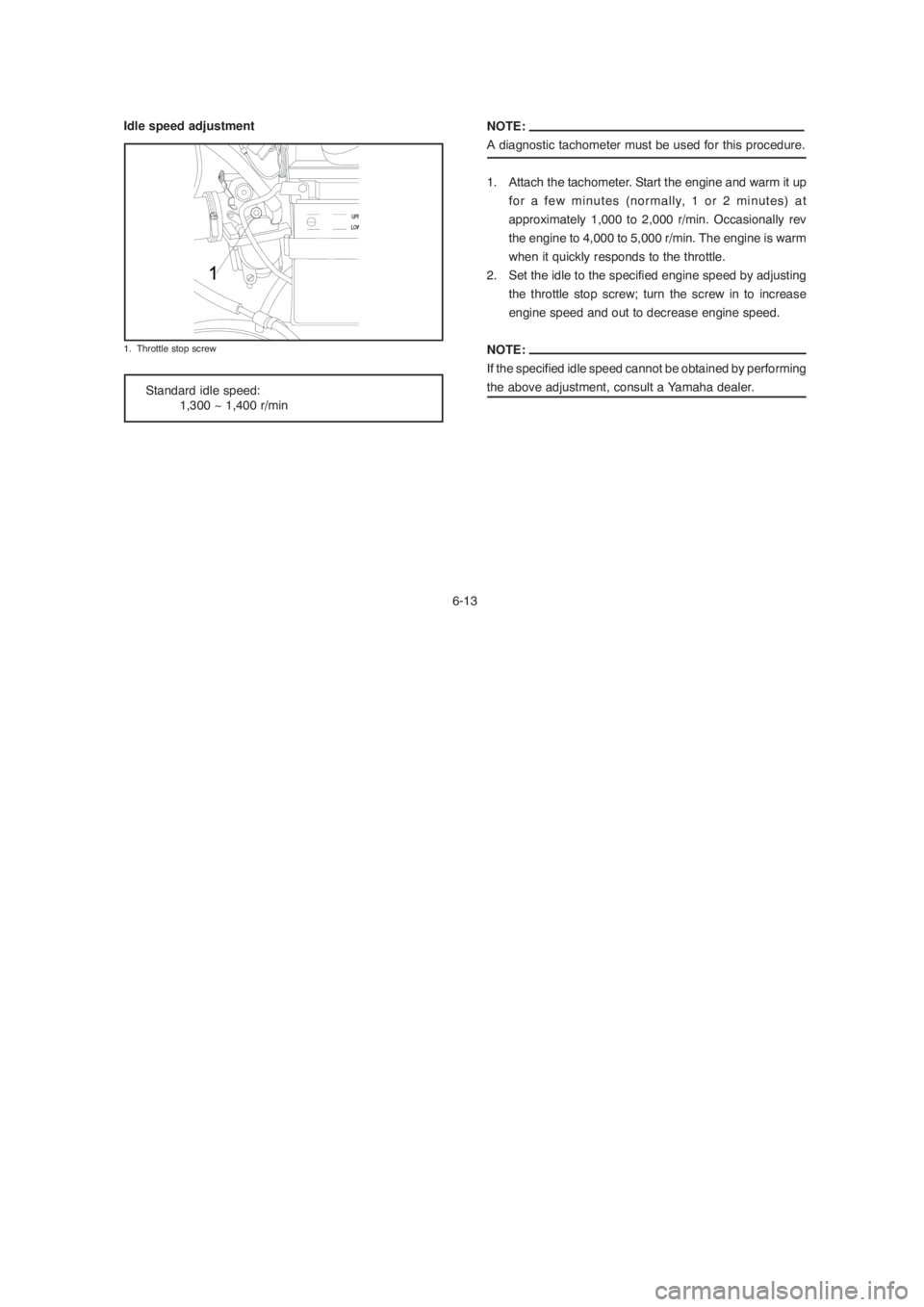

2. Set the idle to the specified engine speed by adjusting

the throttle stop screw; turn the screw in to increase

engine speed and out to decrease engine speed.

NOTE:

If the specified idle speed cannot be obtained by performing

the above adjustment, consult a Yamaha dealer.

6-13

Standard idle speed:

1,300 ~ 1,400 r/min

1. Throttle stop screw

Idle speed adjustment

NOTE:

A diagnostic tachometer must be used for this procedure.

1. Attach the tachometer. Start the engine and warm it up

for a few minutes (normally, 1 or 2 minutes) at

approximately 1,000 to 2,000 r/min. Occasionally rev

the engine to 4,000 to 5,000 r/min. The engine is warm

when it quickly responds to the throttle.

2. Set the idle to the specified engine speed by adjusting

the throttle stop screw; turn the screw in to increase

engine speed and out to decrease engine speed.

NOTE:

If the specified idle speed cannot be obtained by performing

the above adjustment, consult a Yamaha dealer.

6-13

Standard idle speed:

1,300 ~ 1,400 r/min

1. Throttle stop screw

Idle speed adjustment

Page 54 of 83

NOTE:

Before checking the throttle cable free play, the engine

idling speed should be adjusted.

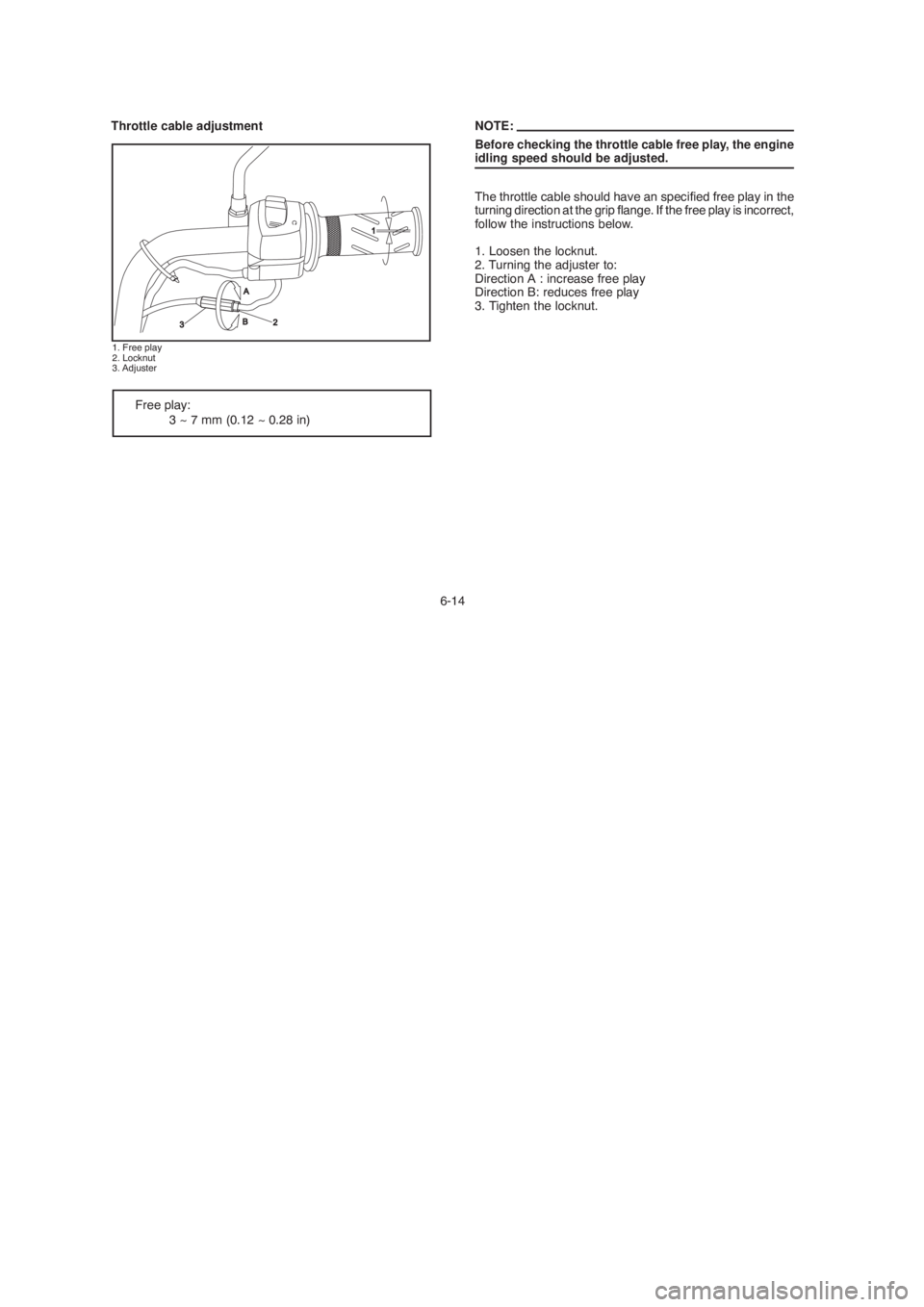

The throttle cable should have an specified free play in the

turning direction at the grip flange. If the free play is incorrect,

follow the instructions below.

1. Loosen the locknut.

2. Turning the adjuster to:

Direction A : increase free play

Direction B: reduces free play

3. Tighten the locknut.

6-14

Free play:

3 ~ 7 mm (0.12 ~ 0.28 in) Throttle cable adjustment

1. Free play

2. Locknut

3. Adjuster

NOTE:

Before checking the throttle cable free play, the engine

idling speed should be adjusted.

The throttle cable should have an specified free play in the

turning direction at the grip flange. If the free play is incorrect,

follow the instructions below.

1. Loosen the locknut.

2. Turning the adjuster to:

Direction A : increase free play

Direction B: reduces free play

3. Tighten the locknut.

6-14

Free play:

3 ~ 7 mm (0.12 ~ 0.28 in) Throttle cable adjustment

1. Free play

2. Locknut

3. Adjuster

Page 55 of 83

6-15

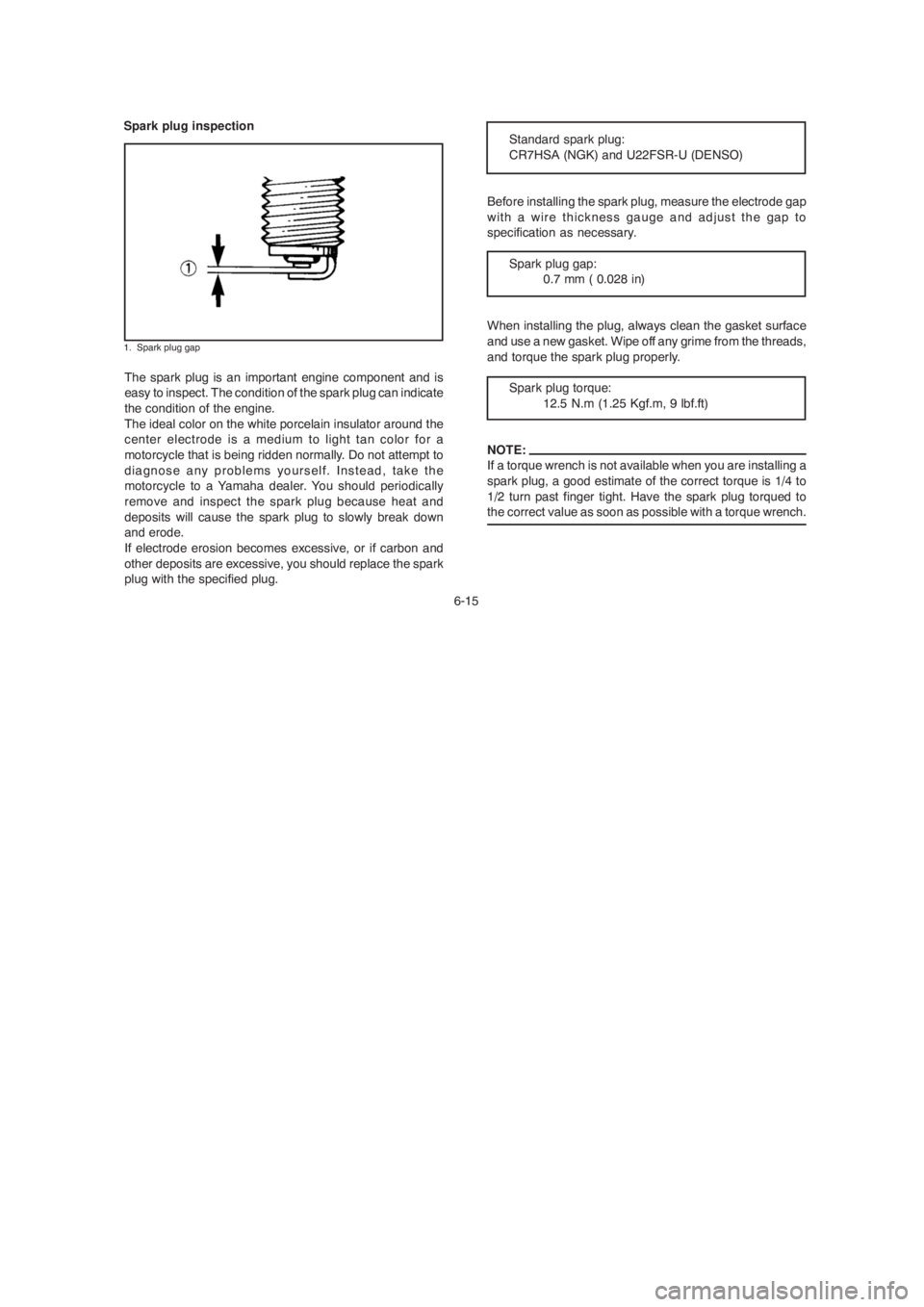

1. Spark plug gap

Spark plug inspection

The spark plug is an important engine component and is

easy to inspect. The condition of the spark plug can indicate

the condition of the engine.

The ideal color on the white porcelain insulator around the

center electrode is a medium to light tan color for a

motorcycle that is being ridden normally. Do not attempt to

diagnose any problems yourself. Instead, take the

motorcycle to a Yamaha dealer. You should periodically

remove and inspect the spark plug because heat and

deposits will cause the spark plug to slowly break down

and erode.

If electrode erosion becomes excessive, or if carbon and

other deposits are excessive, you should replace the spark

plug with the specified plug.Standard spark plug:

CR7HSA (NGK) and U22FSR-U (DENSO)

Before installing the spark plug, measure the electrode gap

with a wire thickness gauge and adjust the gap to

specification as necessary.

Spark plug gap:

0.7 mm ( 0.028 in)

When installing the plug, always clean the gasket surface

and use a new gasket. Wipe off any grime from the threads,

and torque the spark plug properly.

Spark plug torque:

12.5 N.m (1.25 Kgf.m, 9 lbf.ft)

NOTE:

If a torque wrench is not available when you are installing a

spark plug, a good estimate of the correct torque is 1/4 to

1/2 turn past finger tight. Have the spark plug torqued to

the correct value as soon as possible with a torque wrench.

6-15

1. Spark plug gap

Spark plug inspection

The spark plug is an important engine component and is

easy to inspect. The condition of the spark plug can indicate

the condition of the engine.

The ideal color on the white porcelain insulator around the

center electrode is a medium to light tan color for a

motorcycle that is being ridden normally. Do not attempt to

diagnose any problems yourself. Instead, take the

motorcycle to a Yamaha dealer. You should periodically

remove and inspect the spark plug because heat and

deposits will cause the spark plug to slowly break down

and erode.

If electrode erosion becomes excessive, or if carbon and

other deposits are excessive, you should replace the spark

plug with the specified plug.Standard spark plug:

CR7HSA (NGK) and U22FSR-U (DENSO)

Before installing the spark plug, measure the electrode gap

with a wire thickness gauge and adjust the gap to

specification as necessary.

Spark plug gap:

0.7 mm ( 0.028 in)

When installing the plug, always clean the gasket surface

and use a new gasket. Wipe off any grime from the threads,

and torque the spark plug properly.

Spark plug torque:

12.5 N.m (1.25 Kgf.m, 9 lbf.ft)

NOTE:

If a torque wrench is not available when you are installing a

spark plug, a good estimate of the correct torque is 1/4 to

1/2 turn past finger tight. Have the spark plug torqued to

the correct value as soon as possible with a torque wrench.

Page 60 of 83

6-20

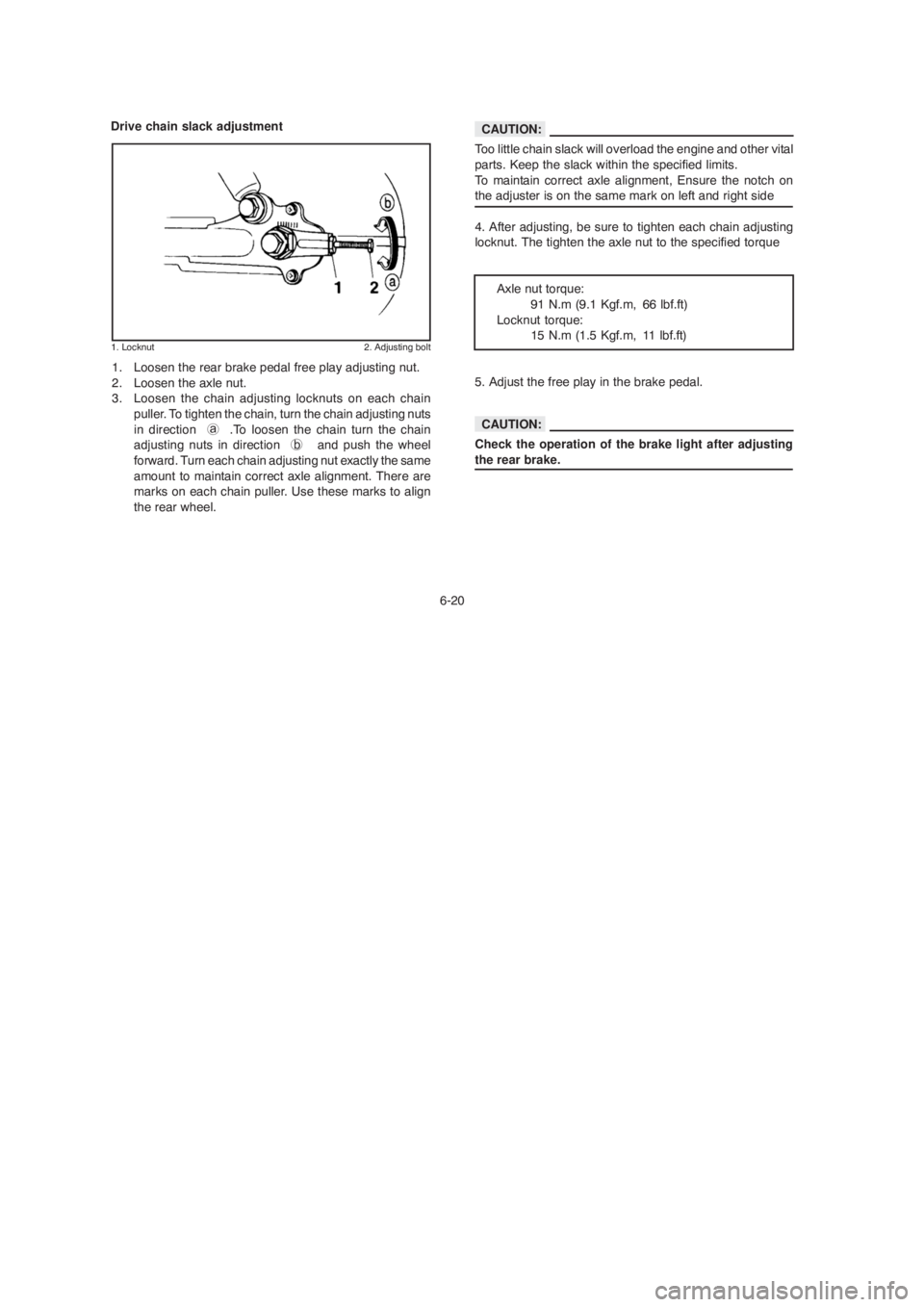

Drive chain slack adjustment

1. Locknut 2. Adjusting bolt

1. Loosen the rear brake pedal free play adjusting nut.

2. Loosen the axle nut.

3. Loosen the chain adjusting locknuts on each chain

puller. To tighten the chain, turn the chain adjusting nuts

in direction a .To loosen the chain turn the chain

adjusting nuts in direction b and push the wheel

forward. Turn each chain adjusting nut exactly the same

amount to maintain correct axle alignment. There are

marks on each chain puller. Use these marks to align

the rear wheel.Too little chain slack will overload the engine and other vital

parts. Keep the slack within the specified limits.

To maintain correct axle alignment, Ensure the notch on

the adjuster is on the same mark on left and right side

4. After adjusting, be sure to tighten each chain adjusting

locknut. The tighten the axle nut to the specified torque

Axle nut torque:

91 N.m (9.1 Kgf.m, 66 lbf.ft)

Locknut torque:

15 N.m (1.5 Kgf.m, 11 lbf.ft)

5. Adjust the free play in the brake pedal.

Check the operation of the brake light after adjusting

the rear brake.

CAUTION:

CAUTION:

6-20

Drive chain slack adjustment

1. Locknut 2. Adjusting bolt

1. Loosen the rear brake pedal free play adjusting nut.

2. Loosen the axle nut.

3. Loosen the chain adjusting locknuts on each chain

puller. To tighten the chain, turn the chain adjusting nuts

in direction a .To loosen the chain turn the chain

adjusting nuts in direction b and push the wheel

forward. Turn each chain adjusting nut exactly the same

amount to maintain correct axle alignment. There are

marks on each chain puller. Use these marks to align

the rear wheel.Too little chain slack will overload the engine and other vital

parts. Keep the slack within the specified limits.

To maintain correct axle alignment, Ensure the notch on

the adjuster is on the same mark on left and right side

4. After adjusting, be sure to tighten each chain adjusting

locknut. The tighten the axle nut to the specified torque

Axle nut torque:

91 N.m (9.1 Kgf.m, 66 lbf.ft)

Locknut torque:

15 N.m (1.5 Kgf.m, 11 lbf.ft)

5. Adjust the free play in the brake pedal.

Check the operation of the brake light after adjusting

the rear brake.

CAUTION:

CAUTION:

Page 61 of 83

6-21 Drive chain lubrication

The chain consists of many parts which work with each

other. If the chain is not maintained properly, it will wear out

quickly. Therefore, the chain must be serviced regularly.

This service is especially necessary when riding in dusty

areas.

1. Use Yamaha Chain and Cable Lube or any

brands of spray-type chain lubricant. First,

remove all dirt and mud from the chain with a

brush or cloth, then spray lubricant between both

rows of side plates and on all center rollers. The

chain should be lubricated every 500 km (300 mi).

2. To clean the chain, remove it from the machine,

dip it in solvent, and clean out as much dirt as

possible. Take the chain out of the solvent and

dry it. Immediately lubricate the chain to prevent

it from rusting.Cable inspection and lubrication

Damage to the outer housing of cables may allow

internal rusting and cause interfere with cable

movement. Replace damaged cables as soon as

possible to prevent unsafe conditions.

Lubricate the inner cable and the cable end. If it does not

operate smoothly, ask a Yamaha dealer to replace them.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

WARNING:

6-21 Drive chain lubrication

The chain consists of many parts which work with each

other. If the chain is not maintained properly, it will wear out

quickly. Therefore, the chain must be serviced regularly.

This service is especially necessary when riding in dusty

areas.

1. Use Yamaha Chain and Cable Lube or any

brands of spray-type chain lubricant. First,

remove all dirt and mud from the chain with a

brush or cloth, then spray lubricant between both

rows of side plates and on all center rollers. The

chain should be lubricated every 500 km (300 mi).

2. To clean the chain, remove it from the machine,

dip it in solvent, and clean out as much dirt as

possible. Take the chain out of the solvent and

dry it. Immediately lubricate the chain to prevent

it from rusting.Cable inspection and lubrication

Damage to the outer housing of cables may allow

internal rusting and cause interfere with cable

movement. Replace damaged cables as soon as

possible to prevent unsafe conditions.

Lubricate the inner cable and the cable end. If it does not

operate smoothly, ask a Yamaha dealer to replace them.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

WARNING:

Page 62 of 83

6-22

Throttle cable and grip lubrication

The throttle twist grip assembly should be greased at the

time the cable is lubricated, since the grip must be removed

to get at the end of the throttle cable.

After removing the screws, hold the end of the cable up in

the air and put in several drops of lubricant. With the throttle

grip disassembled, coat the metal surface of the grip

assembly with a suitable all-purpose grease.Brake and shift pedals

Lubricate the pivoting parts.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

Brake and clutch levers

Lubricate the pivoting parts.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

Sidestand

Lubricate the pivoting parts. Check to see that the sidestand

moves up and down smoothly.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

WARNING:

If the sidestand does not move smoothly, consult a

Yamaha dealer.

CAUTION:

6-22

Throttle cable and grip lubrication

The throttle twist grip assembly should be greased at the

time the cable is lubricated, since the grip must be removed

to get at the end of the throttle cable.

After removing the screws, hold the end of the cable up in

the air and put in several drops of lubricant. With the throttle

grip disassembled, coat the metal surface of the grip

assembly with a suitable all-purpose grease.Brake and shift pedals

Lubricate the pivoting parts.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

Brake and clutch levers

Lubricate the pivoting parts.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

Sidestand

Lubricate the pivoting parts. Check to see that the sidestand

moves up and down smoothly.

RECOMMENDED LUBRICANT:

Engine oil SAE 20W50

WARNING:

If the sidestand does not move smoothly, consult a

Yamaha dealer.

CAUTION:

Page 64 of 83

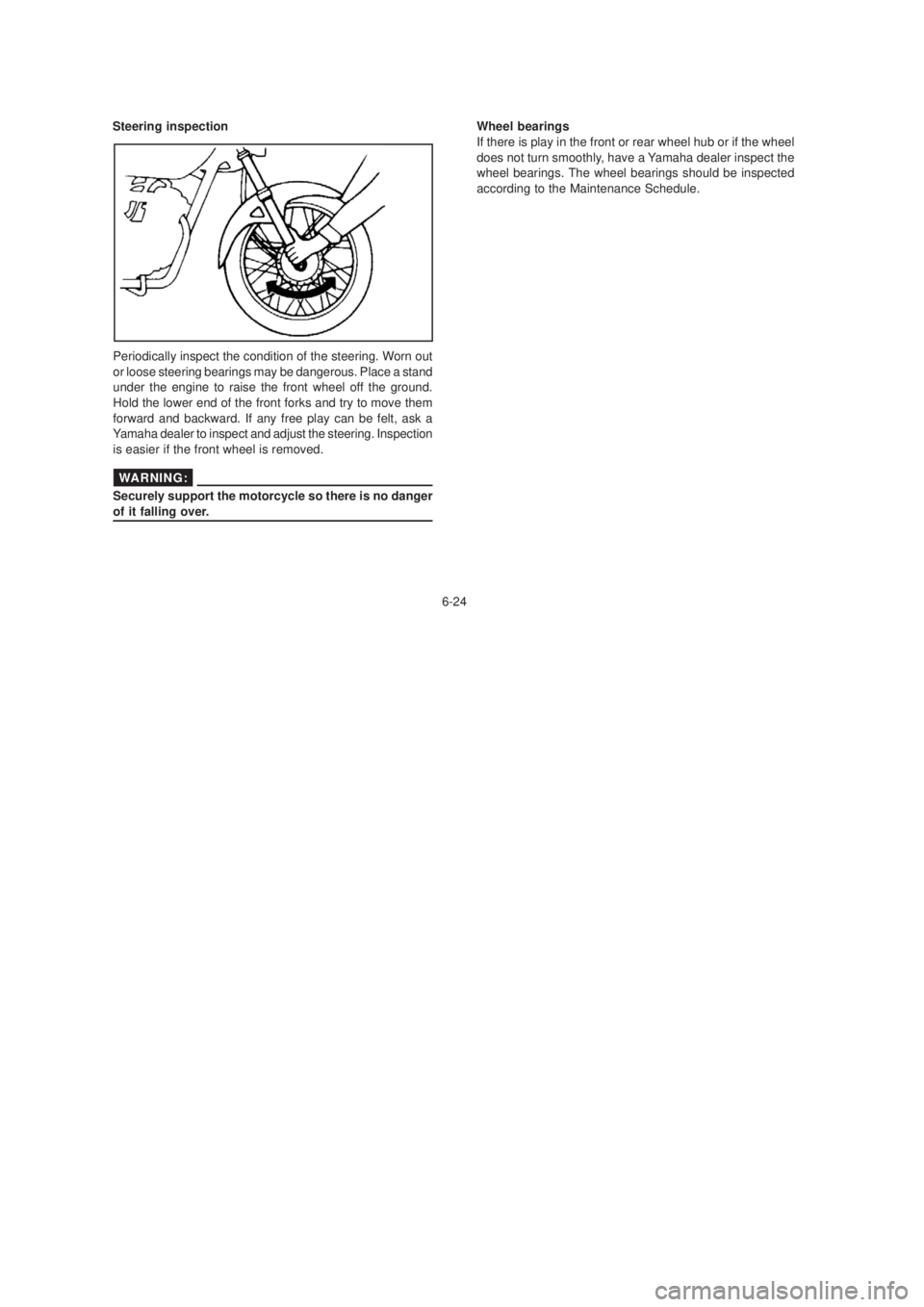

6-24

Periodically inspect the condition of the steering. Worn out

or loose steering bearings may be dangerous. Place a stand

under the engine to raise the front wheel off the ground.

Hold the lower end of the front forks and try to move them

forward and backward. If any free play can be felt, ask a

Yamaha dealer to inspect and adjust the steering. Inspection

is easier if the front wheel is removed.

Securely support the motorcycle so there is no danger

of it falling over.Wheel bearings

If there is play in the front or rear wheel hub or if the wheel

does not turn smoothly, have a Yamaha dealer inspect the

wheel bearings. The wheel bearings should be inspected

according to the Maintenance Schedule.

Steering inspection

WARNING:

6-24

Periodically inspect the condition of the steering. Worn out

or loose steering bearings may be dangerous. Place a stand

under the engine to raise the front wheel off the ground.

Hold the lower end of the front forks and try to move them

forward and backward. If any free play can be felt, ask a

Yamaha dealer to inspect and adjust the steering. Inspection

is easier if the front wheel is removed.

Securely support the motorcycle so there is no danger

of it falling over. Wheel bearings

If there is play in the front or rear wheel hub or if the wheel

does not turn smoothly, have a Yamaha dealer inspect the

wheel bearings. The wheel bearings should be inspected

according to the Maintenance Schedule.

Steering inspection

WARNING:

Page 75 of 83

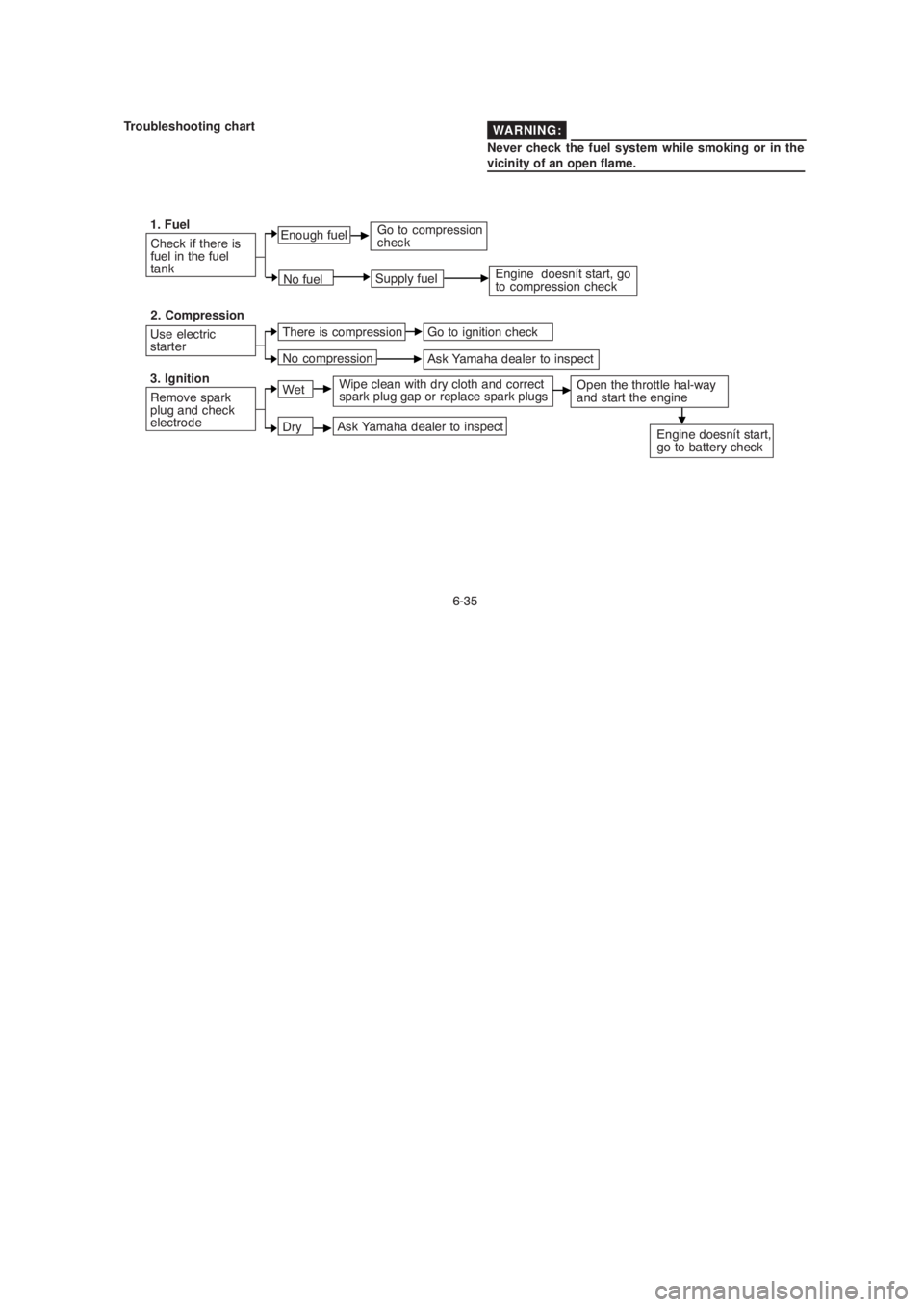

6-35Never check the fuel system while smoking or in the

vicinity of an open flame.

Check if there is

fuel in the fuel

tank

Use electric

starter

Remove spark

plug and check

electrode 1. Fuel

2. Compression

3. IgnitionEnough fuel

No fuel

There is compression

No compression

Wet

DrySupply fuel

Go to ignition check

Ask Yamaha dealer to inspect

Wipe clean with dry cloth and correct

spark plug gap or replace spark plugs

Ask Yamaha dealer to inspect

Troubleshooting chart

Go to compression

check

Engine doesnít start, go

to compression check

Open the throttle hal-way

and start the engine

Engine doesnít start,

go to battery check

WARNING:

6-35Never check the fuel system while smoking or in the

vicinity of an open flame.

Check if there is

fuel in the fuel

tank

Use electric

starter

Remove spark

plug and check

electrode 1. Fuel

2. Compression

3. IgnitionEnough fuel

No fuel

There is compression

No compression

Wet

DrySupply fuel

Go to ignition check

Ask Yamaha dealer to inspect

Wipe clean with dry cloth and correct

spark plug gap or replace spark plugs

Ask Yamaha dealer to inspect

Troubleshooting chart

Go to compression

check

Engine doesnít start, go

to compression check

Open the throttle hal-way

and start the engine

Engine doesnít start,

go to battery check

WARNING:

Page 76 of 83

7-1 CLEANING AND STORAGE

A. CLEANING

Frequent, thorough cleaning of your motorcycle will not only

enhance its appearance but will improve its general

performance and extend the useful life of many components.

1. Before cleaning the motorcycle:

a. Block off the end of the exhaust pipe to prevent water

entry; a plastic bag and strong rubber band may be

used.

b. Make sure the spark plug and all filler caps are properly

installed.

2. If the engine case is excessively greasy, apply

degreaser with a paint brush. Do not apply degreaser

to the chain, sprockets, or wheel axles.

3. Rinse the dirt and degreaser off with a garden hose,

Use only enough pressure to do the job.

Excessive hose pressure may cause water seepage and

deterioration of wheel bearings, front fork, brakes,

transmission seals and electrical parts.Many expensive repair bills have resulted from improper

high pressure detergent applications such as those

available in coin-operated car washers.

4. Once the majority of the dirt has been hosed off, wash

all surfaces with warm water and mild, detergent-type

soap. An old toothbrush or bottle brush is handy for

hard-to-get-at places.

5. Rinse the motorcycle off immediately with clean water

and dry all surfaces with a chamois, clean towel, or

soft absorbent cloth.

6. Dry the chain and lubricate it to prevent rust.

7. Clean the seat with a vinyl upholstery cleaner to keep

the cover pliable and glossy.

8. Automotive-type wax may be applied to all painted and

chrome-plated surfaces. Avoid combination cleaner-

waxes. Many contain abrasives which may mar the paint

or protective finish. When finished, start the engine and

let it idle for several minutes.

CAUTION:

CAUTION:

7-1 CLEANING AND STORAGE

A. CLEANING

Frequent, thorough cleaning of your motorcycle will not only

enhance its appearance but will improve its general

performance and extend the useful life of many components.

1. Before cleaning the motorcycle:

a. Block off the end of the exhaust pipe to prevent water

entry; a plastic bag and strong rubber band may be

used.

b. Make sure the spark plug and all filler caps are properly

installed.

2. If the engine case is excessively greasy, apply

degreaser with a paint brush. Do not apply degreaser

to the chain, sprockets, or wheel axles.

3. Rinse the dirt and degreaser off with a garden hose,

Use only enough pressure to do the job.

Excessive hose pressure may cause water seepage and

deterioration of wheel bearings, front fork, brakes,

transmission seals and electrical parts.Many expensive repair bills have resulted from improper

high pressure detergent applications such as those

available in coin-operated car washers.

4. Once the majority of the dirt has been hosed off, wash

all surfaces with warm water and mild, detergent-type

soap. An old toothbrush or bottle brush is handy for

hard-to-get-at places.

5. Rinse the motorcycle off immediately with clean water

and dry all surfaces with a chamois, clean towel, or

soft absorbent cloth.

6. Dry the chain and lubricate it to prevent rust.

7. Clean the seat with a vinyl upholstery cleaner to keep

the cover pliable and glossy.

8. Automotive-type wax may be applied to all painted and

chrome-plated surfaces. Avoid combination cleaner-

waxes. Many contain abrasives which may mar the paint

or protective finish. When finished, start the engine and

let it idle for several minutes.

CAUTION:

CAUTION:

Page 77 of 83

7-2 B. STORAGE

Long term storage (30 days or more) of your machine will

require some preventive procedures to guard against

deterioration. After thoroughly cleaning the machine,

prepare for storage as follows:

1. Drain the fuel tank, fuel lines, and carburetor float

bowl(s).

2. Remove the spark plug(s), pour about one tablespoon

of SAE 20W50 motor oil in the spark plug hole(s) and

reinstall the spark plug(s).

Kick the engine over several times (with the

ignition off) to coat the cylinder walls with oil.

3. Remove the drive chain. Clean it thoroughly with

solvent and lubricate it.

Reinstall the chain or store it in a plastic bag

(tied to frame for safe-keeping).

4. Lubricate all control cables.

5. Block up the frame to raise both wheels off the

ground.

6. Tie a plastic bag over the exhaust pipe outlet to

prevent moisture from entering.7. If storing in a humid or salt-air atmosphere, coat

all exposed metal surfaces with a light film of

oil. Do not apply oil to any rubber parts or the

seat cover.

8. Remove the battery and charge it. Store it in a dry place

and recharge it once a month. Do not store the battery

in an excessively warm or cold place (less than 0∫C

(30∫F) or more than 30∫C (90∫F).

NOTE:

Make any necessary repairs before storing the machine.

7-2 B. STORAGE

Long term storage (30 days or more) of your machine will

require some preventive procedures to guard against

deterioration. After thoroughly cleaning the machine,

prepare for storage as follows:

1. Drain the fuel tank, fuel lines, and carburetor float

bowl(s).

2. Remove the spark plug(s), pour about one tablespoon

of SAE 20W50 motor oil in the spark plug hole(s) and

reinstall the spark plug(s).

Kick the engine over several times (with the

ignition off) to coat the cylinder walls with oil.

3. Remove the drive chain. Clean it thoroughly with

solvent and lubricate it.

Reinstall the chain or store it in a plastic bag

(tied to frame for safe-keeping).

4. Lubricate all control cables.

5. Block up the frame to raise both wheels off the

ground.

6. Tie a plastic bag over the exhaust pipe outlet to

prevent moisture from entering.7. If storing in a humid or salt-air atmosphere, coat

all exposed metal surfaces with a light film of

oil. Do not apply oil to any rubber parts or the

seat cover.

8. Remove the battery and charge it. Store it in a dry place

and recharge it once a month. Do not store the battery

in an excessively warm or cold place (less than 0∫C

(30∫F) or more than 30∫C (90∫F).

NOTE:

Make any necessary repairs before storing the machine.