maintenance YAMAHA YFM350R-W 2007 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2007, Model line: YFM350R-W, Model: YAMAHA YFM350R-W 2007Pages: 134, PDF Size: 6.62 MB

Page 103 of 134

8-25

8

NOTE:If the cable length cannot be adjusted to specifica-tion, consult a Yamaha dealer.

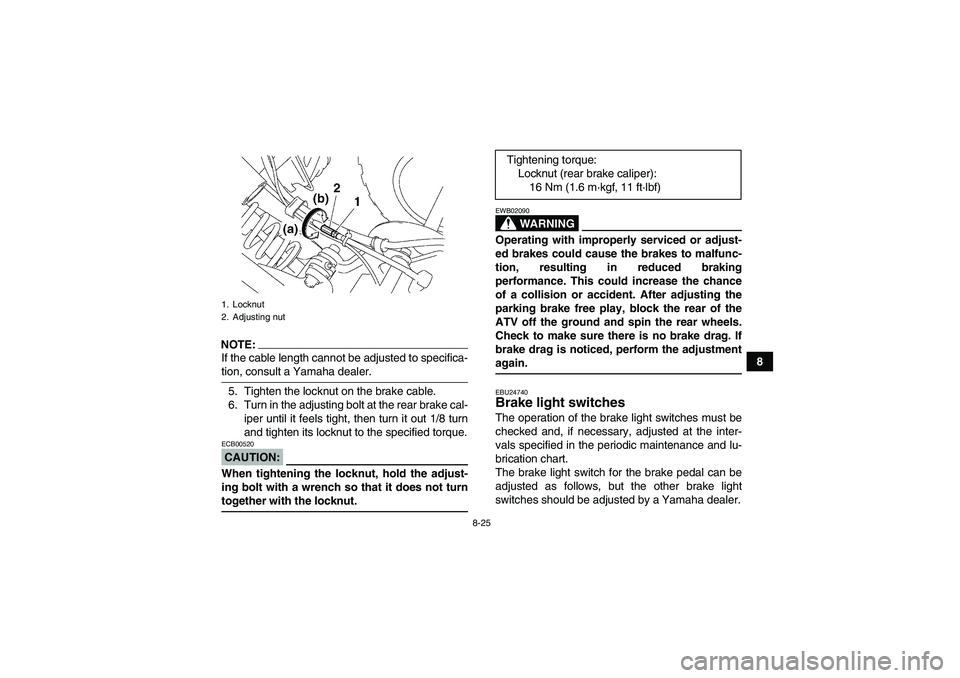

5. Tighten the locknut on the brake cable.

6. Turn in the adjusting bolt at the rear brake cal-

iper until it feels tight, then turn it out 1/8 turn

and tighten its locknut to the specified torque.CAUTION:ECB00520When tightening the locknut, hold the adjust-

ing bolt with a wrench so that it does not turntogether with the locknut.

WARNING

EWB02090Operating with improperly serviced or adjust-

ed brakes could cause the brakes to malfunc-

tion, resulting in reduced braking

performance. This could increase the chance

of a collision or accident. After adjusting the

parking brake free play, block the rear of the

ATV off the ground and spin the rear wheels.

Check to make sure there is no brake drag. If

brake drag is noticed, perform the adjustmentagain.EBU24740Brake light switches The operation of the brake light switches must be

checked and, if necessary, adjusted at the inter-

vals specified in the periodic maintenance and lu-

brication chart.

The brake light switch for the brake pedal can be

adjusted as follows, but the other brake light

switches should be adjusted by a Yamaha dealer.

1. Locknut

2. Adjusting nut

Tightening torque:

Locknut (rear brake caliper):

16 Nm (1.6 m·kgf, 11 ft·lbf)

U10P60E0.book Page 25 Thursday, June 15, 2006 4:19 PM

Page 104 of 134

8-26

8

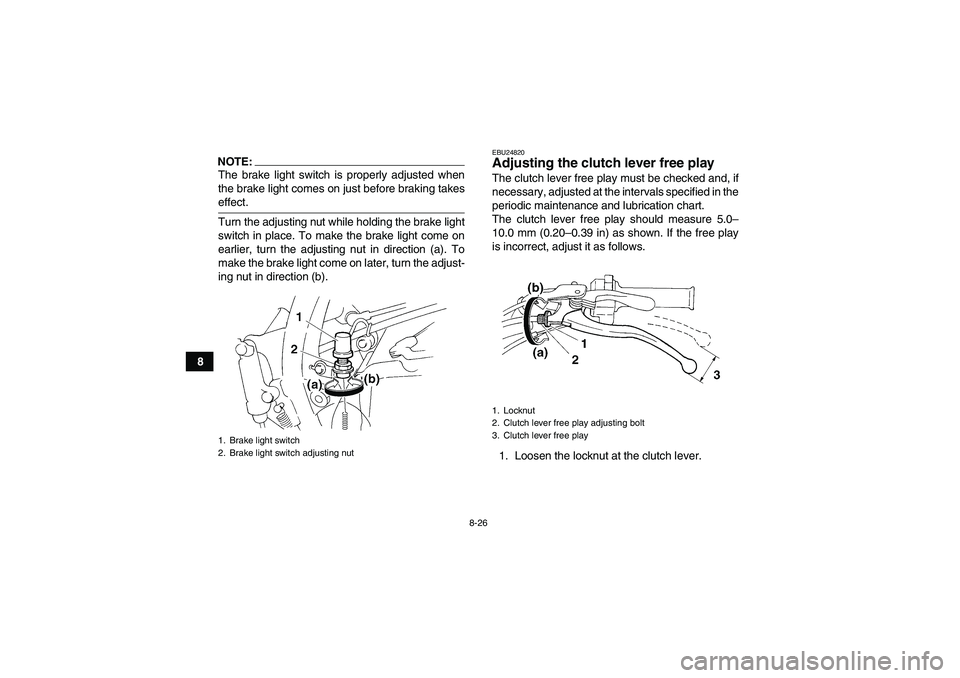

NOTE:The brake light switch is properly adjusted when

the brake light comes on just before braking takeseffect.

Turn the adjusting nut while holding the brake light

switch in place. To make the brake light come on

earlier, turn the adjusting nut in direction (a). To

make the brake light come on later, turn the adjust-

ing nut in direction (b).

EBU24820Adjusting the clutch lever free play The clutch lever free play must be checked and, if

necessary, adjusted at the intervals specified in the

periodic maintenance and lubrication chart.

The clutch lever free play should measure 5.0–

10.0 mm (0.20–0.39 in) as shown. If the free play

is incorrect, adjust it as follows.

1. Loosen the locknut at the clutch lever.

1. Brake light switch

2. Brake light switch adjusting nut

1. Locknut

2. Clutch lever free play adjusting bolt

3. Clutch lever free play

U10P60E0.book Page 26 Thursday, June 15, 2006 4:19 PM

Page 108 of 134

8-30

8

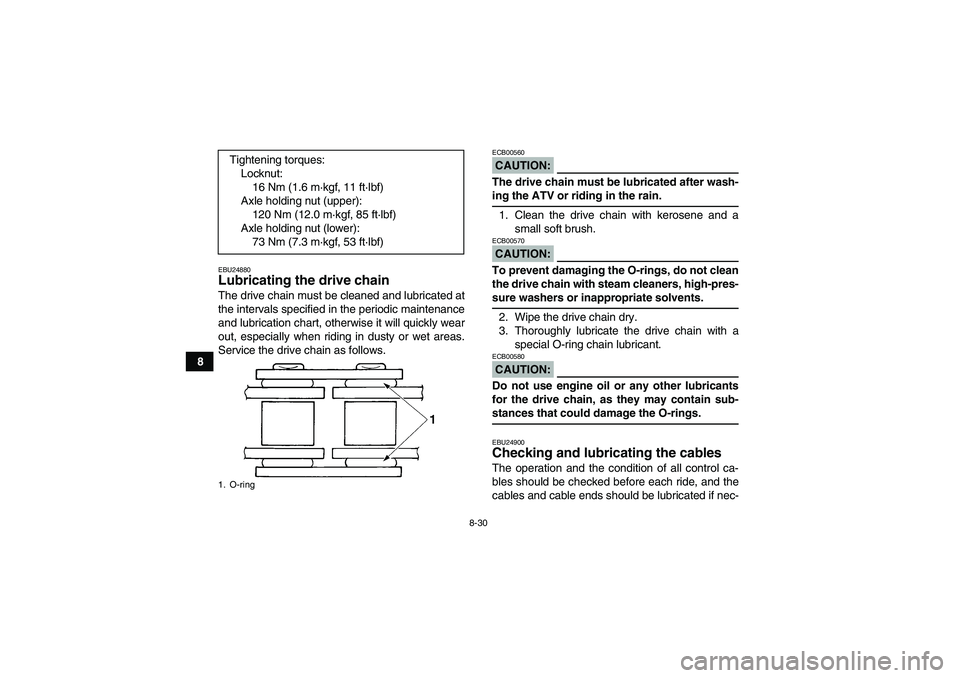

EBU24880Lubricating the drive chain The drive chain must be cleaned and lubricated at

the intervals specified in the periodic maintenance

and lubrication chart, otherwise it will quickly wear

out, especially when riding in dusty or wet areas.

Service the drive chain as follows.

CAUTION:ECB00560The drive chain must be lubricated after wash-ing the ATV or riding in the rain.

1. Clean the drive chain with kerosene and a

small soft brush.CAUTION:ECB00570To prevent damaging the O-rings, do not clean

the drive chain with steam cleaners, high-pres-sure washers or inappropriate solvents.

2. Wipe the drive chain dry.

3. Thoroughly lubricate the drive chain with a

special O-ring chain lubricant.CAUTION:ECB00580Do not use engine oil or any other lubricants

for the drive chain, as they may contain sub-stances that could damage the O-rings.EBU24900Checking and lubricating the cables The operation and the condition of all control ca-

bles should be checked before each ride, and the

cables and cable ends should be lubricated if nec- Tightening torques:

Locknut:

16 Nm (1.6 m·kgf, 11 ft·lbf)

Axle holding nut (upper):

120 Nm (12.0 m·kgf, 85 ft·lbf)

Axle holding nut (lower):

73 Nm (7.3 m·kgf, 53 ft·lbf)

1. O-ringU10P60E0.book Page 30 Thursday, June 15, 2006 4:19 PM

Page 110 of 134

8-32

8

EBU24930Checking and lubricating the brake and

shift pedals The operation of the brake and shift pedals should

be checked before each ride, and the pedal pivots

should be lubricated if necessary.

Brake pedalShift pedal

EBU24961Checking the wheel bearings The front and rear wheel bearings must be

checked at the intervals specified in the periodic

maintenance and lubrication chart. If there is play

in a wheel hub or if a wheel does not turn smoothly,

have a Yamaha dealer check the wheel bearings.EBU24992Lubricating the swingarm pivots The swingarm pivots must be lubricated at the in-

tervals specified in the periodic maintenance and

lubrication chart. Recommended lubricant:

Lithium-soap-based grease (all-purpose

grease)

U10P60E0.book Page 32 Thursday, June 15, 2006 4:19 PM

Page 111 of 134

8-33

8

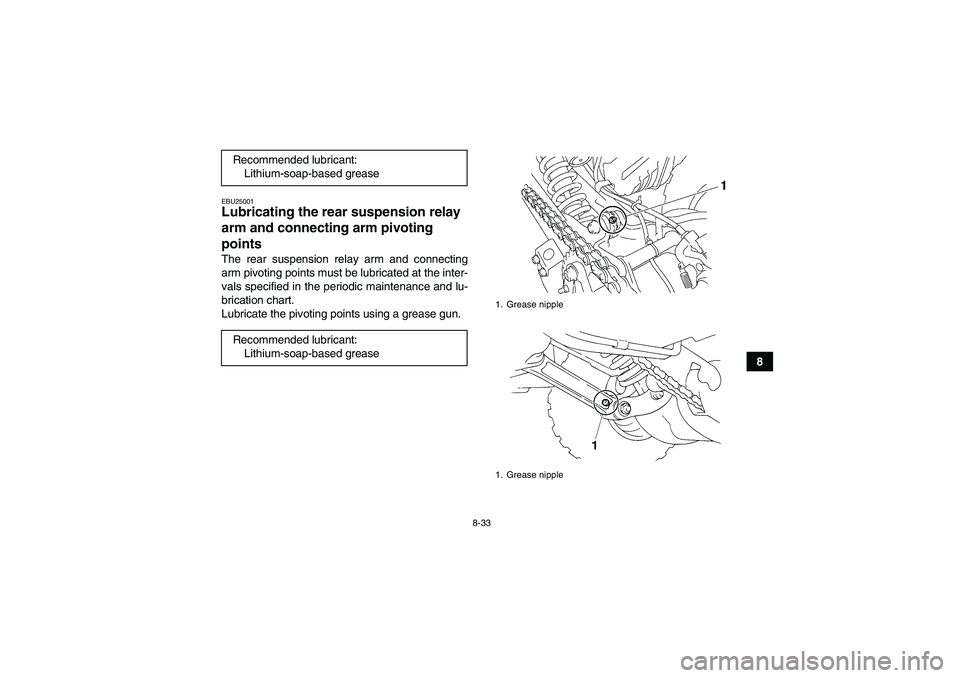

EBU25001Lubricating the rear suspension relay

arm and connecting arm pivoting

points The rear suspension relay arm and connecting

arm pivoting points must be lubricated at the inter-

vals specified in the periodic maintenance and lu-

brication chart.

Lubricate the pivoting points using a grease gun.Recommended lubricant:

Lithium-soap-based grease

Recommended lubricant:

Lithium-soap-based grease

1. Grease nipple

1. Grease nipple

U10P60E0.book Page 33 Thursday, June 15, 2006 4:19 PM

Page 113 of 134

8-35

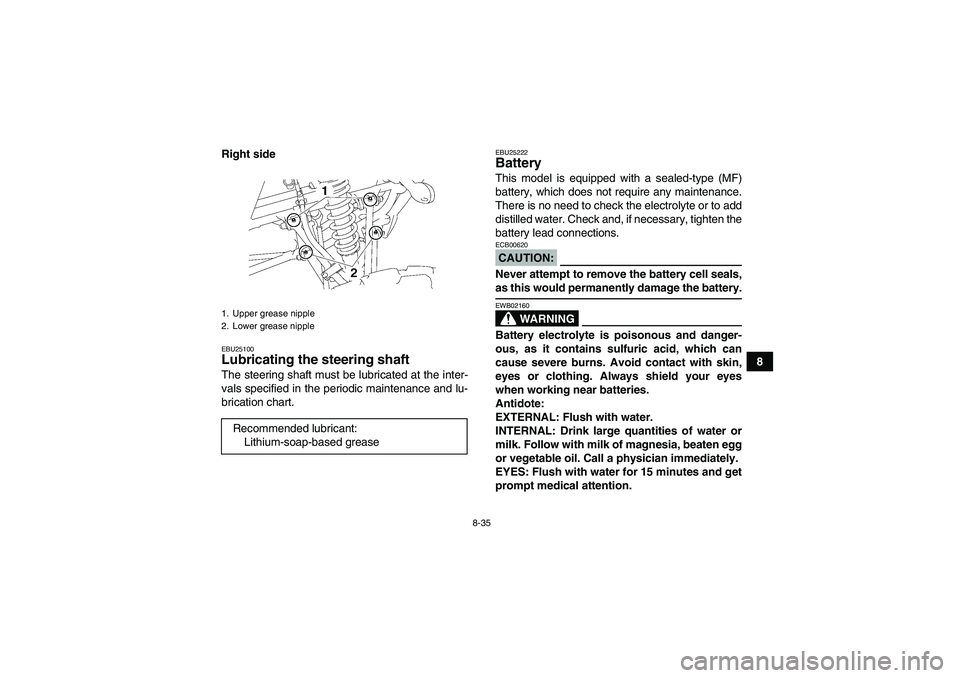

8 Right side

EBU25100Lubricating the steering shaft The steering shaft must be lubricated at the inter-

vals specified in the periodic maintenance and lu-

brication chart.

EBU25222Battery This model is equipped with a sealed-type (MF)

battery, which does not require any maintenance.

There is no need to check the electrolyte or to add

distilled water. Check and, if necessary, tighten the

battery lead connections.CAUTION:ECB00620Never attempt to remove the battery cell seals,as this would permanently damage the battery.

WARNING

EWB02160Battery electrolyte is poisonous and danger-

ous, as it contains sulfuric acid, which can

cause severe burns. Avoid contact with skin,

eyes or clothing. Always shield your eyes

when working near batteries.

Antidote:

EXTERNAL: Flush with water.

INTERNAL: Drink large quantities of water or

milk. Follow with milk of magnesia, beaten egg

or vegetable oil. Call a physician immediately.

EYES: Flush with water for 15 minutes and get

prompt medical attention.

1. Upper grease nipple

2. Lower grease nippleRecommended lubricant:

Lithium-soap-based grease

U10P60E0.book Page 35 Thursday, June 15, 2006 4:19 PM

Page 132 of 134

License plate light bulb, replacing ................................ 8-39

Light switch .................................................................... 4-4MMain switch .................................................................... 4-1

Model label ................................................................... 11-1NNeutral indicator light ..................................................... 4-2OOwner’s manual and tool kit ........................................... 8-1PParking ........................................................................... 6-7

Parking brake free play, adjusting ................................ 8-24

Parking brake lever ........................................................ 4-7

Parking on a slope ......................................................... 6-8

Part locations ................................................................. 3-1

Periodic maintenance and lubrication chart ................... 8-3

Pre-operation check list .................................................. 5-1RReverse indicator light .................................................... 4-2

Riding your ATV ............................................................. 7-1SSafety information .......................................................... 1-1

Seat .............................................................................. 4-14

Shifting ........................................................................... 6-4

Shift pedal ...................................................................... 4-8

Shock absorber assemblies, adjusting the front .......... 4-14

Shock absorber assembly, adjusting the rear .............. 4-16

Spark arrester, cleaning ............................................... 8-16

Spark plug, checking ...................................................... 8-8

Specifications ............................................................... 10-1

Speed limiter .................................................................. 4-5

Speedometer .................................................................. 4-2Starter (choke) ............................................................. 4-12

Start switch ..................................................................... 4-3

Steering lock ................................................................ 4-13

Steering shaft, lubricating ............................................. 8-35

Storage ........................................................................... 9-2

Suspension, lubricating the upper and lower arm

pivots ......................................................................... 8-34

Suspension relay arm and connecting arm pivoting

points, lubricating the rear ......................................... 8-33

Swingarm pivots, lubricating ........................................ 8-32

TTail/brake light bulb, replacing ..................................... 8-38

Throttle cable free play, adjusting ................................ 8-19

Throttle lever ........................................................... 4-4, 5-4

Tire pressure, measuring ............................................... 5-5

Tires ............................................................................... 5-4

Tire wear limit ................................................................. 5-6

Troubleshooting ........................................................... 8-42

Troubleshooting chart .................................................. 8-43

Turn signal indicator light ............................................... 4-2

Turn signal light bulb, replacing ................................... 8-38

Turn signal switch .......................................................... 4-4VValve clearance ............................................................ 8-19

Vehicle identification number ....................................... 11-1WWheel bearings, checking ............................................ 8-32

Wheel, installing ........................................................... 8-41

Wheel, removing .......................................................... 8-40

U10P60E0.book Page 2 Thursday, June 15, 2006 4:19 PM