torque YAMAHA YS125 2017 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2017, Model line: YS125, Model: YAMAHA YS125 2017Pages: 90, PDF Size: 2.24 MB

Page 37 of 90

Periodic maintenance an d a djustment

6-2

6

EAU17342

Owner’s tool kitThe owner’s tool kit is located behind

panel B. (See page 6-8.)

The service information included in this

manual and the tools provided in the

owner’s tool kit are intended to assist

you in the performance of preventive

maintenance and minor repairs. How-

ever, additional tools such as a torque

wrench may be necessary to perform

certain maintenance work correctly.TIPIf you do not have the tools or experi-

ence required for a particular job, have

a Yamaha dealer perform it for you.1. Owner’s tool kit

1

UBT4E0E0.book Page 2 Thursday, November 17, 2016 10:55 AM

Page 46 of 90

Periodic maintenance an d a djustment

6-11

6

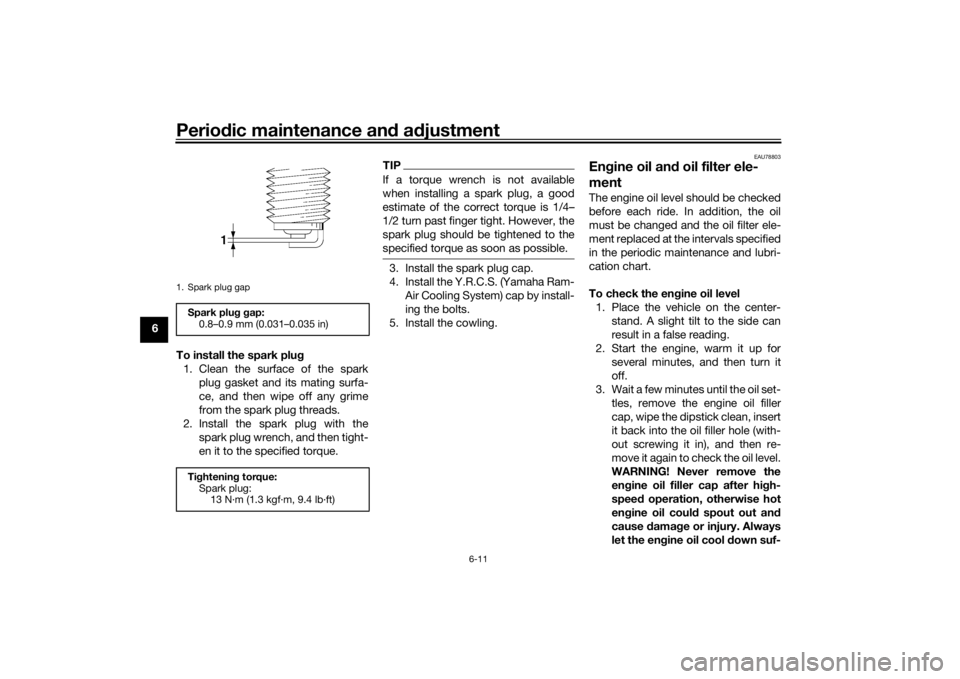

To install the spark plu g

1. Clean the surface of the spark plug gasket and its mating surfa-

ce, and then wipe off any grime

from the spark plug threads.

2. Install the spark plug with the spark plug wrench, and then tight-

en it to the specified torque.

TIPIf a torque wrench is not available

when installing a spark plug, a good

estimate of the correct torque is 1/4–

1/2 turn past finger tight. However, the

spark plug should be tightened to the

specified torque as soon as possible.3. Install the spark plug cap.

4. Install the Y.R.C.S. (Yamaha Ram-Air Cooling System) cap by install-

ing the bolts.

5. Install the cowling.

EAU78803

En gine oil an d oil filter ele-

mentThe engine oil level should be checked

before each ride. In addition, the oil

must be changed and the oil filter ele-

ment replaced at the intervals specified

in the periodic maintenance and lubri-

cation chart.

To check the en gine oil level

1. Place the vehicle on the center- stand. A slight tilt to the side can

result in a false reading.

2. Start the engine, warm it up for several minutes, and then turn it

off.

3. Wait a few minutes until the oil set- tles, remove the engine oil filler

cap, wipe the dipstick clean, insert

it back into the oil filler hole (with-

out screwing it in), and then re-

move it again to check the oil level.

WARNING! Never remove the

engine oil filler cap after hi gh-

speed operation, otherwise hot

en gine oil coul d spout out an d

cause damag e or injury. Always

let the en gine oil cool down suf-

1. Spark plug gapSpark plu g g ap:

0.8–0.9 mm (0.031–0.035 in)

Ti ghtenin g torque:

Spark plug: 13 N·m (1.3 kgf·m, 9.4 lb·ft)

UBT4E0E0.book Page 11 Thursday, November 17, 2016 10:55 AM

Page 48 of 90

Periodic maintenance an d a djustment

6-13

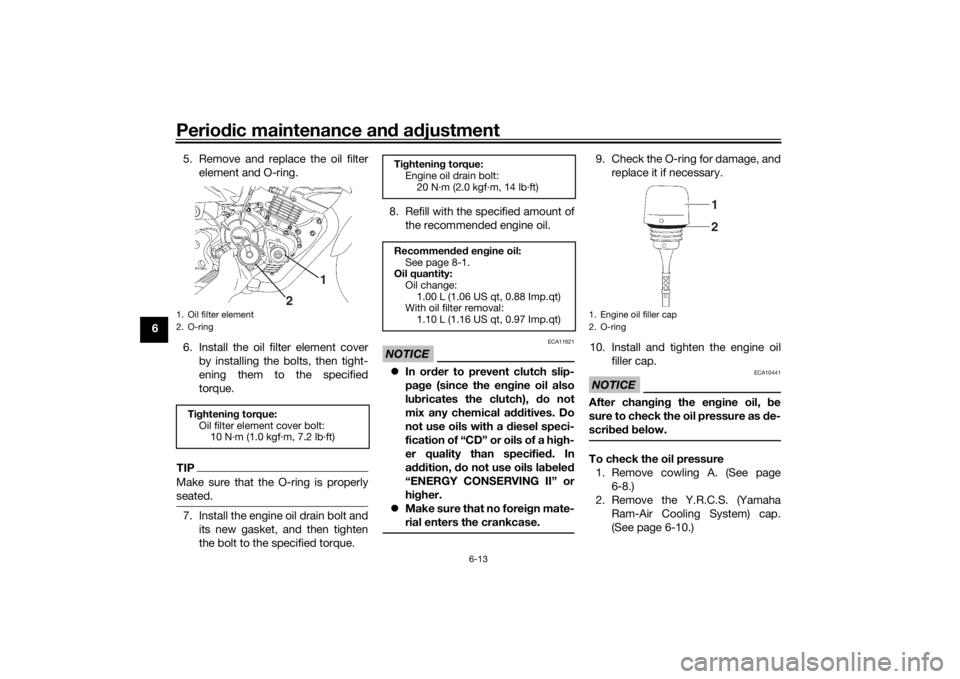

6 5. Remove and replace the oil filter

element and O-ring.

6. Install the oil filter element cover by installing the bolts, then tight-

ening them to the specified

torque.

TIPMake sure that the O-ring is properly

seated.7. Install the engine oil drain bolt andits new gasket, and then tighten

the bolt to the specified torque. 8. Refill with the specified amount of

the recommended engine oil.

NOTICE

ECA11621

In or der to prevent clutch slip-

pa ge (since the en gine oil also

lu bricates the clutch), do not

mix any chemical additives. Do

not use oils with a diesel speci-

fication of “CD” or oils of a hi gh-

er quality than specifie d. In

a ddition, do not use oils la beled

“ENERGY CONSERVING II” or

hi gher.

Make sure that no forei gn mate-

rial enters the crankcase.

9. Check the O-ring for damage, and replace it if necessary.

10. Install and tighten the engine oil filler cap.NOTICE

ECA10441

After chan gin g the en gine oil, b e

sure to check the oil pressure as de-

scri bed b elow.To check the oil pressure

1. Remove cowling A. (See page 6-8.)

2. Remove the Y.R.C.S. (Yamaha Ram-Air Cooling System) cap.

(See page 6-10.)

1. Oil filter element

2. O-ringTightenin g torque:

Oil filter element cover bolt: 10 N·m (1.0 kgf·m, 7.2 lb·ft)

2 1

Ti

ghtenin g torque:

Engine oil drain bolt:

20 N·m (2.0 kgf·m, 14 lb·ft)

Recommen ded en gine oil:

See page 8-1.

Oil quantity:

Oil change:1.00 L (1.06 US qt, 0.88 Imp.qt)

With oil filter removal:

1.10 L (1.16 US qt, 0.97 Imp.qt)

1. Engine oil filler cap

2. O-ring

21

UBT4E0E0.book Page 13 Thursday, November 17, 2016 10:55 AM

Page 49 of 90

Periodic maintenance an d a djustment

6-14

6

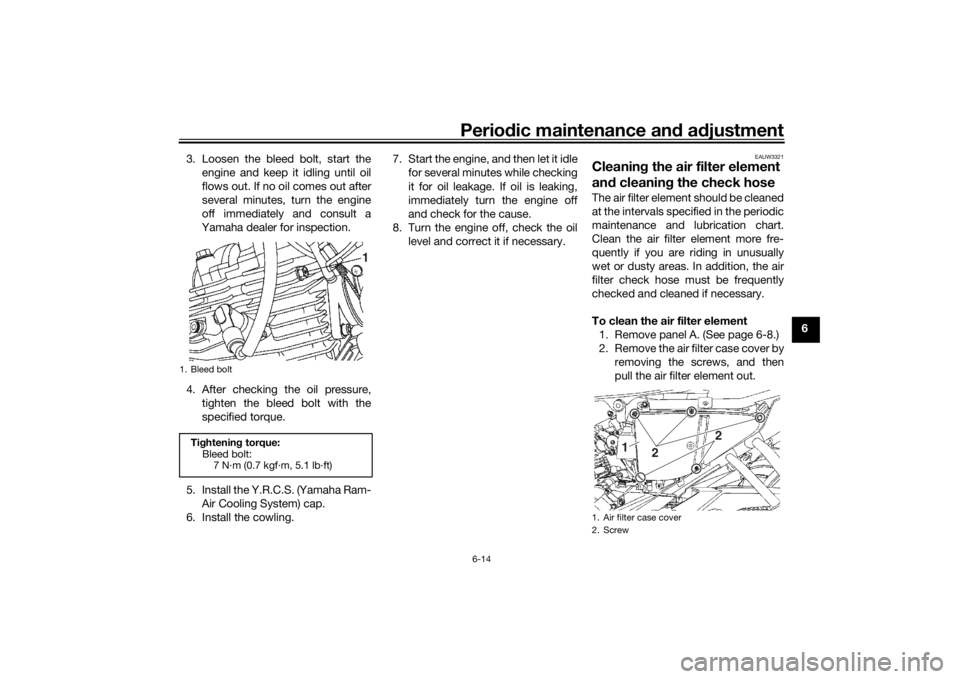

3. Loosen the bleed bolt, start the

engine and keep it idling until oil

flows out. If no oil comes out after

several minutes, turn the engine

off immediately and consult a

Yamaha dealer for inspection.

4. After checking the oil pressure, tighten the bleed bolt with the

specified torque.

5. Install the Y.R.C.S. (Yamaha Ram- Air Cooling System) cap.

6. Install the cowling. 7. Start the engine, and then let it idle

for several minutes while checking

it for oil leakage. If oil is leaking,

immediately turn the engine off

and check for the cause.

8. Turn the engine off, check the oil level and correct it if necessary.

EAUW3321

Cleanin g the air filter element

an d cleanin g the check hoseThe air filter element should be cleaned

at the intervals specified in the periodic

maintenance and lubrication chart.

Clean the air filter element more fre-

quently if you are riding in unusually

wet or dusty areas. In addition, the air

filter check hose must be frequently

checked and cleaned if necessary.

To clean the air filter element

1. Remove panel A. (See page 6-8.)

2. Remove the air filter case cover by removing the screws, and then

pull the air filter element out.

1. Bleed boltTightenin g torque:

Bleed bolt: 7 N·m (0.7 kgf·m, 5.1 lb·ft)

1

1. Air filter case cover

2. Screw

2 2

1

UBT4E0E0.book Page 14 Thursday, November 17, 2016 10:55 AM

Page 59 of 90

Periodic maintenance an d a djustment

6-24

6

EAU22762

Drive chain slackThe drive chain slack should be

checked before each ride and adjusted

if necessary.

EAU22799

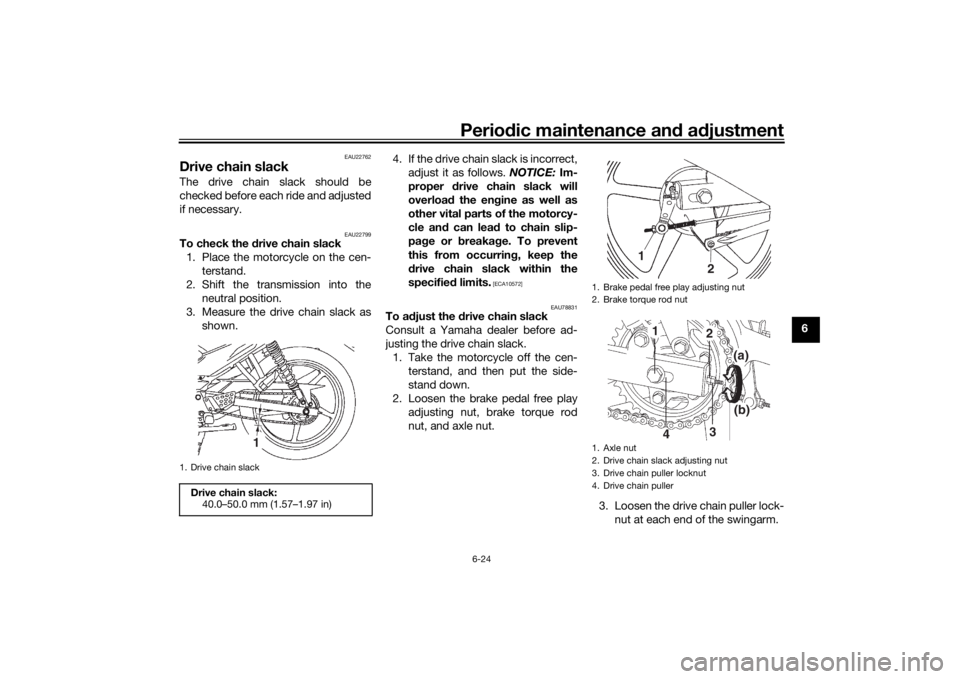

To check the drive chain slack

1. Place the motorcycle on the cen- terstand.

2. Shift the transmission into the neutral position.

3. Measure the drive chain slack as shown. 4. If the drive chain slack is incorrect,

adjust it as follows. NOTICE: Im-

proper drive chain slack will

overloa d the en gine as well as

other vital parts of the motorcy-

cle an d can lead to chain slip-

pa ge or b reakag e. To prevent

this from occurrin g, keep the

d rive chain slack within the

specifie d limits.

[ECA10572]

EAU78831

To adjust the drive chain slack

Consult a Yamaha dealer before ad-

justing the drive chain slack. 1. Take the motorcycle off the cen- terstand, and then put the side-

stand down.

2. Loosen the brake pedal free play adjusting nut, brake torque rod

nut, and axle nut.

3. Loosen the drive chain puller lock-nut at each end of the swingarm.

1. Drive chain slackDrive chain slack:40.0–50.0 mm (1.57–1.97 in)

1

1. Brake pedal free play adjusting nut

2. Brake torque rod nut

1. Axle nut

2. Drive chain slack adjusting nut

3. Drive chain puller locknut

4. Drive chain puller

1

2

4 31

2

(a)(b)

UBT4E0E0.book Page 24 Thursday, November 17, 2016 10:55 AM

Page 60 of 90

Periodic maintenance an d a djustment

6-25

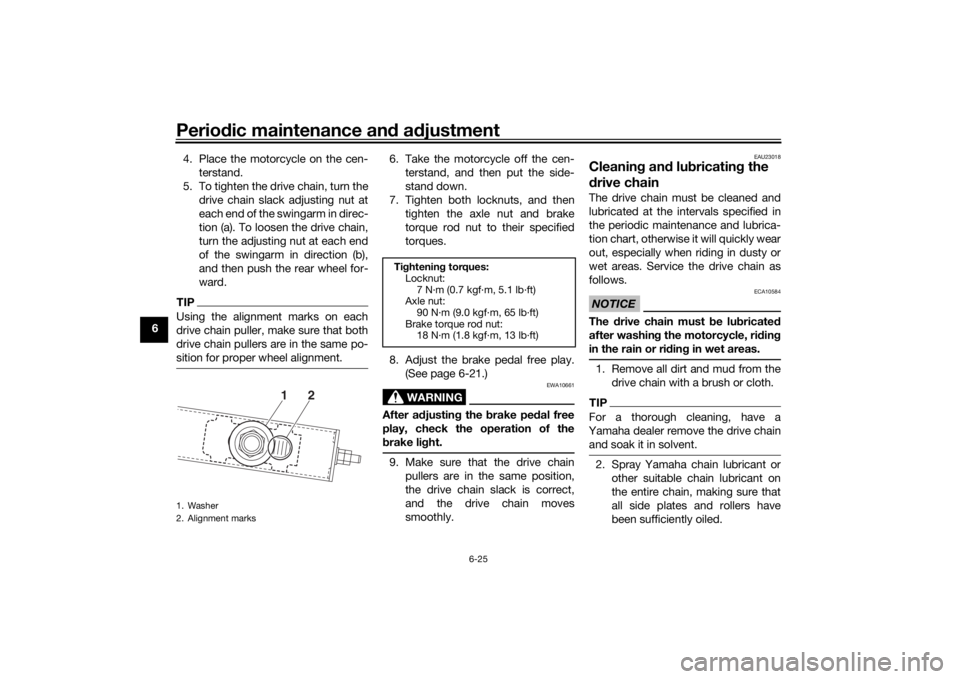

6 4. Place the motorcycle on the cen-

terstand.

5. To tighten the drive chain, turn the drive chain slack adjusting nut at

each end of the swingarm in direc-

tion (a). To loosen the drive chain,

turn the adjusting nut at each end

of the swingarm in direction (b),

and then push the rear wheel for-

ward.

TIPUsing the alignment marks on each

drive chain puller, make sure that both

drive chain pullers are in the same po-

sition for proper wheel alignment.

6. Take the motorcycle off the cen-terstand, and then put the side-

stand down.

7. Tighten both locknuts, and then tighten the axle nut and brake

torque rod nut to their specified

torques.

8. Adjust the brake pedal free play. (See page 6-21.)

WARNING

EWA10661

After a djustin g the brake pe dal free

play, check the operation of the

b rake li ght.9. Make sure that the drive chain

pullers are in the same position,

the drive chain slack is correct,

and the drive chain moves

smoothly.

EAU23018

Cleanin g an d lu bricatin g the

d rive chainThe drive chain must be cleaned and

lubricated at the intervals specified in

the periodic maintenance and lubrica-

tion chart, otherwise it will quickly wear

out, especially when riding in dusty or

wet areas. Service the drive chain as

follows.NOTICE

ECA10584

The drive chain must be lu bricated

after washin g the motorcycle, ri din g

in the rain or ri din g in wet areas.1. Remove all dirt and mud from the

drive chain with a brush or cloth.TIPFor a thorough cleaning, have a

Yamaha dealer remove the drive chain and soak it in solvent.2. Spray Yamaha chain lubricant or other suitable chain lubricant on

the entire chain, making sure that

all side plates and rollers have

been sufficiently oiled.

1. Washer

2. Alignment marks

1

2

Tightenin g torques:

Locknut: 7 N·m (0.7 kgf·m, 5.1 lb·ft)

Axle nut:

90 N·m (9.0 kgf·m, 65 lb·ft)

Brake torque rod nut: 18 N·m (1.8 kgf·m, 13 lb·ft)

UBT4E0E0.book Page 25 Thursday, November 17, 2016 10:55 AM

Page 69 of 90

Periodic maintenance an d a djustment

6-34

6

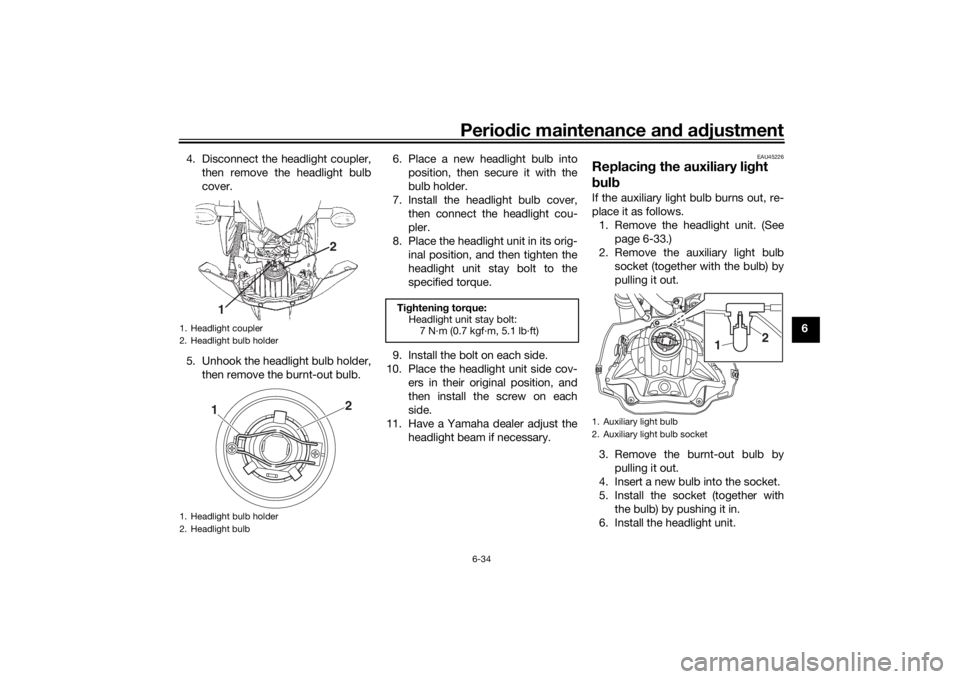

4. Disconnect the headlight coupler,

then remove the headlight bulb

cover.

5. Unhook the headlight bulb holder, then remove the burnt-out bulb. 6. Place a new headlight bulb into

position, then secure it with the

bulb holder.

7. Install the headlight bulb cover, then connect the headlight cou-

pler.

8. Place the headlight unit in its orig- inal position, and then tighten the

headlight unit stay bolt to the

specified torque.

9. Install the bolt on each side.

10. Place the headlight unit side cov- ers in their original position, and

then install the screw on each

side.

11. Have a Yamaha dealer adjust the headlight beam if necessary.

EAU45226

Replacin g the auxiliary li ght

b ul b If the auxiliary light bulb burns out, re-

place it as follows.

1. Remove the headlight unit. (See page 6-33.)

2. Remove the auxiliary light bulb socket (together with the bulb) by

pulling it out.

3. Remove the burnt-out bulb by pulling it out.

4. Insert a new bulb into the socket.

5. Install the socket (together with the bulb) by pushing it in.

6. Install the headlight unit.

1. Headlight coupler

2. Headlight bulb holder

1. Headlight bulb holder

2. Headlight bulb

1 21

2

Ti

ghtenin g torque:

Headlight unit stay bolt: 7 N·m (0.7 kgf·m, 5.1 lb·ft)

1. Auxiliary light bulb

2. Auxiliary light bulb socket

1

2

UBT4E0E0.book Page 34 Thursday, November 17, 2016 10:55 AM

Page 72 of 90

Periodic maintenance an d a djustment

6-37

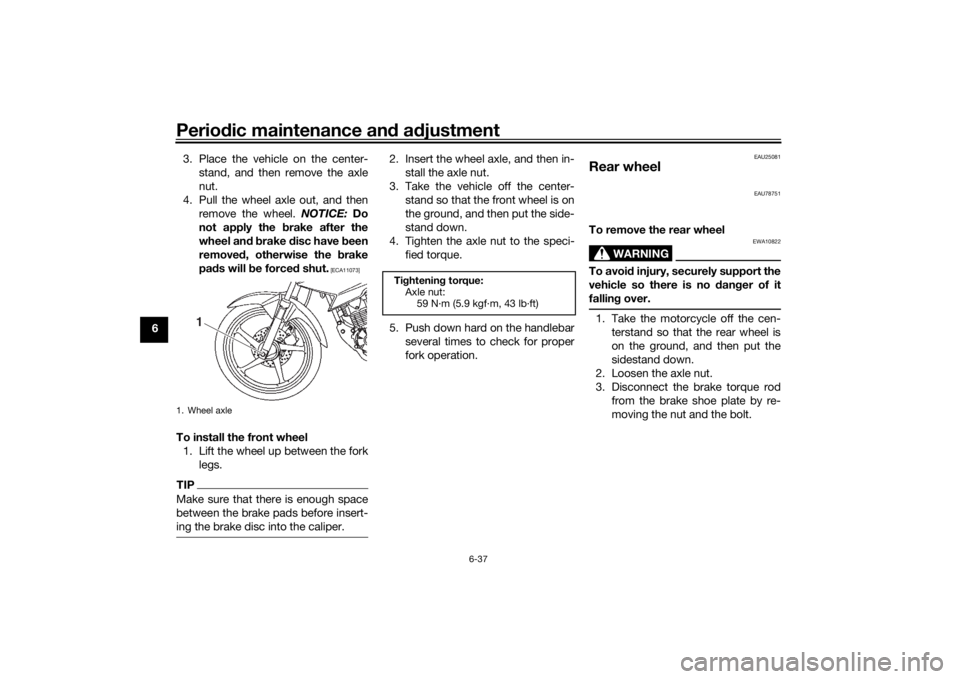

6 3. Place the vehicle on the center-

stand, and then remove the axle

nut.

4. Pull the wheel axle out, and then remove the wheel. NOTICE: Do

not apply the b rake after the

wheel an d b rake disc have b een

remove d, otherwise the brake

pa ds will be forced shut.

[ECA11073]

To install the front wheel

1. Lift the wheel up between the fork legs.TIPMake sure that there is enough space

between the brake pads before insert-

ing the brake disc into the caliper.

2. Insert the wheel axle, and then in-stall the axle nut.

3. Take the vehicle off the center- stand so that the front wheel is on

the ground, and then put the side-

stand down.

4. Tighten the axle nut to the speci- fied torque.

5. Push down hard on the handlebar several times to check for proper

fork operation.

EAU25081

Rear wheel

EAU78751

To remove the rear wheel

WARNING

EWA10822

To avoi d injury, securely support the

vehicle so there is no dan ger of it

fallin g over.1. Take the motorcycle off the cen-

terstand so that the rear wheel is

on the ground, and then put the

sidestand down.

2. Loosen the axle nut.

3. Disconnect the brake torque rod from the brake shoe plate by re-

moving the nut and the bolt.

1. Wheel axle

1

Tightenin g torque:

Axle nut: 59 N·m (5.9 kgf·m, 43 lb·ft)

UBT4E0E0.book Page 37 Thursday, November 17, 2016 10:55 AM

Page 73 of 90

Periodic maintenance an d a djustment

6-38

6

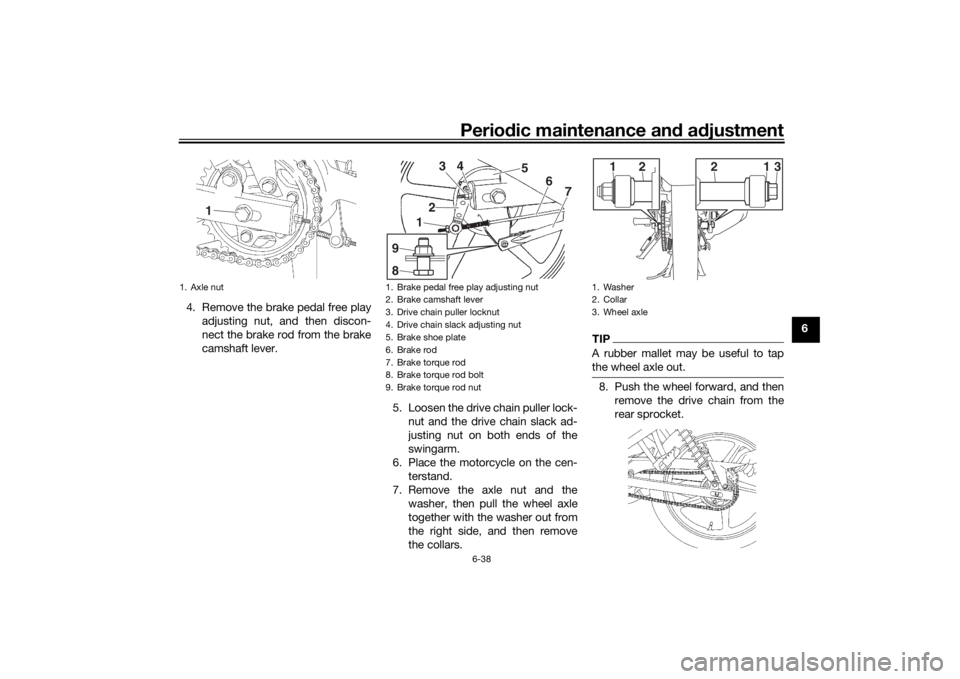

4. Remove the brake pedal free play

adjusting nut, and then discon-

nect the brake rod from the brake

camshaft lever.

5. Loosen the drive chain puller lock-nut and the drive chain slack ad-

justing nut on both ends of the

swingarm.

6. Place the motorcycle on the cen- terstand.

7. Remove the axle nut and the washer, then pull the wheel axle

together with the washer out from

the right side, and then remove

the collars.

TIPA rubber mallet may be useful to tap

the wheel axle out.8. Push the wheel forward, and thenremove the drive chain from the

rear sprocket.

1. Axle nut

1

1. Brake pedal free play adjusting nut

2. Brake camshaft lever

3. Drive chain puller locknut

4. Drive chain slack adjusting nut

5. Brake shoe plate

6. Brake rod

7. Brake torque rod

8. Brake torque rod bolt

9. Brake torque rod nut

234

5

67

1

98

1. Washer

2. Collar

3. Wheel axle

2

1

2

31

UBT4E0E0.book Page 38 Thursday, November 17, 2016 10:55 AM

Page 74 of 90

Periodic maintenance an d a djustment

6-39

6

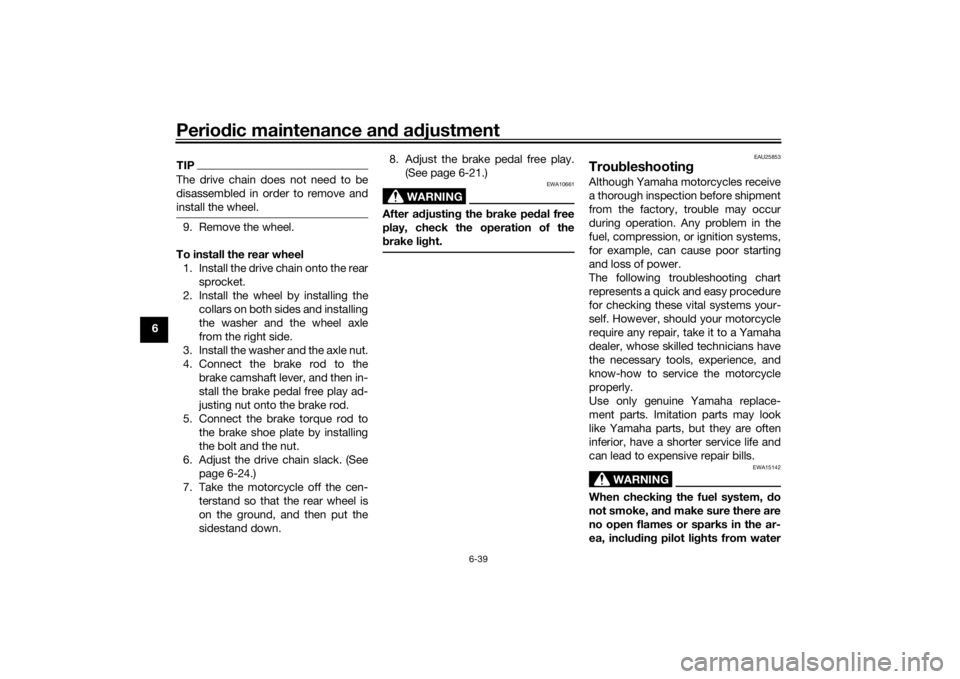

TIPThe drive chain does not need to be

disassembled in order to remove and

install the wheel.9. Remove the wheel.

To install the rear wheel 1. Install the drive chain onto the rear sprocket.

2. Install the wheel by installing the collars on both sides and installing

the washer and the wheel axle

from the right side.

3. Install the washer and the axle nut.

4. Connect the brake rod to the brake camshaft lever, and then in-

stall the brake pedal free play ad-

justing nut onto the brake rod.

5. Connect the brake torque rod to the brake shoe plate by installing

the bolt and the nut.

6. Adjust the drive chain slack. (See page 6-24.)

7. Take the motorcycle off the cen- terstand so that the rear wheel is

on the ground, and then put the

sidestand down. 8. Adjust the brake pedal free play.

(See page 6-21.)

WARNING

EWA10661

After a djustin g the brake pe dal free

play, check the operation of the

b rake li ght.

EAU25853

Trou bleshootin gAlthough Yamaha motorcycles receive

a thorough inspection before shipment

from the factory, trouble may occur

during operation. Any problem in the

fuel, compression, or ignition systems,

for example, can cause poor starting

and loss of power.

The following troubleshooting chart

represents a quick and easy procedure

for checking these vital systems your-

self. However, should your motorcycle

require any repair, take it to a Yamaha

dealer, whose skilled technicians have

the necessary tools, experience, and

know-how to service the motorcycle

properly.

Use only genuine Yamaha replace-

ment parts. Imitation parts may look

like Yamaha parts, but they are often

inferior, have a shorter service life and

can lead to expensive repair bills.

WARNING

EWA15142

When checkin g the fuel system, do

not smoke, an d make sure there are

no open flames or sparks in the ar-

ea, inclu din g pilot li ghts from water

UBT4E0E0.book Page 39 Thursday, November 17, 2016 10:55 AM