maintenance YAMAHA YBR125 2007 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YBR125, Model: YAMAHA YBR125 2007Pages: 79, PDF Size: 2.08 MB

Page 1 of 79

PRINTED IN INDIA2Y14(OM-01)284-11-06-Eger Engine Lifewer Maintenance Costwer Exhaust Smoke

uces Wear and TearSGSG4STROKE MOTOR OIL20W40

4

OWNER'S MANUAL

1B5-F8199-E0

1B56

YAMAHAYAMAHA

1B5-F8199-E0

Page 3 of 79

INTRODUCTION

Congratulations on your purchase of the . This motorcycle has been produced using the latest

technology in our modern plant, to provide you a happy, enjoyable and safe riding for many thousand

kilometers and years. It represents the high degree of craftsmanship and reliability that have made

a leader in these fields.

This Owner's Manual will give you an understanding of the operation, inspection and basic maintenance of

this Motorcycle. To ensure a long trouble free performance, please take due care and ensure proper

maintenance of your Motorcycle as recommended in this Owner's Manual. Always demand only

Genuine Spare Parts and Yamalube oil. If you have any queries regarding the operation or maintenance of

your Motorcycle, please consult your DEALER who will be too happy to help you.

This Owner's Manual also includes the GREEN BOOK containing Guidelines, DO's and DON'Ts to be

followed by the Owner/ User of the Motorcycle for keeping Environment Clean and Green. You are

requested to please read the GREEN BOOK carefully.

We Provide

At Your Caring Service,

A-3, Industrial Area, Noida Dadri Road

Surajpur-201 306 (India)LIBERO

YAMAHA

YAMAHA

YAMAHAYAMAHA MOTOR INDIA PVT. LTD.

Page 5 of 79

ROAD SAFETY TIPS....................................... 1-1

DESCRIPTION................................................ 2-1

Left view ........................................................ 2-1

Right view ...................................................... 2-2

Controls/Instruments................................... 2-3

INSTRUMENT AND CONTROL

FUNCTIONS.................................................... 3-1

Main switch cum steering lock ..................... 3-1

Speedometer................................................ 3-2

Fuel gauge .................................................... 3-2

Indicator lights .............................................. 3-2

Handlebar switches ..................................... 3-3

Clutch lever ................................................... 3-3

Shift pedal ..................................................... 3-4

Front brake lever ........................................... 3-4

Rear brake pedal .......................................... 3-4

Fuel tank cap ................................................ 3-5

Fuel............................................................... 3-5

Fuel cock ....................................................... 3-6

Starter Lever .................................................. 3-7

Kick starter .................................................... 3-7

Seat............................................................... 3-8Storage compartment .................................. 3-9

Rear shock absorber adjustment ............... 3-9

Handle Seat, Lifting Handle, stay Lock .......3-10

PRE-OPERATION CHECKS ........................... 4-1

Pre-operation check list ............................... 4-1

OPERATION AND IMPORTANT RIDING

POINTS............................................................ 5-1

Starting and warming up a

cold engine ................................................... 5-1

Starting a warm engine ................................ 5-2

Shifting.......................................................... 5-2

Tips for reducing fuel consumption ............. 5-3

Running-in.................................................... 5-3

Parking.......................................................... 5-4

PERIODIC MAINTENANCE AND MINOR

REPAIR ............................................................ 6-1

Tool kit ........................................................... 6-1

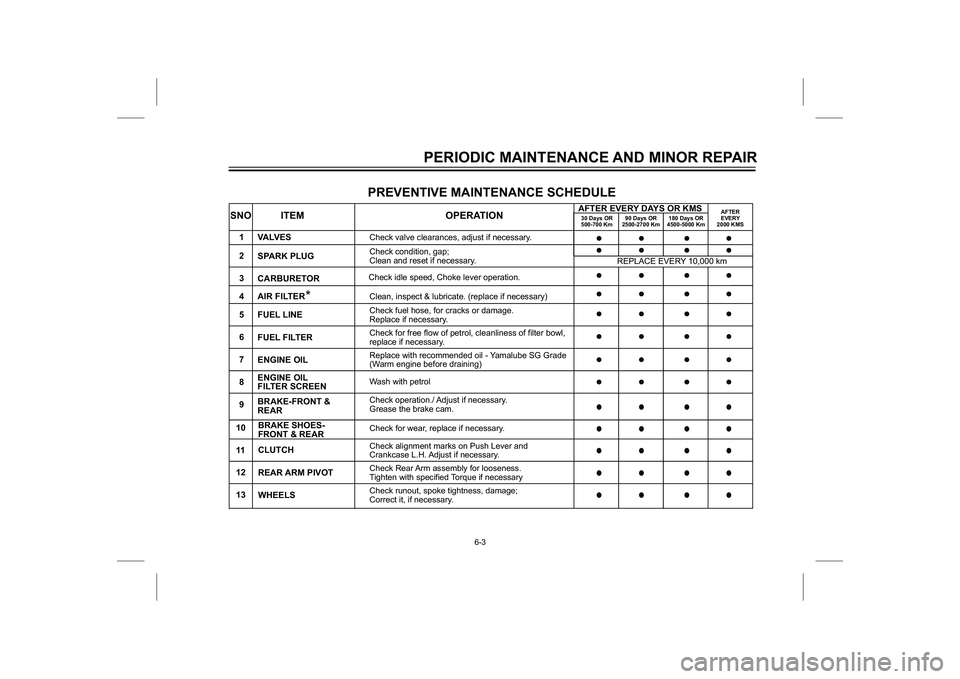

Preventive maintenance schedule .............. 6-3

Panel removal and installation .................... 6-5

Spark plug inspection .................................. 6-7

Engine OIl ..................................................... 6-8

1

4

23

65

TABLE OF CONTENTS

Libero5TS8.pmd11/3/2006, 8:50 PM 1

Page 27 of 79

WARNINGPERIODIC MAINTENANCE AND MINOR REPAIR

Periodic inspection, adjustment and

lubrication will keep your Motorcycle

in the safest and most efficient

condition possible. Safety is an

obligation of the Motorcycle owner.

The maintenance and lubrication

schedule chart should be considered

strictly as a guide to general

maintenance and lubrication

intervals. YOU MUST TAKE INTO

CONSIDERATION THAT

WEATHER, TERRAIN,

GEOGRAPHICAL LOCATIONS,

AND A VARIETY OF INDIVIDUAL

USES ALL TEND TO DEMAND

THAT EACH OWNER ALTER THIS

TIME SCHEDULE TO SHORTER

INTERVALS TO MATCH THE

ENVIRONMENT. The most impor-

tant points of Motorcycle inspection,

adjustment, and lubrication are

explained in the following pages.If you are not familiar with

Motorcycle service, this work

should be done by a YAMAHA

dealer.

1. Tool kitTool kitThe service information included in

this manual is intended to provide

you, the owner, with the necessary

information for completing some of

your own preventive maintenance

and minor repairs. The tools

provided in the owner's tool kit are to

assist you in the performance of

periodic maintenance. However,

some other tools such as a torque

wrench are also necessary to

perform the maintenance correctly.

6-1

1

1

Page 28 of 79

KEEP YOUR MOTORCYCLE TUNED IN PERFECT CONDITION

WARNING

NOTE :PERIODIC MAINTENANCE AND MINOR REPAIRIf you do not have necessary tools

required during a service operation,

take your Motorcycle to a YAMAHA

dealer for service.

Modifications to this Motorcycle

not approved by YAMAHA may

cause loss of performance, and

render it unsafe for use. Consult

a YAMAHA dealer before

attempting any changes.

6-2

Page 29 of 79

PERIODIC MAINTENANCE AND MINOR REPAIR

6-3

PREVENTIVE MAINTENANCE SCHEDULE

VA LV E S

SPARK PLUG

CARBURETOR

AIR FILTER

FUEL LINE

FUEL FILTER

ENGINE OIL

ENGINE OIL

FILTER SCREEN

BRAKE-FRONT &

REAR

Check valve clearances, adjust if necessary.

Check condition, gap;

Clean and reset if necessary.

Check idle speed, Choke lever operation.

Clean, inspect & lubricate. (replace if necessary)

Check fuel hose, for cracks or damage.

Replace if necessary.

Check for free flow of petrol, cleanliness of filter bowl,

replace if necessary.

Replace with recommended oil - Yamalube SG Grade

(Warm engine before draining)

Wash with petrol

Check operation./ Adjust if necessary.

Grease the brake cam.

ITEM OPERATION SNO

1

2

3

5 4

6

7

8

9

*

WHEELS 13FRONT & REAR

REAR ARM PIVOT CLUTCH

12 11BRAKE SHOES-

10

Check runout, spoke tightness, damage;

Correct it, if necessary. Check for wear, replace if necessary.

Check alignment marks on Push Lever and

Tighten with specified Torque if necessary Check Rear Arm assembly for looseness. Crankcase L.H. Adjust if necessary.

30 Days OR

500-700 KmAFTER EVERY DAYS OR KMS

REPLACE EVERY 10,000 km90 Days OR

2500-2700 Km180 Days OR

4500-5000 KmAFTER

EVERY

2000 KMS

Page 30 of 79

PERIODIC MAINTENANCE AND MINOR REPAIR

6-4

PREVENTIVE MAINTENANCE SCHEDULE

EVERY 10,000 KM EVERY 10,000 KM

17

Check operation/oil leakage.

REAR SHOCK

ABSORBER

Replace if necessary.

STEERING BEARING

FRONT FORKS 16 15

Check operation/oil leakage. Repair if necessary. Check Bearing assembly for looseness;

Correct if necessary.

Relace oil Repack grease

S.NO ITEMOPERATION

DRIVE CHAIN

NUTS, BOLTS AND

FASTENERS

CENTERSTAND AND

SIDE STAND

Check Chain slack, alignment. Adjust if necessary.

Clean periodically & lubricate.

Check all Chassis fittings and fasteners for looseness.

Tighten as per specification.

Check operation and lubricate if necessary.

Check electrolyte level and top it up if necessary.

Check specific gravity and charge if required.

Check breather pipe for blockage and routing.

CONTROL CABLES

-THROTTLE

-CLUTCH

-FRONT BRAKE 18

19

20

21

BATTERY

22

Readjust or replace as required. Check operation, free play, cable damage

EVERY MONTH

IT IS RECOMMENDED THAT THE ABOVE BE SERVICED BY AUTHORIZED DEALER.

SERVICE MORE FREQUENTLY WHEN THE VEHICLE IS DRIVEN IN DUSTY AREAS.YAMAHA*

EVERY 10,000 KMS

WHEEL BEARING 14

Check Bearing assembly for looseness, damage;

Replace if necessary.

Repack grease

30 Days OR

500-700 KmAFTER EVERY DAYS OR KMS

90 Days OR

2500-2700 Km180 Days OR

4500-5000 KmAFTER

EVERY

2000 KMS

Page 31 of 79

1. Panel APanel removal and installa-

tionThe panels illustrated need to be

removed to perform some of the

maintenance described in this

manual. Refer to this section each

time a panel has to be removed or

reinstalled.

2. Panel BPERIODIC MAINTENANCE AND MINOR REPAIR

6-51. Lug

2. Panel A

3. Lug

Removal of Panel AUnlock the panel.

Pull the lug 1 towards you to remove

it from the fuel tank.

Slide the panel A towards the Front

of the motorcycle for removing the

lug 3 to free the panel.

2

3 1

2

1

Page 32 of 79

PERIODIC MAINTENANCE AND MINOR REPAIR

6-6 1. Lug

2. Lug

Removal of Panel BLoosen screw completely and follow

the same procedure as for

removing panel A.

1. Lug

2. LugInstallation of Panel ASlide the panel towards the Rear of

the motorcycle for inserting the lug

2 in the slot given in the frame.

Insert and push the lug 1 in the

fuel tank ensuring proper seating.

After proper seating of the panel A,

lock it.

1. Lug.

2. LugInstallation of Panel BFollow the same procedure as given

for installation of panel A and tighten

the screw for locking.

2 1

1 2

1

2

1

Page 33 of 79

A. Spark plug gapSpark plug inspectionThe spark plug is an important engine

component and is easy to inspect.

The condition of the spark plug can

indicate the condition of the engine.

The ideal color on the white insulator

around the center electrode is a

medium-to-light tan color for a

Motorcycle that is being riddennormally. Do not attempt to diagnose

any problems yourself. Instead, take

the Motorcycle to a YAMAHA dealer.

You should periodically remove and

inspect the spark plug because heat

and deposits will cause the spark plug

to slowly break down and erode. If

electrode erosion becomes exces-

sive, or if carbon and other deposits

are excessive, you should replace the

spark plug with the specified plug.

Before installing the spark plug,

measure the electrode gap with a wire

thickness gauge; adjust the gap to

specification as necessary.

PERIODIC MAINTENANCE AND MINOR REPAIR

6-7

A.- Spark plug gap: 0.8 ±0.1 mm

When installing the plug, always

clean the gasket surface and use a

new gasket. Wipe off any grime from

the threads and tighten the spark plug

to the specified torque.

Tightening torque:

Spark plug:

12 ft-lb (1.75 m-kg)NOTE :If a torque wrench is not available

when you are installing a spark plug,

a good estimate of the correct

torque is 1/4 to 1/2 turn past finger

using a box spanner.

AALWAYS USE ONLY THE STANDARD RECOMMENDED MAKE AND TYPE OF

SPARK PLUG

Specified spark plug:

P-RA7HC-(CHAMPION)