check engine YAMAHA YFM660R 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YFM660R, Model: YAMAHA YFM660R 2005Pages: 432, PDF Size: 17.18 MB

Page 273 of 432

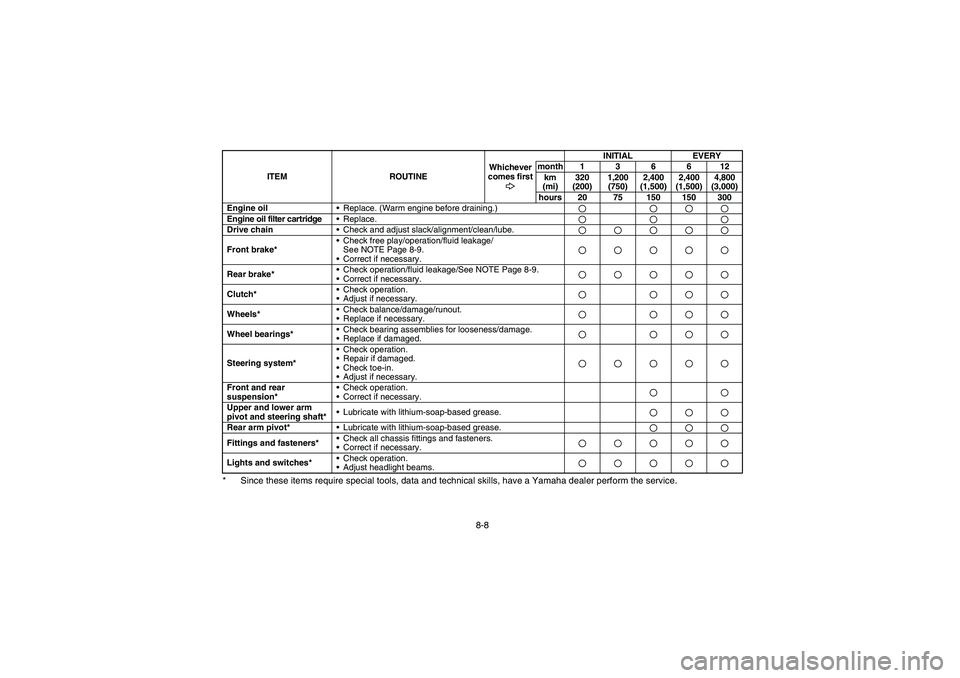

8-8 * Since these items require special tools, data and technical skills, have a Yamaha dealer perform the service.

Engine oil

Replace. (Warm engine before draining.)Engine oil filter cartridge

Replace.Drive chain

Check and adjust slack/alignment/clean/lube.Front brake*Check free play/operation/fluid leakage/

See NOTE Page 8-9.

Correct if necessary.Rear brake*Check operation/fluid leakage/See NOTE Page 8-9.

Correct if necessary.Clutch*Check operation.

Adjust if necessary.Wheels*Check balance/damage/runout.

Replace if necessary.Wheel bearings*Check bearing assemblies for looseness/damage.

Replace if damaged.Steering system*Check operation.

Repair if damaged.

Check toe-in.

Adjust if necessary.Front and rear

suspension*Check operation.

Correct if necessary.Upper and lower arm

pivot and steering shaft*Lubricate with lithium-soap-based grease.Rear arm pivot*

Lubricate with lithium-soap-based grease.Fittings and fasteners*Check all chassis fittings and fasteners.

Correct if necessary.Lights and switches*Check operation.

Adjust headlight beams.

ITEM ROUTINEWhichever

comes firstINITIAL EVERY

month136612

km

(mi)320

(200)1,200

(750)2,400

(1,500)2,400

(1,500)4,800

(3,000)

hours 20 75 150 150 300

U5LP64.book Page 8 Thursday, April 1, 2004 4:53 PM

Page 284 of 432

8-19 1. Engine oil tank

2. Engine oil tank filler cap

3. Dipstick

4. Maximum level mark

5. Minimum level mark

1. Réservoir d’huile de moteur

2. Bouchon de remplissage de l’huile de moteur

3. Jauge

4. Repère de niveau maximum

5. Repère de niveau minimum

1. Depósito de aceite de motor

2. Tapa de relleno del depósito de aceite de motor

3. Varilla de medición

4. Marca de nivel máximo

5. Marca de nivel mínimo

EBU12382

Engine oil and oil filter cartridge

The engine oil level should be checked before

each ride. In addition, the oil must be changed and

the oil filter cartridge replaced at the intervals

specified in the periodic maintenance and lubrica-

tion chart.

To check the engine oil level

1. Place the ATV on a level surface.

2. Start the engine, warm it up until the engine

oil has reached a normal temperature of

60°C, let it continue to idle for twenty to thirty

seconds. During this period, rev the engine

two or three times to approximately

3,000 r/min, and then turn the engine off.NOTE:_ To achieve the proper engine oil temperature for

an accurate oil level reading, the engine must

have first completely cooled down, and then

warmed up again for several minutes to normal

operating temperature. _

U5LP64.book Page 19 Thursday, April 1, 2004 4:53 PM

Page 286 of 432

8-21

3. Wait a few minutes until the oil settles, re-

move the engine oil tank filler cap, wipe the

dipstick clean with a clean rag, insert it back

into the filler hole (without screwing it in), and

then remove it again to check the oil level.NOTE:_ The engine oil should be between the minimum

and maximum level marks. _4. If the engine oil is below the minimum level

mark, add sufficient oil of the recommended

type to raise it to the correct level.NOTE:_ When adding oil, be careful not to overfill the en-

gine oil tank; the oil level rises faster starting from

the half-level-portion on the dipstick. _5. Insert the dipstick into the oil filler hole, and

then tighten the oil filler cap.

U5LP64.book Page 21 Thursday, April 1, 2004 4:53 PM

Page 290 of 432

8-25 1. Crankcase engine oil drain bolt

1. Boulon de vidange d’huile du carter

1. Perno de drenaje de aceite de motor del cárter

1. Engine oil tank drain bolt

1. Boulon de vidange du réservoir d’huile de moteur

1. Perno de drenaje del depósito aceite de motor

4. Remove the crankcase engine oil drain bolt.

5. Remove the engine oil tank filler cap and the

oil tank drain bolt.

6. Check the washers for damage, and replace

if necessary.NOTE:_ Skip steps 7–9 if the oil filter cartridge is not being

replaced. _

U5LP64.book Page 25 Thursday, April 1, 2004 4:53 PM

Page 294 of 432

8-29

11. Pour only 1.75 L of the specified amount of

recommended engine oil through the engine

oil tank filler hole, insert the dipstick, and then

tighten the oil tank filler cap.

12. Start the engine, rev it several times, and

then turn it off.

13. Remove the engine oil tank filler cap, and

then gradually fill the oil tank with the remain-

ing oil quantity while regularly checking the oil

level on the dipstick.

14. Install the engine oil tank filler cap.Tightening torques:

Crankcase engine oil drain bolt:

30 Nm (3.0 m·kgf)

Engine oil tank drain bolt:

25 Nm (2.5 m·kgf)

U5LP64.book Page 29 Thursday, April 1, 2004 4:53 PM

Page 298 of 432

8-33

15. Start the engine, and then let it idle for seve-

ral minutes while checking it for oil leakage. If

oil is leaking, immediately turn the engine off

and check for the cause.

16. Turn the engine off, and then check the oil

level and correct it if necessary.

17. Install the engine guard by installing the bolts.

U5LP64.book Page 33 Thursday, April 1, 2004 4:53 PM

Page 300 of 432

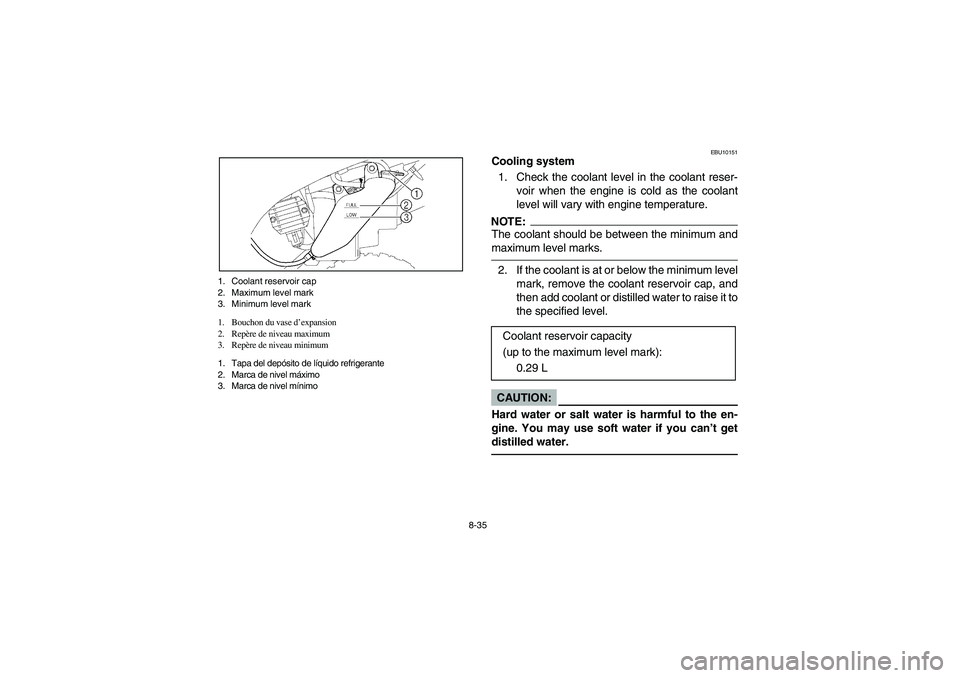

8-35 1. Coolant reservoir cap

2. Maximum level mark

3. Minimum level mark

1. Bouchon du vase d’expansion

2. Repère de niveau maximum

3. Repère de niveau minimum

1. Tapa del depósito de líquido refrigerante

2. Marca de nivel máximo

3. Marca de nivel mínimo

EBU10151

Cooling system

1. Check the coolant level in the coolant reser-

voir when the engine is cold as the coolant

level will vary with engine temperature.NOTE:_ The coolant should be between the minimum and

maximum level marks. _2. If the coolant is at or below the minimum level

mark, remove the coolant reservoir cap, and

then add coolant or distilled water to raise it to

the specified level.CAUTION:_ Hard water or salt water is harmful to the en-

gine. You may use soft water if you can’t get

distilled water. _

Coolant reservoir capacity

(up to the maximum level mark):

0.29 L

U5LP64.book Page 35 Thursday, April 1, 2004 4:53 PM

Page 310 of 432

8-45

CAUTION:_ Hard water or salt water is harmful to the en-

gine. You may use soft water if you cannot get

distilled water. _12. Install the radiator cap and the coolant reser-

voir cap.

13. Start the engine and let it idle for several min-

utes. Stop the engine, and then check the

coolant level in the radiator. If it is low, add

more coolant until it reaches the top of the ra-

diator.

14. Check the coolant level in the reservoir. If it is

low, add coolant to the maximum level mark.

15. Start the engine and then check for coolant

leakage.NOTE:_ If any leakage is found, have a Yamaha dealer

check the cooling system. _16. Install the panel.

U5LP64.book Page 45 Thursday, April 1, 2004 4:53 PM

Page 318 of 432

8-53 1. Check hose

1. Flexible de contrôle

1. Manguito de comprobación

1. Air filter case cover 2. Holder (× 6)

1. Couvercle du boîtier de filtre à air 2. Support (× 6)

1. Tapa de la caja del filtro 2. Soporte (× 6)

EBU12121

Air filter element cleaningNOTE:_ There is a check hose at the bottom of the air filter

case. If dust or water collects in this hose, empty

the hose and clean the air filter element and air fil-

ter case. _1. Remove the seat. (See page 4-33 for seat re-

moval and installation procedures.)

2. Remove the air filter case cover by unhook-

ing the holders.

3. Remove the air filter element.

4. Remove the air filter element from its frame.

5. Wash the air filter element gently but thor-

oughly in solvent.

WARNING

_ Always use parts cleaning solvent to clean the

air filter element. Never use low flash point sol-

vents or gasoline to clean the air filter element

because the engine could catch fire or ex-

plode. _

U5LP64.book Page 53 Thursday, April 1, 2004 4:53 PM

Page 322 of 432

8-57 1. Hose

1. Flexible

1. Manguera

11. Install the air filter case cover and be sure to

connect the hose.

12. Install the seat.NOTE:_ The air filter element should be cleaned every 20–

40 hours. It should be cleaned and lubricated more

often if the machine is operated in extremely dusty

areas. Each time air filter element maintenance is

performed, check the air inlet to the air filter case

for obstructions. Check the air filter element rubber

joint to the carburetor and manifold fittings for an

airtight seal. Tighten all fittings securely to avoid

the possibility of unfiltered air entering the engine. _CAUTION:_ Never operate the engine with the air filter ele-

ment removed. This will allow unfiltered air to

enter, causing rapid engine wear and possible

engine damage. Additionally, operation with-

out the air filter element will affect carburetor

jetting with subsequent poor performance and

possible engine overheating. _

U5LP64.book Page 57 Thursday, April 1, 2004 4:53 PM