torque YAMAHA YFM90R 2020 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: YFM90R, Model: YAMAHA YFM90R 2020Pages: 126, PDF Size: 5.66 MB

Page 87 of 126

8-10

8

2. Check the spark plug for electrode erosion

and excessive carbon or other deposits, and

replace it if necessary.

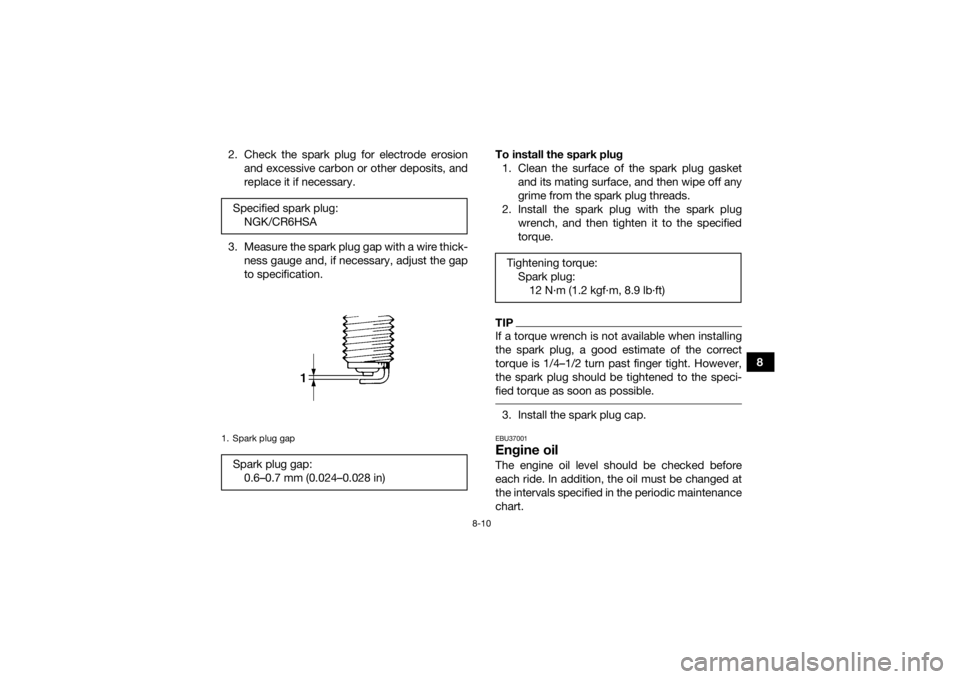

3. Measure the spark plug gap with a wire thick- ness gauge and, if necessary, adjust the gap

to specification. To install the spark plug

1. Clean the surface of the spark plug gasket and its mating surface, and then wipe off any

grime from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tighten it to the specified

torque.

TIPIf a torque wrench is not available when installing

the spark plug, a good estimate of the correct

torque is 1/4–1/2 turn past finger tight. However,

the spark plug should be tightened to the speci-

fied torque as soon as possible. 3. Install the spark plug cap.EBU37001Engine oilThe engine oil level should be checked before

each ride. In addition, the oil must be changed at

the intervals specified in the periodic maintenance

chart.

Specified spark plug:

NGK/CR6HSA

1. Spark plug gapSpark plug gap:0.6–0.7 mm (0.024–0.028 in)

Tightening torque:Spark plug:12 N·m (1.2 kgf·m, 8.9 lb·ft)

UBD364E0.book Page 10 Monday, January 28, 2019 9:30 AM

Page 89 of 126

8-12

8

2. Start the engine, warm it up for several minu-

tes, and then turn it off.

3. Place an oil pan under the engine to collect the used oil.

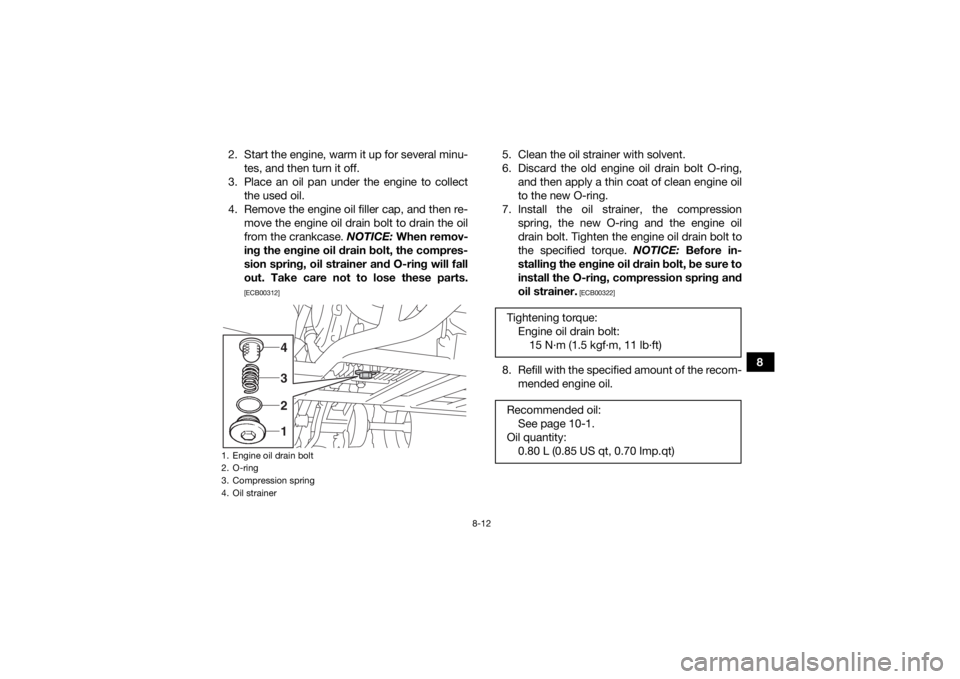

4. Remove the engine oil filler cap, and then re- move the engine oil drain bolt to drain the oil

from the crankcase. NOTICE: When remov-

ing the engine oil drain bolt, the compres-

sion spring, oil strainer and O-ring will fall

out. Take care not to lose these parts.

[ECB00312]

5. Clean the oil strainer with solvent.

6. Discard the old engine oil drain bolt O-ring, and then apply a thin coat of clean engine oil

to the new O-ring.

7. Install the oil strainer, the compression spring, the new O-ring and the engine oil

drain bolt. Tighten the engine oil drain bolt to

the specified torque. NOTICE: Before in-

stalling the engine oil drain bolt, be sure to

install the O-ring, compression spring and

oil strainer.

[ECB00322]

8. Refill with the specified amount of the recom- mended engine oil.

1. Engine oil drain bolt

2. O-ring

3. Compression spring

4. Oil strainer

4321

Tightening torque:Engine oil drain bolt:15 N·m (1.5 kgf·m, 11 lb·ft)

Recommended oil: See page 10-1.

Oil quantity: 0.80 L (0.85 US qt, 0.70 Imp.qt)

UBD364E0.book Page 12 Monday, January 28, 2019 9:30 AM

Page 92 of 126

8-15

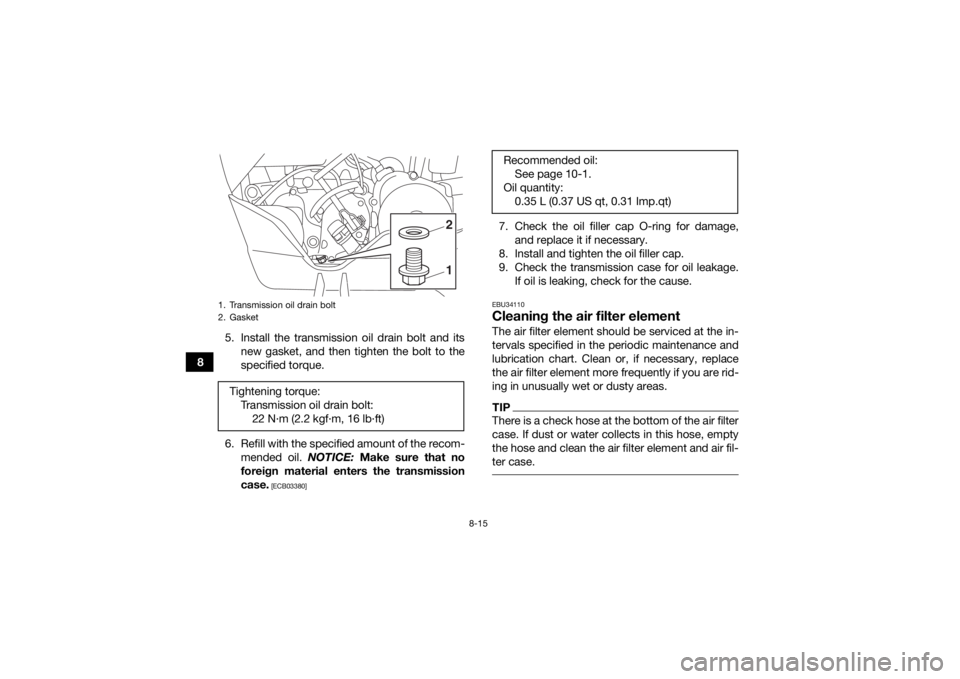

85. Install the transmission oil drain bolt and its

new gasket, and then tighten the bolt to the

specified torque.

6. Refill with the specified amount of the recom- mended oil. NOTICE: Make sure that no

foreign material enters the transmission

case.

[ECB03380]

7. Check the oil filler cap O-ring for damage, and replace it if necessary.

8. Install and tighten the oil filler cap.

9. Check the transmission case for oil leakage. If oil is leaking, check for the cause.EBU34110Cleaning the air filter elementThe air filter element should be serviced at the in-

tervals specified in the periodic maintenance and

lubrication chart. Clean or, if necessary, replace

the air filter element more frequently if you are rid-

ing in unusually wet or dusty areas.TIPThere is a check hose at the bottom of the air filter

case. If dust or water collects in this hose, empty

the hose and clean the air filter element and air fil-

ter case.

1. Transmission oil drain bolt

2. GasketTightening torque:Transmission oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

12

Recommended oil:See page 10-1.

Oil quantity: 0.35 L (0.37 US qt, 0.31 Imp.qt)

UBD364E0.book Page 15 Monday, January 28, 2019 9:30 AM

Page 96 of 126

8-19

83. Tap the spark arrester lightly, and then use a

wire brush to remove any carbon deposits.

4. Insert the spark arrester into the muffler and align the bolt hole.

5. Install the tailpipe bolt and nut, and then tight- en the nut to the specified torque.

WARNING

EWB02342Always let the exhaust system cool prior to

touching exhaust components.

Do not start the engine with the spark arrester

removed. Sparks or exhaust particulate can

cause eye injury, burns, or start a fire. EBU23941Adjusting the carburetorThe carburetor should be checked and, if neces-

sary, adjusted at the intervals specified in the pe-

riodic maintenance and lubrication chart. The

carburetor is an important part of the engine and

requires very sophisticated adjustment. There-

fore, most carburetor adjustments should be left to a Yamaha dealer, who has the necessary pro-

fessional knowledge and experience. The adjust-

ment described in the following section, however,

may be performed by the owner as part of routine

maintenance.

NOTICEECB00481The carburetor has been set and extensively

tested at the Yamaha factory. Changing these

settings without sufficient technical knowl-

edge may result in poor performance of or

damage to the engine. EBU24001Adjusting the engine idling speedThe engine idling speed must be checked and, if

necessary, adjusted as follows at the intervals

specified in the periodic maintenance and lubrica-

tion chart.TIPA diagnostic tachometer is needed to make this

adjustment. 1. Start the engine and warm it up.

Tightening torque:

Tailpipe nut:10 N·m (1.0 kgf·m, 7.4 lb·ft)

UBD364E0.book Page 19 Monday, January 28, 2019 9:30 AM

Page 104 of 126

8-27

84. To tighten the drive chain, turn the drive chain

slack adjusting nut in direction (a). To loosen

the drive chain, turn the adjusting nut in direc-

tion (b) and push the rear wheels forward.

NOTICE: Improper drive chain slack will

overload the engine as well as other vital

parts of the ATV and can lead to drive

chain slippage or breakage. To prevent

this from occurring, keep the drive chain

slack within the specified limits.

[ECB00543]

5. Tighten the locknut, and then the bolts and nuts to their specified torques.

6. Adjust the rear brake lever free play. (See page 8-24.)

EBU24883Lubricating the drive chainThe drive chain must be cleaned and lubricated at

the intervals specified in the periodic maintenance

and lubrication chart, otherwise it will quickly wear

out, especially when riding in dusty or wet areas.

Service the drive chain as follows.NOTICEECB00562The drive chain must be lubricated after wash-

ing the ATV or riding in the rain or wet areas. 1. Clean the drive chain with kerosene and asmall soft brush. NOTICE: To prevent dam-

aging the O-rings, do not clean the drive

chain with steam cleaners, high-pressure

washers or inappropriate solvents.

[ECB00572]

Tightening torques: Locknut:22 N·m (2.2 kgf·m, 16 lb·ft)

Bolt: 45 N·m (4.5 kgf·m, 33 lb·ft)

Nut: 54 N·m (5.4 kgf·m, 40 lb·ft)

UBD364E0.book Page 27 Monday, January 28, 2019 9:30 AM

Page 113 of 126

8-36

8

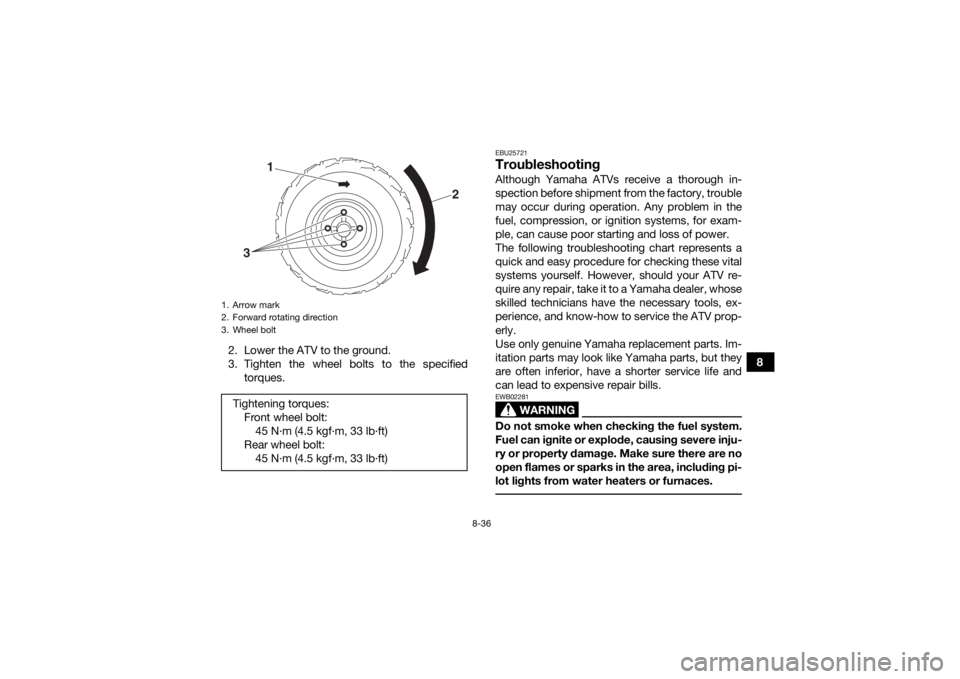

2. Lower the ATV to the ground.

3. Tighten the wheel bolts to the specified

torques.

EBU25721TroubleshootingAlthough Yamaha ATVs receive a thorough in-

spection before shipment from the factory, trouble

may occur during operation. Any problem in the

fuel, compression, or ignition systems, for exam-

ple, can cause poor starting and loss of power.

The following troubleshooting chart represents a

quick and easy procedure for checking these vital

systems yourself. However, should your ATV re-

quire any repair, take it to a Yamaha dealer, whose

skilled technicians have the necessary tools, ex-

perience, and know-how to service the ATV prop-

erly.

Use only genuine Yamaha replacement parts. Im-

itation parts may look like Yamaha parts, but they

are often inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWB02281Do not smoke when checking the fuel system.

Fuel can ignite or explode, causing severe inju-

ry or property damage. Make sure there are no

open flames or sparks in the area, including pi-

lot lights from water heaters or furnaces.

1. Arrow mark

2. Forward rotating direction

3. Wheel boltTightening torques:Front wheel bolt:45 N·m (4.5 kgf·m, 33 lb·ft)

Rear wheel bolt: 45 N·m (4.5 kgf·m, 33 lb·ft)3

1

2

UBD364E0.book Page 36 Monday, January 28, 2019 9:30 AM