YAMAHA YFZ50 2020 Owners Manual

Manufacturer: YAMAHA, Model Year: 2020, Model line: YFZ50, Model: YAMAHA YFZ50 2020Pages: 126, PDF Size: 5.44 MB

Page 111 of 126

8-36

8

3. Remove the blown fuse, and then install a

new fuse of the specified amperage.

WARNING! Always use a fuse of the spec- ified rating, and never use a substitute ob-

ject in place of the proper fuse. An

improper fuse or a substitute object can

cause damage to the electrical system,

which could lead to a fire.

[EWB02173]

4. Turn on the main switch and start the engine.

5. Install the panel.

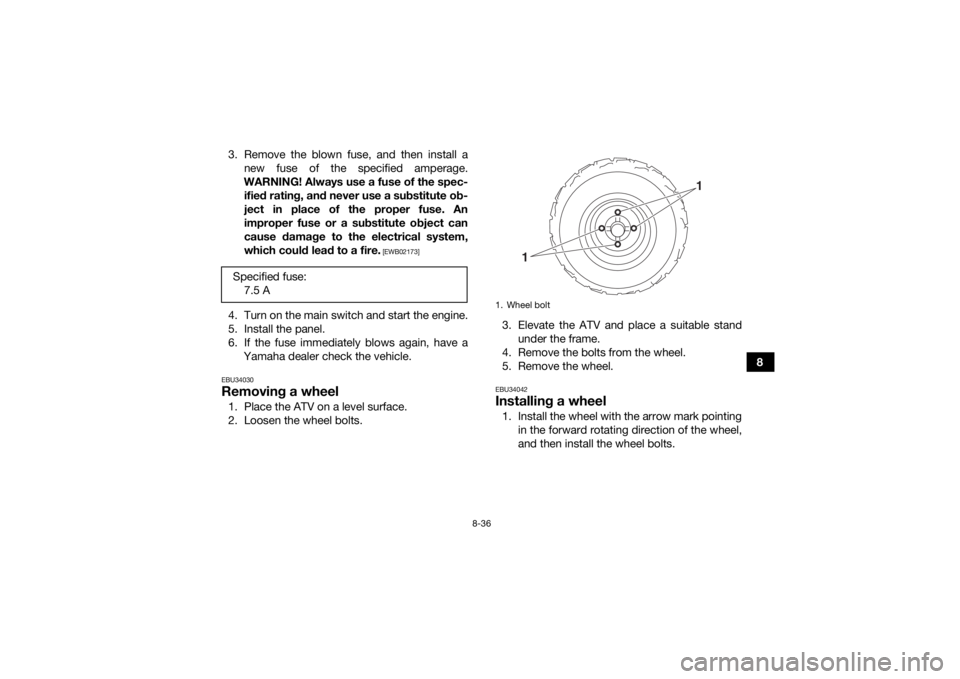

6. If the fuse immediately blows again, have a Yamaha dealer check the vehicle.EBU34030Removing a wheel1. Place the ATV on a level surface.

2. Loosen the wheel bolts. 3. Elevate the ATV and place a suitable stand

under the frame.

4. Remove the bolts from the wheel.

5. Remove the wheel.

EBU34042Installing a wheel1. Install the wheel with the arrow mark pointing in the forward rotating direction of the wheel,

and then install the wheel bolts.

Specified fuse:

7.5 A1. Wheel bolt

1

1

UBW463E0.book Page 36 Monday, January 28, 2019 10:22 AM

Page 112 of 126

8-37

82. Lower the ATV to the ground.

3. Tighten the wheel bolts to the specified

torques.

EBU25721TroubleshootingAlthough Yamaha ATVs receive a thorough in-

spection before shipment from the factory, trouble

may occur during operation. Any problem in the

fuel, compression, or ignition systems, for exam-

ple, can cause poor starting and loss of power.

The following troubleshooting chart represents a

quick and easy procedure for checking these vital

systems yourself. However, should your ATV re-

quire any repair, take it to a Yamaha dealer, whose

skilled technicians have the necessary tools, ex-

perience, and know-how to service the ATV prop-

erly.

Use only genuine Yamaha replacement parts. Im-

itation parts may look like Yamaha parts, but they

are often inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWB02281Do not smoke when checking the fuel system.

Fuel can ignite or explode, causing severe inju-

ry or property damage. Make sure there are no

open flames or sparks in the area, including pi-

lot lights from water heaters or furnaces.

1. Arrow mark

2. Forward rotating direction

3. Wheel boltTightening torques:Front wheel bolt:45 N·m (4.5 kgf·m, 33 lb·ft)

Rear wheel bolt: 45 N·m (4.5 kgf·m, 33 lb·ft)3

1

2

UBW463E0.book Page 37 Monday, January 28, 2019 10:22 AM

Page 113 of 126

8-38

8

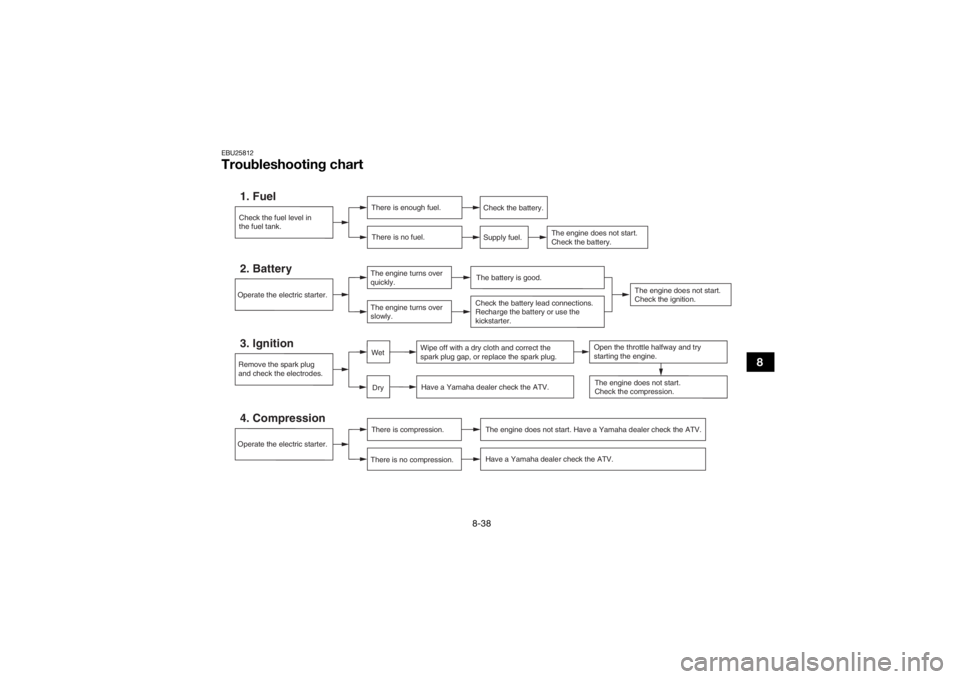

EBU25812Troubleshooting chart

Check the fuel level in

the fuel tank.1. Fuel

There is enough fuel.There is no fuel.

Check the battery.

Supply fuel.

The engine does not start.

Check the battery.

The engine does not start.

Check the ignition.

Operate the electric starter.4. Compression

There is compression.

There is no compression.

The engine does not start. Have a Yamaha dealer check the ATV.Have a Yamaha dealer check the ATV.

Remove the spark plug

and check the electrodes.3. Ignition

Wipe off with a dry cloth and correct the

spark plug gap, or replace the spark plug.

Have a Yamaha dealer check the ATV.

The engine does not start.

Check the compression.

Operate the electric starter.2. Battery

The engine turns over

quickly.

The engine turns over

slowly.

The battery is good.Check the battery lead connections.

Recharge the battery or use the

kickstarter.

DryWet

Open the throttle halfway and try

starting the engine.

UBW463E0.book Page 38 Monday, January 28, 2019 10:22 AM

Page 114 of 126

9-1

9

EBU25861

CLEANING AND STORAGE

EBU25903CleaningFrequent, thorough cleaning of your ATV will not

only enhance its appearance but will improve its

general performance and extend the useful life of

many components.1. Before cleaning the ATV: a. Block off the end of the exhaust pipe toprevent water entry. A plastic bag and

strong rubber band may be used.

b. Make sure the spark plug and all filler caps are properly installed.

2. If the engine case is excessively greasy, apply degreaser with a paint brush. Do not apply

degreaser to the chain, sprockets or wheel

axles.

3. Rinse the dirt and degreaser off with a garden hose. Use only enough pressure to do the

job. WARNING! Wet brakes may have re-

duced stopping ability, increasing the

chance of an accident. Test the brakes af-

ter washing. Apply the brakes several

times at slow speeds to let friction dry out

the linings.

[EWB02312]

NOTICE: Excessive wa- ter pressure may cause water seepage

and deterioration of wheel bearings,

brakes, transmission seals and electrical

devices. Many expensive repair bills have

resulted from improper high-pressure de-

tergent applications such as those avail-

able in coin-operated car washers.

[ECB00712]

4. Once most of the dirt has been hosed off,

wash all surfaces with warm water and mild,

detergent-type soap. An old toothbrush or

bottle brush is handy for hard-to-reach plac-

es.

5. Rinse the ATV off immediately with clean wa- ter and dry all surfaces with a chamois, clean

towel or soft absorbing cloth.

6. Dry the chain and lubricate it to prevent it from rusting.

7. Clean the seat with a vinyl upholstery cleaner to keep the cover pliable and glossy.

8. Automotive type wax may be applied to all painted and chrome plated surfaces. Avoid

combination cleaner-waxes. Many contain

UBW463E0.book Page 1 Monday, January 28, 2019 10:22 AM

Page 115 of 126

9-2

9

abrasives which may mar the paint or protec-

tive finish. When finished cleaning, start the

engine and let it idle for several minutes.

EBU30362StorageShort-term

Always store your ATV in a cool, dry place and, if

necessary, protect it against dust with a porous

cover.

NOTICE: Storing the ATV in a poorly ven-

tilated room or covering it with a tarp while it is

still wet, will allow water and humidity to seep

in and cause rust. To prevent corrosion, avoid

damp cellars, stables (because of the presence

of ammonia) and areas where strong chemi-

cals are stored.

[ECB00722]

Long-term

Before storing your ATV for several months: 1. Make any necessary repairs and perform all outstanding maintenance.

2. Follow all the instructions in the Cleaning sec- tion of this chapter. 3. Fill up the fuel tank and add fuel stabilizer (Fu-

el Med Rx if available), and then run the en-

gine for 5 minutes to distribute the treated

fuel.

4. Turn the fuel cock lever off, and then drain the carburetor float chamber by loosening the

drain bolt. Pour the drained fuel into the fuel

tank.

5. Perform the following steps to protect the en- gine from internal corrosion.a. Remove the spark plug cap and spark plug.

b. Pour a teaspoonful of engine oil into the spark plug bore.

c. Install the spark plug cap onto the spark plug, and then place the spark plug on the

cylinder head so that the electrodes are

grounded. (This will limit sparking during

the next step.)

d. Turn the engine over several times with the starter. (This will coat the cylinder wall

with oil.)

Specified amount:

7.5 ml per liter of fuel (1 oz per gallon)UBW463E0.book Page 2 Monday, January 28, 2019 10:22 AM

Page 116 of 126

9-3

9e. Install the spark plug and the spark plug

cap.

6. Lubricate all control cables and the pivoting points of all levers.

7. Put the frame on stands or blocks to raise all wheels off the ground. (Alternatively, turn the

wheels each month to prevent the tires from

degrading in one spot.)

8. Cover the muffler outlet with a plastic bag to prevent moisture from entering it.

9. Remove the battery and fully charge it. (See page 8-32.)

UBW463E0.book Page 3 Monday, January 28, 2019 10:22 AM

Page 117 of 126

10-1

10

EBU25963

SPECIFICATIONS

Dimensions:Overall length:1250 mm (49.2 in)

Overall width: 820 mm (32.3 in)

Overall height:

770 mm (30.3 in)

Seat height: 585 mm (23.0 in)

Wheelbase: 830 mm (32.7 in)

Ground clearance:

125 mm (4.9 in)

Minimum turning radius: 2.3 m (7.55 ft)

Maximum water depth: 11 cm (4 in)Weight:Curb weight:100.0 kg (220 lb)Loading:Maximum loading limit:

41.0 kg (90 lb)

(Total weight of rider, cargo, accessories, and tongue)Noise and vibration level:Noise level (77/311/EEC):74.0 dB(A) at 3625 r/min Uncertainty of measurement:

0.3 dB(A)

Vibration on seat (EN1032, ISO5008): Will not exceed 0.5 m/s²

Uncertainty of measurement: 0.1 m/s²

Vibration on handle (EN1032, ISO5008):

4.6 m/s²

Uncertainty of measurement: 0.4 m/s²

Engine:Combustion cycle:

4-stroke

Cooling system: Air cooled

Valve train: SOHC

Number of cylinders:

Single cylinder

Displacement: 49 cm³

Bore × stroke:

39.0 × 41.4 mm (1.54 × 1.63 in)

Compression ratio:

8.5 : 1

Starting system: Electric starter and kickstarter

Lubrication system: Wet sump

UBW463E0.book Page 1 Monday, January 28, 2019 10:22 AM

Page 118 of 126

10-2

10

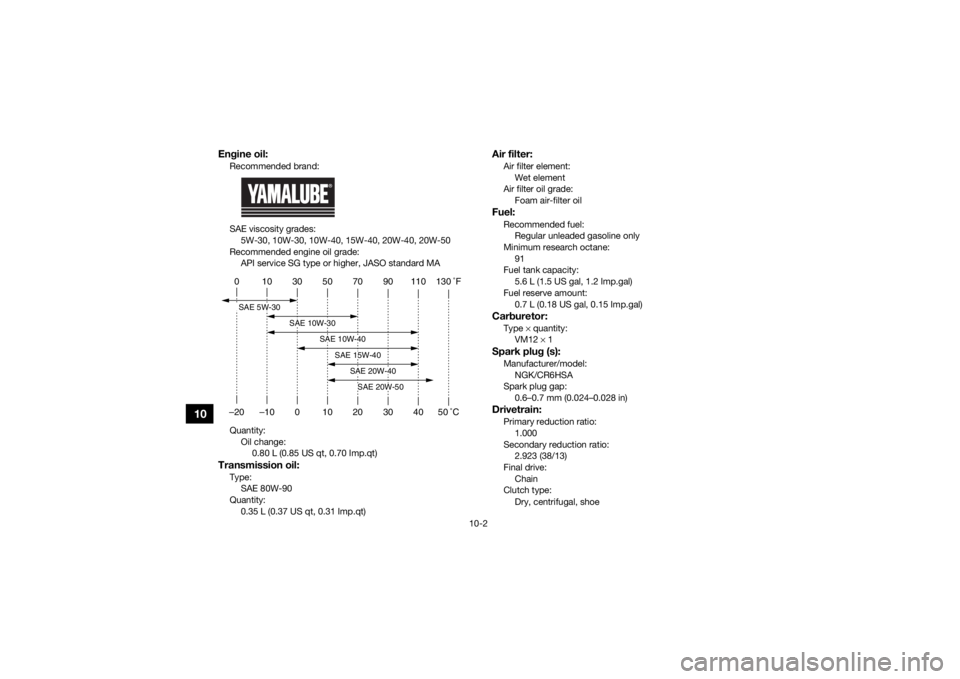

Engine oil:Recommended brand:

SAE viscosity grades:5W-30, 10W-30, 10W-40, 15W-40, 20W-40, 20W-50

Recommended engine oil grade: API service SG type or higher, JASO standard MA

Quantity: Oil change: 0.80 L (0.85 US qt, 0.70 Imp.qt)Transmission oil:Type:SAE 80W-90

Quantity: 0.35 L (0.37 US qt, 0.31 Imp.qt)

Air filter:Air filter element:Wet element

Air filter oil grade:

Foam air-filter oilFuel:Recommended fuel:Regular unleaded gasoline only

Minimum research octane:

91

Fuel tank capacity: 5.6 L (1.5 US gal, 1.2 Imp.gal)

Fuel reserve amount: 0.7 L (0.18 US gal, 0.15 Imp.gal)Carburetor:Type × quantity:

VM12 × 1Spark plug (s):Manufacturer/model:

NGK/CR6HSA

Spark plug gap: 0.6–0.7 mm (0.024–0.028 in)Drivetrain:Primary reduction ratio:

1.000

Secondary reduction ratio: 2.923 (38/13)

Final drive: Chain

Clutch type:

Dry, centrifugal, shoe

0 10 30 50 70 90 110 130 ˚F

–20 –10 0 10 20 30 40 50 ˚CSAE 5W-30

SAE 10W-30

SAE 10W-40

SAE 15W-40

SAE 20W-40SAE 20W-50

UBW463E0.book Page 2 Monday, January 28, 2019 10:22 AM

Page 119 of 126

10-3

10

Transmission type:CVT automatic

Gear ratio: Transmission ratio:2.140–0.710 : 1

Forward gear: 10.967 (49/15 x 47/14)Front tire:Size:AT16x6.5-7

Manufacturer/model: DURO/DI2040Rear tire:Size:AT16x7-7

Manufacturer/model: DURO/DI2041Tire air pressure (measured on cold tires):Vehicle load:0.0–41.0 kg (0–90 lb)

Recommended: Front:15.0 kPa (0.150 kgf/cm², 2.2 psi)

Rear: 15.0 kPa (0.150 kgf/cm², 2.2 psi)

Minimum:

Front:12.0 kPa (0.120 kgf/cm², 1.7 psi)

Rear:

12.0 kPa (0.120 kgf/cm², 1.7 psi)

Front wheel:Rim size:7 x 5.2ATRear wheel:Rim size:7 x 5.2ATFront brake:Type:

Mechanical leading, trailing drum brakeRear brake:Type:Mechanical leading, trailing drum brakeFront suspension:Type:Swing axle

Spring: Coil spring

Shock absorber:

Gas-hydraulic damper

Wheel travel: 60 mm (2.4 in)Rear suspension:Type:

Swingarm

Spring: Coil spring

Shock absorber: Gas-hydraulic damper

Wheel travel:

51 mm (2.0 in)

UBW463E0.book Page 3 Monday, January 28, 2019 10:22 AM

Page 120 of 126

10-4

10

Electrical system:System voltage:12 V

Ignition system:

CDI

Charging system: AC magnetoBattery:Model:

GTX5L-BS

Voltage, capacity: 12 V, 4.0 AhFuses:Main fuse:

7.5 AEBU30403Noise and vibration levels statement (for Eu-

rope)

The figures quoted are emission levels and are not

necessarily safe working levels. Whilst there is a

correlation between the emission and exposure

levels, this cannot be used reliably to determine

whether or not further precautions are required.

Factors that influence the actual level of exposure

of work-force include the characteristics of the

work room, the other sources of noise, etc. i.e. the

number of machines and other adjacent process- es, and the length of time for which an operator is

exposed to the noise. Also the permissible expo-

sure level can vary from country. This information,

however, will enable the user of the machine to

make a better evaluation of the hazard and risk.UBW463E0.book Page 4 Monday, January 28, 2019 10:22 AM