suspension YAMAHA YFM700R 2016 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2016, Model line: YFM700R, Model: YAMAHA YFM700R 2016Pages: 160, PDF Size: 3.75 MB

Page 10 of 160

Drive chain slack ....................................... 8-38

Lubricating the drive chain........................ 8-40

Checking and lubricating the cables......... 8-40

Checking and lubricating the brake and clutch levers ............................................ 8-41

Checking the shift pedal ........................... 8-41

Checking and lubricating the brake pedal ....................................................... 8-41

Checking the wheel hub bearings............. 8-42

Lubricating the swingarm pivots ............... 8-42

Lubricating the rear suspension relay arm and connecting arm pivoting points ....... 8-43

Lubricating the upper and lower arm pivots ...................................................... 8-44

Lubricating the steering shaft ................... 8-45

Battery....................................................... 8-45

Replacing a fuse ....................................... 8-48

Replacing a headlight bulb ....................... 8-50

Adjusting a headlight beam ...................... 8-51

Tail/brake light........................................... 8-52

Removing a wheel ..................................... 8-52

Installing a wheel....................................... 8-52

Troubleshooting ........................................ 8-53

Troubleshooting charts ............................. 8-54

CLEANING AND STORAGE ........................... 9-1 Cleaning ...................................................... 9-1 Storage ....................................................... 9-2

SPECIFICATIONS ........................................ 10-1

CONSUMER INFORMATION....................... 11-1 Identification numbers .............................. 11-1

INDEX .......................................................... 12-1

U2LS61E0.book Page 3 Friday, April 17, 2015 8:25 AM

Page 24 of 160

2-5

2ungrounded or broken wiring. Visually check

for broken wiring and leaking fuel. Leaking

fuel can be confirmed by the odor of gasoline.

4. Once immediate safety hazards are con- firmed not to exist, you may remove your hel-

met to more closely inspect your vehicle.

Check for external signs of wear, broken

parts, fluid leaks, cracks in the frame, sus-

pension damage, wheel damage, and so on.

Fuel, oil, and coolant usually give off a notice-

able odor.

5. If your vehicle will not restart or if it is unsafe to ride, then turn off all vehicle systems (en-

gine stop switch, main switch, and fuel cock),

and then signal or go for help.

Aftermarket Parts, Accessories, and Modifica-

tions

While you may find aftermarket products similar in

design and quality to genuine Yamaha accesso-

ries, recognize that some aftermarket accessories

or modifications are not suitable because of po-

tential safety hazards to you or others. Installing

aftermarket products or having other modifica-

tions performed to your vehicle that change any of

the vehicle’s design or operation characteristics

can put you and others at greater risk of serious injury or death. You are responsible for injuries re-

lated to changes in the vehicle. Keep the following

guidelines in mind, as well as those provided un-

der “Loading” when mounting accessories.

Never install accessories that would impair the

performance of your ATV. Carefully inspect the

accessory before using it to make sure that it

does not in any way reduce ground clearance,

limit suspension travel, steering travel or control

operation.

Accessories fitted to the ATV can create insta-

bility due to improper weight distribution.

Bulky or large accessories may seriously affect

the stability of the ATV.

Certain accessories can displace the operator

from his or her normal riding position. This im-

proper position limits the freedom of movement

of the operator and may limit control ability,

therefore, such accessories are not recom-

mended.

Use caution when adding electrical accesso-

ries. If electrical accessories exceed the capac-

ity of the ATV’s electrical system, an electric

failure could result, which could cause a dan-

gerous loss of lights or engine power.

U2LS61E0.book Page 5 Friday, April 17, 2015 8:25 AM

Page 41 of 160

4-13

4

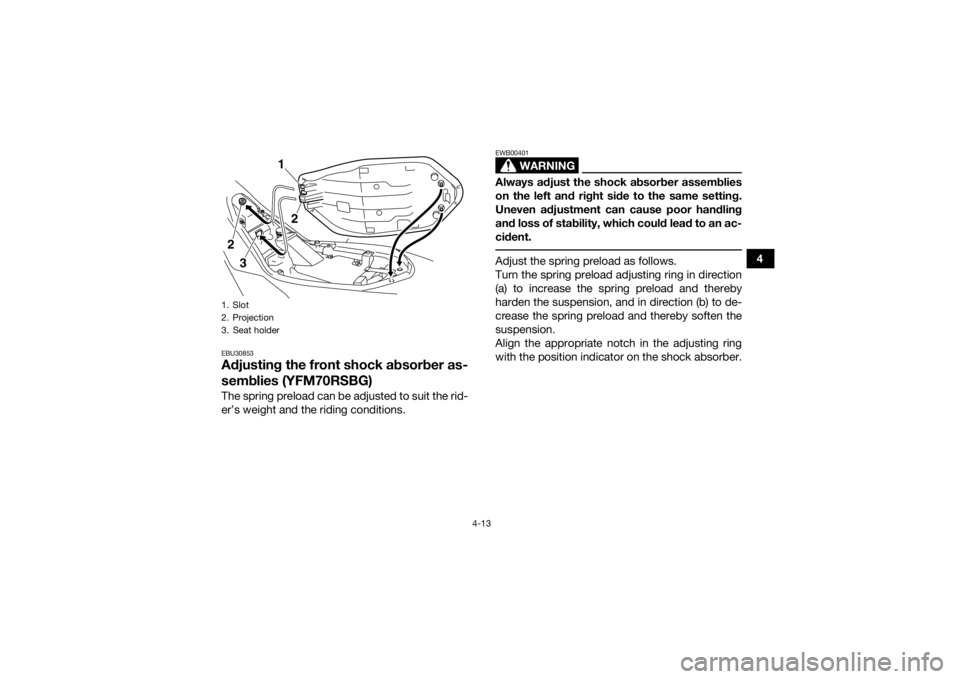

EBU30853Adjusting the front shock absorber as-

semblies (YFM70RSBG)The spring preload can be adjusted to suit the rid-

er’s weight and the riding conditions.

WARNING

EWB00401Always adjust the shock absorber assemblies

on the left and right side to the same setting.

Uneven adjustment can cause poor handling

and loss of stability, which could lead to an ac-

cident. Adjust the spring preload as follows.

Turn the spring preload adjusting ring in direction

(a) to increase the spring preload and thereby

harden the suspension, and in direction (b) to de-

crease the spring preload and thereby soften the

suspension.

Align the appropriate notch in the adjusting ring

with the position indicator on the shock absorber.

1. Slot

2. Projection

3. Seat holder

1

2

3

2

U2LS61E0.book Page 13 Friday, April 17, 2015 8:25 AM

Page 43 of 160

4-15

4

Do not tamper with or attempt to open the

cylinder assemblies.

Do not subject the shock absorber assem-

blies to an open flame or other high heat

source. This may cause the unit to explode

due to excessive gas pressure.

Do not deform or damage the cylinders in

any way. Cylinder damage will result in poor

damping performance.

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service.

EBU30981Adjusting the front shock absorber as-

semblies (YFM70RSSG)These shock absorber assemblies are equipped

with a spring preload adjusting nut, a rebound

damping force adjusting screw, with a compres-

sion damping force adjusting bolt (for fast com-

pression damping), and a compression damping

force adjusting screw (for slow compression

damping).

WARNING

EWB02492Suspension components become hot during

operation. Never touch the compression

damping force adjusting bolt and screw, the

rebound damping force adjusting screw or

the oil reservoir with your bare hand or skin

until suspension components have cooled.

Always adjust the shock absorber assem-

blies on the left and right side to the same

setting. Uneven adjustment can cause poor

handling and loss of stability, which could

lead to an accident. NOTICEECB00091Never turn an adjusting mechanism beyond

the minimum and maximum settings. TIPAlthough the total number of clicks or turns of a

damping force adjusting mechanism may not ex-

actly match the following specifications due to

small differences in production, the actual number

of clicks or turns always represents the entire ad-

justing range. To obtain a precise adjustment, it

U2LS61E0.book Page 15 Friday, April 17, 2015 8:25 AM

Page 44 of 160

4-16

4would be advisable to check the number of clicks

or turns of each damping force adjusting mecha-

nism and to modify the specifications as neces-

sary.

Spring preload

1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

TIPA special wrench can be obtained at a Yamaha

dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the higher the spring

preload; the longer distance A is, the lower the

spring preload. With each complete turn of the

adjusting nut, distance A is changed by 1.5 mm

(0.06 in).

1. Spring preload adjusting nut

2. Locknut

3. Special wrench

2

1

3

(a)

(b)

Spring preload setting:Minimum (soft):Distance A = 268.0 mm (10.55 in)

Standard: Distance A = 262.0 mm (10.31 in)

Maximum (hard): Distance A = 253.0 mm (9.96 in)

U2LS61E0.book Page 16 Friday, April 17, 2015 8:25 AM

Page 48 of 160

4-20

4

Do not dispose of a damaged or worn out

shock absorber assembly yourself. Take the

shock absorber assembly to a Yamaha deal-

er for any service.

EBU19047Adjusting the rear shock absorber as-

sembly (YFM70RSBG)The spring preload can be adjusted to suit the rid-

er’s weight and the riding conditions.NOTICEECB01091Never turn the adjusting mechanism beyond

the minimum and maximum settings. Adjust the spring preload as follows.

1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

TIPA special wrench can be obtained at a Yamaha

dealer to make this adjustment.

The spring preload setting is determined by

measuring distance A, shown in the illustration.

The shorter distance A is, the higher the spring

preload; the longer distance A is, the lower the

spring preload. With each complete turn of the

adjusting nut, distance A is changed by 1.5 mm

(0.06 in). 1. Spring preload adjusting nut

2. Locknut

3. Special wrench

1

(b)

(a)

2

3

U2LS61E0.book Page 20 Friday, April 17, 2015 8:25 AM

Page 50 of 160

4-22

4

EBU30991Adjusting the rear shock absorber as-

sembly (YFM70RSSG)This shock absorber assembly is equipped with a

spring preload adjusting nut, a rebound damping

force adjusting screw, with a compression damp-

ing force adjusting bolt (for fast compression

damping), and a compression damping force ad-

justing screw (for slow compression damping).

WARNING

EWB02681Suspension components become hot during

operation. Never touch the compression

damping force adjusting bolt and screw, the

rebound damping force adjusting screw or the

oil reservoir with your bare hand or skin until

the suspension components have cooled. NOTICEECB00091Never turn an adjusting mechanism beyond

the minimum and maximum settings.

TIPAlthough the total number of clicks or turns of a

damping force adjusting mechanism may not ex-

actly match the following specifications due to

small differences in production, the actual number

of clicks or turns always represents the entire ad-

justing range. To obtain a precise adjustment, it

would be advisable to check the number of clicks

or turns of each damping force adjusting mecha-

nism and to modify the specifications as neces-

sary. Spring preload1. Loosen the locknut.

2. Turn the spring preload adjusting nut in direc- tion (a) to increase the spring preload and

thereby harden the suspension, and in direc-

tion (b) to decrease the spring preload and

thereby soften the suspension.

U2LS61E0.book Page 22 Friday, April 17, 2015 8:25 AM

Page 99 of 160

8-7

8

14*Drive chain roller • Check for wear and replace if necessary. √√√

15 *Chassis fasteners • Make sure that all nuts, bolts, and screws are

properly tightened. √√√√√

16 *Shock absorber as-

semblies • Check operation and correct if necessary.

• Check for oil leakage and replace if necessary.

√√√

17 *Rear suspension re-

lay arm and con-

necting arm

pivoting points • Check operation and correct if necessary.

• Lubricate with lithium-soap-based grease.

√√√√

18 *Steering shaft • Lubricate with lithium-soap-based grease. √√√

19 *Steering system • Check operation and repair or replace if dam-

aged.

• Check toe-in and adjust if necessary. √√√√√

20 *Engine mount • Check for cracks or other damage, and replace if

necessary. √√√

21 Engine oil • Change.

• Check ATV for oil leakage, and correct if neces-

sary. √ √√√

22 Engine oil filter ele-

ment • Replace.

√√√

NO. ITEM

CHECK OR MAINTENANCE

JOB INITIAL EVERY

Whichev- er comes first month136612

km (mi) 320

(200) 1300

(800) 2500

(1600) 2500

(1600) 5000

(3200)

hours 20 80 160 160 320U2LS61E0.book Page 7 Friday, April 17, 2015 8:25 AM

Page 135 of 160

8-43

8

EBU25005Lubricating the rear suspension relay

arm and connecting arm pivoting

pointsThe rear suspension relay arm and connecting

arm pivoting points must be lubricated at the inter-

vals specified in the periodic maintenance and lu-

brication chart.TIPFor parts equipped with a grease nipple, use a

grease gun. Recommended lubricant:Lithium-soap-based grease

1. Grease nipple

1. Grease nipple

1

1

U2LS61E0.book Page 43 Friday, April 17, 2015 8:25 AM

Page 154 of 160

10-4

10

Rim size:9 x 8.0ATFront brake:Type:

Disc brake

Operation: Right hand operation

Specified brake fluid: DOT 4Rear brake:Type:Disc brake

Operation: Right foot operation

Specified brake fluid:

DOT 4Front suspension:Type:Double wishbone

Spring/shock absorber type:

Coil spring/gas-oil damper

Wheel travel: 230 mm (9.1 in)Rear suspension:Type:

Swingarm (link suspension)

Spring/shock absorber type: Coil spring/gas-oil damper

Wheel travel: 256 mm (10.1 in)

Electrical system:Ignition system:TCI

Charging system:

AC magnetoBattery:Model:GT9B-4

Voltage, capacity:

12 V, 8.0 AhHeadlight:Bulb type:Krypton bulbBulb voltage, wattage × quantity:Headlight:

12 V, 30.0/30.0 W × 2

Tail/brake light: LED

Neutral indicator light:

LED

Fuel level warning light: LED

Reverse indicator light: LED

Coolant temperature warning light:

LED

Engine trouble warning light: LEDFuses:Main fuse:

30.0 A

U2LS61E0.book Page 4 Friday, April 17, 2015 8:25 AM