torque YAMAHA YXZ1000R 2020 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2020, Model line: YXZ1000R, Model: YAMAHA YXZ1000R 2020Pages: 198, PDF Size: 8.22 MB

Page 139 of 198

9-26

9

12. Install the rear bottom panel by installingthe bolts, and then tightening them to the

specified torque. 13. Install the side panel bolts, and then tight-

en them to the specified torque.1. Bolt A

2. Bolt B

3. Bolt CTightening torques:Bolt A:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt B: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt C: 7 N·m (0.7 kgf·m, 5.2 lb·ft)1

3

2

3

1. Rear bottom panel

2. Bolt A

3. Bolt BTightening torques: Bolt A:7 N·m (0.7 kgf·m, 5.2 lb·ft)

Bolt B: 7 N·m (0.7 kgf·m, 5.2 lb·ft)

3

1

2

2

UB5J7BE0.book Page 26 Tuesday, June 18, 2019 10:07 AM

Page 140 of 198

9-27

9

EBU38630Why YamalubeYAMALUBE oil is a Genuine YAMAHA Partborn of the engineers’ passion and belief that

engine oil is an important liquid engine com-

ponent. We form teams of specialists in the

fields of mechanical engineering, chemistry,

electronics and track testing, and have them

develop the engine together with the oil it will use. Yamalube oils take full advantage of the

base oil’s qualities and blend in the ideal ba-

lance of additives to make sure the final oil

clears our performance standards. Thus,

Yamalube mineral, semisynthetic and syn-

thetic oils have their own distinct characters

and value. Yamaha’s experience gained over

many years of research and development into

oil since the 1960’s helps make Yamalube the

best choice for your Yamaha engine.

EBU35108Transmission oilCheck the oil level and change the transmis-

sion oil at the intervals specified in the period-

ic maintenance chart.

1. Bolt BTightening torque: Bolt B:7 N·m (0.7 kgf·m, 5.2 lb·ft)

1

1

UB5J7BE0.book Page 27 Tuesday, June 18, 2019 10:07 AM

Page 142 of 198

9-29

9

TIPAdd a sufficient amount to raise to the maxi-

mum level mark, but do not overfill. 5. Check the O-ring for damage, and re-place it if necessary.

6. Install the transmission oil filler cap.

7. Install the panel.

To change the transmission oil 1. Place an oil pan under the transmission case to collect the used oil.

2. Remove the transmission oil filler cap.

3. Remove the transmission oil drain bolt and gasket.

TIPOil will flow out immediately when the drain

bolt is loosened. Take care not to lose the

bolt. 4. After draining the oil, install the transmis-sion oil drain bolt with a new gasket.

5. Tighten the drain bolt to the specified torque.1. Transmission oil drain bolt

2. Gasket2

1

UB5J7BE0.book Page 29 Tuesday, June 18, 2019 10:07 AM

Page 143 of 198

9-30

9

6. Check the O-ring for damage, and re-place it if necessary.

7. Refill the transmission with the specified amount of the recommended oil.

8. Install the transmission oil filler cap.

9. Start the engine and let it idle while checking for oil leakage.

10. Stop the engine and check the oil level one last time.EBU36054Final gear oilCheck the oil level and change the final gear

oil at the intervals specified in the periodic

maintenance chart.

NOTICEECB03590When checking or changing the final gear

oil, make sure that no foreign material en-

ters the final gear case. If necessary, clean

the final gear oil filler bolt and surrounding

area. TIPIf the recommended gear oil is not available,

SAE 80W-90 API GL-4 or GL-5 hypoid gear

oil may be used instead. Checking the final gear oil level1. Park the vehicle on a level surface.

Tightening torque: Transmission oil drain bolt:20 N·m (2.0 kgf·m, 15 lb·ft)

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.47 L (0.50 US qt, 0.41 Imp.qt)

UB5J7BE0.book Page 30 Tuesday, June 18, 2019 10:07 AM

Page 144 of 198

9-31

9

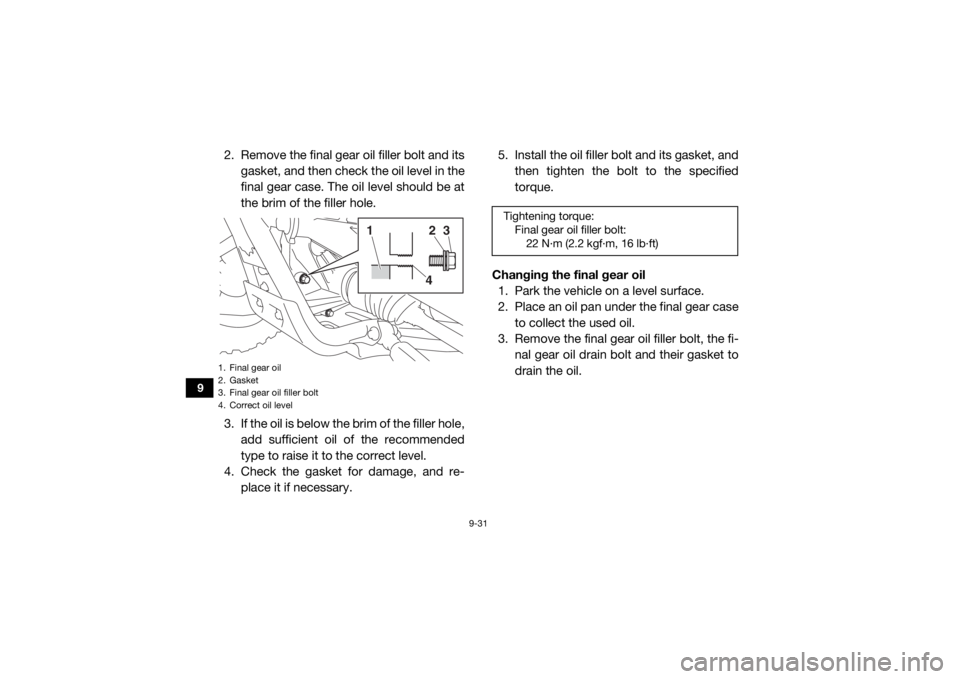

2. Remove the final gear oil filler bolt and itsgasket, and then check the oil level in the

final gear case. The oil level should be at

the brim of the filler hole.

3. If the oil is below the brim of the filler hole, add sufficient oil of the recommended

type to raise it to the correct level.

4. Check the gasket for damage, and re- place it if necessary. 5. Install the oil filler bolt and its gasket, and

then tighten the bolt to the specified

torque.

Changing the final gear oil 1. Park the vehicle on a level surface.

2. Place an oil pan under the final gear case

to collect the used oil.

3. Remove the final gear oil filler bolt, the fi-

nal gear oil drain bolt and their gasket to

drain the oil.1. Final gear oil

2. Gasket

3. Final gear oil filler bolt

4. Correct oil level

24

3

1

Tightening torque:Final gear oil filler bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

UB5J7BE0.book Page 31 Tuesday, June 18, 2019 10:07 AM

Page 145 of 198

9-32

9

4. Install the drain bolt and its new gasket,and then tighten the bolt to the specified

torque.

5. Refill with the recommended final gear oil up to the brim of the filler hole.

6. Check the oil filler bolt gasket for dam- age, and replace it if necessary. 7. Install the oil filler bolt and its gasket, and

then tighten the bolt to the specified

torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.

EBU36064Differential gear oilCheck the oil level and change the differential

gear oil at the intervals specified in the period-

ic maintenance chart.NOTICEECB03600When checking or changing the differen-

tial gear oil, make sure that no foreign ma-

terial enters the differential gear case. If

necessary, clean the differential gear oil

filler bolt and surrounding area.

1. Final gear oil drain bolt

2. GasketTightening torque:Final gear oil drain bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

21

Tightening torque: Final gear oil filler bolt:22 N·m (2.2 kgf·m, 16 lb·ft)

UB5J7BE0.book Page 32 Tuesday, June 18, 2019 10:07 AM

Page 146 of 198

9-33

9

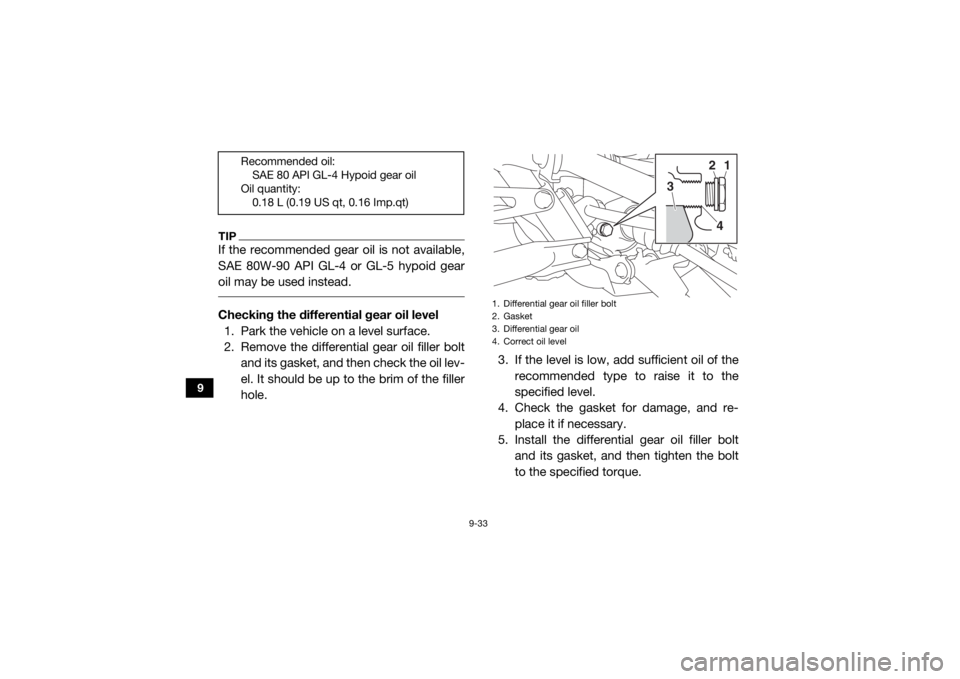

TIPIf the recommended gear oil is not available,

SAE 80W-90 API GL-4 or GL-5 hypoid gear

oil may be used instead. Checking the differential gear oil level1. Park the vehicle on a level surface.

2. Remove the differential gear oil filler bolt and its gasket, and then check the oil lev-

el. It should be up to the brim of the filler

hole. 3. If the level is low, add sufficient oil of the

recommended type to raise it to the

specified level.

4. Check the gasket for damage, and re- place it if necessary.

5. Install the differential gear oil filler bolt

and its gasket, and then tighten the bolt

to the specified torque.

Recommended oil:SAE 80 API GL-4 Hypoid gear oil

Oil quantity: 0.18 L (0.19 US qt, 0.16 Imp.qt)

1. Differential gear oil filler bolt

2. Gasket

3. Differential gear oil

4. Correct oil level

1

2

3

4

UB5J7BE0.book Page 33 Tuesday, June 18, 2019 10:07 AM

Page 147 of 198

9-34

9

Changing the differential gear oil1. Park the vehicle on a level surface.

2. Place an oil pan under the differential

gear case to collect the used oil.

3. Remove the differential gear oil filler bolt,

the differential gear oil drain bolt and their

gasket to drain the oil. 4. Install the differential gear oil drain bolt

and its new gasket, and then tighten the

bolt to the specified torque.

5. Refill the differential gear case with the recommended oil.

6. Check the oil filler bolt gasket for dam- age, and replace it if necessary.

7. Install the differential gear oil filler bolt and its gasket, and then tighten the bolt

to the specified torque.

8. Check for oil leakage. If oil leakage is found, check for the cause.Tightening torque:Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)1. Differential gear oil drain bolt

2. Gasket

1 2

Tightening torque: Differential gear oil drain bolt:9.8 N·m (0.98 kgf·m, 7.2 lb·ft)

Tightening torque: Differential gear oil filler bolt:23 N·m (2.3 kgf·m, 17 lb·ft)

UB5J7BE0.book Page 34 Tuesday, June 18, 2019 10:07 AM

Page 151 of 198

9-38

9

The porcelain insulator around the center

electrode of each spark plug should be a me-

dium-to-light tan color (the ideal color when

the vehicle is ridden normally), and all spark

plugs installed in the engine should have a

similar color. If any spark plug shows a dis-

tinctly different color, the engine could be op-

erating improperly. Do not attempt to

diagnose such problems yourself. Instead,

have a Yamaha dealer check the vehicle.

If a spark plug shows signs of electrode ero-

sion and excessive carbon or other deposits,

it should be replaced.

Before installing a spark plug, the spark plug

gap should be measured with a wire thick-

ness gauge and, if necessary, adjusted to

specification. Clean the surface of the spark plug gasket

and its mating surface, and then wipe off any

grime from the spark plug threads.Specified spark plug:

NGK/CR9EB

1. Spark plug gapSpark plug gap:0.7–0.8 mm (0.028–0.031 in)

Tightening torque: Spark plug:13 N·m (1.3 kgf·m, 9.6 lb·ft)

1

UB5J7BE0.book Page 38 Tuesday, June 18, 2019 10:07 AM

Page 152 of 198

9-39

9

TIPIf a torque wrench is not available when in-

stalling the spark plug, a good estimate of the

correct torque is 1/4–1/2 turn past finger tight.

However, the spark plug should be tightened

to the specified torque as soon as possible. NOTICEECB02900Do not use any tools to remove or install

the spark plug cap, otherwise the ignition

coil coupler may be damaged. The spark

plug cap may be difficult to remove be-

cause the rubber seal on the end of the cap

fits tightly. To remove the spark plug cap,

simply twist it back and forth while pulling

it out; to install it, twist it back and forth

while pushing it in.

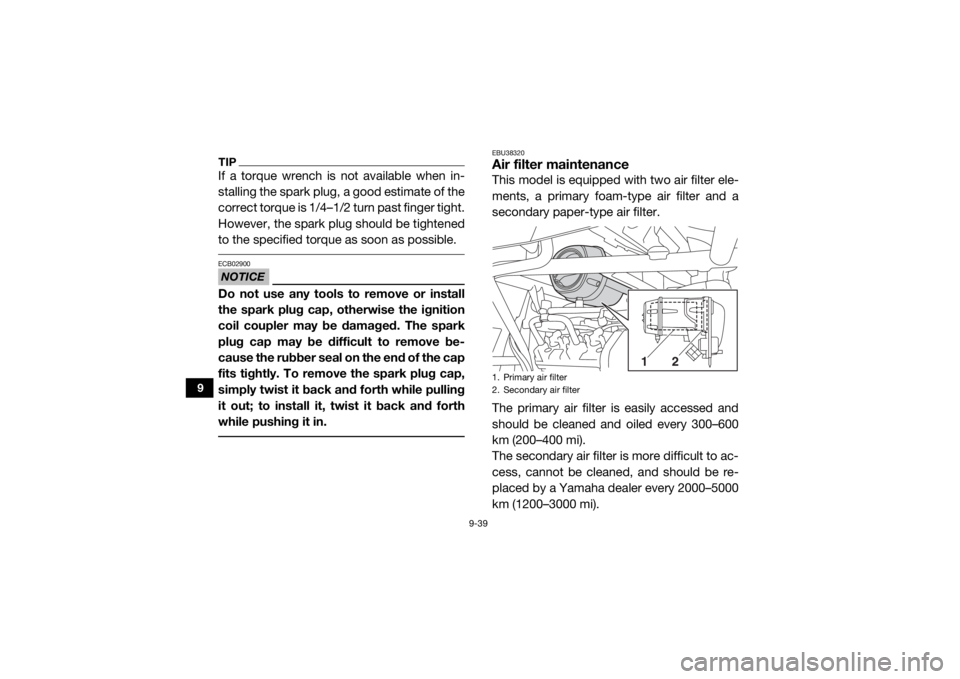

EBU38320Air filter maintenanceThis model is equipped with two air filter ele-

ments, a primary foam-type air filter and a

secondary paper-type air filter.

The primary air filter is easily accessed and

should be cleaned and oiled every 300–600

km (200–400 mi).

The secondary air filter is more difficult to ac-

cess, cannot be cleaned, and should be re-

placed by a Yamaha dealer every 2000–5000

km (1200–3000 mi).1. Primary air filter

2. Secondary air filter

1

2

UB5J7BE0.book Page 39 Tuesday, June 18, 2019 10:07 AM