engine YAMAHA YFM80R 2003 Service Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2003, Model line: YFM80R, Model: YAMAHA YFM80R 2003Pages: 342, PDF Size: 5.84 MB

Page 251 of 342

8-15

Engine oil replacement

1. Place the ATV on a level place.

2. Warm up the engine for several minutes

and stop it.

3. Place a container under the engine.

4. Remove the dipstick and drain bolt to drain

the oil.

5. Inspect the O-ring and replace if damaged.

6. Install the drain bolt and tighten to specifi-

cation.

q

1. Drain bolt1. Bouchon de vidange1. Perno de drenaje

Tightening torque:

Drain bolt:

20 Nm (2.0 m0kgf)

5TH-9-61 8 4/17/02 4:46 PM Page 8-15

Page 253 of 342

8-17

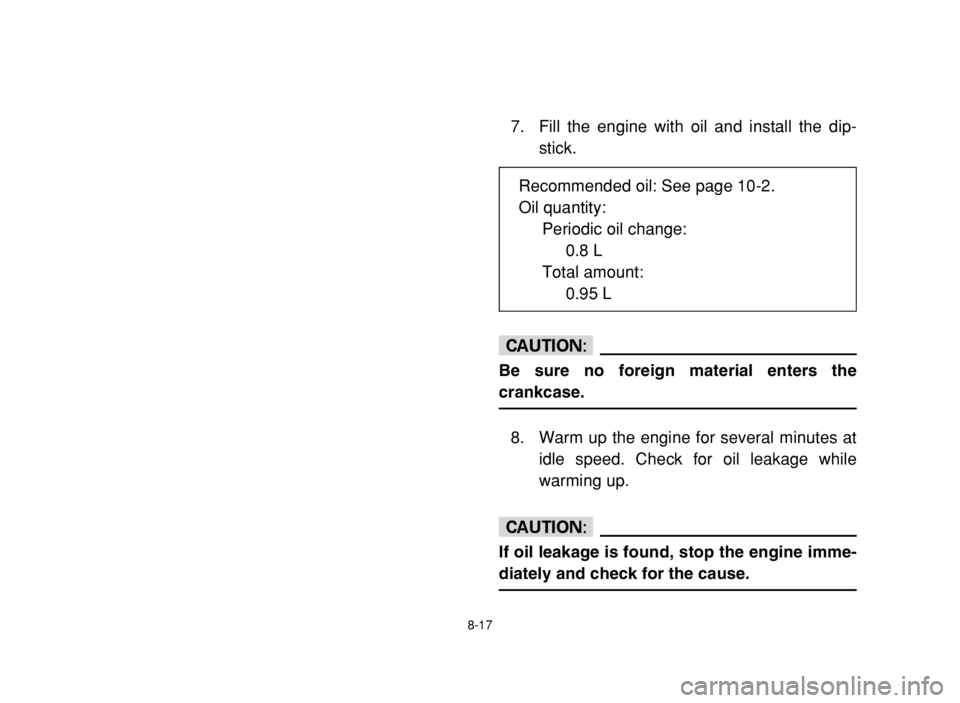

7. Fill the engine with oil and install the dip-

stick.

cC

Be sure no foreign material enters the

crankcase.

8. Warm up the engine for several minutes at

idle speed. Check for oil leakage while

warming up.

cC

If oil leakage is found, stop the engine imme-

diately and check for the cause.

Recommended oil: See page 10-2.

Oil quantity:

Periodic oil change:

0.8 L

Total amount:

0.95 L

5TH-9-61 8 4/17/02 4:46 PM Page 8-17

Page 259 of 342

8-23

EBU00870

Spark plug inspection

The spark plug is an important engine compo-

nent and is easy to inspect. The condition of the

spark plug can indicate the condition of the

engine.

For example, a very white center electrode

porcelain color could indicate an intake air leak

or carburetion problem for that cylinder. Do not

attempt to diagnose such problems yourself.

Instead, take the ATV to a Yamaha dealer. You

should periodically remove and inspect the

spark plug because heat and deposits will cause

the spark plug to slowly break down and erode.

If electrode erosion becomes excessive, you

should replace the spark plug with one of the

proper type.

5TH-9-61 8 4/17/02 4:46 PM Page 8-23

Page 265 of 342

w

q

1. Fastener 2. Air filter element1. Attache 2. Elément du filtre à air1. Sujeción 2. Elemento filtrante de aire

8-29

2. Remove the air filter case cover by

unhooking the fasteners.

3. Remove the air filter element by unhooking

the fastener.

4. Wash the air filter element gently but thor-

oughly in solvent.

w

Always use parts cleaning solvent to clean

the air filter element. Never use low flash

point solvents or gasoline to clean the air fil-

ter element because the engine could catch

fire or explode.

5. Squeeze the excess solvent out of the air

filter element and let it dry.

cC

Do not twist the air filter element when

squeezing it.

6. Inspect the air filter element. If damaged,

replace it.

7. Apply SAE10W30 motor oil to the air filter

element.

q

ww

1. Air filter case cover 2. Fastener (×4)1 . Couvercle du boîtier de filtre à air 2 .Attache (×4)1.Cubierta de la caja del filtro de aire2. Sujeción (×4)

5TH-9-61 8 4/17/02 4:46 PM Page 8-29

Page 267 of 342

8-31

NOTE:

The air filter element should be wet but not dripping.

8. Install the air filter element, the air filter

case cover and the front cover.

NOTE:

The air filter element should be cleaned every

20–40 hours. It should be cleaned and lubricat-

ed more often if the machine is operated in

extremely dusty areas. Each time air filter ele-

ment maintenance is performed, check the air

inlet of the air filter case for obstructions. Check

the air cleaner rubber joint to the carburetor and

manifold fittings for an air-tight seal. Tighten all

fittings securely to avoid the possibility of unfil-

tered air entering the engine.

cC

Never operate the engine with the air filter

element removed. This will allow unfiltered

air to enter, causing rapid engine wear and

possible engine damage. Additionally, opera-

tion without the filter element will affect car-

buretor jetting with subsequent poor perfor-

mance and possible engine overheating.

5TH-9-61 8 4/17/02 4:46 PM Page 8-31

Page 269 of 342

8-33

EBU01035

Air intake restrictor plate removal

To obtain full engine performance capability,

removing the air intake restrictor plate is

required.

1. Remove the air filter element. (See page

8-27 for removal and installation procedures.)

2. Remove the air intake restrictor plate.

NOTE:

Store the air intake restrictor plate with the

owner’s manual so you can install it whenever

you want to reduce the top speed available.

3. Install the air filter element.

q

1. Air intake restrictor plate1. Cache réducteur d’air admis1. Placa de restricción de admisión de aire

5TH-9-61 8 4/17/02 4:46 PM Page 8-33

Page 271 of 342

EBU00296

Carburetor adjustment

The carburetor is a vital part of the engine and

requires very sophisticated adjustment. Most

adjusting should be left to a Yamaha dealer who

has the professional knowledge and experience

to do so. However, the idling speed may be per-

formed by the owner as a part of the usual main-

tenance routine.

cC

The carburetor was set at the Yamaha facto-

ry after many tests. If the settings are dis-

turbed by someone without sufficient techni-

cal knowledge, poor engine performance and

damage may result.

8-35

5TH-9-61 8 4/17/02 4:46 PM Page 8-35

Page 273 of 342

8-37

EBU01143

Idle speed adjustment

NOTE:

A diagnostic tachometer must be used for this

procedure.

1. Start the engine and warm it up for a few

minutes at approximately 1,000 to 2,000

r/min. Occasionally rev the engine to 4,000

to 5,000 r/min. The engine is warm when it

quickly responds to the throttle.

2. Connect the tachometer and set the idle to

the specified idling speed by adjusting the

throttle stop screw. Turn the screw in direc-

tion ato increase the engine speed, and

in direction bto decrease the engine

speed.q

a b

1. Throttle stop screw1. Vis de butée de papillon1. Tornillo tope del acelerador

Specified idle speed:

1,700–1,900 r/min

5TH-9-61 8 4/17/02 4:46 PM Page 8-37

Page 275 of 342

8-39

EBU00303

Valve clearance adjustment

The correct valve clearance changes with use,

resulting in improper fuel/air supply or engine

noise. To prevent this, the valve clearance must

be adjusted regularly. This adjustment however,

should be left to a professional Yamaha service

technician.

EBU00304

Cam chain adjustment

The cam chain becomes loose with use, result-

ing in improper valve timing and engine noise.

To prevent this, the cam chain tensioner must

be adjusted regularly. This adjustment should be

left to a Yamaha service technician.

5TH-9-61 8 4/17/02 4:46 PM Page 8-39

Page 289 of 342

8-53

EBU00570

Cable inspection and lubrication

w

Inspect cables frequently and replace if dam-

aged. Corrosion can result when the outer

covering of control cables becomes dam-

aged. Cables can also become frayed or

kinked. Operation of controls could be

restricted, which could cause an accident or

injury.

Lubricate the inner cables and the cable ends. If

the cables do not operate smoothly, ask a

Yamaha dealer to replace them.

Recommended lubricant:

Engine oil

5TH-9-61 8 4/17/02 4:46 PM Page 8-53