torque YAMAHA YFM80 2002 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2002, Model line: YFM80, Model: YAMAHA YFM80 2002Pages: 336, PDF Size: 3.94 MB

Page 105 of 336

5-17

EBU00151

Throttle lever

Check to see that the throttle lever operates cor-

rectly. It must open smoothly and spring back to

idle position when released. Repair as neces-

sary for proper operation.

EBU00152

Fittings and Fasteners

Always check the tightness of chassis fittings

and fasteners before a ride. Take the machine

to a Yamaha dealer or refer to the Service

Manual for correct tightening torque.

EBU00154

Switches

Check the operation of the start switch, engine

stop switch and any other switches. Repair as

necessary for proper operation.

EBU00499

Battery

Check fluid level and fill if necessary. Use only

distilled water if refilling is necessary. (See

pages 8-57 ~ 8-63.)

5NE-9-61 4~5 4/26/01 1:26 PM Page 40

Page 235 of 336

8-3

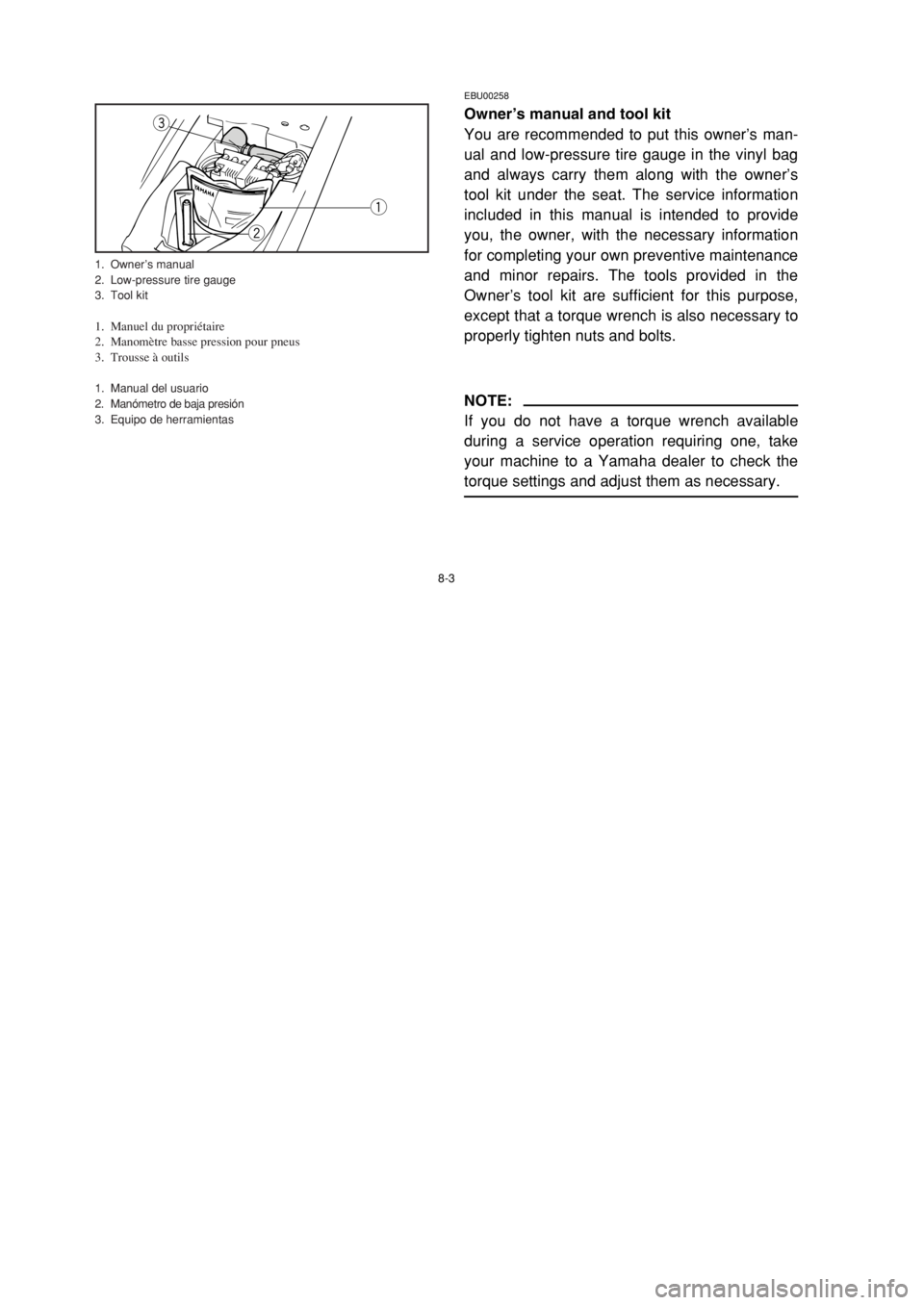

EBU00258

Owner’s manual and tool kit

You are recommended to put this owner’s man-

ual and low-pressure tire gauge in the vinyl bag

and always carry them along with the owner’s

tool kit under the seat. The service information

included in this manual is intended to provide

you, the owner, with the necessary information

for completing your own preventive maintenance

and minor repairs. The tools provided in the

Owner’s tool kit are sufficient for this purpose,

except that a torque wrench is also necessary to

properly tighten nuts and bolts.

NOTE:

If you do not have a torque wrench available

during a service operation requiring one, take

your machine to a Yamaha dealer to check the

torque settings and adjust them as necessary.

q

w

e

1. Owner’s manual

2. Low-pressure tire gauge

3. Tool kit

1. Manuel du propriétaire

2. Manomètre basse pression pour pneus

3. Trousse à outils

1. Manual del usuario

2. Manómetro de baja presión

3. Equipo de herramientas

5NE-9-61 8 4/26/01 1:29 PM Page 2

Page 247 of 336

8-15

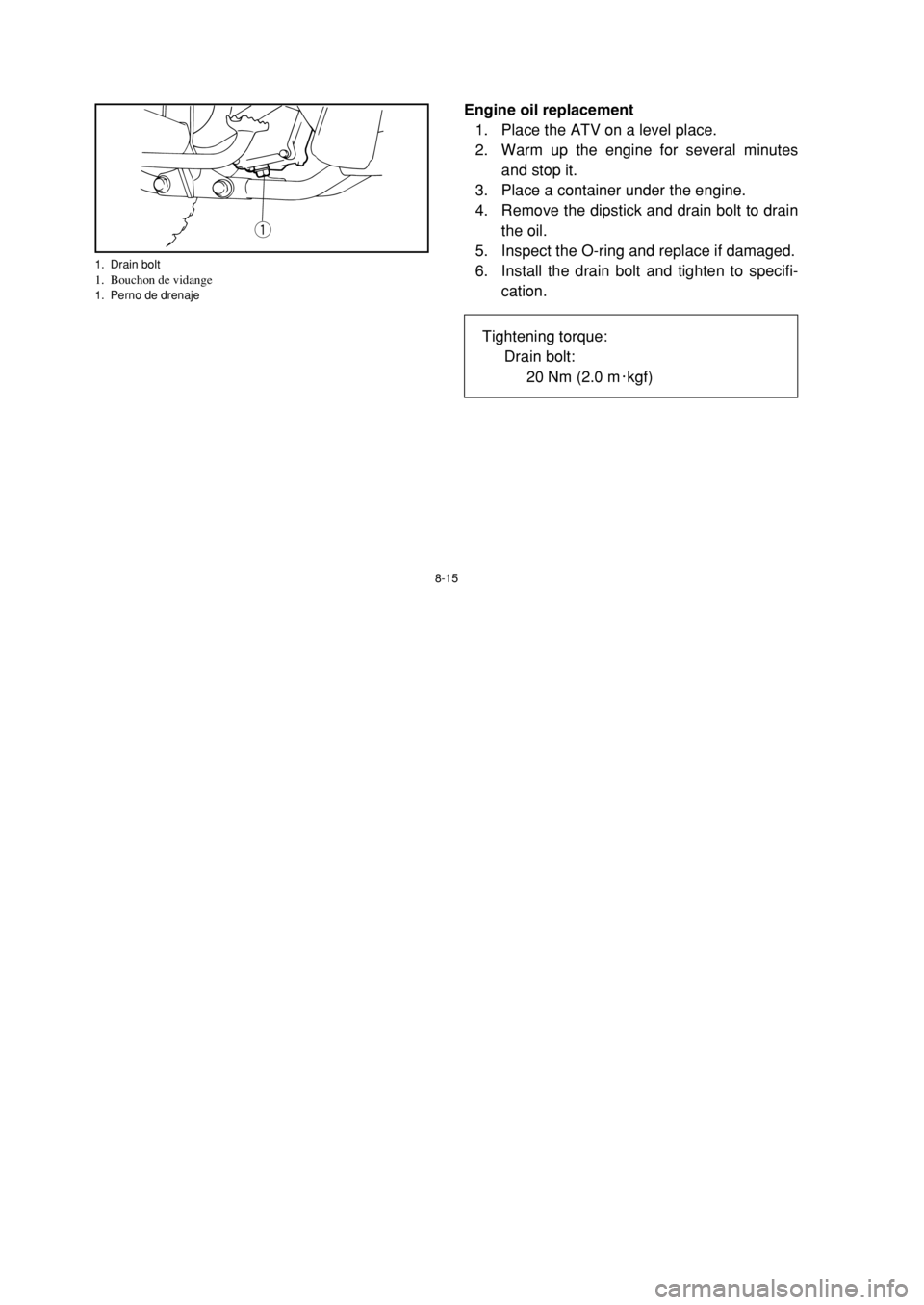

Engine oil replacement

1. Place the ATV on a level place.

2. Warm up the engine for several minutes

and stop it.

3. Place a container under the engine.

4. Remove the dipstick and drain bolt to drain

the oil.

5. Inspect the O-ring and replace if damaged.

6. Install the drain bolt and tighten to specifi-

cation.

q

1. Drain bolt1. Bouchon de vidange1. Perno de drenaje

Tightening torque:

Drain bolt:

20 Nm (2.0 m0kgf)

5NE-9-61 8 4/26/01 1:29 PM Page 14

Page 253 of 336

8-21

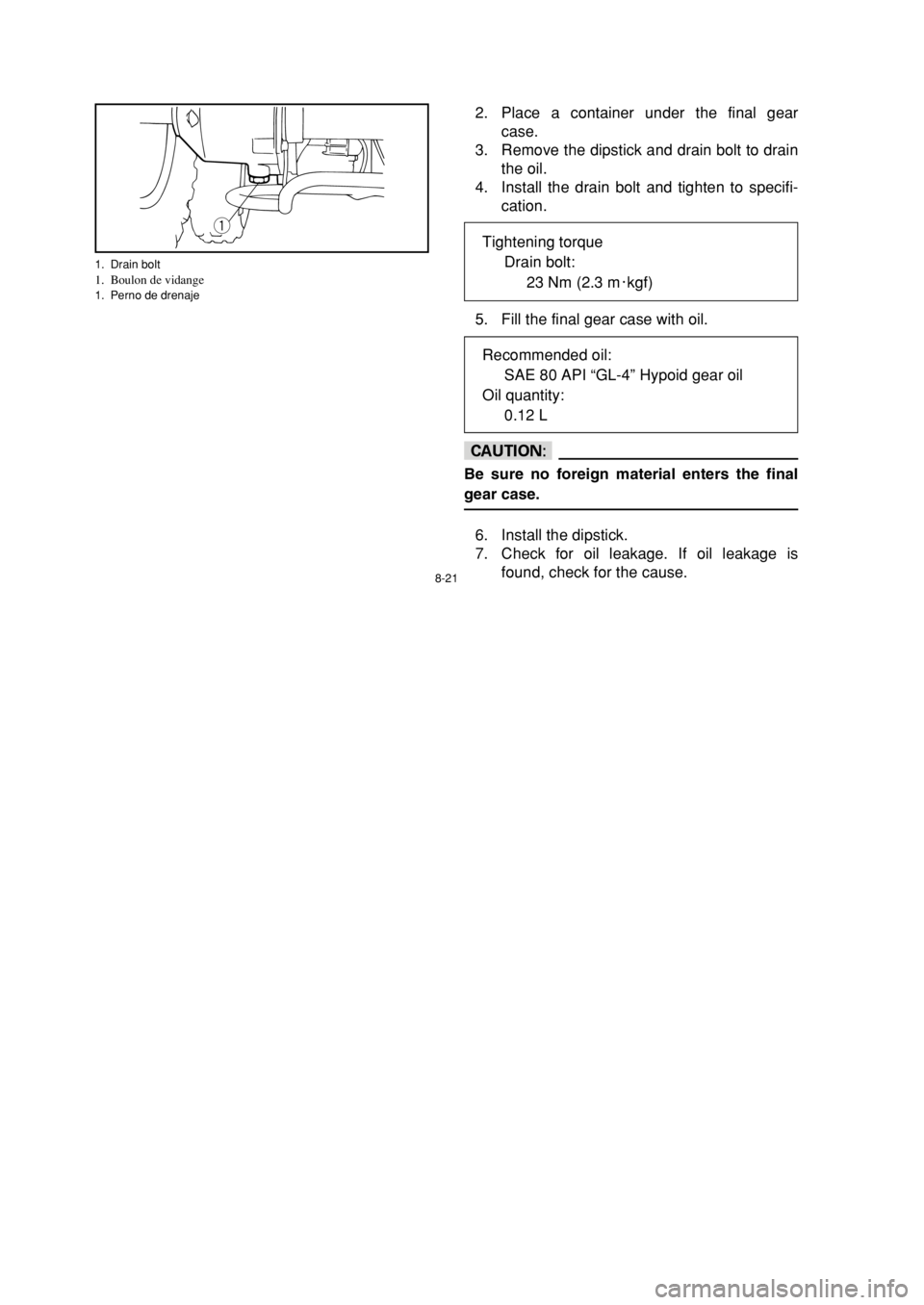

2. Place a container under the final gear

case.

3. Remove the dipstick and drain bolt to drain

the oil.

4. Install the drain bolt and tighten to specifi-

cation.

5. Fill the final gear case with oil.

cC

Be sure no foreign material enters the final

gear case.

6. Install the dipstick.

7. Check for oil leakage. If oil leakage is

found, check for the cause.

q��

1. Drain bolt1. Boulon de vidange1. Perno de drenaje

Tightening torque

Drain bolt:

23 Nm (2.3 m0kgf)

Recommended oil:

SAE 80 API “GL-4” Hypoid gear oil

Oil quantity:

0.12 L

5NE-9-61 8 4/26/01 1:29 PM Page 20

Page 257 of 336

8-25

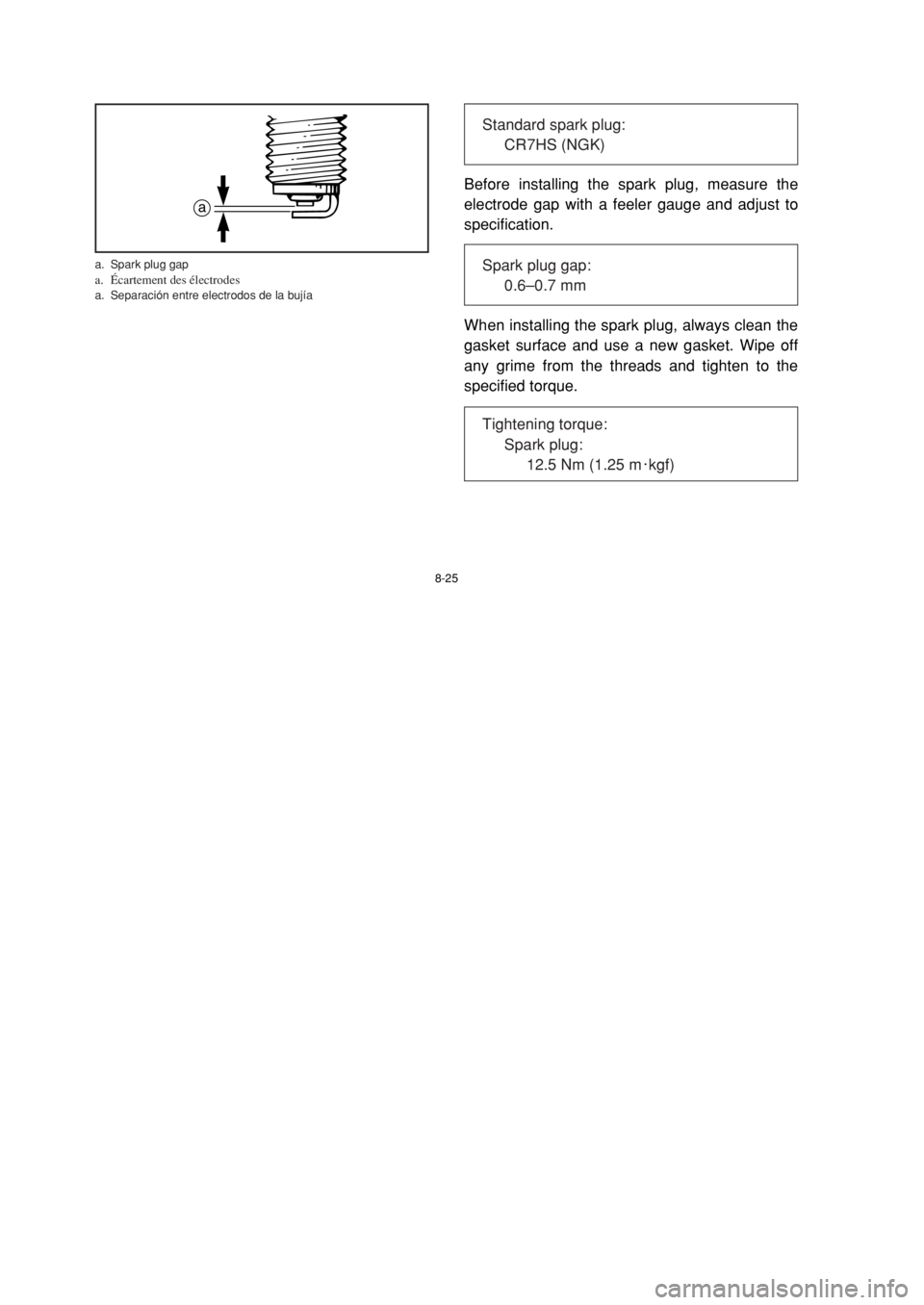

Before installing the spark plug, measure the

electrode gap with a feeler gauge and adjust to

specification.

When installing the spark plug, always clean the

gasket surface and use a new gasket. Wipe off

any grime from the threads and tighten to the

specified torque.

a

a. Spark plug gapa. Écartement des électrodesa. Separación entre electrodos de la bujía

Spark plug gap:

0.6–0.7 mm

Tightening torque:

Spark plug:

12.5 Nm (1.25 m0kgf)

Standard spark plug:

CR7HS (NGK)

5NE-9-61 8 4/26/01 1:29 PM Page 24

Page 281 of 336

8-49

EBU00872

Clutch adjustment

1. Remove the rubber cap.

2. Loosen the locknut.

3. Slowly turn the adjusting bolt clockwise

until resistance is felt. Then turn it 1/8

counterclockwise.

4. Tighten the locknut to the specified torque.

NOTE:

Turn the adjusting bolt clockwise to decrease

the clutch free play and turn it counterclockwise

to increase the free play.

5. Install the rubber cap securely.

qw

e

1. Rubber cap 2. Locknut 3. Adjusting bolt

1. Bouchon en caoutchouc

2. Contre-écrou 3. Boulon de réglage

1. Tapa de goma 2. Contratuerca 3. Perno de ajuste

Tightening torque:

8 Nm (0.8 m0kgf)

5NE-9-61 8 4/26/01 1:29 PM Page 48

Page 287 of 336

8-55

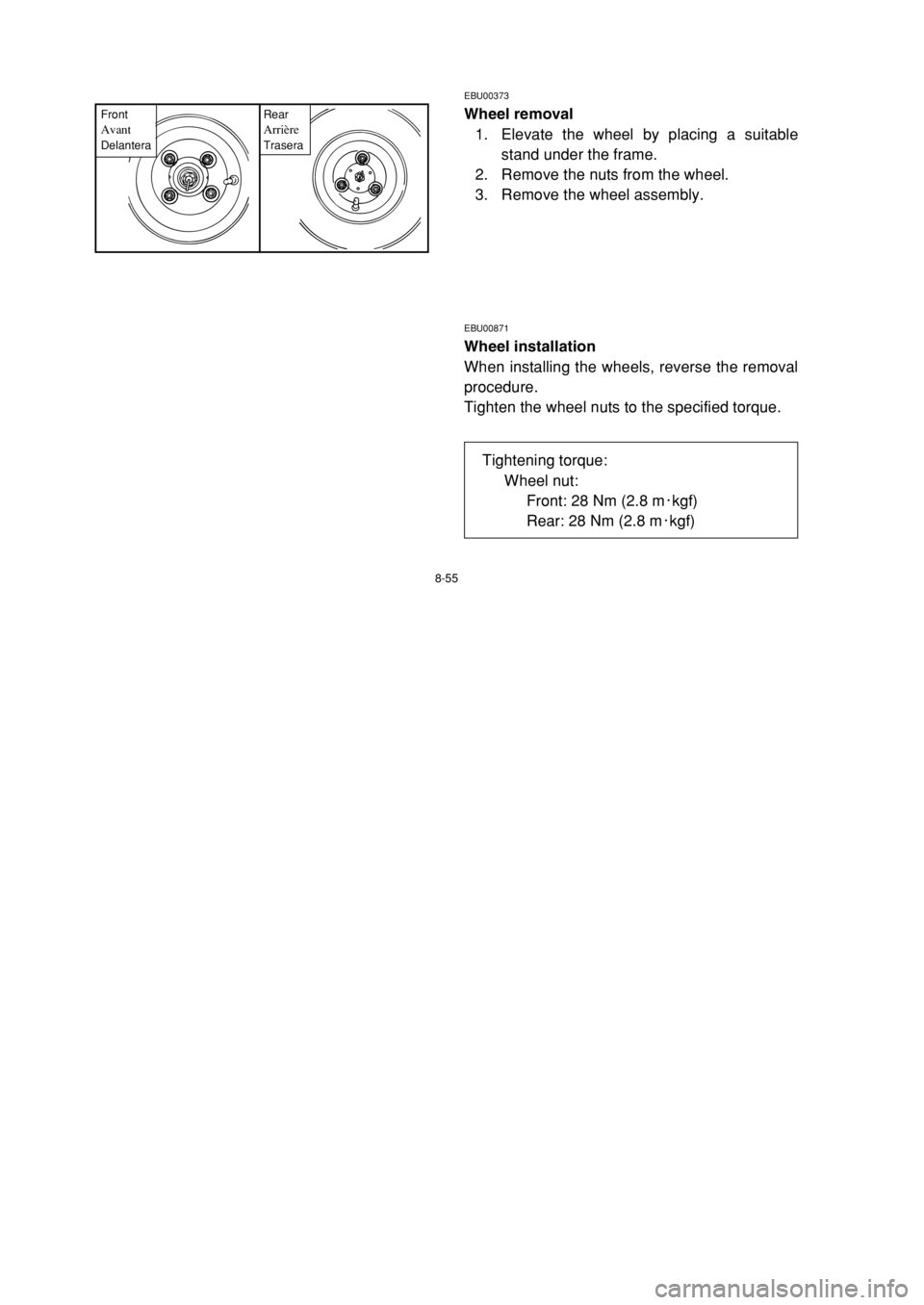

EBU00373

Wheel removal

1. Elevate the wheel by placing a suitable

stand under the frame.

2. Remove the nuts from the wheel.

3. Remove the wheel assembly.

EBU00871

Wheel installation

When installing the wheels, reverse the removal

procedure.

Tighten the wheel nuts to the specified torque.

Tightening torque:

Wheel nut:

Front: 28 Nm (2.8 m0kgf)

Rear: 28 Nm (2.8 m0kgf)

FrontAvantDelantera

RearArrièreTrasera

5NE-9-61 8 4/26/01 1:29 PM Page 54

Page 333 of 336

11-1

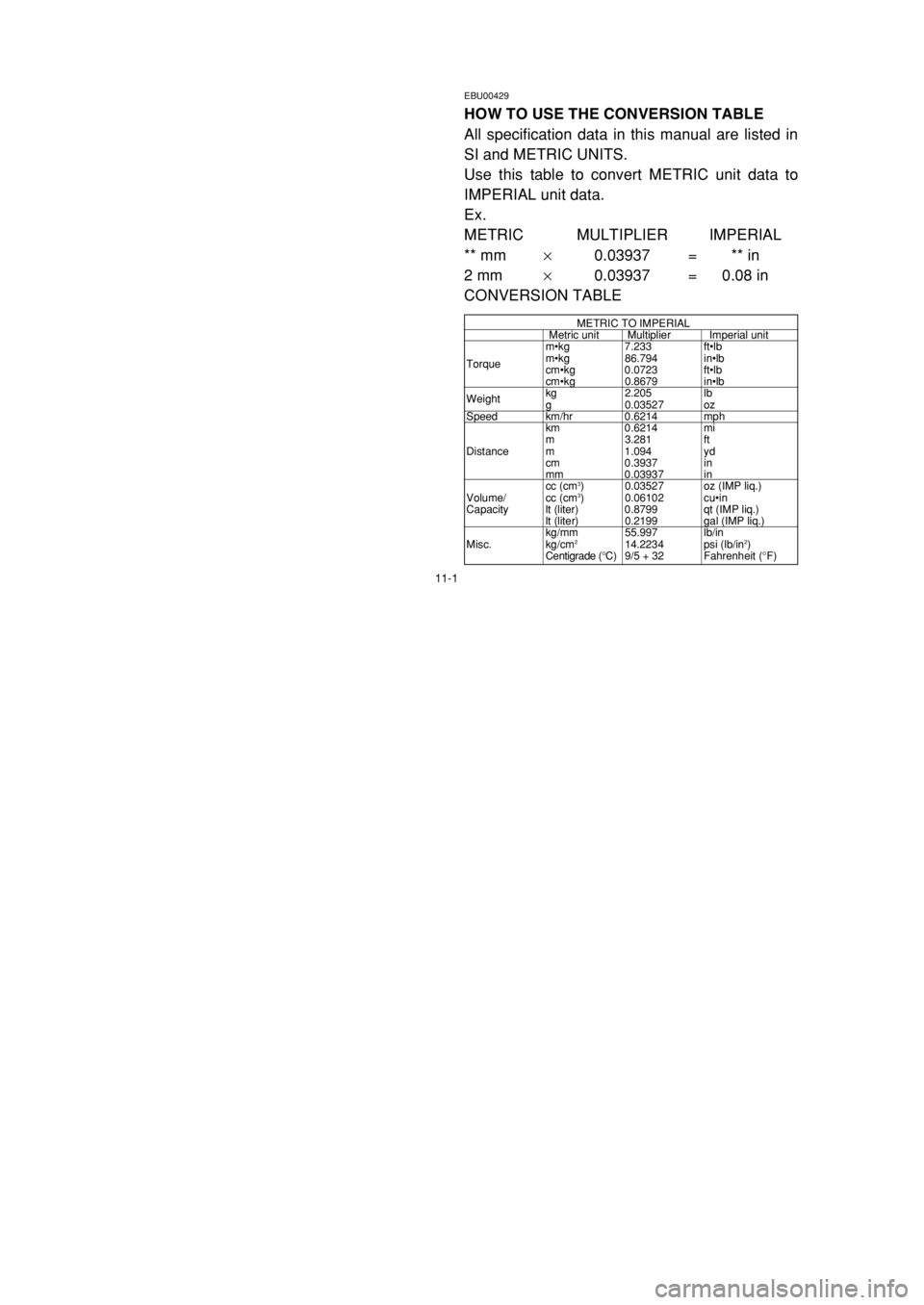

EBU00429

HOW TO USE THE CONVERSION TABLE

All specification data in this manual are listed in

SI and METRIC UNITS.

Use this table to convert METRIC unit data to

IMPERIAL unit data.

Ex.

METRIC MULTIPLIER IMPERIAL

** mm×0.03937 = ** in

2 mm×0.03937 = 0.08 in

CONVERSION TABLE

METRIC TO IMPERIAL

Metric unit Multiplier Imperial unit

m•kg 7.233 ft•lb

m•kg 86.794 in•lb

Torque

cm•kg 0.0723 ft•lb

cm•kg 0.8679 in•lb

kg 2.205 lb

Weight

g 0.03527 oz

Speed km/hr 0.6214 mph

km 0.6214 mi

m 3.281 ft

Distance m 1.094 yd

cm 0.3937 in

mm 0.03937 in

cc (cm

3) 0.03527 oz (IMP liq.)

Volume/ cc (cm3) 0.06102 cu•in

Capacity lt (liter) 0.8799 qt (IMP liq.)

lt (liter) 0.2199 gal (IMP liq.)

kg/mm 55.997 lb/in

Misc. kg/cm

214.2234 psi (lb/in2)

Centigrade (°C)9/5 + 32 Fahrenheit (°F)

5NE-9-61 9~ 4/26/01 1:30 PM Page 324