engine YAMAHA YZ125LC 2013 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2013, Model line: YZ125LC, Model: YAMAHA YZ125LC 2013Pages: 168, PDF Size: 8.19 MB

Page 24 of 168

1-14

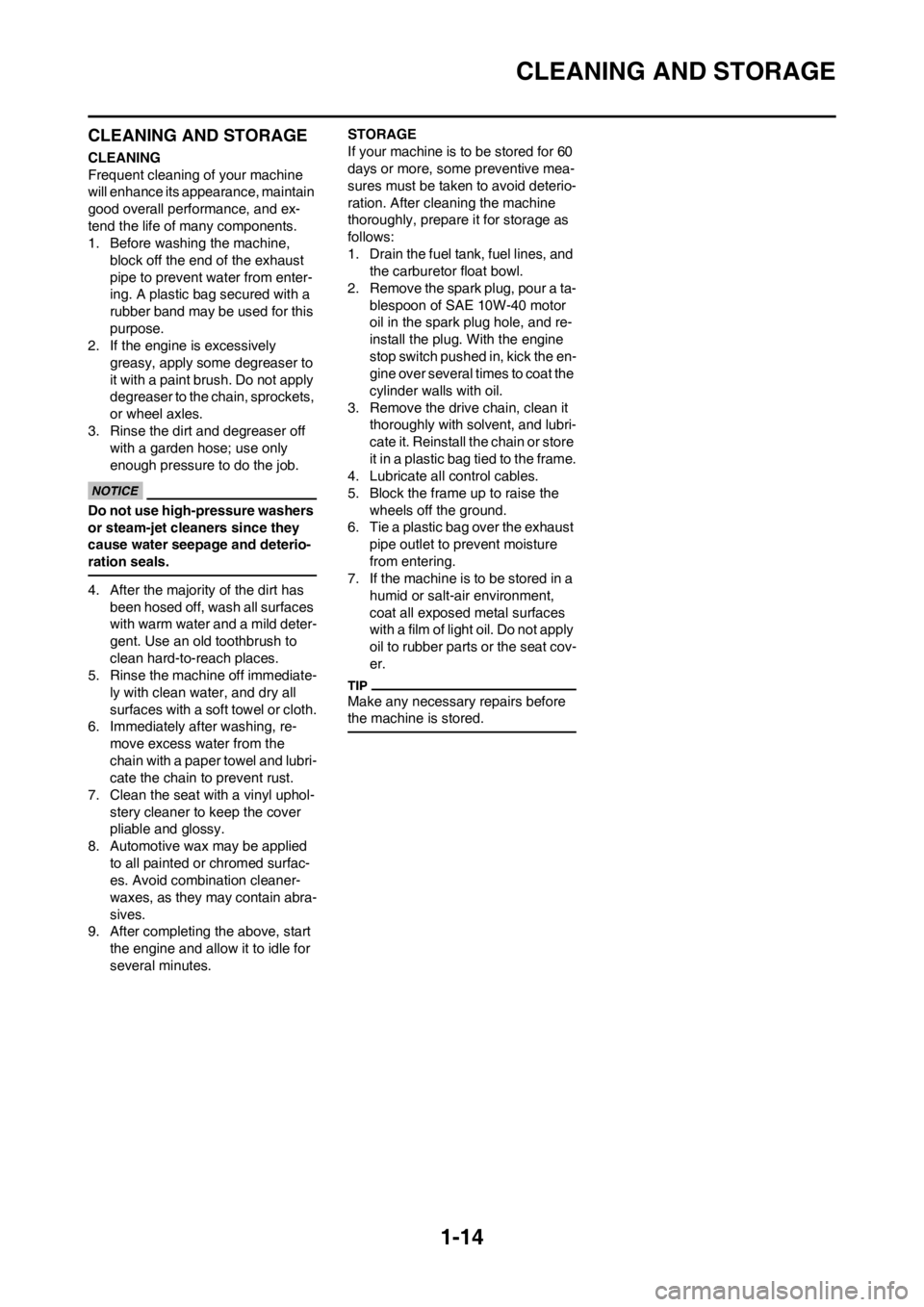

CLEANING AND STORAGE

CLEANING AND STORAGE

CLEANING

Frequent cleaning of your machine

will enhance its appearance, maintain

good overall performance, and ex-

tend the life of many components.

1. Before washing the machine,

block off the end of the exhaust

pipe to prevent water from enter-

ing. A plastic bag secured with a

rubber band may be used for this

purpose.

2. If the engine is excessively

greasy, apply some degreaser to

it with a paint brush. Do not apply

degreaser to the chain, sprockets,

or wheel axles.

3. Rinse the dirt and degreaser off

with a garden hose; use only

enough pressure to do the job.

Do not use high-pressure washers

or steam-jet cleaners since they

cause water seepage and deterio-

ration seals.

4. After the majority of the dirt has

been hosed off, wash all surfaces

with warm water and a mild deter-

gent. Use an old toothbrush to

clean hard-to-reach places.

5. Rinse the machine off immediate-

ly with clean water, and dry all

surfaces with a soft towel or cloth.

6. Immediately after washing, re-

move excess water from the

chain with a paper towel and lubri-

cate the chain to prevent rust.

7. Clean the seat with a vinyl uphol-

stery cleaner to keep the cover

pliable and glossy.

8. Automotive wax may be applied

to all painted or chromed surfac-

es. Avoid combination cleaner-

waxes, as they may contain abra-

sives.

9. After completing the above, start

the engine and allow it to idle for

several minutes.STORAGE

If your machine is to be stored for 60

days or more, some preventive mea-

sures must be taken to avoid deterio-

ration. After cleaning the machine

thoroughly, prepare it for storage as

follows:

1. Drain the fuel tank, fuel lines, and

the carburetor float bowl.

2. Remove the spark plug, pour a ta-

blespoon of SAE 10W-40 motor

oil in the spark plug hole, and re-

install the plug. With the engine

stop switch pushed in, kick the en-

gine over several times to coat the

cylinder walls with oil.

3. Remove the drive chain, clean it

thoroughly with solvent, and lubri-

cate it. Reinstall the chain or store

it in a plastic bag tied to the frame.

4. Lubricate all control cables.

5. Block the frame up to raise the

wheels off the ground.

6. Tie a plastic bag over the exhaust

pipe outlet to prevent moisture

from entering.

7. If the machine is to be stored in a

humid or salt-air environment,

coat all exposed metal surfaces

with a film of light oil. Do not apply

oil to rubber parts or the seat cov-

er.

Make any necessary repairs before

the machine is stored.

Page 25 of 168

2-1

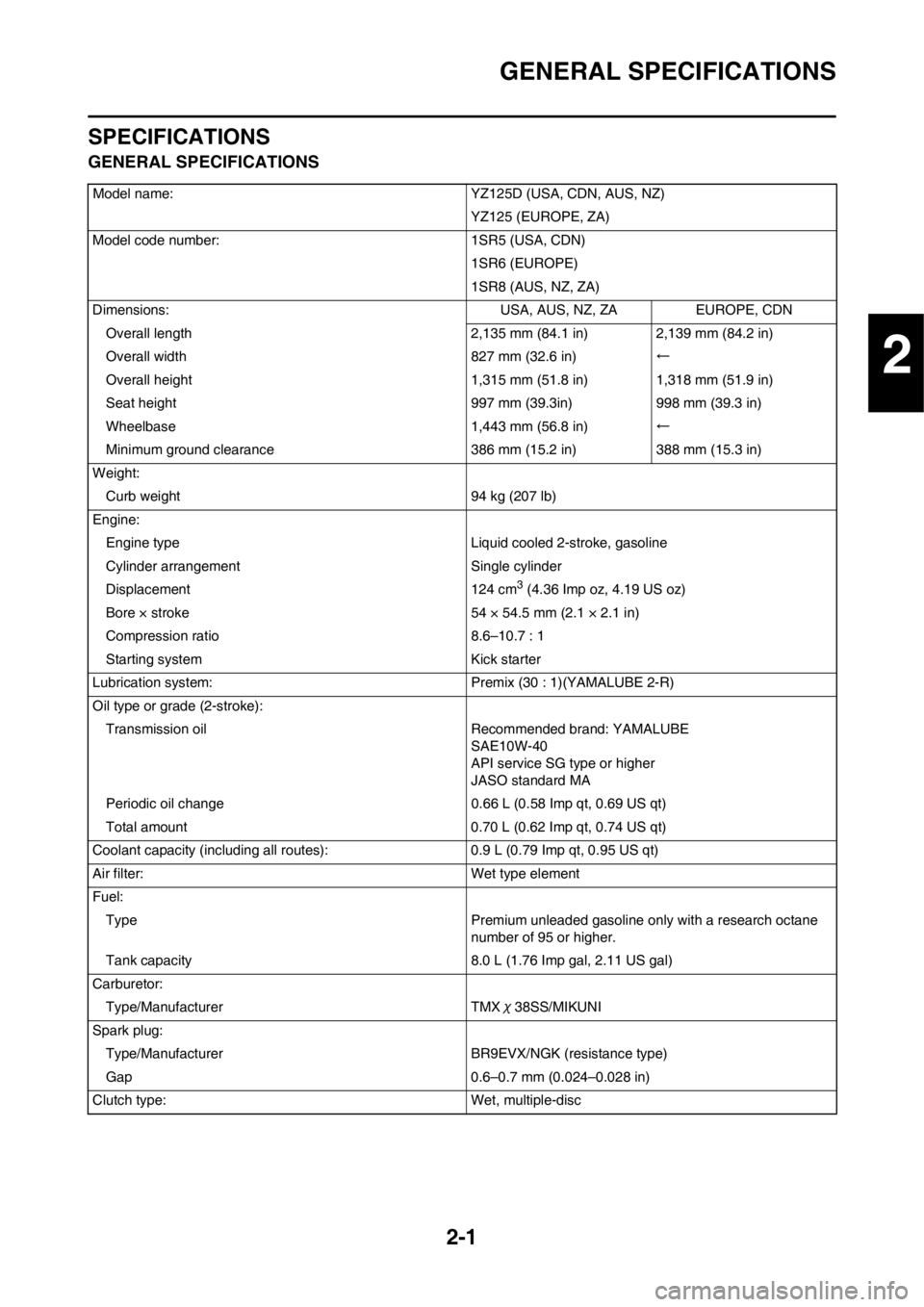

GENERAL SPECIFICATIONS

SPECIFICATIONS

GENERAL SPECIFICATIONS

Model name:YZ125D (USA, CDN, AUS, NZ)

YZ125 (EUROPE, ZA)

Model code number: 1SR5 (USA, CDN)

1SR6 (EUROPE)

1SR8 (AUS, NZ, ZA)

Dimensions: USA, AUS, NZ, ZAEUROPE, CDN

Overall length 2,135 mm (84.1 in) 2,139 mm (84.2 in)

Overall width 827 mm (32.6 in)←

Overall height 1,315 mm (51.8 in) 1,318 mm (51.9 in)

Seat height 997 mm (39.3in)998 mm (39.3 in)

Wheelbase 1,443 mm (56.8 in)←

Minimum ground clearance 386 mm (15.2 in)388 mm (15.3 in)

Weight: Curb weight 94 kg (207 lb)

Engine: Engine type Liquid cooled 2-stroke, gasoline

Cylinder arrangement Single cylinder

Displacement 124 cm

3 (4.36 Imp oz, 4.19 US oz)

Bore × stroke 54 × 54.5 mm (2.1 × 2.1 in)

Compression ratio 8.6–10.7 : 1

Starting system Kick starter

Lubrication system: Premix (30 : 1)(YAMALUBE 2-R)

Oil type or grade (2-stroke): Transmission oil Recommended brand: YAMALUBE SAE10W-40

API service SG type or higher

JASO standard MA

Periodic oil change 0.66 L (0.58 Imp qt, 0.69 US qt)

Total amount 0.70 L (0.62 Imp qt, 0.74 US qt)

Coolant capacity (including all routes): 0.9 L (0.79 Imp qt, 0.95 US qt)

Air filter: Wet type element

Fuel: Type Premium unleaded gasoline on ly with a research octane

number of 95 or higher.

Tank capacity 8.0 L (1.76 Imp gal, 2.11 US gal)

Carburetor: Type/Manufacturer TMX χ38SS/MIKUNI

Spark plug: Type/Manufacturer BR9EVX/NGK (resistance type)

Gap 0.6–0.7 mm (0.024–0.028 in)

Clutch type: Wet, multiple-disc

2

Page 26 of 168

2-2

MAINTENANCE SPECIFICATIONS

MAINTENANCE SPECIFICATIONS

ENGINETransmission:

Primary reduction system Gear

Primary reduction ratio 3.368 (64/19)

Final drive Chain

Secondary reduction ratio 3.692 (48/13)

Transmission type Constant mesh, 6-speed

Operation Left foot operation

Gear ratio:

1st 2.385 (31/13)

2nd 1.933 (29/15)

3rd 1.588 (27/17)

4th 1.353 (23/17)

5th 1.200 (24/20)

6th 1.095 (23/21)

Chassis: USA, AUS, ZA, NZ EUROPE, CDN

Frame type Semi double cradle←

Caster angle 25.50 ° 25.60 °

Trail 105 mm (4.1 in) 107 mm (4.2 in)

Tire:

Type With tube

Size (front) 80/100-21 51M

Size (rear) 100/90-19 57M

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm

2, 15 psi)

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Electrical:

Ignition system CDI magneto

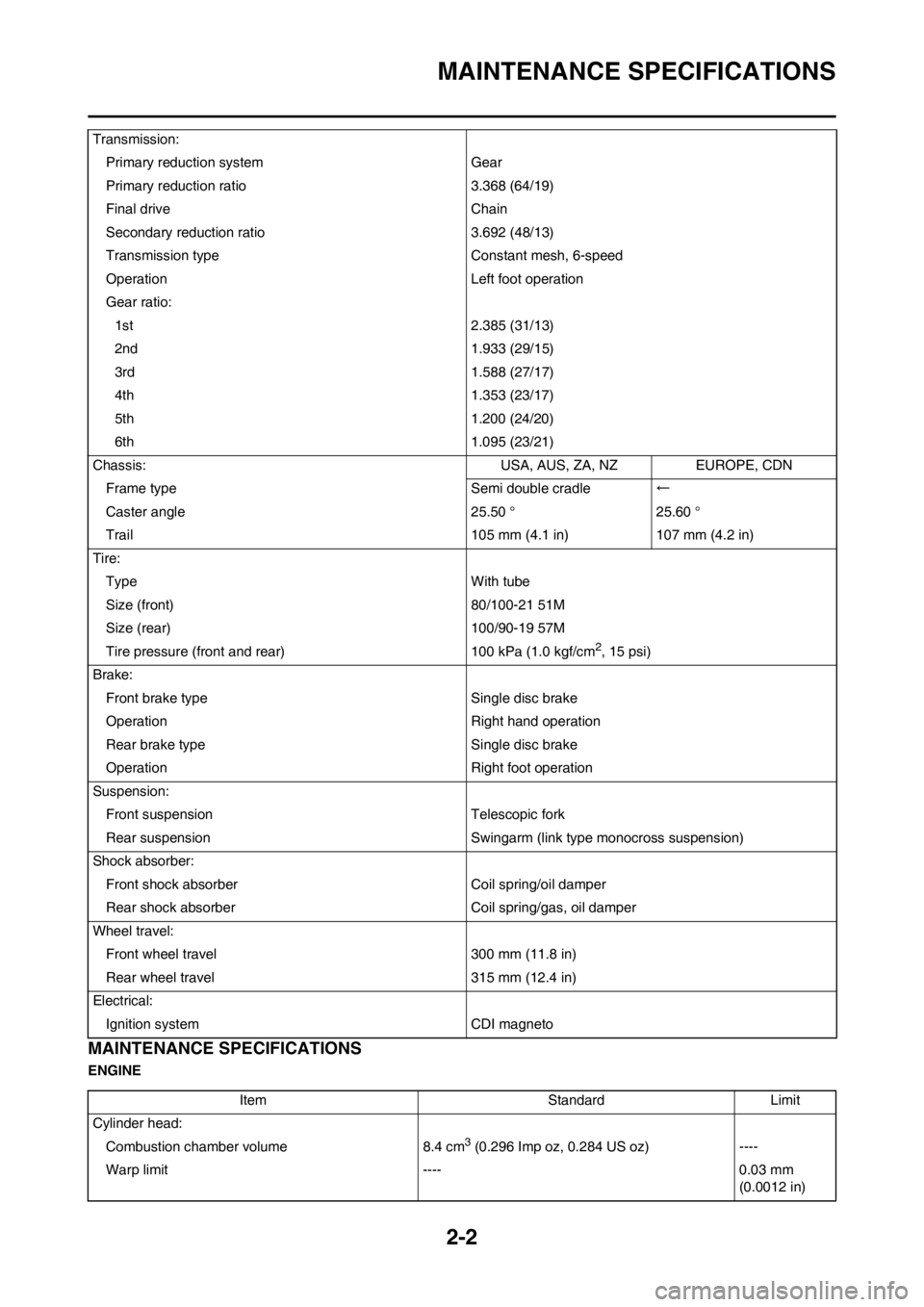

Item Standard Limit

Cylinder head:

Combustion chamber volume 8.4 cm

3 (0.296 Imp oz, 0.284 US oz) ----

Warp limit ---- 0.03 mm

(0.0012 in)

Page 31 of 168

2-7

TIGHTENING TORQUES

ELECTRICAL

TIGHTENING TORQUES

ENGINE

△- marked portion shall be checked for torque tightening after break-in or before each race.

Item Standard Limit

Ignition system:

Ignition timing (B.T.D.C.) 0.48 mm (0.019 in) ----

Advancer type Electrical ----

CDI:

Magneto-model (stator)/Manufacturer 1C3-10/YAMAHA ----

Charging coil 1 resistance (color) 720–1,080 Ωat 20 °C (68 °F) (Green/

White-Black/Red) ----

Charging coil 2 resistance (color) 44–66 Ωat 20 °C (68 °F) (Black-Green/

Blue) ----

Pickup coil resistance (color) 248–372 Ωat 20 °C (68 °F) (White/Blue-

White/Red) ----

CDI unit-model/manufacturer 1C3-10/YAMAHA (USA, CDN)

1SR-00/YAMAHA (EUROPE, AUS, ZA,

NZ)----

Ignition coil:

Model/manufacturer 1C3-00/YAMAHA ----

Minimum spark gap 6 mm (0.24 in) ----

Primary winding resistance 0.24–0.36 Ωat 20 °C (68 °F) ----

Secondary winding resistance 5.7–8.5 kΩat 20 °C (68 °F) ----

Spark plug cap:

Resistance 4–6 kΩat 20 °C (68 °F) ----

ItemThread

sizeQ'ty Tightening torque Remarks

Spark plug M14S 1 20 Nm (2.0 m•kg, 14 ft•lb)

Cylinder head (nut) M8 5 28 Nm (2.8 m•kg, 20 ft•lb)Copper

washer

Cylinder head (stud) M8 5 13 Nm (1.3 m•kg, 9.4 ft•lb)

Cylinder (nut) M8 4 30 Nm (3.0 m•kg, 22 ft•lb)

Cylinder (stud) M10 4 13 Nm (1.3 m•kg, 9.4 ft•lb)

Power valve:

Cover M5 4 5 Nm (0.5 m•kg, 3.6 ft•lb) YPVS

Link lever M4 1 4 Nm (0.4 m•kg, 2.9 ft•lb) YPVS

Holder (power valve) M5 4 8 Nm (0.8 m•kg, 5.8 ft•lb) YPVS

Push rod M5 1 5 Nm (0.5 m•kg, 3.6 ft•lb) YPVS

Thrust plate M5 1 4 Nm (0.4 m•kg, 2.9 ft•lb) YPVS

Governor fork M4 2 5 Nm (0.5 m•kg, 3.6 ft•lb) YPVS

Housing M5 3 4 Nm (0.4 m•kg, 2.9 ft•lb) YPVS

Water pump housing cover M6 4 10 Nm (1.0 m•kg, 7.2 ft•lb)

Coolant drain bolt M6 1 10 Nm (1.0 m•kg, 7.2 ft•lb)Copper

washer

Radiator M6 6 10 Nm (1.0 m•kg, 7.2 ft•lb)

Radiator guard M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Page 33 of 168

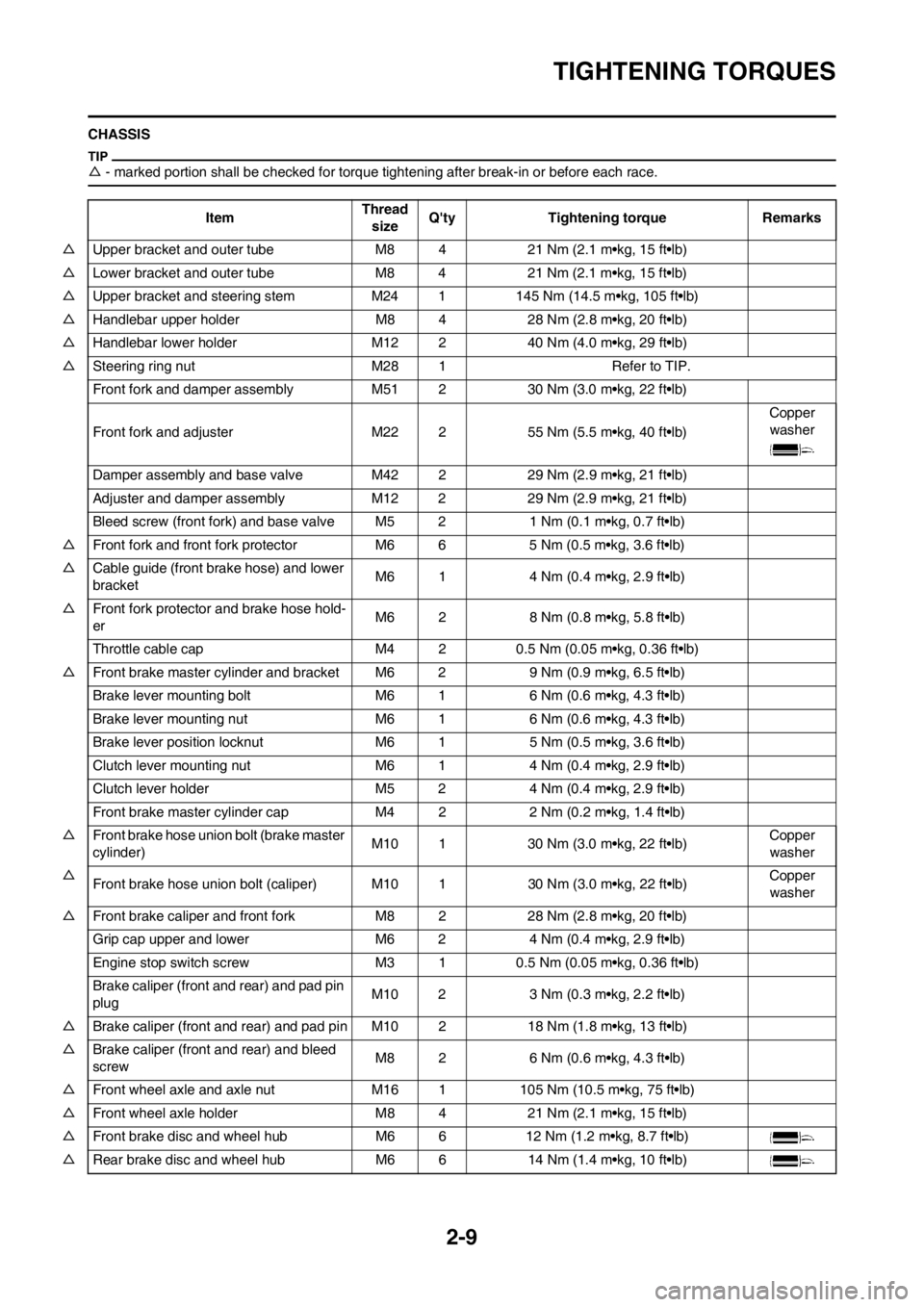

2-9

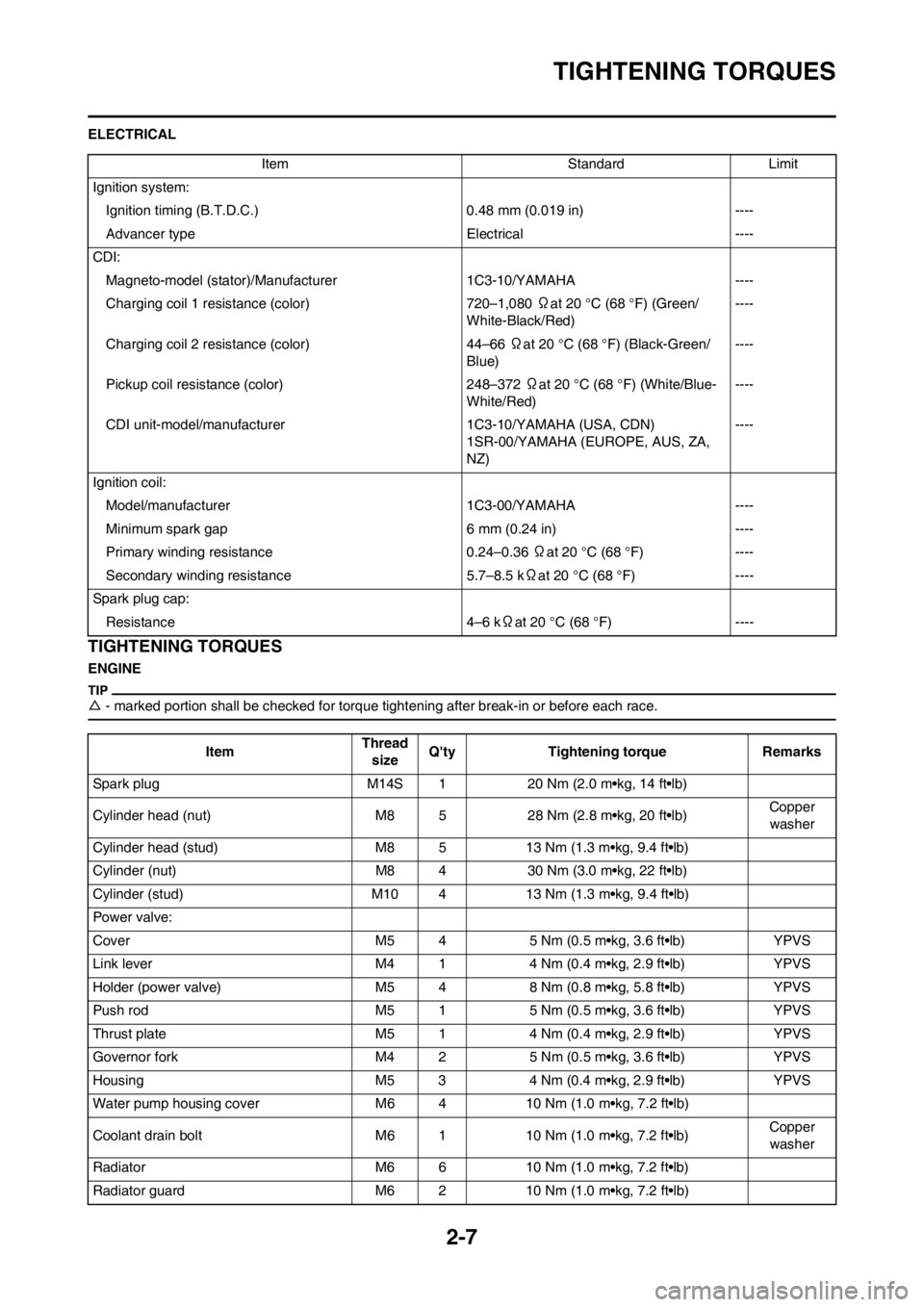

TIGHTENING TORQUES

CHASSIS

△- marked portion shall be checked for torque tightening after break-in or before each race.

ItemThread

sizeQ'ty Tightening torque Remarks

△Upper bracket and outer tube M84 21 Nm (2.1 m•kg, 15 ft•lb)

△Lower bracket and outer tube M8 4 21 Nm (2.1 m•kg, 15 ft•lb)

△Upper bracket and steering stem M24 1 145 Nm (14.5 m•kg, 105 ft•lb)

△Handlebar upper holder M8 4 28 Nm (2.8 m•kg, 20 ft•lb)

△Handlebar lower holder M12 2 40 Nm (4.0 m•kg, 29 ft•lb)

△Steering ring nut M28 1 Refer to TIP.

Front fork and damper assembly M51 2 30 Nm (3.0 m•kg, 22 ft•lb)

Front fork and adjuster M22 2 55 Nm (5.5 m•kg, 40 ft•lb)Copper

washer

Damper assembly and base valve M42 2 29 Nm (2.9 m•kg, 21 ft•lb)

Adjuster and damper assembly M12 2 29 Nm (2.9 m•kg, 21 ft•lb)

Bleed screw (front fork) and base valve M5 2 1 Nm (0.1 m•kg, 0.7 ft•lb)

△Front fork and front fork protector M6 6 5 Nm (0.5 m•kg, 3.6 ft•lb)

△Cable guide (front brake hose) and lower

bracketM6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Front fork protector and brake hose hold-

erM6 2 8 Nm (0.8 m•kg, 5.8 ft•lb)

Throttle cable cap M4 2 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

△Front brake master cylinder and bracket M6 2 9 Nm (0.9 m•kg, 6.5 ft•lb)

Brake lever mounting bolt M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever mounting nut M6 1 6 Nm (0.6 m•kg, 4.3 ft•lb)

Brake lever position locknut M6 1 5 Nm (0.5 m•kg, 3.6 ft•lb)

Clutch lever mounting nut M6 1 4 Nm (0.4 m•kg, 2.9 ft•lb)

Clutch lever holder M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Front brake master cylinder cap M4 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

△Front brake hose union bolt (brake master

cylinder)M10 1 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△

Front brake hose union bolt (caliper) M10 1 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Front brake caliper and front fork M8 2 28 Nm (2.8 m•kg, 20 ft•lb)

Grip cap upper and lower M6 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Engine stop switch screw M3 1 0.5 Nm (0.05 m•kg, 0.36 ft•lb)

Brake caliper (front and rear) and pad pin

plugM10 2 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Brake caliper (front and rear) and pad pin M10 2 18 Nm (1.8 m•kg, 13 ft•lb)

△Brake caliper (front and rear) and bleed

screwM8 2 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Front wheel axle and axle nut M16 1 105 Nm (10.5 m•kg, 75 ft•lb)

△Front wheel axle holder M8 4 21 Nm (2.1 m•kg, 15 ft•lb)

△Front brake disc and wheel hub M6 6 12 Nm (1.2 m•kg, 8.7 ft•lb)

△Rear brake disc and wheel hub M6 6 14 Nm (1.4 m•kg, 10 ft•lb)

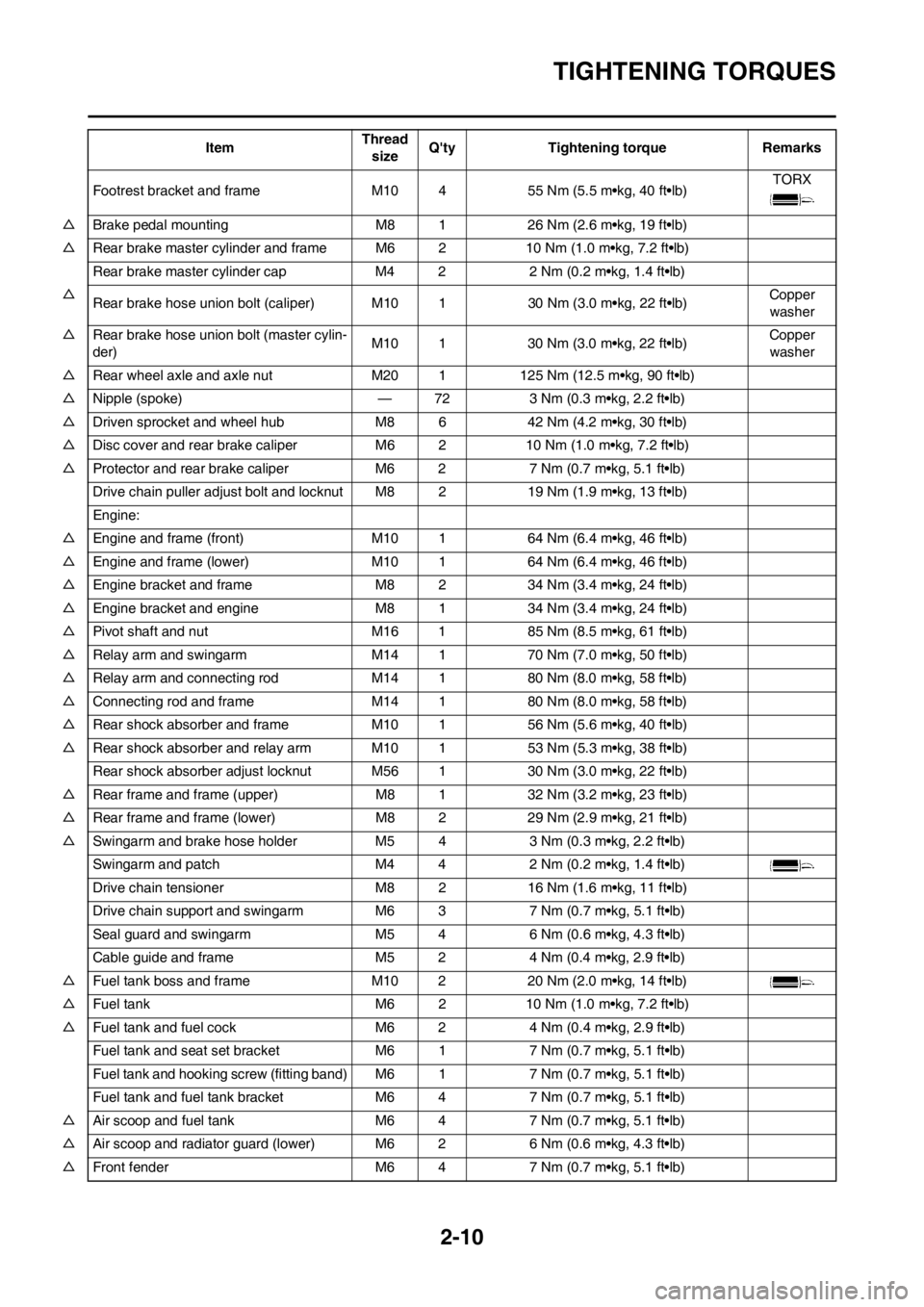

Page 34 of 168

2-10

TIGHTENING TORQUES

Footrest bracket and frame M10 4 55 Nm (5.5 m•kg, 40 ft•lb)T O R X

△Brake pedal mounting M8 1 26 Nm (2.6 m•kg, 19 ft•lb)

△Rear brake master cylinder and frame M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

Rear brake master cylinder cap M4 2 2 Nm (0.2 m•kg, 1.4 ft•lb)

△

Rear brake hose union bolt (caliper) M10 1 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Rear brake hose union bolt (master cylin-

der)M10 1 30 Nm (3.0 m•kg, 22 ft•lb)Copper

washer

△Rear wheel axle and axle nut M20 1 125 Nm (12.5 m•kg, 90 ft•lb)

△Nipple (spoke) — 72 3 Nm (0.3 m•kg, 2.2 ft•lb)

△Driven sprocket and wheel hub M8 6 42 Nm (4.2 m•kg, 30 ft•lb)

△Disc cover and rear brake caliper M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

△Protector and rear brake caliper M6 2 7 Nm (0.7 m•kg, 5.1 ft•lb)

Drive chain puller adjust bolt and locknut M8 2 19 Nm (1.9 m•kg, 13 ft•lb)

Engine:

△Engine and frame (front) M10 1 64 Nm (6.4 m•kg, 46 ft•lb)

△Engine and frame (lower) M10 1 64 Nm (6.4 m•kg, 46 ft•lb)

△Engine bracket and frame M8 2 34 Nm (3.4 m•kg, 24 ft•lb)

△Engine bracket and engine M8 1 34 Nm (3.4 m•kg, 24 ft•lb)

△Pivot shaft and nut M16 1 85 Nm (8.5 m•kg, 61 ft•lb)

△Relay arm and swingarm M14 1 70 Nm (7.0 m•kg, 50 ft•lb)

△Relay arm and connecting rod M14 1 80 Nm (8.0 m•kg, 58 ft•lb)

△Connecting rod and frame M14 1 80 Nm (8.0 m•kg, 58 ft•lb)

△Rear shock absorber and frame M10 1 56 Nm (5.6 m•kg, 40 ft•lb)

△Rear shock absorber and relay arm M10 1 53 Nm (5.3 m•kg, 38 ft•lb)

Rear shock absorber adjust locknut M56 1 30 Nm (3.0 m•kg, 22 ft•lb)

△Rear frame and frame (upper) M8 1 32 Nm (3.2 m•kg, 23 ft•lb)

△Rear frame and frame (lower) M8 2 29 Nm (2.9 m•kg, 21 ft•lb)

△Swingarm and brake hose holder M54 3 Nm (0.3 m•kg, 2.2 ft•lb)

Swingarm and patch M4 4 2 Nm (0.2 m•kg, 1.4 ft•lb)

Drive chain tensioner M8 2 16 Nm (1.6 m•kg, 11 ft•lb)

Drive chain support and swingarm M6 37 Nm (0.7 m•kg, 5.1 ft•lb)

Seal guard and swingarm M5 4 6 Nm (0.6 m•kg, 4.3 ft•lb)

Cable guide and frame M5 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

△Fuel tank boss and frame M10 2 20 Nm (2.0 m•kg, 14 ft•lb)

△Fuel tank M6 2 10 Nm (1.0 m•kg, 7.2 ft•lb)

△Fuel tank and fuel cock M6 2 4 Nm (0.4 m•kg, 2.9 ft•lb)

Fuel tank and seat set bracket M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Fuel tank and hooking screw (fitting band) M6 1 7 Nm (0.7 m•kg, 5.1 ft•lb)

Fuel tank and fuel tank bracket M6 4 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Air scoop and fuel tank M6 4 7 Nm (0.7 m•kg, 5.1 ft•lb)

△Air scoop and radiator guard (lower) M6 2 6 Nm (0.6 m•kg, 4.3 ft•lb)

△Front fender M6 4 7 Nm (0.7 m•kg, 5.1 ft•lb)ItemThread

sizeQ'ty Tightening torque Remarks

Page 36 of 168

2-12

TIGHTENING TORQUES

GENERAL TORQUE

SPECIFICATIONS

This chart specifies torque for stan-

dard fasteners with standard I.S.O.

pitch threads. Torque specifications

for special components or assem-

blies are included in the applicable

sections of this book. To avoid warp-

age, tighten multi-fastener assem-

blies in a crisscross fashion, in

progressive stages, until full torque is

reached. Unless otherwise specified,

torque specifications call for clean,

dry threads. Components should be

at room temperature.A. Distance between flats

B. Outside thread diameter

DEFINITION OF UNITS

A

(Nut)B

(Bolt

)TORQUE SPECIFI-

CATION

Nm m•kg ft•lb

10

mm6 mm 6 0.6 4.3

12

mm8 mm 15 1.5 11

14

mm10

mm30 3.0 22

17

mm12

mm55 5.5 40

19

mm14

mm85 8.5 61

22

mm16

mm130 13 94

Unit Read Definition Measure

mm

millimeter 10-3 meter Length

cmcentimeter 10-2 meter Length

kgkilogram 103 gram Weight

NNewton 1 kg × m/sec2Force

NmNewton meter N × m Torque

m•kgMeter kilogram m × kg Torque

PaPascal N/m2Pressure

N/mmNewton per millimeter N/mm Spring rate

LLiter — Volume or capacity

cm3Cubic centimeter — Volume or capacity

r/minRevolution per minute — Engine speed

Page 38 of 168

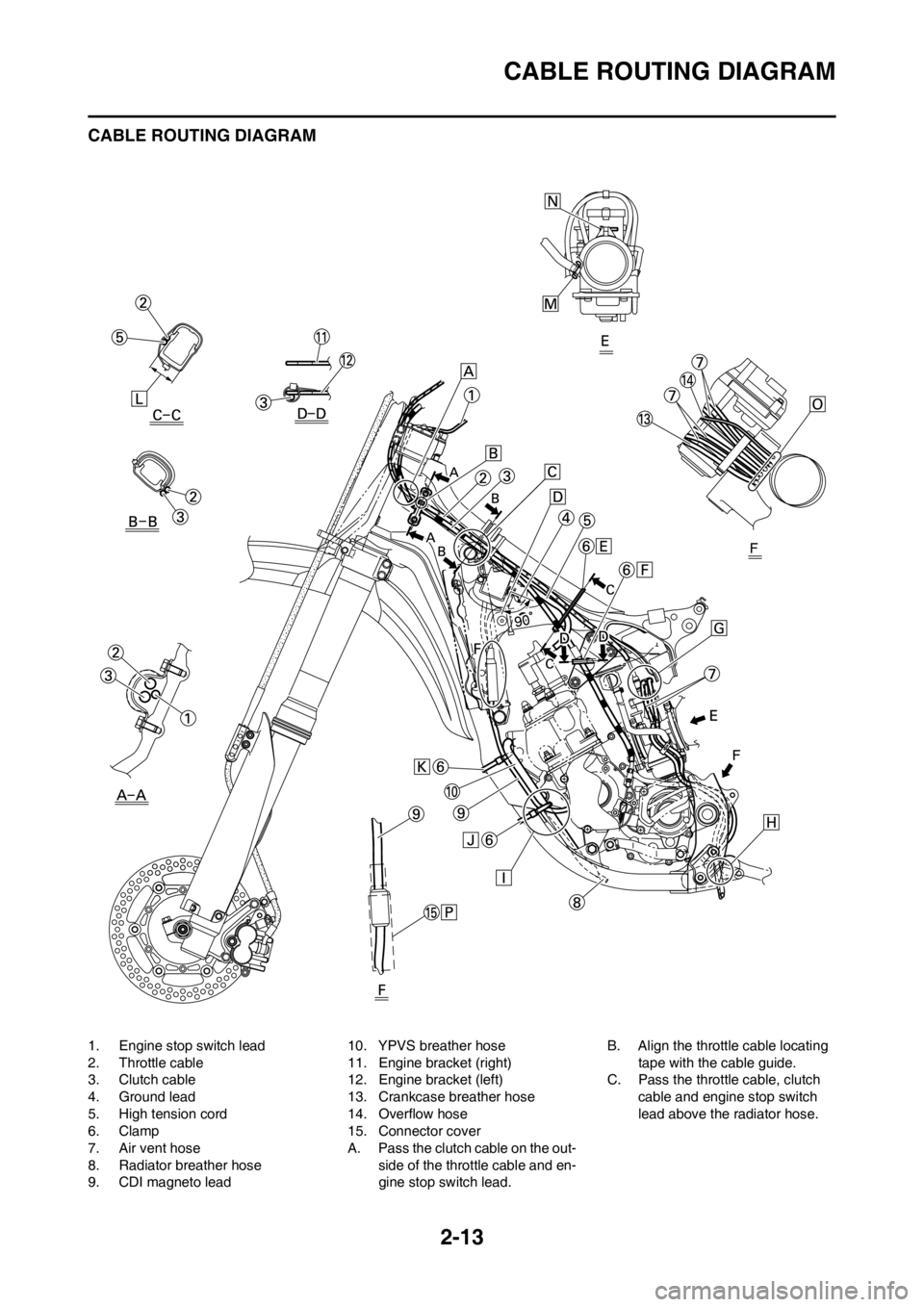

2-13

CABLE ROUTING DIAGRAM

CABLE ROUTING DIAGRAM

1. Engine stop switch lead

2. Throttle cable

3. Clutch cable

4. Ground lead

5. High tension cord

6. Clamp

7. Air vent hose

8. Radiator breather hose

9. CDI magneto lead10. YPVS breather hose

11. Engine bracket (right)

12. Engine bracket (left)

13. Crankcase breather hose

14. Overflow hose

15. Connector cover

A. Pass the clutch cable on the out-

side of the throttle cable and en-

gine stop switch lead.B. Align the throttle cable locating

tape with the cable guide.

C. Pass the throttle cable, clutch

cable and engine stop switch

lead above the radiator hose.

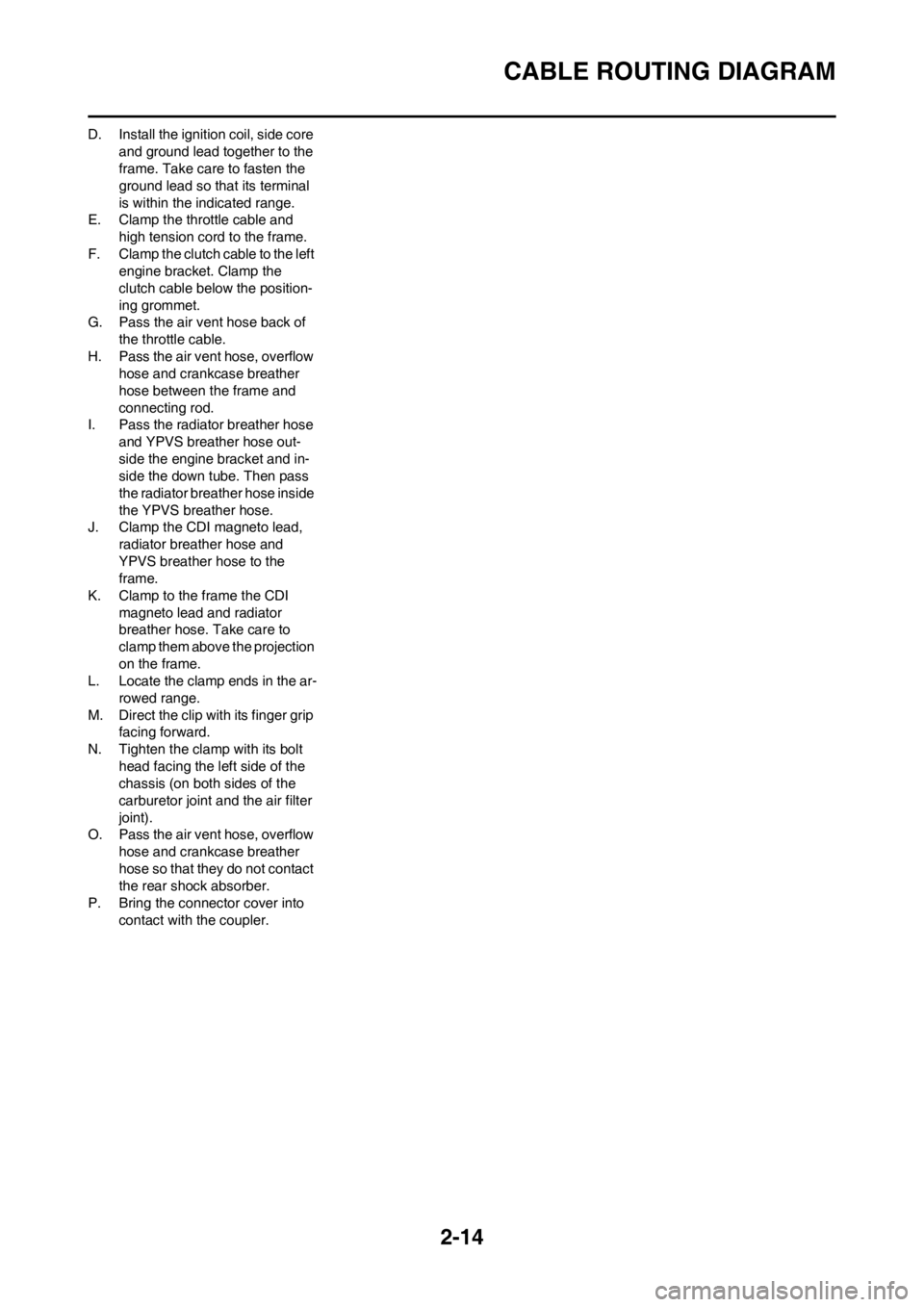

Page 39 of 168

2-14

CABLE ROUTING DIAGRAM

D. Install the ignition coil, side core

and ground lead together to the

frame. Take care to fasten the

ground lead so that its terminal

is within the indicated range.

E. Clamp the throttle cable and

high tension cord to the frame.

F. Clamp the clutch cable to the left

engine bracket. Clamp the

clutch cable below the position-

ing grommet.

G. Pass the air vent hose back of

the throttle cable.

H. Pass the air vent hose, overflow

hose and crankcase breather

hose between the frame and

connecting rod.

I. Pass the radiator breather hose

and YPVS breather hose out-

side the engine bracket and in-

side the down tube. Then pass

the radiator breather hose inside

the YPVS breather hose.

J. Clamp the CDI magneto lead,

radiator breather hose and

YPVS breather hose to the

frame.

K. Clamp to the frame the CDI

magneto lead and radiator

breather hose. Take care to

clamp them above the projection

on the frame.

L. Locate the clamp ends in the ar-

rowed range.

M. Direct the clip with its finger grip

facing forward.

N. Tighten the clamp with its bolt

head facing the left side of the

chassis (on both sides of the

carburetor joint and the air filter

joint).

O. Pass the air vent hose, overflow

hose and crankcase breather

hose so that they do not contact

the rear shock absorber.

P. Bring the connector cover into

contact with the coupler.

Page 40 of 168

2-15

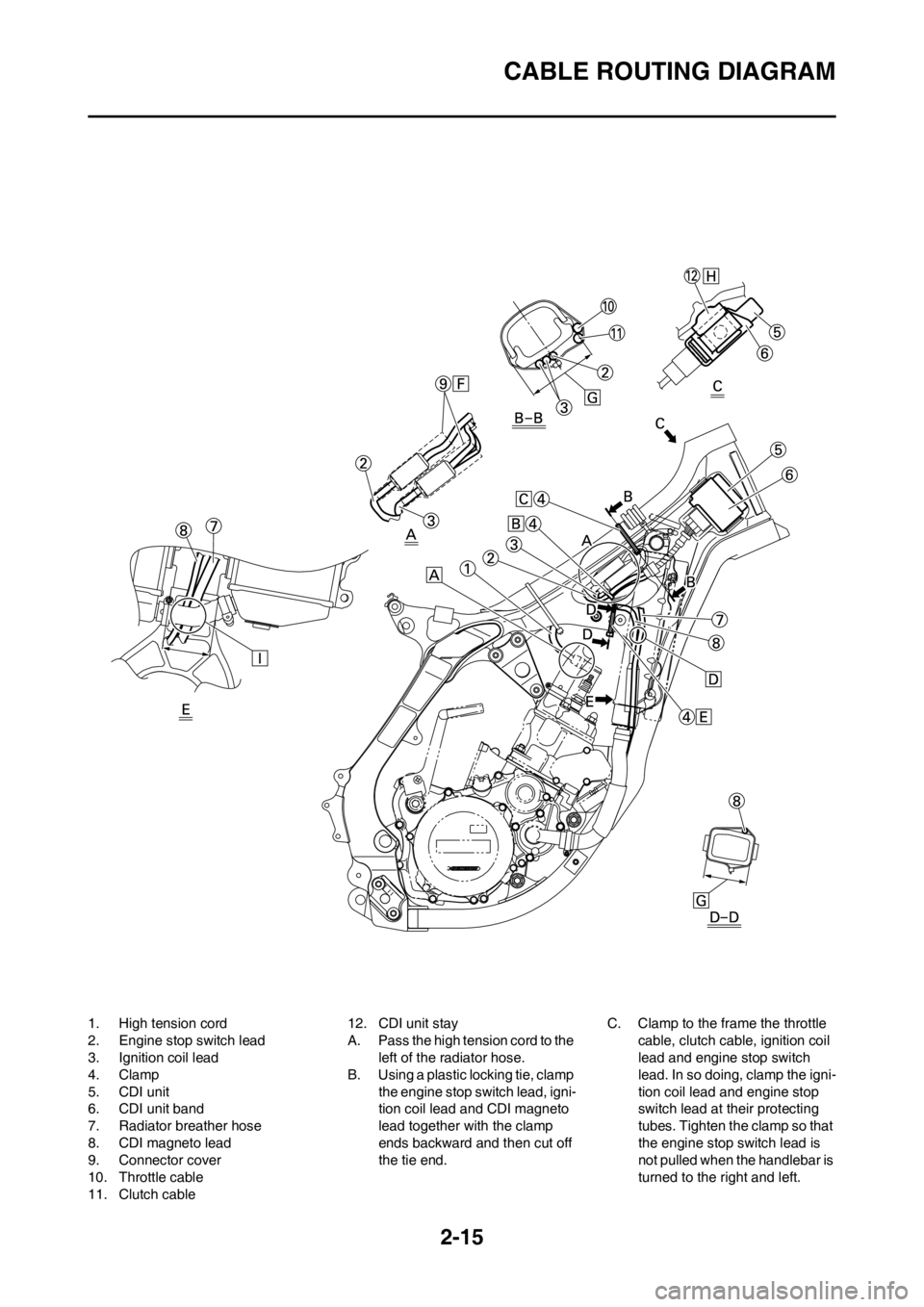

CABLE ROUTING DIAGRAM

1. High tension cord

2. Engine stop switch lead

3. Ignition coil lead

4. Clamp

5. CDI unit

6. CDI unit band

7. Radiator breather hose

8. CDI magneto lead

9. Connector cover

10. Throttle cable

11. Clutch cable12. CDI unit stay

A. Pass the high tension cord to the

left of the radiator hose.

B. Using a plastic locking tie, clamp

the engine stop switch lead, igni-

tion coil lead and CDI magneto

lead together with the clamp

ends backward and then cut off

the tie end.C. Clamp to the frame the throttle

cable, clutch cable, ignition coil

lead and engine stop switch

lead. In so doing, clamp the igni-

tion coil lead and engine stop

switch lead at their protecting

tubes. Tighten the clamp so that

the engine stop switch lead is

not pulled when the handlebar is

turned to the right and left.