lock YAMAHA YD110 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YD110, Model: YAMAHA YD110 2005Pages: 156, PDF Size: 1.49 MB

Page 56 of 156

![YAMAHA YD110 2005 User Guide 1. Tread depth

VsªªM MsIFk

2. Side wall

lkbM okWy

Tyres

Vk;j

To ensure maximum performance, long

service and safe operation, note the

following:vR;f/kd dk;Z{kerk] nh?kZ l£ol v©j lqjf{kr

dk;Z YAMAHA YD110 2005 User Guide 1. Tread depth

VsªªM MsIFk

2. Side wall

lkbM okWy

Tyres

Vk;j

To ensure maximum performance, long

service and safe operation, note the

following:vR;f/kd dk;Z{kerk] nh?kZ l£ol v©j lqjf{kr

dk;Z](/img/51/53675/w960_53675-55.png)

1. Tread depth

VsªªM MsIFk

2. Side wall

lkbM okWy

Tyres

Vk;j

To ensure maximum performance, long

service and safe operation, note the

following:vR;f/kd dk;Z{kerk] nh?kZ l£ol v©j lqjf{kr

dk;Z ds fy, fuEufyf[kr ij /;ku nsa %1. Tyre air pressure

Always check and correct the tyre

pressure before operating the

Motorcycle.

Vk;j esa gok dk ncko

e¨Vj&lkbZfdy pykus ls igys ges'kk Vk;j

esa gok ds ncko d¨ tk¡p ys v©j bls

O;ofLFkr djasA

1. Free play

Ýh Iys

2. Locknut

ykWd uV

3. Adjusting nut

,Mt¯LVx uV

1. Loosen the locknut.

ykWd uV dks

ç to increase free play and in

direction è to decrease free play.

Ýh Iys d¨ c<+kus ds fy, ,Mt¯LVx uV

d¨ , dh fn'kk esa ?kqek,¡ rFkk Ýh Iys d¨

de djus ds fy, bls ch fn'kk esa ?kqek,¡A

3. Tighten the locknut.

ykWd uV d¨ dl nsaA

Valve clearance adjustment:okYo dh Dyh;jsal dk rkyesy %The correct valve clearance changes

with use, resulting in improper fuel/

air supply or engine noise. To prevent

this, the valve clearance must be

adjusted regularly. This adjustment

however, should be left to a YMI

dealer.mfpr okYo Dyh;jsal t¨ fd batu ds ç;¨x

ds lkFk cnyrk jgrk gS] vuqfprb±/ku@gok

dh lIykbZ vFkok batu esa 'k¨j dk dkj.k curk

gSA blds cpus ds fy, okYo ds Dyh;jsal d¨

yxkrkj O;ofLFkr djrs jguk pkfg,A oSls bl

rjg ds ,MtLVesaV ¼ rkyesy½ d¨ okbZñ,eñvkbZñ

Mhyj }kjk gh djok;k tkuk pkfg,A

KEEP RECOMMENDED TYRE PRESSURE IN BOTH THE TYRES

n¨u¨ Vk;j¨a esa vuqe¨fnr ok;q&ncko gh j[ksaA

6.18

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

1

2

3ç è

PG1_55.pmd2/25/2005, 10:04 AM 54

Page 60 of 156

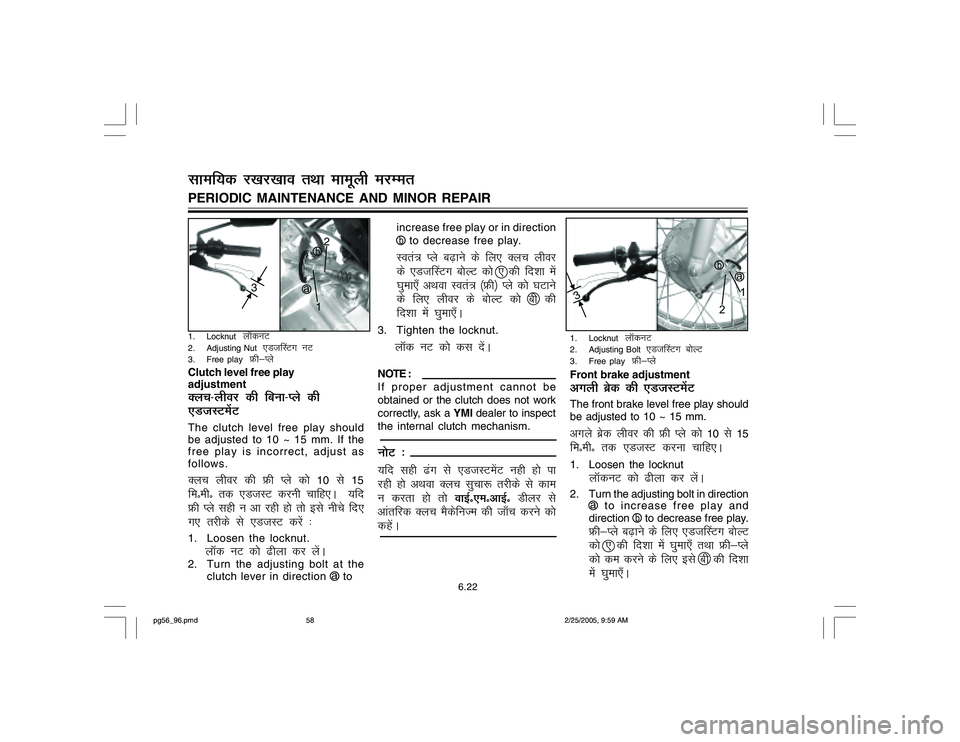

1. Locknut

ykWduV

2. Adjusting Nut

,Mt¯LVx uV

3. Free play

Ýh&Iys

Clutch level free play

adjustment

Dyp&yhoj dh fcuk&Iys dh

,MtLVesaVThe clutch level free play should

be adjusted to 10 ~ 15 mm. If the

free play is incorrect, adjust as

follows.Dyp yhoj dh Ýh Iys d¨

10

ls

15

feñehñ rd ,MtLV djuh pkfg,A ;fn

Ýh Iys lgh u vk jgh g¨ r¨ bls uhps fn,

x, rjhds ls ,MtLV djsa %1. Loosen the locknut.

ykWd uV d¨

clutch lever in direction ç toincrease free play or in direction

è to decrease free play.

Lora=k Iys c<+kus ds fy, Dyp yhoj

ds ,Mt¯LVx c¨YV d¨ , dh fn'kk esa

?kqek,¡ vFkok Lora=k ¼Ýh½ Iys d¨ ?kVkus

ds fy, yhoj ds c¨YV d¨ ch dh

fn'kk esa ?kqek,¡A

3. Tighten the locknut.

ykWd uV d¨ dl nsaA

NOTE :

If proper adjustment cannot be

obtained or the clutch does not work

correctly, ask a YMI dealer to inspect

the internal clutch mechanism.u¨V %;fn lgh

u djrk g¨ r¨ okbZñ,eñvkbZñ Mhyj ls

vkarfjd Dyp eSdsfuTe dh tk¡p djus d¨

dgsaA

1. Locknut

ykWduV

2. Adjusting Bolt

,Mt¯LVx c¨YV

3. Free play

Ýh&Iys

Front brake adjustment

vxyh czsd dh ,MtLVesaVThe front brake level free play should

be adjusted to 10 ~ 15 mm.vxys czsd yhoj dh Ýh Iys d¨

10 ls

15

feñehñ rd ,MtLV djuk pkfg,A1. Loosen the locknut

ykWduV d¨

ç to increase free play and

direction è to decrease free play.

Ýh&Iys c<+kus ds fy, ,Mt¯LVx c¨YV

d¨ , dh fn'kk esa ?kqek,¡ rFkk Ýh&Iys

d¨ de djus ds fy, bls ch dh fn'kk

esa ?kqek,¡A

6.22

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

12

çè

3

ç è

1

2

3

pg56_96.pmd2/25/2005, 9:59 AM 58

Page 61 of 156

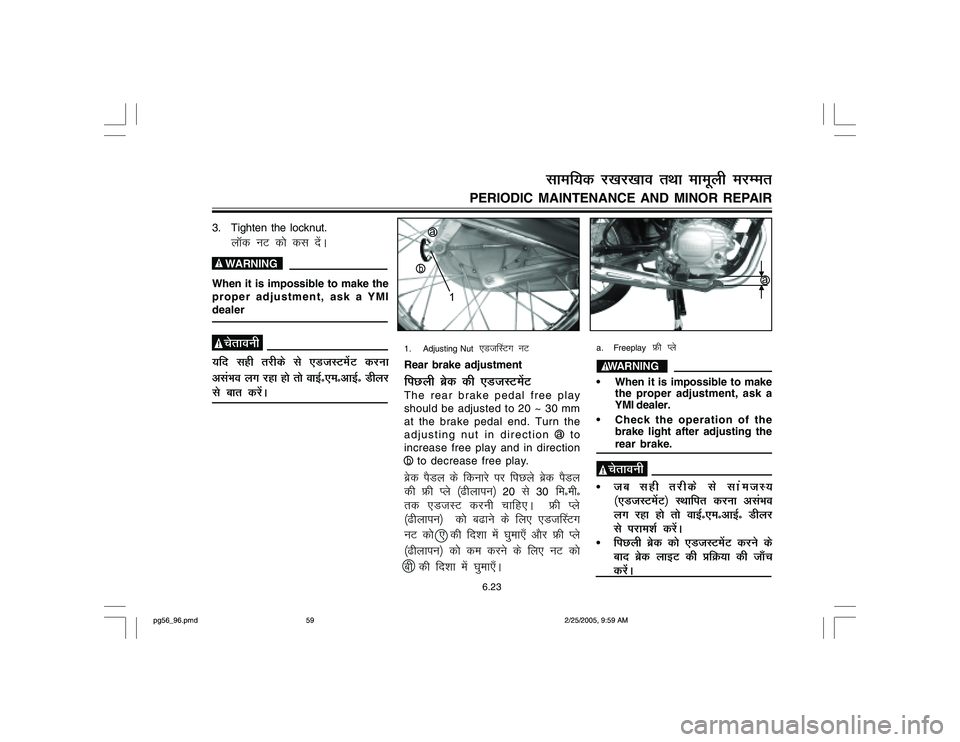

1. Adjusting Nut

,Mt¯LVx uV

Rear brake adjustment

fiNyh czsd dh ,MtLVesaVThe rear brake pedal free play

should be adjusted to 20 ~ 30 mm

at the brake pedal end. Turn the

adjusting nut in direction ç to

increase free play and in direction

è to decrease free play.czsd iSMy ds fdukjs ij fiNys czsd iSMy

dh Ýh Iys ¼

ls

30

feñehñ

rd ,MtLV djuh pkfg,A Ýh Iys

¼

¼

a. Freeplay

Ýh Iys

WARNING• When it is impossible to make

the proper adjustment, ask a

YMI dealer.

Check the operation of the

brake light after adjusting the

rear brake. psrkouh

tc lgh rjhds ls lkaetL;

¼,MtLVesaV½ LFkkfir djuk vlaHko

yx jgk g¨ r¨ okbZñ,eñvkbZñ Mhyj

ls ijke'kZ djsaA

fiNyh czsd d¨ ,MtLVesaV djus ds

ckn czsd ykbV dh çfØ;k dh tk¡p

djsaA

6.23

3. Tighten the locknut.

ykWd uV d¨ dl nsaA

WARNINGWhen it is impossible to make the

proper adjustment, ask a YMI

dealer psrkouh;fn lgh rjhds ls ,MtLVesaV djuk

vlaHko yx jgk g¨ r¨ okbZñ,eñvkbZñ Mhyj

ls ckr djsaA

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

ç

è

1ç

pg56_96.pmd2/25/2005, 9:59 AM 59

Page 64 of 156

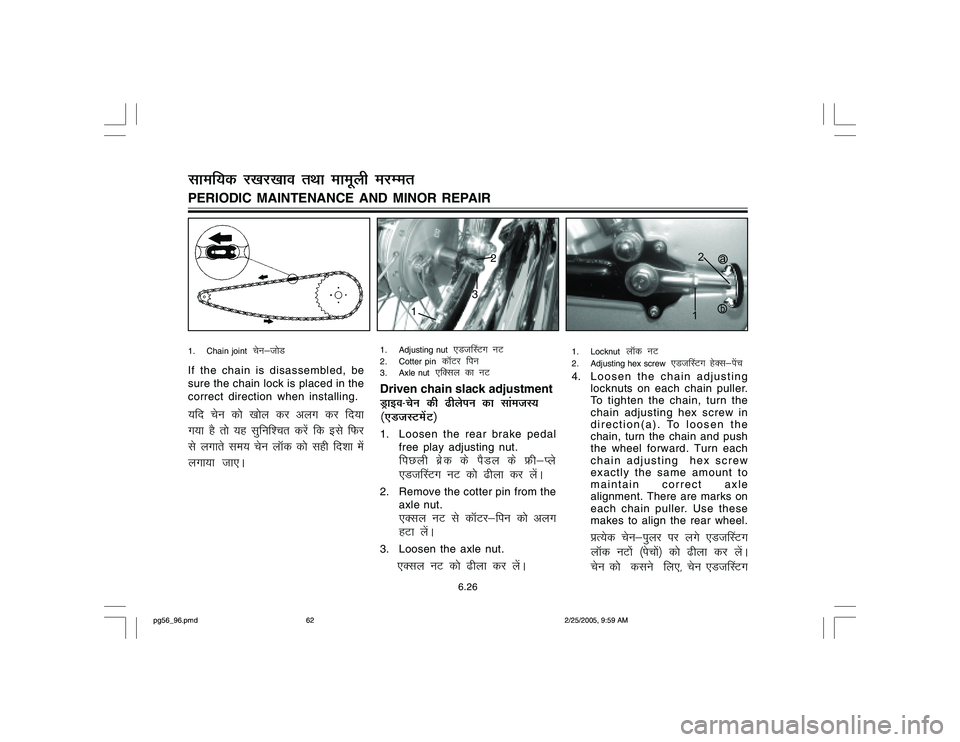

1. Chain joint

psu&t¨M

If the chain is disassembled, be

sure the chain lock is placed in the

correct direction when installing.

;fn psu d¨ [k¨y dj vyx dj fn;k

x;k gS r¨ ;g lqfuf'pr djsa fd bls fQj

ls yxkrs le; psu ykWd d¨ lgh fn'kk esa

yxk;k tk,A

1. Adjusting nut

,Mt¯LVx uV

2. Cotter pin

dkWVj fiu

3. Axle nut

,fDly dk uV

Driven chain slack adjustmentMªkbo&psu dh

free play adjusting nut.

fiNyh czsd ds iSMy ds Ýh&Iys

,Mt¯LVx uV d¨

axle nut.

,Dly uV ls dkWVj&fiu d¨ vyx

gVk ysaA

3. Loosen the axle nut.

,Dly uV d¨

1. Locknut

ykWd uV

2. Adjusting hex screw

,Mt¯LVx gsDl&isap

4. Loosen the chain adjusting

locknuts on each chain puller.

To tighten the chain, turn the

chain adjusting hex screw in

direction(a). To loosen the

chain, turn the chain and push

the wheel forward. Turn each

chain adjusting hex screw

exactly the same amount to

maintain correct axle

alignment. There are marks on

each chain puller. Use these

makes to align the rear wheel.

çR;sd psu&iqyj ij yxs ,Mt¯LVx

ykWd uV¨a ¼isp¨a½ d¨

PERIODIC MAINTENANCE AND MINOR REPAIRlkef;d j[kj[kko rFkk ekewyh ejEer

12

3ç

è

2

1

pg56_96.pmd2/25/2005, 9:59 AM 62

Page 65 of 156

1. Cotter pin

dkWVj fiu

6. Insert a new cotter pin into the axle

nut and bend the end of the cotter

pin as shown. If the notch in the

axle nut and the cotter pin hole do

not match, tighten the nut slightly

to align them.

,fDly ds uV esa ,d u;k dkWVj fiu

yxk,¡] v©j tSlk fd fp=k esa fn[kk;k

x;k gS] dkWVj fiu ds ,d fljs d¨ e¨M+

nsaA ;fn ,fDly uV dh u¨ad ¼ukWp½

rFkk dkWVj&fiu ds usd ds lkFk fey

ugh ikrh gS r¨ bUgs vkil esa feykus ds

fy, uV d¨ /khjs&/khjs dlsaA

WARNINGAlways use a new cotter pin on the

axle nut.

lko/kkuh %

psu dh f'kfFkyrk d¨ fo'ks"k #i ls

of.kZr fufnZ"V dh xbZ lhekv¨a esa gh

çfrikfnr ¼esauVsau½ djsaA

,fDly dh lgh ,ykbuesaV çfrikfnr

djus ds fy, ;g lqfuf'pr djsa fd

,MtLVj ij yxk gqvk fu'kku ckb±

rFkk nkb± v¨j ls ,d gh fpUg ¼fu'kku½

ij feyrh gSA

5. After adjusting, be sure to

tighten each chain adjusting

locknut. Then tighten the axle

nut to the specified torque.

,MtLVesaV djus ds ckn gj ,d psu

,Mt¯LVx ykWd uV d¨ vo'; dl

nsaA rRi'pkr~ ,fDly uV d¨ fu£n"V

VkdZ rd dl nsaA

Tightening torque

dlk x;k VkdZ

:

Axle nut

,fDly uV %

65 ft-lb (9.05 m-kg)

"kV~&isap ¼gsDl&LØ;w½ d¨ , dh fn'kk

esa ?kqek,¡ rFkk bls

ch dh fn'kk esa ?kqek,¡ v©j ifg, ij

vkxs dh v¨j ncko MkysA ,Dly dh

lgh ,ykbuesaV ¼iafDrcðrk½ d¨

çfrikfnr ¼esauVsau½ djus ds fy, çR;sd

psu ,Mt¯LVx "kV&isap ¼gsDl&LØ;ww½

d¨ Bhd rjg ls leku nwjh rd

?kqek,¡A çR;sd psu iqyj ij fu'kku

yxs gq, gSA fiNys ifg, d¨ lgh

rjg ls yxkus ds fy, bu fpUg¨ dk

ç;¨x djsaA

CAUTION : Maintain chain slackness

within specified limits as per

specifications.

To maintain correct axle

alignment, Ensure the notch

on the adjuster is on the same

Mark on Left and Right

Side.

6.27

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

pg56_96.pmd2/25/2005, 9:59 AM 63

Page 77 of 156

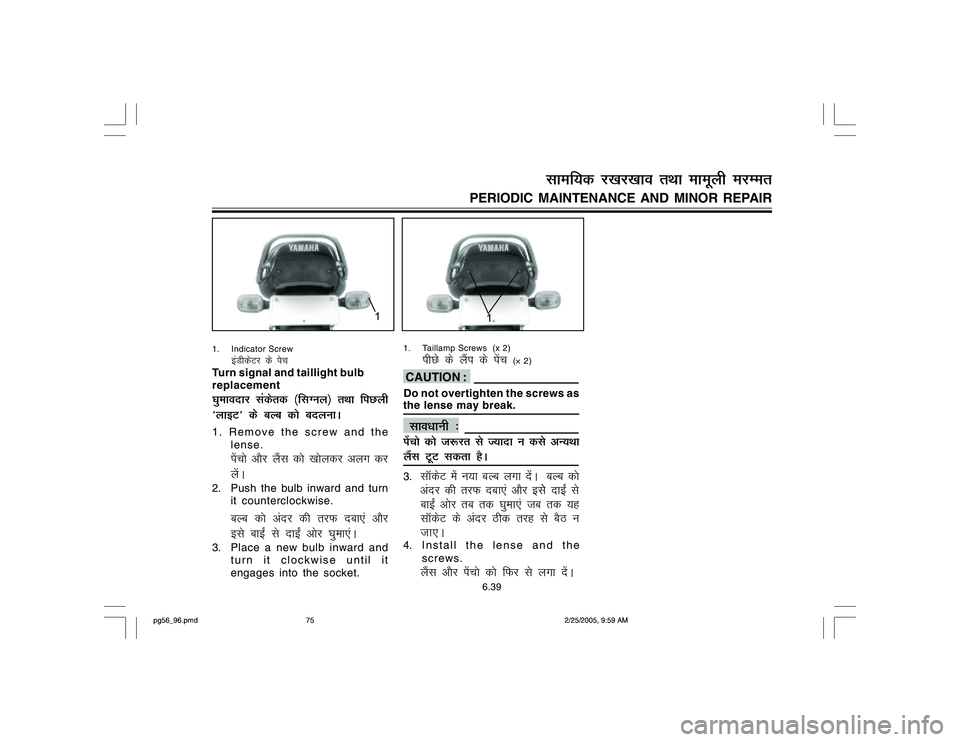

1. Indicator Screw

baMhdsVj ds isp

Turn signal and taillight bulb

replacement

?kqekonkj ladsrd ¼flXuy½ rFkk fiNyh

^ykbV* dss cYc dks cnyukA1. Remove the screw and the

lense.

isapks vkSj ySal dks [kksydj vyx dj

ysaA

2. Push the bulb inward and turn

it counterclockwise.

cYc dks vanj dh rjQ nck,a vkSj

bls ckb± ls nkb± vksj ?kqek,aA

3. Place a new bulb inward and

turn it clockwise until it

engages into the socket.

1. Taillamp Screws (x 2)

ihNs ds ySai ds isap

(× 2 )

CAUTION :Do not overtighten the screws as

the lense may break. lko/kkuh %isapks dks t:jr ls T;knk u dls vU;Fkk

ySal VwV ldrk gSA3.

lkWdsV esa u;k cYc yxk nsaaA cYc dks

vanj dh rjQ nck,a vkSj blss nkb± ls

ckb± vksj rc rd ?kqek,a tc rd ;g

lkWdsV ds vanj Bhd rjg ls cSB u

tk,A

4. Install the lense and the

screws.

ySal vkSj isapks dks fQj ls yxk nsaA

6.39

PERIODIC MAINTENANCE AND MINOR REPAIR

lkef;d j[kj[kko rFkk ekewyh ejEer

1

1

pg56_96.pmd2/25/2005, 9:59 AM 75

Page 86 of 156

1. Before cleaning the Motorcycle :

eksVjlkbfdy dh lQkbZ djus ls

igys %

a. Block off the end of the exhaust

pipe to prevent water entry; a

plastic bag and string rubber

band may be used.

,XtkWLV ikbZi ¼fudkl&ikbi½ ls ikuh

ds izos'k dks jksdus ds fy, ikbi ds

,d fljs dks IykfLVd cSx vkSj jcj

cSaM dk iz;ksx djds] can fd;k tk

ldrk gSA

b. Make sure the spark plug and all

filler caps are properly installed.

lqfuf'pr djssa fd LikWdZ Iyx vkSj

lHkh fQYyj&dSSIl Bhd rjg ls yxk,

x;s gksaA

2. If the engine case is excessively

greasy, apply degreaser with a

paint brush. Do not apply

degreaser to the chain,

sprockets, or wheel axles.

;fn batu dk dsl vR;kf/kd :i ls

fpduk gS rks isaV czq'k dh lgk;rk ls

bl ij ^fpdukbZ vojks/kd* yxk,aA

psu] LizkWdsV~l vFkok ifg, ds ,Dlyksa

ij fM&xzhlj dk mi;ksx u djsaA

A. CLEANING

lQkbZ

Frequent, thorough cleaning of your

Motorcycle will not only enhance its

appearance but will improve its

general performance and extend the

useful life of many components.tYnh&tYnh] iwjh rjg lQkbZ u dsoy

vkidh eksVjlkbfdy dks ns[kus esa vPNk

cukrh gS cfYd bldh lk/kkj.k dk;Z{kerk

esa lq/kkj ykrh gS vkSj blls cgqr ls iqtsZ

ds dk;Z&dky esa o f) gksrh gS CAUTION :

Improper cleaning can damage

the cowlings, panels and other

plastic parts. Use only a soft,

clean cloth or sponge with mild

detergent and water to clean

plastic.

Do not use any harsh chemical

products on plastic parts. Be

sure to avoid using cloths or

sponges which have been in

contact with strong or abrasive

cleaning products, solvent or

thinner, fuel (gasoline), rust

removers or inhibitors, brake

fluid, antifreeze or electrolyte.

lko/kkuh %

xyr rjhds ls dh xbZ lQkbZ ls

eksVjlkbfdy ds dkůyx] iSuy rFkk

vU; IykWfLVd ds iqtsZ [kjkc gks ldrs

gSaA IykWfLVd ds iqtksZa dks lkQ djus

ds fy, eghu fMVtsZaV vkSj ikuh ds

lkFk dsoy lkQ] eqyk;e diM+s dk

gh iz;ksx djsaA IykfLVd ds iqtsZ

¼daiksusaV~l½ ds fy, fdlh rst

dsehdYl dk iz;ksx u djsaA

lqfuf'pr djsa fd mu diM+ksa vFkok

Liat ds iz;ksx ls cpk tk, tks

'kfDr'kkyh vFkok ,cjsflo lQkbZ

mRiknksa] nzkod] vFkok fFkuj] b±/ku]

¼xSl½ tax izfrjks/kdksa vFkok

tax&fueZwydksa] cszd ds b±/ku] 'khr

fojks/kh ¼,aVh&Ýht½ vFkok bysDVªksykbV

ds laidZ esa vk tkrs gSaA

7.1

CLEANING AND STORAGElQkbZ rFkk HkaMkj.k

pg56_96.pmd2/25/2005, 9:59 AM 84

Page 88 of 156

![YAMAHA YD110 2005 User Guide 2.

b±/ku dh [kkyh Vadh dks ckgj fudky

ysa] Vadh esa ,d di

SAE 10W30 or

20W40

czkaM dk eksVj vkW;y Mkysaa]

fQj Vadh ds van:uh lrg dh dks¯Vx

djus ds fy, Vadh dks vPNh rjg ls

fgyk,a vkSj Qkyrw rsy d YAMAHA YD110 2005 User Guide 2.

b±/ku dh [kkyh Vadh dks ckgj fudky

ysa] Vadh esa ,d di

SAE 10W30 or

20W40

czkaM dk eksVj vkW;y Mkysaa]

fQj Vadh ds van:uh lrg dh dks¯Vx

djus ds fy, Vadh dks vPNh rjg ls

fgyk,a vkSj Qkyrw rsy d](/img/51/53675/w960_53675-87.png)

2.

b±/ku dh [kkyh Vadh dks ckgj fudky

ysa] Vadh esa ,d di

SAE 10W30 or

20W40

czkaM dk eksVj vkW;y Mkysaa]

fQj Vadh ds van:uh lrg dh dks¯Vx

djus ds fy, Vadh dks vPNh rjg ls

fgyk,a vkSj Qkyrw rsy dks ckgj fudky

nsaA Vadh dks fQj ls ;FkkLFkku ij

yxk nsaA

3. Remove the spark plug, pour

about one tablespoon of SAE

10W30 or 20W40 motor oil in the

spark plug hole. Reinstall spark

plug. Kick the engine over several

times (with the ignition off) to coat

the cylinder wall with oil.

LikWdZ Iyx dks ckgj fudky ys]

SAE

10W30 or 20W40

czkaM dk ,d cM+k

pEep LikWdZ Iyx ds Nsn esa ¼gksy½

Mkysa vkSj bls fQj ls okil yxk nsaA

batu dks dqN le; rd fdd yxkrs

jgsa ¼bXuh'u dks can j[krs gq,½ ftlls

flyh.Mj dh fnokjksa dh vkW;y&dks¯Vx

gks tk,A

4. Remove the drive chain.

Thoroughly clean the chain

withsolvent and lubricate it.

Reinstall the chain or store it in a

B. STORAGEch- Hk.Mkj.k ¼LVksjst½Long term storage (60 days or more)

of your Motorcycle will require more

preventive procedures to guard

against deterioration. After thoroughly

cleaning the Motorcycle, prepare for

storage as follows:vkidh eksVjlkbfdy dks yEch vof/k rd

¼60

fnu ;k mlls Åij½ ^LVksj* djds

j[kus ij bls u"V gksus ls cpkus ds fy,

lko/kkuho'k dqN izfØ;k,a viukuh iM+rh

gSaA eksVjlkbfdy dks iwjh rjg lQkbZ

djus ds ckn] fuEufyf[kr ckrkssa dk vuqlj.k

djds] bls ^LVksj* djus dh rS;kjh djsa %

1. Drain the fuel tank, fuel lines, and

carburetor float bowl.

b±/ku dh Vadh] b±/ku dh ykbZuksa] vkSj

dkjC;wjsVj ds ¶yksV&ckÅy dks [kkyh

djs ysaA

2. Remove the empty fuel tank, pour

a cup of SAE 10W30 or 20W40

motor oil in the tank, shake the

tank to coat the inner surfaces tank

to coat the inner surfaces

thoroughly and drain off the excess

oil. Reinstall the tank.plastic bag (tied to frame for

safekeeping).

M ªkbo&pSu dks ckgj fudky ysaA

bls iwjh rjg ls nzkod ¼lkWYosaV½ ls

lkQ djsa vkSj bl ij xzhl bR;kfn

yxk nsaA pSu dks fQj ls yxk nsa

vFkok bls ,d IykWfLVd & cSx esa

^LVksj* djds j[k ysaA ¼lqjf{kr j[kus

ds fy, Ýse ds lkFk cka/k nsa½A

5. Lubricate all control cables.

lHkh daVªksy&dscyksa ¼rkjksa½ dh xzh¯lx

dj ysaA

6. Block up the frame to raise both

wheels off the ground.

nksuksa ifgvksa dks t+ehu ls Åij mBkus

ds fy, Ýse dks jksddj j[ksaA

7. Tie a plastic bag over the

exhaust pipe outlet to prevent

moisture from entering.

ueh dks ^,XtkWLV&ikbi* ¼fudkl&uyh½

ds vanj vkus ls cpkus dss fy, ikbi

dks ckgj ls IykWfLVd cSx ls

CLEANING AND STORAGElQkbZ rFkk HkaMkj.k

7.3

pg56_96.pmd2/25/2005, 9:59 AM 86

Page 99 of 156

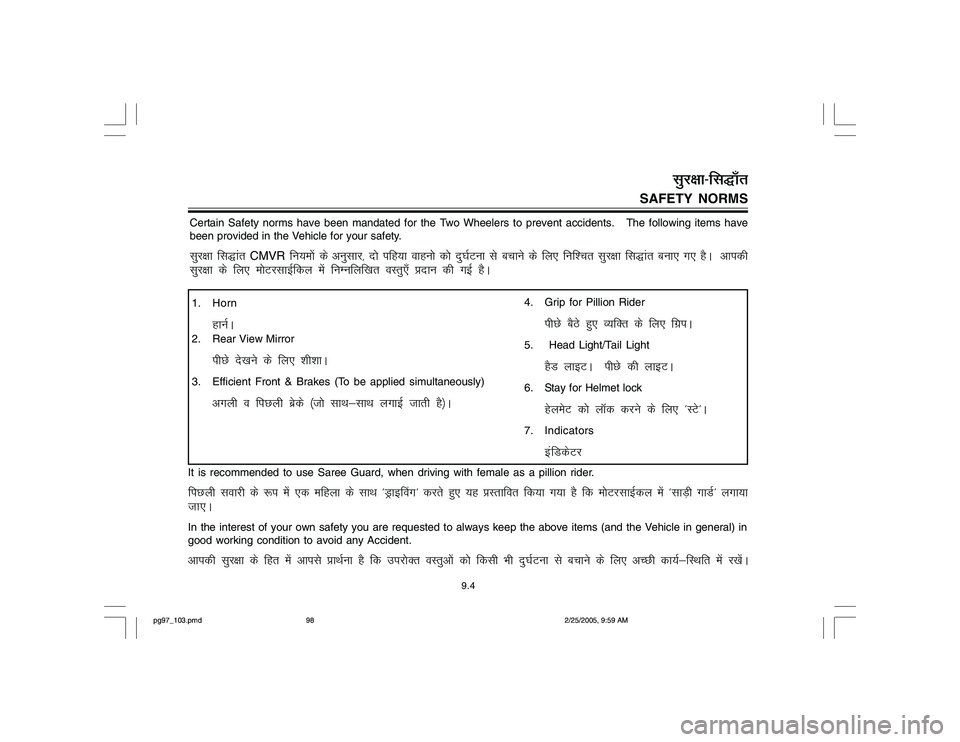

SAFETY NORMS

9.4

lqj{kk&flðk¡r

Certain Safety norms have been mandated for the Two Wheelers to prevent accidents. The following items have

been provided in the Vehicle for your safety.lqj{kk flðkar

CMVR

fu;e¨a ds vuqlkj] n¨ ifg;k okgu¨ d¨ nq?kZVuk ls cpkus ds fy, fuf'pr lqj{kk flðkar cuk, x, gSA vkidh

lqj{kk ds fy, e¨VjlkbZfdy esa fuEufyf[kr oLrq,¡ çnku dh xbZ gSA

It is recommended to use Saree Guard, when driving with female as a pillion rider.fiNyh lokjh ds :i esa ,d efgyk ds lkFk *Mªkb¯ox^ djrs gq, ;g çLrkfor fd;k x;k gS fd e¨VjlkbZdy esa *lkM+h xkMZ^ yxk;k

tk,AIn the interest of your own safety you are requested to always keep the above items (and the Vehicle in general) in

good working condition to avoid any Accident.vkidh lqj{kk ds fgr esa vkils çkFkZuk gS fd mij¨Dr oLrqv¨a d¨ fdlh Hkh nq?kZVuk ls cpkus ds fy, vPNh dk;Z&fLFkfr esa j[ksaA1. Horn

gkuZA

2. Rear View Mirror

ihNs ns[kus ds fy, 'kh'kkA

3. Efficient Front & Brakes (To be applied simultaneously)

vxyh o fiNyh czsds ¼t¨ lkFk&lkFk yxkbZ tkrh gS½A

4. Grip for Pillion Rider

ihNs cSBs gq, O;fDr ds fy, fxziA

5. Head Light/Tail Light

gSM ykbVA ihNs dh ykbVA

6. Stay for Helmet lock

gsyesV d¨ ykWd djus ds fy, *LVs^A

7. Indicators

bafMdsVj

pg97_103.pmd2/25/2005, 9:59 AM 98

Page 136 of 156

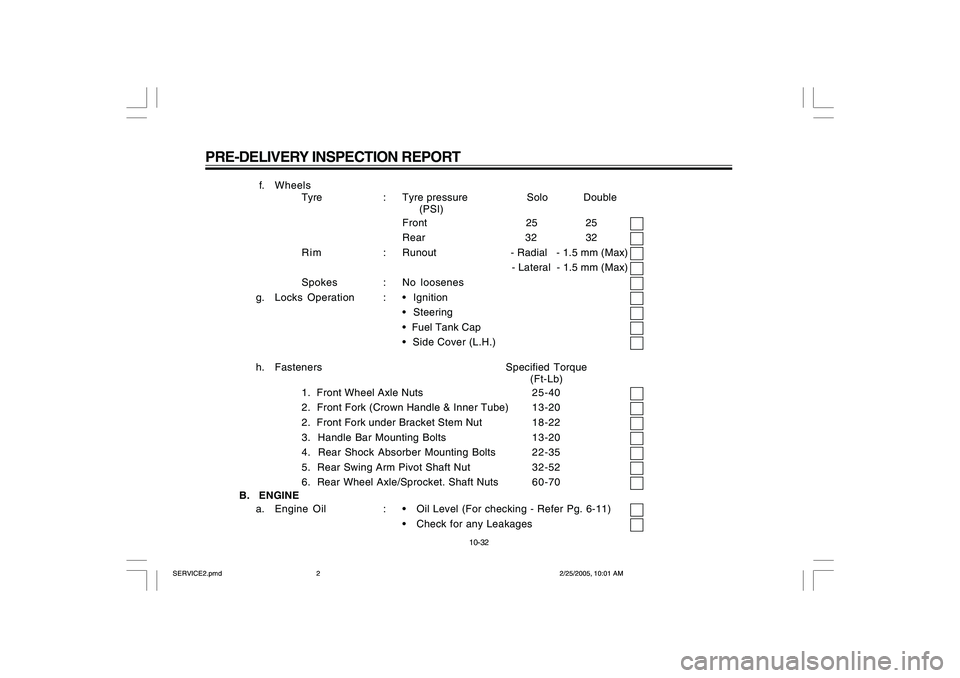

PRE-DELIVERY INSPECTION REPORT

f. Wheels

Tyre :Tyre pressure Solo Double

(PSI)

Front 25 25

Rear 32 32

R i m : Runout - Radial - 1.5 mm (Max)

- Lateral - 1.5 mm (Max)

Spokes : No loosenes

g. Locks Operation : • Ignition

Steering Fuel Tank Cap Side Cover (L.H.)

h. Fasteners Specified Torque

(Ft-Lb)

1. Front Wheel Axle Nuts25-40

2. Front Fork (Crown Handle & Inner Tube)13-202. Front Fork under Bracket Stem Nut18-223. Handle Bar Mounting Bolts13-204. Rear Shock Absorber Mounting Bolts22-355. Rear Swing Arm Pivot Shaft Nut32-526. Rear Wheel Axle/Sprocket. Shaft Nuts60-70

B. ENGINE

a. Engine Oil : Oil Level (For checking - Refer Pg. 6-11)

Check for any Leakages

10-32

SERVICE2.pmd2/25/2005, 10:01 AM 2