torque YAMAHA YZ250F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Dimensioni: 24.86 MB

Page 304 of 656

4 - 25

ENGCAMSHAFTS

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

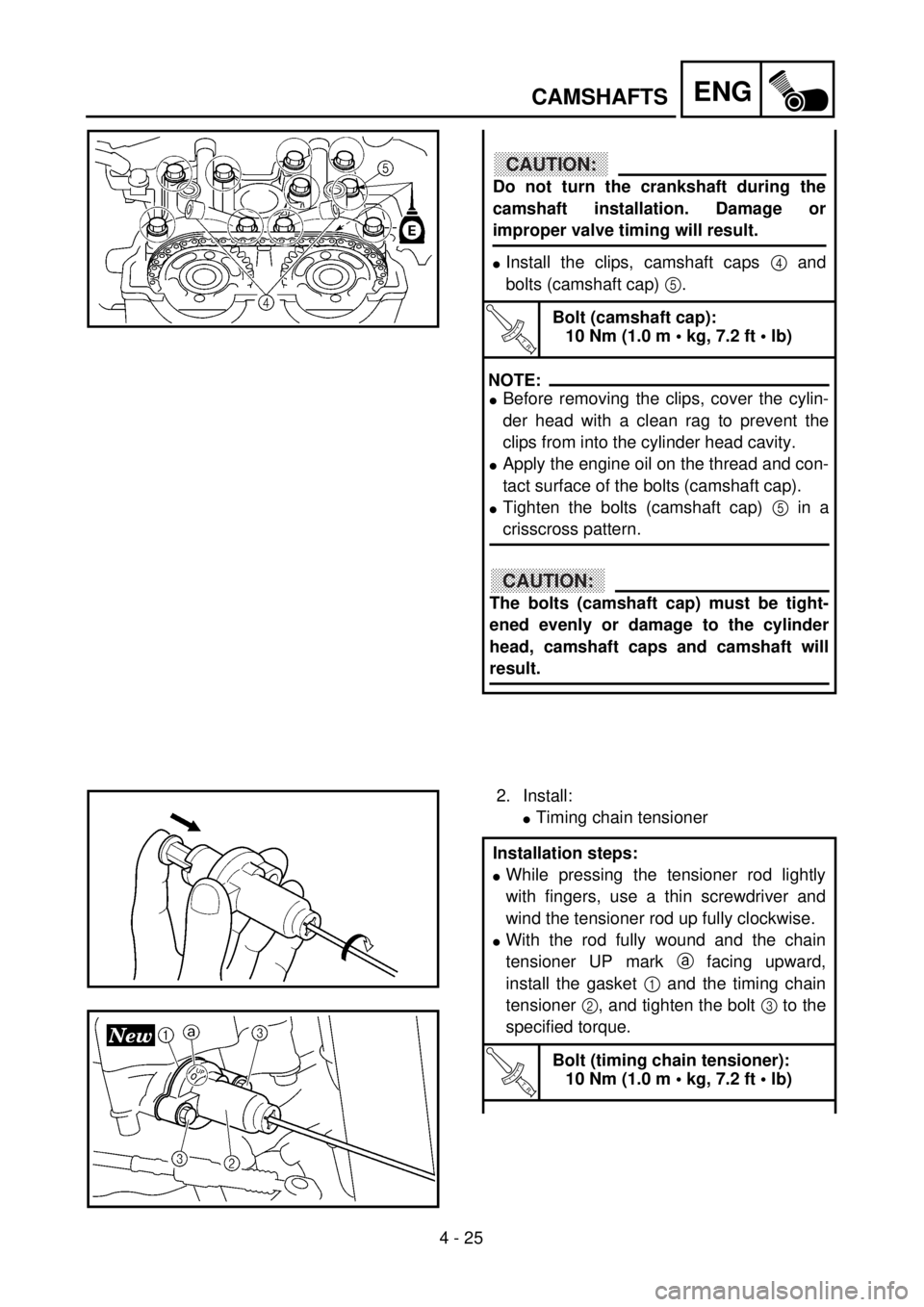

lInstall the clips, camshaft caps 4 and

bolts (camshaft cap) 5.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

NOTE:

lBefore removing the clips, cover the cylin-

der head with a clean rag to prevent the

clips from into the cylinder head cavity.

lApply the engine oil on the thread and con-

tact surface of the bolts (camshaft cap).

lTighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly or damage to the cylinder

head, camshaft caps and camshaft will

result.

2. Install:

lTiming chain tensioner

Installation steps:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

lWith the rod fully wound and the chain

tensioner UP mark a facing upward,

install the gasket 1 and the timing chain

tensioner 2, and tighten the bolt 3 to the

specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

Page 306 of 656

4 - 26

ENG

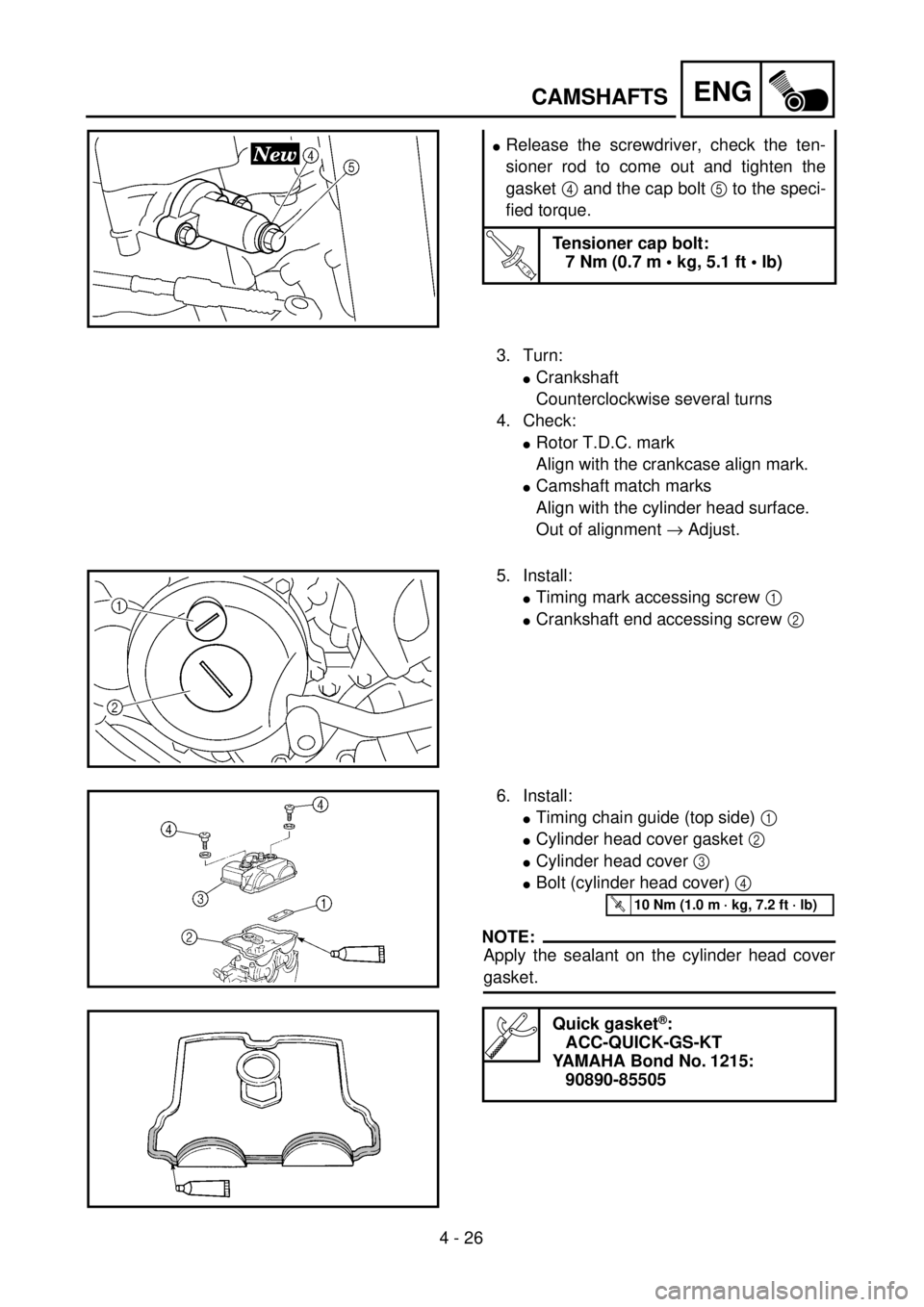

lRelease the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket 4 and the cap bolt 5 to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

3. Turn:

lCrankshaft

Counterclockwise several turns

4. Check:

lRotor T.D.C. mark

Align with the crankcase align mark.

lCamshaft match marks

Align with the cylinder head surface.

Out of alignment ® Adjust.

5. Install:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

6. Install:

lTiming chain guide (top side) 1

lCylinder head cover gasket 2

lCylinder head cover 3

lBolt (cylinder head cover) 4

NOTE:

Apply the sealant on the cylinder head cover

gasket.

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

CAMSHAFTS

Page 425 of 656

ENG

4 - 85

DEPOSE DU MOTEUR

MOTOR DEMONTIEREN

RIMOZIONE DEL MOTORE

2. Montieren:

lSicherungsscheibe 1

lMutter (Antriebsritzel) 2

HINWEIS:

Beim Festziehen der Mutter die Hin-

terradbremse betätigen.

T R..75 Nm (7,5 m · kg)

3. Die Lasche der Sicherungs-

scheibe umbiegen, um die

Mutter zu sichern.

4. Montieren:

lAntriebskettenritzel 1

lKettenschutz 2

lSchraube (Kettenschutz) 3

T R..10 Nm (1,0 m · kg)

Ölschlauch und Leerlaufschalter

1. Montieren:

lO-Ring 1

lPaßstift 2

lÖlschlauch 3

lSchraube (Ölschlauch) 4

HINWEIS:

Lithiumfett auf den O-Ring auftragen.

2. Montieren:

lFeder 1

lStift 2

lO-Ring 3

lLeerlaufschalter 4

lSchraube (Leerlaufschalter)

5

HINWEIS:

Lithiumfett auf den O-Ring auftragen.

T R..10 Nm (1,0 m · kg)

T R..4 Nm (0,4 m · kg)

2. Monter:

lRondelle-frein 1

lEcrou (pignon d’entraînement)

2

N.B.:

Serrer l’écrou en actionnant le frein

arrière.

T R..75 Nm (7,5 m · kg, 54 ft · lb)

3. Courber la languette de la ron-

delle-frein pour verrouiller

l’écrou.

4. Monter:

lGuide de pignon de chaîne de

transmission 1

lCouvercle de chaîne 2

lVis (couvercle de chaîne) 3

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

Durit d’huile et contacteur de point

mort

1. Monter:

lJoint torique 1

lGoujon 2

lDurit d’huile 3

lBoulon (durit d’huile) 4

N.B.:

Enduire le joint torique de graisse à base

de savon au lithium.

2. Monter:

lRessort 1

lGoupille 2

lJoint torque 3

lContacteur de point mort 4

lBoulon (contacteur de point

mort) 5

N.B.:

Enduire le joint torique de graisse à base

de savon au lithium.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

2. Installare:

lRondella di bloccaggio 1

lDado (corona dentata trasmis-

sione) 2

NOTA:

Avvitare il dado agendo sul freno poste-

riore.

T R..75 Nm (7,5 m · kg, 54 ft · lb)

3. Piegare la linguetta della ron-

della di bloccaggio.

4. Installare:

lGuida corona catena di tra-

smissione 1

lCarterino corona catena di tra-

smissione 2

lVite (carterino corona catena di

trasmissione) 3

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

Flessibile dell’olio e interruttore di

folle

1. Installare:

lO-ring 1

lGrano di centraggio 2

lFlessibile dell’olio 3

lBullone (tubo flessibile

dell’olio) 4

NOTA:

Applicare grasso a base di sapone di litio

sull’O-ring.

2. Installare:

lMolla 1

lPerno 2

lO-ring 3

lInterruttore folle 4

lBullone (interruttore folle) 5

NOTA:

Applicare grasso a base di sapone di litio

sull’O-ring.

T R..10 Nm (1,0 m · kg, 7,2 ft · lb)

T R..4 Nm (0,4 m · kg, 2,9 ft · lb)

Page 528 of 656

5 - 38

CHASFRONT FORK

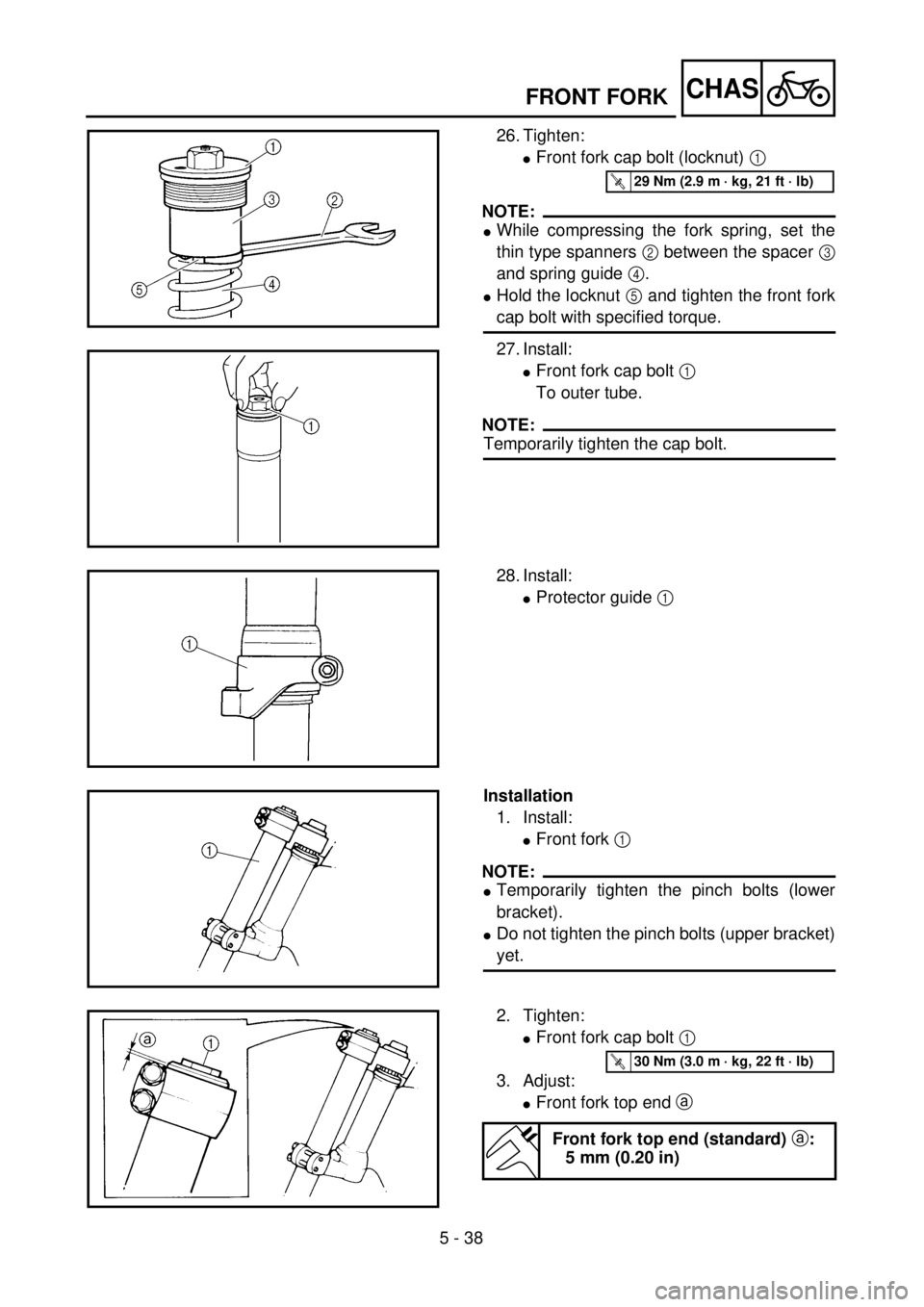

26. Tighten:

lFront fork cap bolt (locknut) 1

NOTE:

lWhile compressing the fork spring, set the

thin type spanners 2 between the spacer 3

and spring guide 4.

lHold the locknut 5 and tighten the front fork

cap bolt with specified torque.

27. Install:

lFront fork cap bolt 1

To outer tube.

NOTE:

Temporarily tighten the cap bolt.

T R..29 Nm (2.9 m · kg, 21 ft · lb)

28. Install:

lProtector guide 1

Installation

1. Install:

lFront fork 1

NOTE:

lTemporarily tighten the pinch bolts (lower

bracket).

lDo not tighten the pinch bolts (upper bracket)

yet.

2. Tighten:

lFront fork cap bolt 1

3. Adjust:

lFront fork top end a

Front fork top end (standard) a:

5 mm (0.20 in)

T R..30 Nm (3.0 m · kg, 22 ft · lb)

Page 530 of 656

5 - 39

CHASFRONT FORK

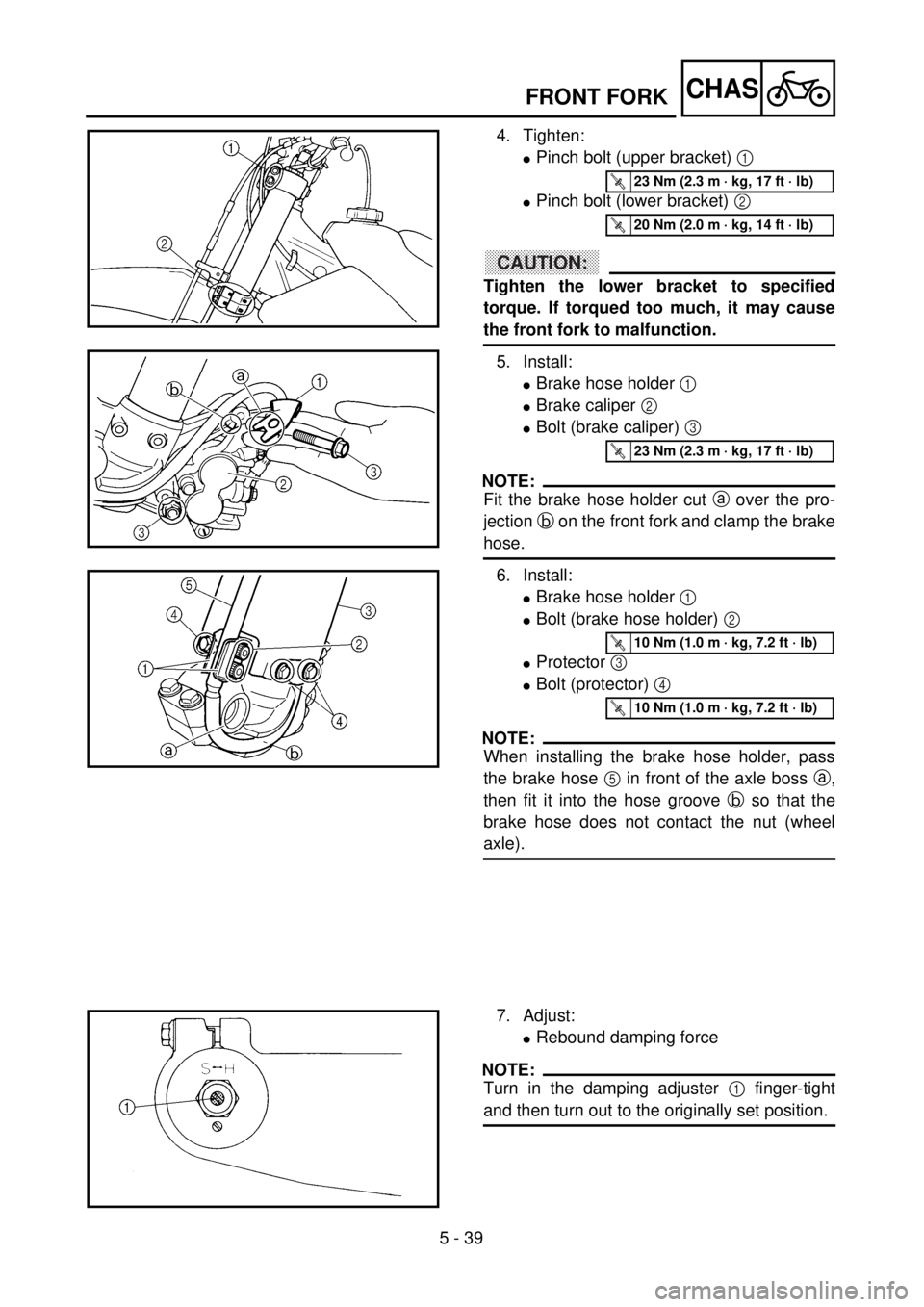

4. Tighten:

lPinch bolt (upper bracket) 1

lPinch bolt (lower bracket) 2

ACHTUNG:CAUTION:

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

5. Install:

lBrake hose holder 1

lBrake caliper 2

lBolt (brake caliper) 3

NOTE:

Fit the brake hose holder cut a over the pro-

jection b on the front fork and clamp the brake

hose.

6. Install:

lBrake hose holder 1

lBolt (brake hose holder) 2

lProtector 3

lBolt (protector) 4

NOTE:

When installing the brake hose holder, pass

the brake hose 5 in front of the axle boss a,

then fit it into the hose groove b so that the

brake hose does not contact the nut (wheel

axle).

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

7. Adjust:

lRebound damping force

NOTE:

Turn in the damping adjuster 1 finger-tight

and then turn out to the originally set position.

Page 550 of 656

5 - 49

CHASSTEERING

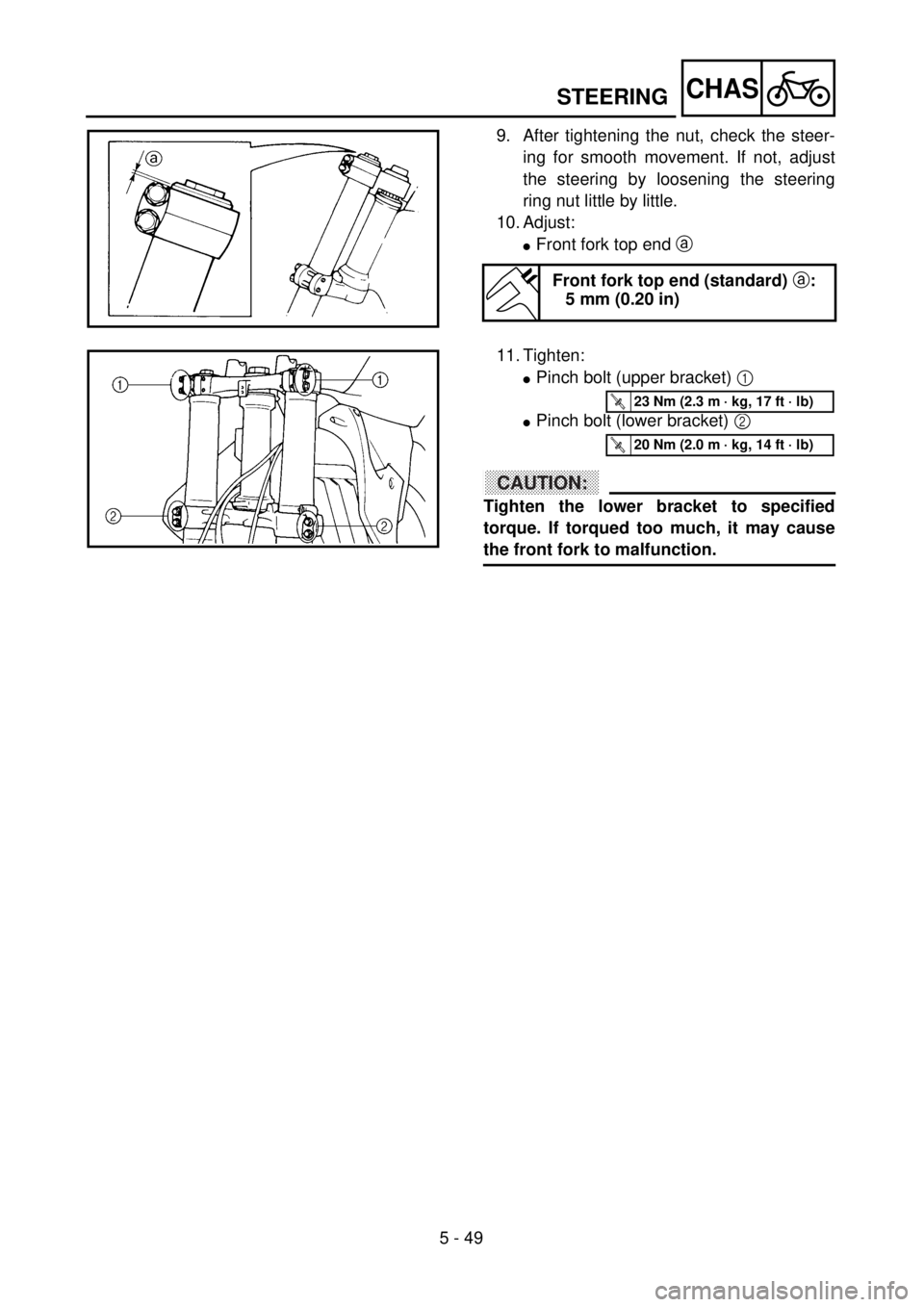

9. After tightening the nut, check the steer-

ing for smooth movement. If not, adjust

the steering by loosening the steering

ring nut little by little.

10. Adjust:

lFront fork top end a

Front fork top end (standard) a:

5 mm (0.20 in)

11. Tighten:

lPinch bolt (upper bracket) 1

lPinch bolt (lower bracket) 2

ACHTUNG:CAUTION:

Tighten the lower bracket to specified

torque. If torqued too much, it may cause

the front fork to malfunction.

T R..23 Nm (2.3 m · kg, 17 ft · lb)

T R..20 Nm (2.0 m · kg, 14 ft · lb)

Page 648 of 656

7 - 21

TUNSETTING

EC72H002

Suspension setting

lFront fork

NOTE:

lIf any of the following symptoms is experienced with the standard position as the base, make

resetting by reference to the adjustment procedure given in the same chart.

lBefore any change, set the rear shock absorber sunken length to the standard figure 90 ~

100 mm (3.5 ~ 3.9 in).

SymptomSection

Check Adjust

JumpLarge

gapMedium

gapSmall

gap

Stiff over entire range

CCC

Compression damping

Oil level (oil amount)

SpringTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with soft spring.

Unsmooth movement

over entire range

CCCC

Outer tube

Inner tube

Under bracket tightening

torqueCheck for any bends, dents, and other noticeable

scars, etc. If any, replace affected parts.

Retighten to specified torque.

Poor initial

movement

C

Rebound damping

Oil sealTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Apply grease in oil seal wall.

Soft over entire range,

bottoming out

CC

Compression damping

Oil level (oil amount)

SpringTurn adjuster clockwise (about 2 clicks) to increase

damping.

Increase oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).

Replace with stiff spring.

Stiff toward stroke end

COil level (oil amount) Decrease oil level by about 5 mm (0.2 in).

Soft toward stroke end,

bottoming out

COil level (oil amount) Increase oil level by about 5 mm (0.2 in).

Stiff initial movement

CCCCCompression dampingTurn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Low front, tending to

lower front posture

CC

Compression damping

Rebound damping

Balance with rear end

Oil level (oil amount)Turn adjuster clockwise (about 2 clicks) to increase

damping.

Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 95 ~ 100 mm (3.7 ~ 3.9 in) when

one passenger is astride seat (lower rear posture).

Increase oil level by about 5 mm (0.2 in).

“Obtrusive” front, tend-

ing to upper front pos-

ture

CC

Compression damping

Balance with rear end

Spring

Oil lever (oil amount)Turn adjuster counterclockwise (about 2 clicks) to

decrease damping.

Set sunken length for 90 ~ 95 mm (3.5 ~ 3.7 in) when

one passenger is astride seat (upper rear posture).

Replace with soft spring.

Decrease oil level by about 5 ~ 10 mm (0.2 ~ 0.4 in).