clutch YAMAHA YZ125LC 2010 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2010, Model line: YZ125LC, Model: YAMAHA YZ125LC 2010Pages: 166, PDF Size: 8.09 MB

Page 37 of 166

2-13

CABLE ROUTING DIAGRAM

D. Install the ignition coil, side core

and ground lead together to the

frame. Take care to fasten the

ground lead so that its terminal

is within the indicated range.

E. Clamp the throttle cable and

high tension cord to the frame.

F. Clamp the clutch cable to the left

engine bracket. Clamp the

clutch cable below the position-

ing grommet.

G. Pass the air vent hose back of

the throttle cable.

H. Pass the air vent hose, overflow

hose and crankcase breather

hose between the frame and

connecting rod.

I. Pass the radiator breather hose

and YPVS breather hose out-

side the engine bracket and in-

side the down tube. Then pass

the radiator breather hose inside

the YPVS breather hose.

J. Clamp the CDI magneto lead,

radiator breather hose and

YPVS breather hose to the

frame.

K. Clamp to the frame the CDI

magneto lead and radiator

breather hose. Take care to

clamp them above the projection

on the frame.

L. Locate the clamp ends in the ar-

rowed range.

M. Pass the air vent hose, overflow

hose and crankcase breather

hose so that they do not contact

the rear shock absorber.

N. Bring the connector cover into

contact with the coupler.

Page 38 of 166

2-14

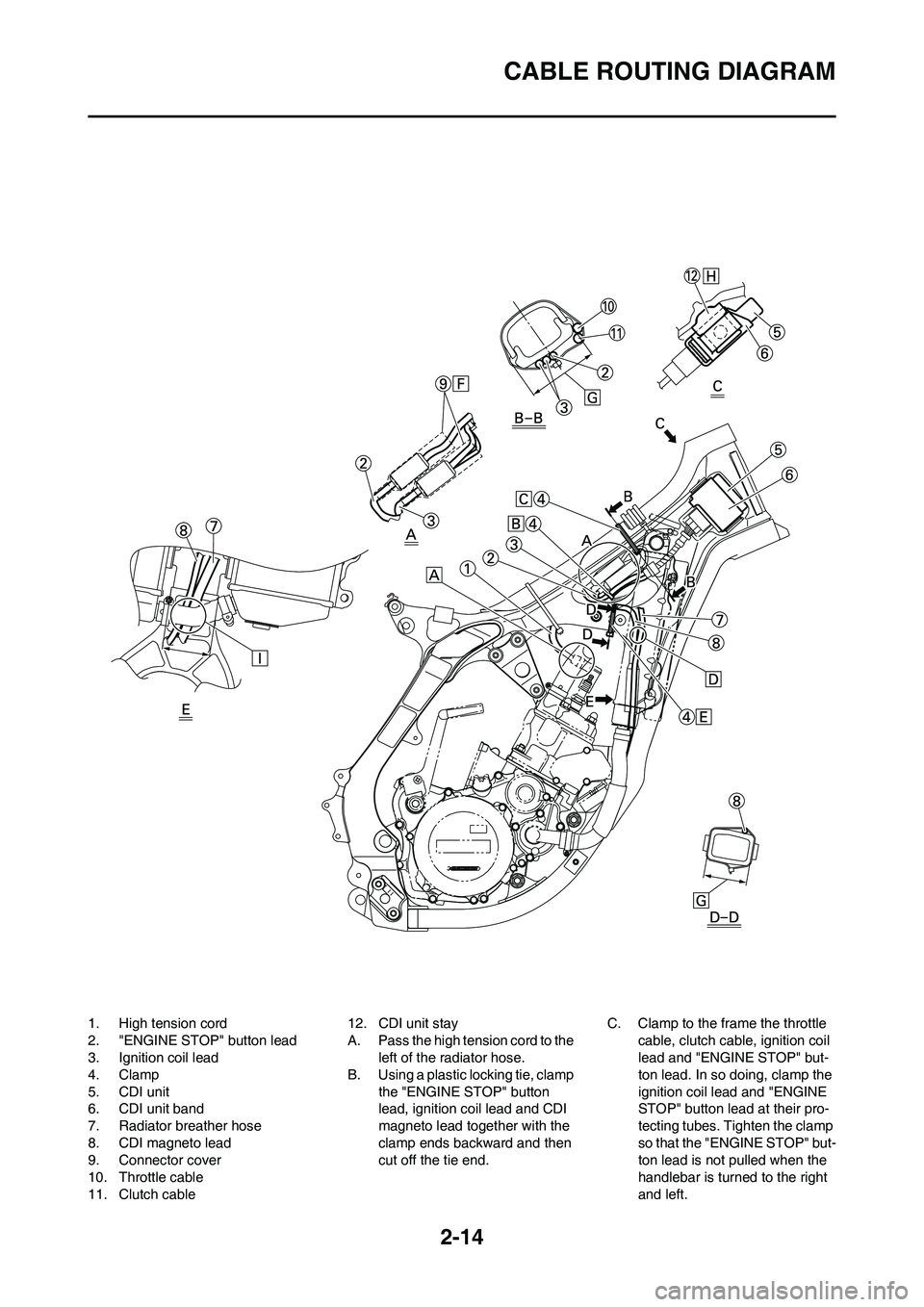

CABLE ROUTING DIAGRAM

1. High tension cord

2. "ENGINE STOP" button lead

3. Ignition coil lead

4. Clamp

5. CDI unit

6. CDI unit band

7. Radiator breather hose

8. CDI magneto lead

9. Connector cover

10. Throttle cable

11. Clutch cable12. CDI unit stay

A. Pass the high tension cord to the

left of the radiator hose.

B. Using a plastic locking tie, clamp

the "ENGINE STOP" button

lead, ignition coil lead and CDI

magneto lead together with the

clamp ends backward and then

cut off the tie end.C. Clamp to the frame the throttle

cable, clutch cable, ignition coil

lead and "ENGINE STOP" but-

ton lead. In so doing, clamp the

ignition coil lead and "ENGINE

STOP" button lead at their pro-

tecting tubes. Tighten the clamp

so that the "ENGINE STOP" but-

ton lead is not pulled when the

handlebar is turned to the right

and left.

Page 41 of 166

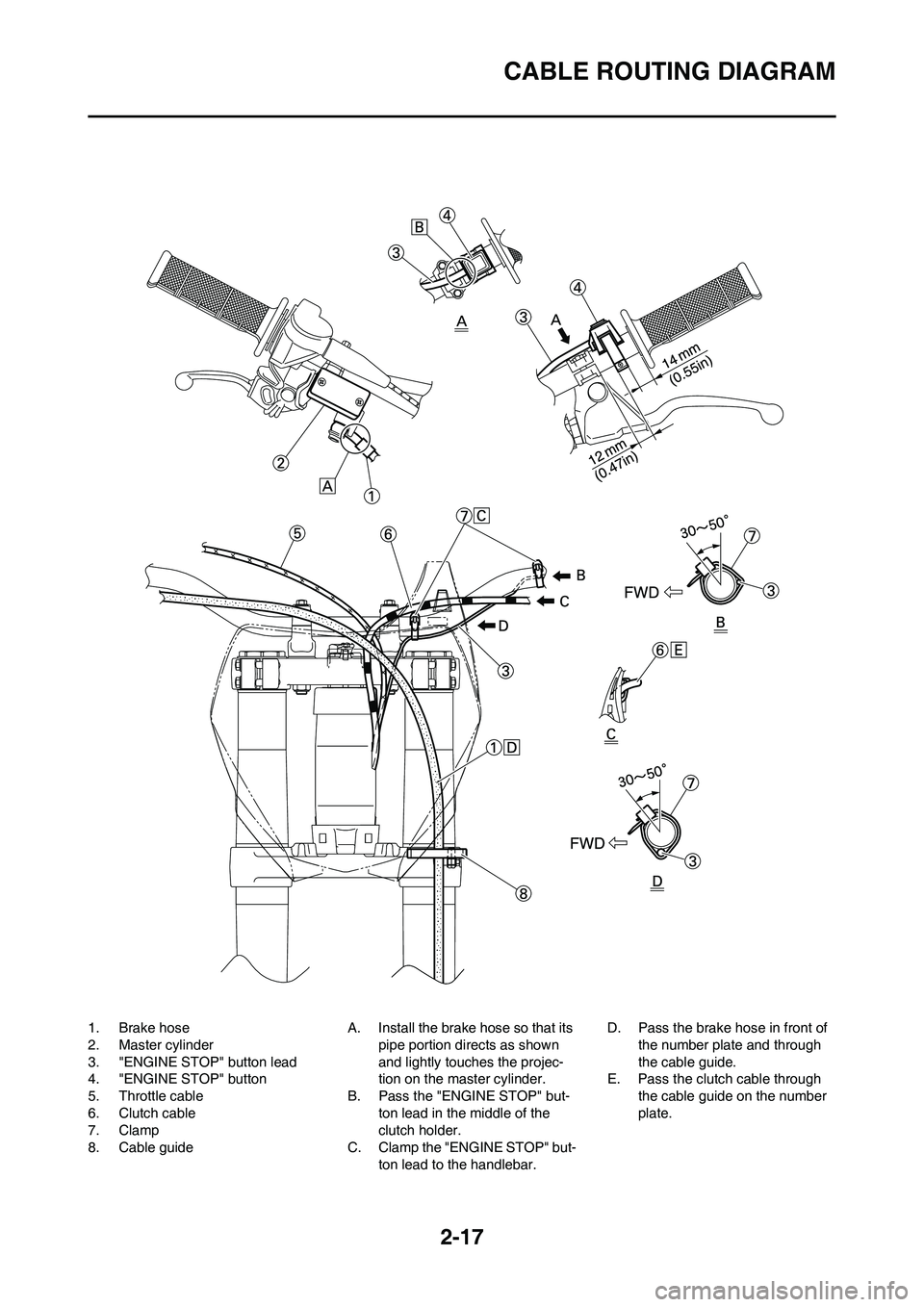

2-17

CABLE ROUTING DIAGRAM

1. Brake hose

2. Master cylinder

3. "ENGINE STOP" button lead

4. "ENGINE STOP" button

5. Throttle cable

6. Clutch cable

7. Clamp

8. Cable guideA. Install the brake hose so that its

pipe portion directs as shown

and lightly touches the projec-

tion on the master cylinder.

B. Pass the "ENGINE STOP" but-

ton lead in the middle of the

clutch holder.

C. Clamp the "ENGINE STOP" but-

ton lead to the handlebar.D. Pass the brake hose in front of

the number plate and through

the cable guide.

E. Pass the clutch cable through

the cable guide on the number

plate.

Page 42 of 166

3-1

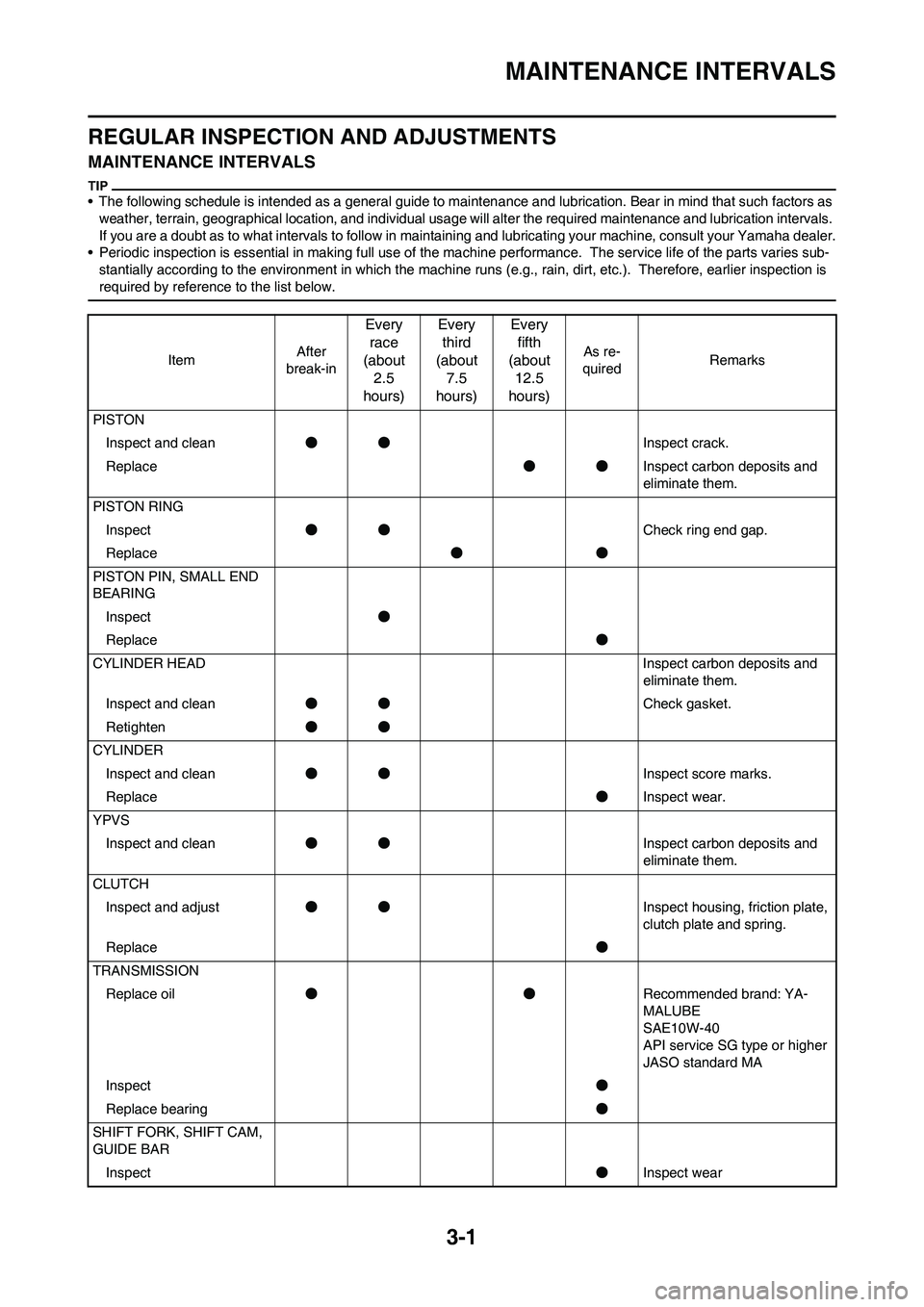

MAINTENANCE INTERVALS

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

• The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind that such factors as

weather, terrain, geographical location, and individual usage will alter the required maintenance and lubrication intervals.

If you are a doubt as to what intervals to follow in maintaining and lubricating your machine, consult your Yamaha dealer.

• Periodic inspection is essential in making full use of the machine performance. The service life of the parts varies sub-

stantially according to the environment in which the machine runs (e.g., rain, dirt, etc.). Therefore, earlier inspection is

required by reference to the list below.

ItemAfter

break-in

Every

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)

As re-

quiredRemarks

PISTON

Inspect and clean●●Inspect crack.

Replace●●Inspect carbon deposits and

eliminate them.

PISTON RING

Inspect●●Check ring end gap.

Replace●●

PISTON PIN, SMALL END

BEARING

Inspect●

Replace●

CYLINDER HEAD Inspect carbon deposits and

eliminate them.

Inspect and clean●●Check gasket.

Retighten●●

CYLINDER

Inspect and clean●●Inspect score marks.

Replace●Inspect wear.

YPVS

Inspect and clean●●Inspect carbon deposits and

eliminate them.

CLUTCH

Inspect and adjust●●Inspect housing, friction plate,

clutch plate and spring.

Replace●

TRANSMISSION

Replace oil●●Recommended brand: YA-

MALUBE

SAE10W-40

API service SG type or higher

JASO standard MA

Inspect●

Replace bearing●

SHIFT FORK, SHIFT CAM,

GUIDE BAR

Inspect●Inspect wear

Page 46 of 166

3-5

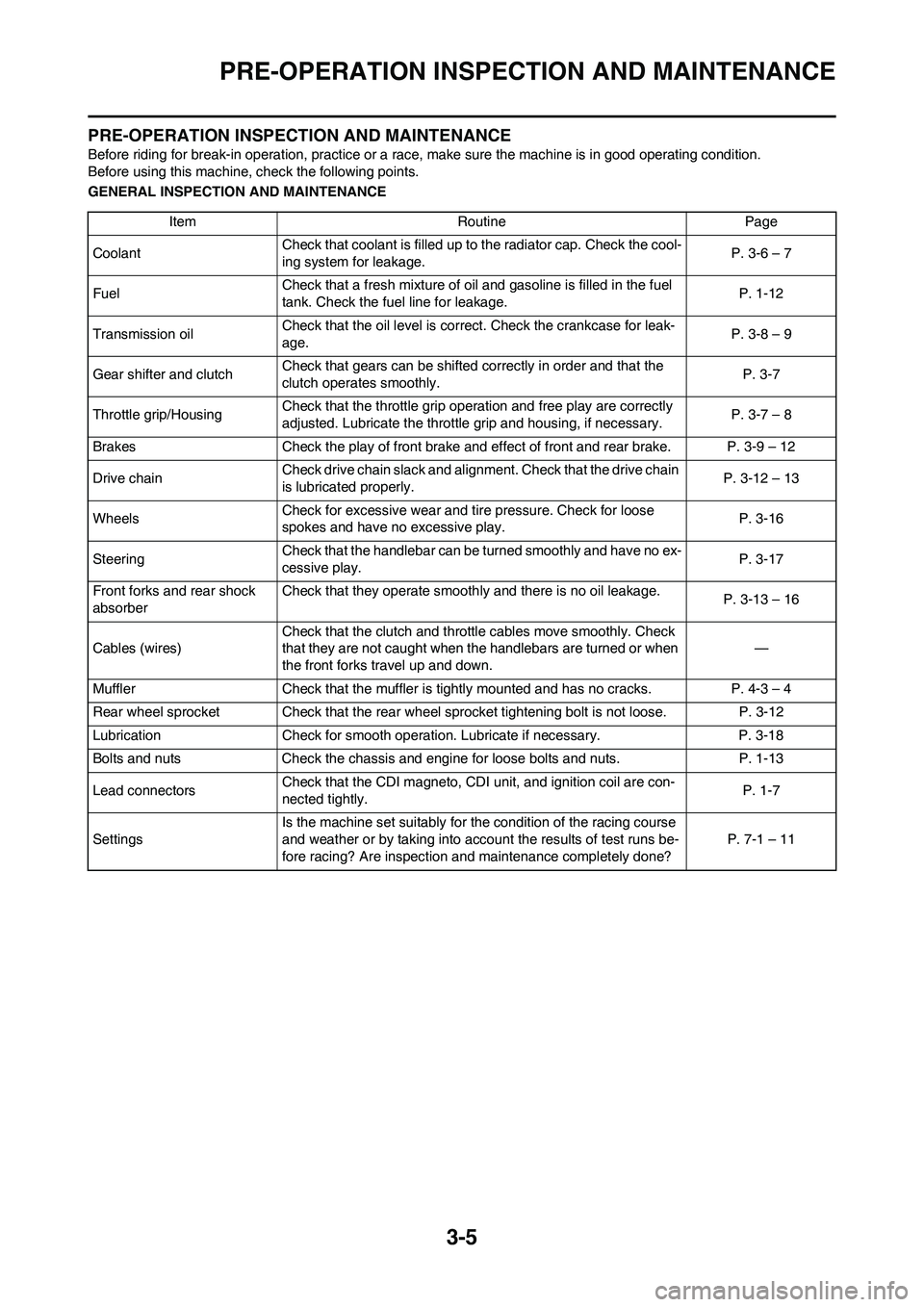

PRE-OPERATION INSPECTION AND MAINTENANCE

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap. Check the cool-

ing system for leakage.P. 3-6 – 7

FuelCheck that a fresh mixture of oil and gasoline is filled in the fuel

tank. Check the fuel line for leakage.P. 1-12

Transmission oilCheck that the oil level is correct. Check the crankcase for leak-

age.P. 3-8 – 9

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P. 3-7

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P. 3-7 – 8

Brakes Check the play of front brake and effect of front and rear brake. P. 3-9 – 12

Drive chainCheck drive chain slack and alignment. Check that the drive chain

is lubricated properly.P. 3-12 – 13

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P. 3-16

SteeringCheck that the handlebar can be turned smoothly and have no ex-

cessive play.P. 3-17

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage.

P. 3-13 – 16

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or when

the front forks travel up and down.—

Muffler Check that the muffler is tightly mounted and has no cracks. P. 4-3 – 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P. 3-12

Lubrication Check for smooth operation. Lubricate if necessary. P. 3-18

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P. 1-13

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P. 1-7

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs be-

fore racing? Are inspection and maintenance completely done?P. 7-1 – 11

Page 48 of 166

3-7

ENGINE

3. Radiator cap

2. Apply the specified pressure.

3. Inspect:

• Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds→

Replace.

CHECKING THE COOLING

SYSTEM

1. Inspect:

• Coolant level

2. Attach:

• Radiator cap tester "1" and adapt-

er "2"

3. Apply the specified pressure.

• Do not apply pressure more than

specified pressure.

• Radiator should be filled fully.

4. Inspect:

• Pressure

Impossible to maintain the speci-

fied pressure for 10 seconds→

Repair.

•Radiator "1"

• Radiator hose joint "2"

Coolant leakage→Repair or re-

place.

• Radiator hose "3"

Swelling→Replace.ADJUSTING THE CLUTCH CABLE

FREE PLAY

1. Check:

• Clutch lever free play "a"

Out of specification→Adjust.

2. Adjust:

• Clutch lever free play

Clutch lever free play adjustment

steps:

a. Loosen the locknuts "1".

b. Turn the adjuster "2" until free

play "a" is within the specified lim-

its.

c. Tighten the locknuts.

• Before adjustment, expose the ad-

juster by moving the boot "3" and

cap "4" away.

• Make minute adjustment on the le-

ver side using the adjuster "5".

• After adjustment, check proper op-

eration of clutch lever.

3. Install:

• Cap "1"

•Boot "2"

Place the tip "a" of the cap in the boot.

ADJUSTING THE THROTTLE

CABLE FREE PLAY

1. Check:

• Throttle grip free play "a"

Out of specification→Adjust.

2. Adjust:

• Throttle grip free play

Throttle grip free play adjustment

steps:

a. Slide the adjuster cover.

b. Loosen the locknut "1".

c. Turn the adjuster "2" until the

specified free play is obtained.

d. Tighten the locknut.

Before adjusting the throttle cable

free play, the engine idle speed

should be adjusted.

After adjusting the throttle cable

free play, start the engine and turn

the handlebar to right and left and

make sure that the engine idling

does not run faster.

Radiator cap opening

pressure:

95–125 kPa (0.95–1.25

kg/cm

2, 13.5–17.8 psi)

Radiator cap tester:

YU-24460-01/90890-

01325

Radiator cap tester

adapter:

YU-33984/90890-01352

Standard pressure:

180 kPa (1.8 kg/cm

2,

25.6 psi)

Clutch lever free play "a"

:

8–13 mm (0.31–0.51 in)

Locknut:

4 Nm (0.4 m•kg, 2.9

ft•lb)Throttle grip free play

"a":

3–5 mm (0.12–0.20 in)

Locknut:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Page 59 of 166

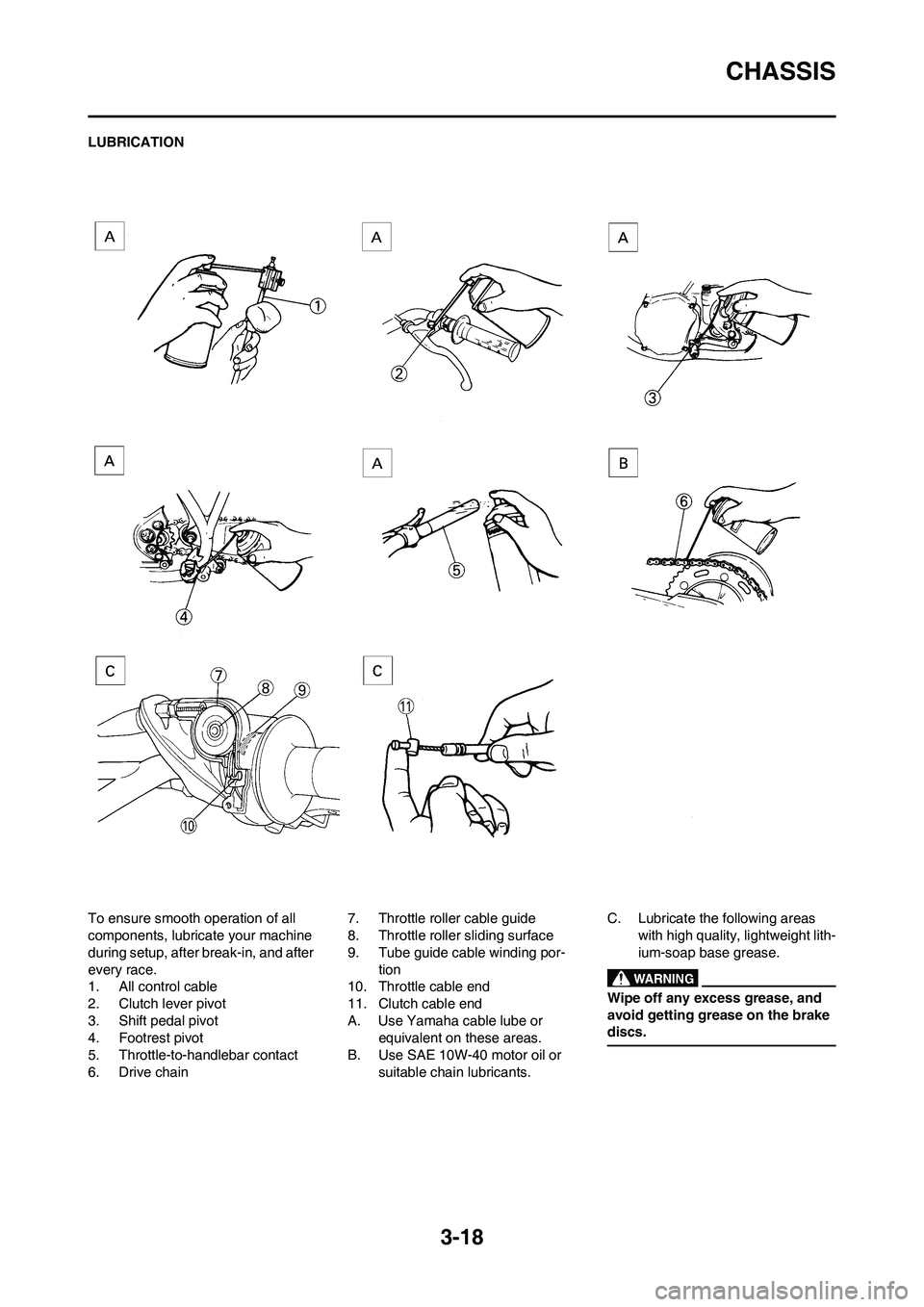

3-18

CHASSIS

LUBRICATION

To ensure smooth operation of all

components, lubricate your machine

during setup, after break-in, and after

every race.

1. All control cable

2. Clutch lever pivot

3. Shift pedal pivot

4. Footrest pivot

5. Throttle-to-handlebar contact

6. Drive chain7. Throttle roller cable guide

8. Throttle roller sliding surface

9. Tube guide cable winding por-

tion

10. Throttle cable end

11. Clutch cable end

A. Use Yamaha cable lube or

equivalent on these areas.

B. Use SAE 10W-40 motor oil or

suitable chain lubricants.C. Lubricate the following areas

with high quality, lightweight lith-

ium-soap base grease.

Wipe off any excess grease, and

avoid getting grease on the brake

discs.

Page 62 of 166

4-2

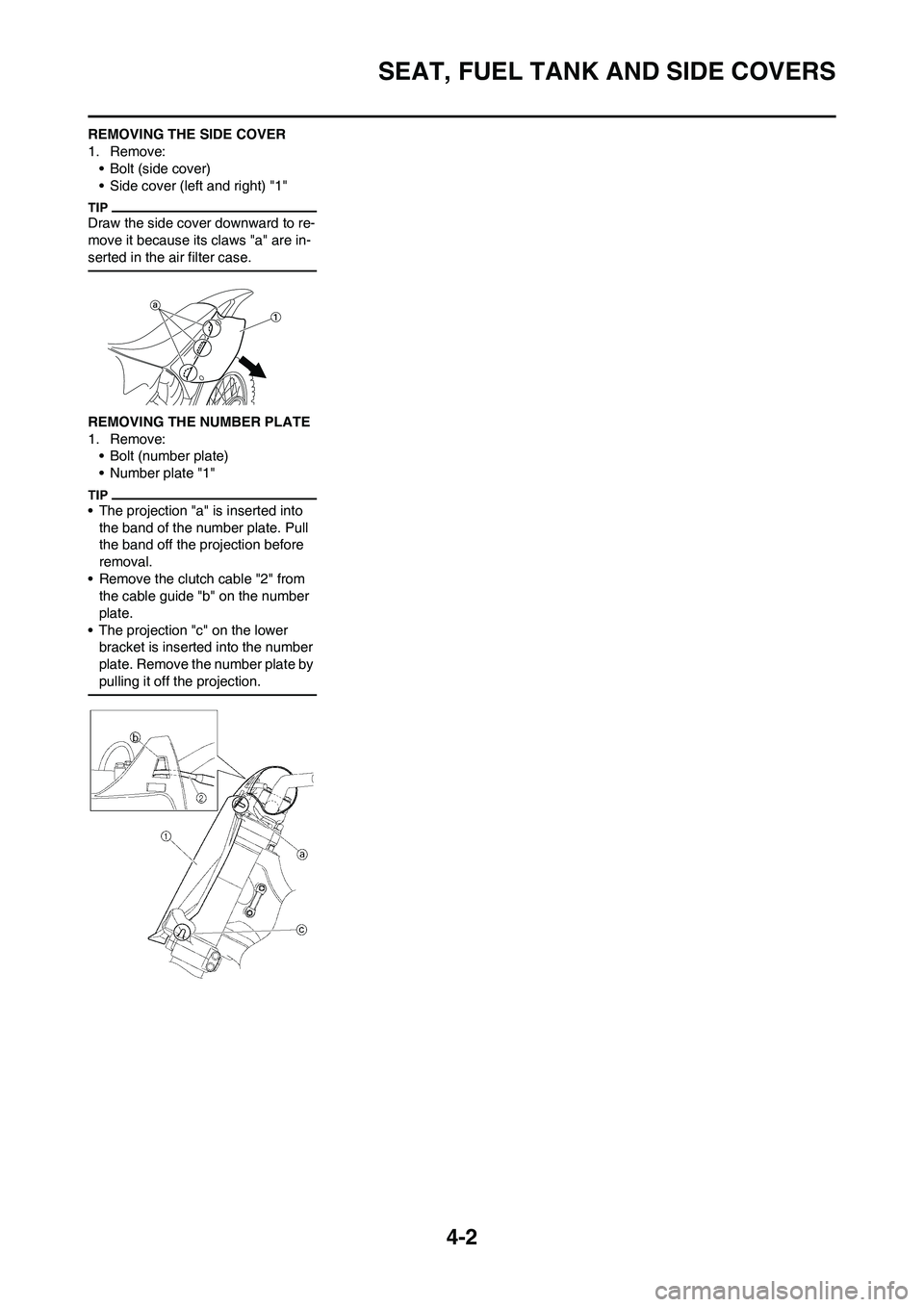

SEAT, FUEL TANK AND SIDE COVERS

REMOVING THE SIDE COVER

1. Remove:

• Bolt (side cover)

• Side cover (left and right) "1"

Draw the side cover downward to re-

move it because its claws "a" are in-

serted in the air filter case.

REMOVING THE NUMBER PLATE

1. Remove:

• Bolt (number plate)

• Number plate "1"

• The projection "a" is inserted into

the band of the number plate. Pull

the band off the projection before

removal.

• Remove the clutch cable "2" from

the cable guide "b" on the number

plate.

• The projection "c" on the lower

bracket is inserted into the number

plate. Remove the number plate by

pulling it off the projection.

Page 79 of 166

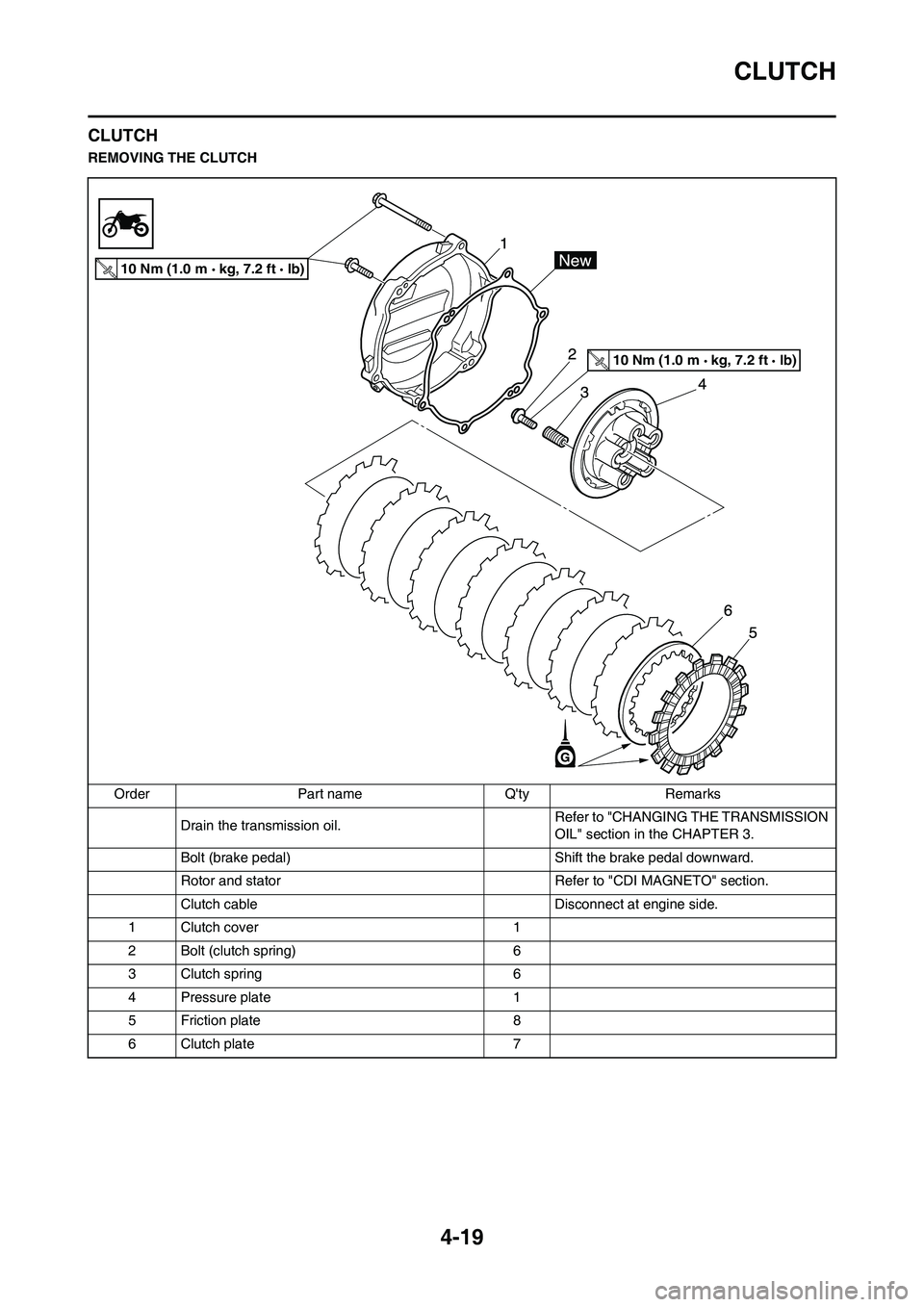

4-19

CLUTCH

CLUTCH

REMOVING THE CLUTCH

Order Part name Q'ty Remarks

Drain the transmission oil.Refer to "CHANGING THE TRANSMISSION

OIL" section in the CHAPTER 3.

Bolt (brake pedal) Shift the brake pedal downward.

Rotor and stator Refer to "CDI MAGNETO" section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Bolt (clutch spring) 6

3 Clutch spring 6

4 Pressure plate 1

5 Friction plate 8

6 Clutch plate 7

10 Nm (1.0 m kg, 7.2 ft lb)

10 Nm (1.0 m kg, 7.2 ft lb)

Page 80 of 166

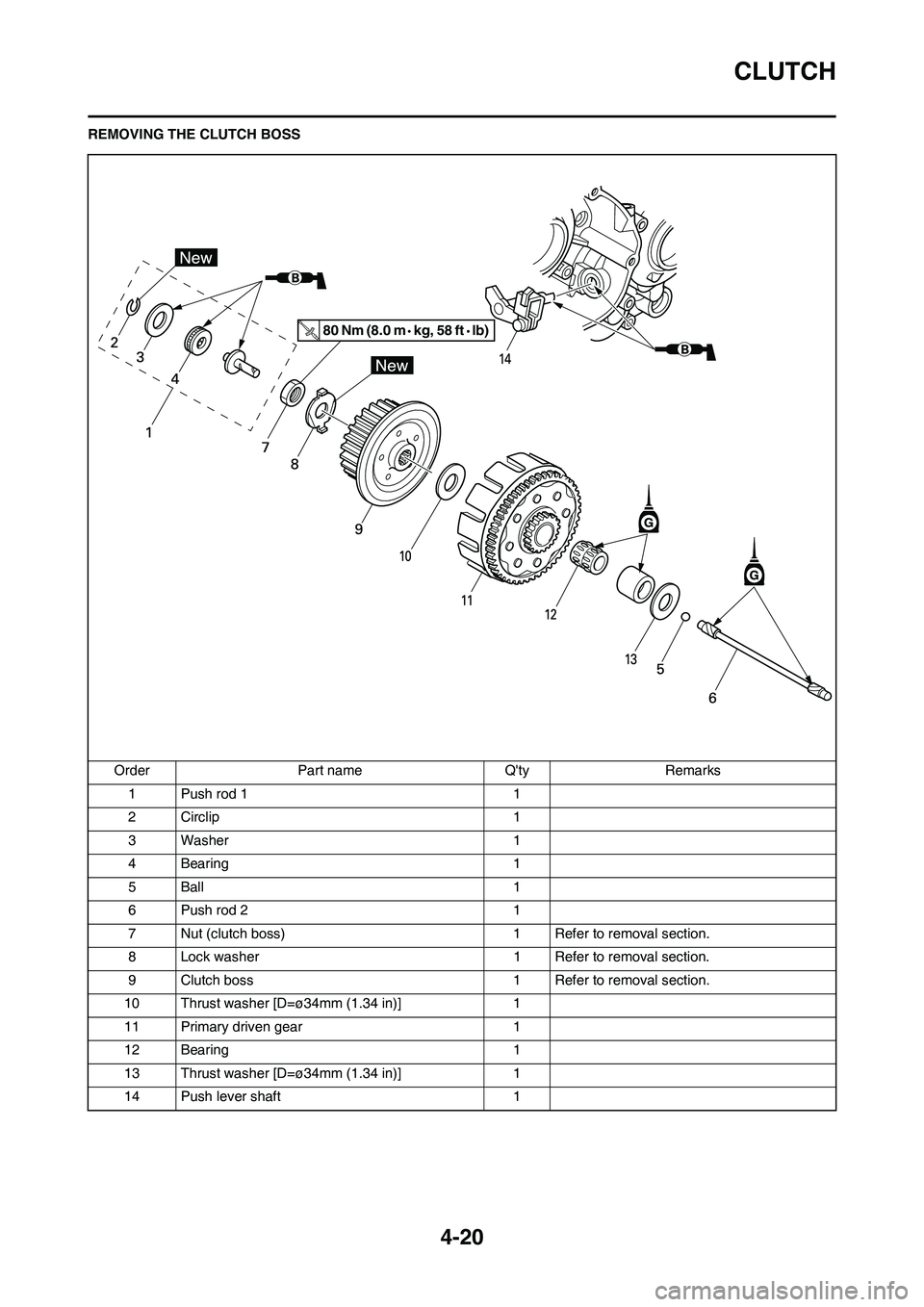

4-20

CLUTCH

REMOVING THE CLUTCH BOSS

Order Part name Q'ty Remarks

1 Push rod 1 1

2 Circlip 1

3 Washer 1

4 Bearing 1

5Ball 1

6 Push rod 2 1

7 Nut (clutch boss) 1 Refer to removal section.

8 Lock washer 1 Refer to removal section.

9 Clutch boss 1 Refer to removal section.

10 Thrust washer [D=ø34mm (1.34 in)] 1

11 Primary driven gear 1

12 Bearing 1

13 Thrust washer [D=ø34mm (1.34 in)] 1

14 Push lever shaft 1

80 Nm (8.0 m kg, 58 ft lb)