clock YAMAHA YZ250F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Dimensioni: 24.86 MB

Page 79 of 656

SPEC

2 - 6

MAINTENANCE SPECIFICATIONS

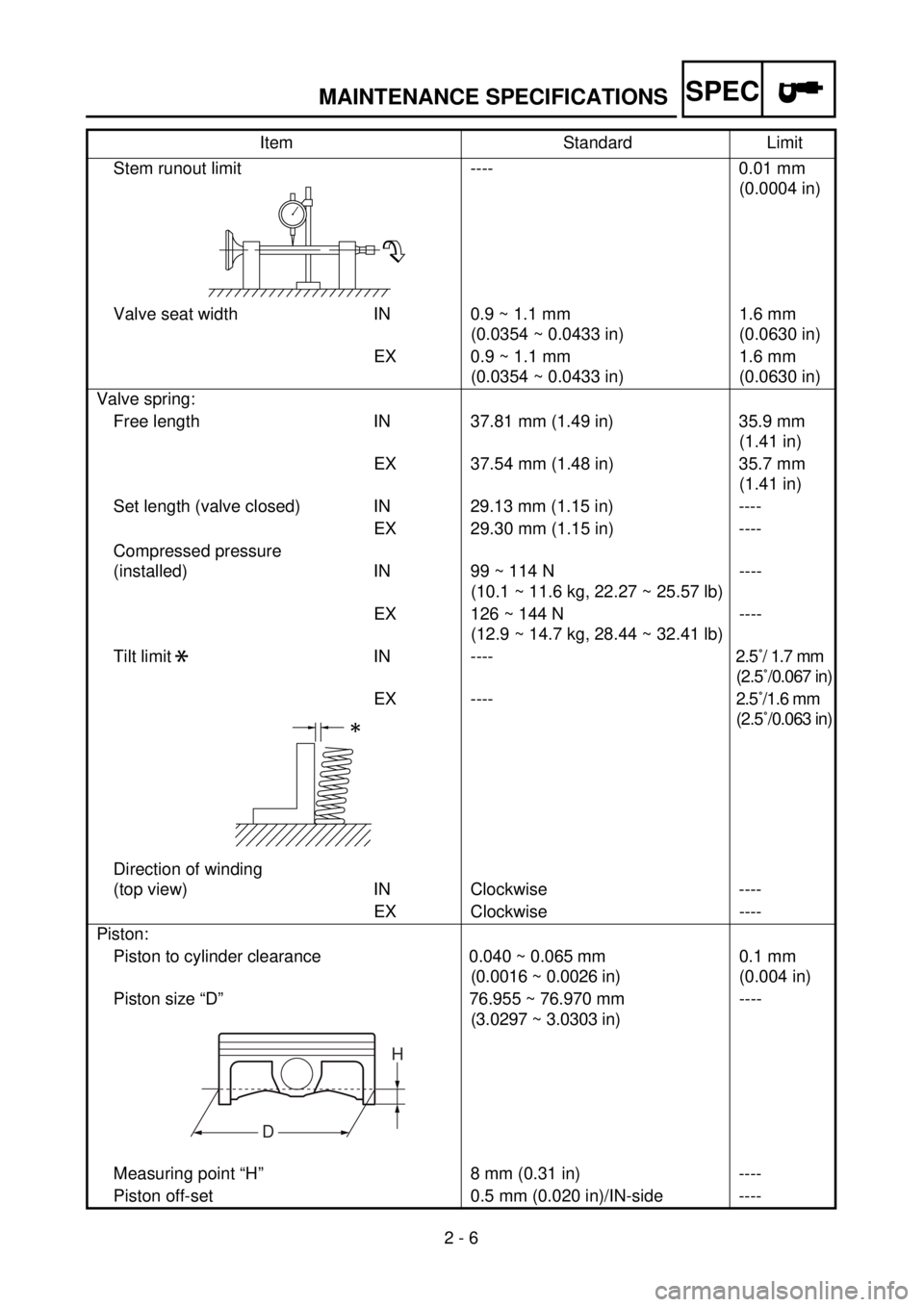

Stem runout limit ---- 0.01 mm

(0.0004 in)

Valve seat width IN 0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)1.6 mm

(0.0630 in)

EX 0.9 ~ 1.1 mm

(0.0354 ~ 0.0433 in)1.6 mm

(0.0630 in)

Valve spring:

Free length IN 37.81 mm (1.49 in) 35.9 mm

(1.41 in)

EX 37.54 mm (1.48 in) 35.7 mm

(1.41 in)

Set length (valve closed) IN 29.13 mm (1.15 in) ----

EX 29.30 mm (1.15 in) ----

Compressed pressure

(installed) IN 99 ~ 114 N

(10.1 ~ 11.6 kg, 22.27 ~ 25.57 lb)----

EX 126 ~ 144 N

(12.9 ~ 14.7 kg, 28.44 ~ 32.41 lb)----

Tilt limit IN ----2.5˚/ 1.7 mm

(2.5˚/0.067 in)

EX ----2.5˚/1.6 mm

(2.5˚/0.063 in)

Direction of winding

(top view) IN Clockwise ----

EX Clockwise ----

Piston:

Piston to cylinder clearance 0.040 ~ 0.065 mm

(0.0016 ~ 0.0026 in)0.1 mm

(0.004 in)

Piston size “D” 76.955 ~ 76.970 mm

(3.0297 ~ 3.0303 in)----

Measuring point “H” 8 mm (0.31 in) ----

Piston off-set 0.5 mm (0.020 in)/IN-side ----Item Standard Limit

*

H

D

Page 168 of 656

3 - 5

INSP

ADJ

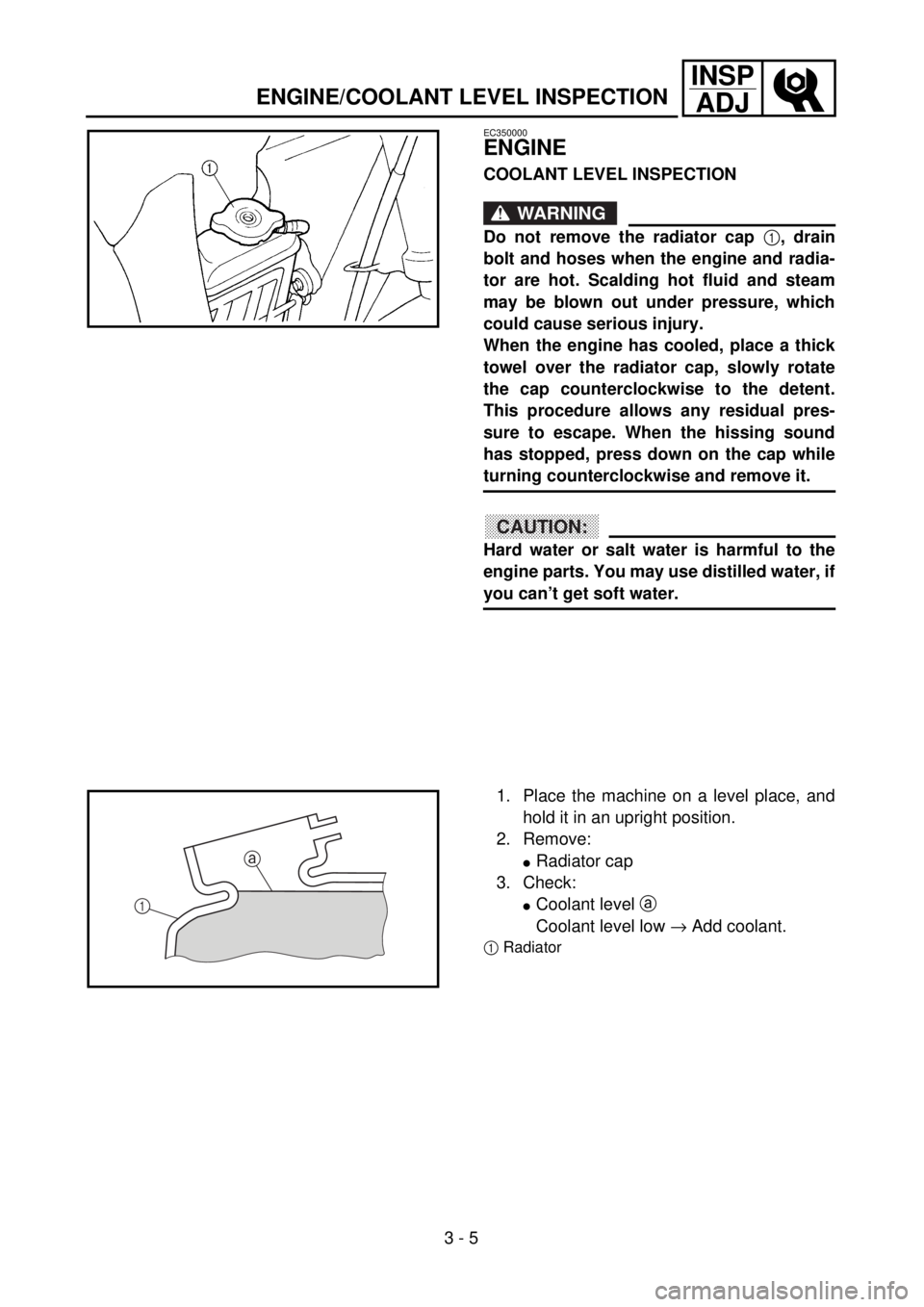

EC350000

ENGINE

COOLANT LEVEL INSPECTION

WARNING

Do not remove the radiator cap 1, drain

bolt and hoses when the engine and radia-

tor are hot. Scalding hot fluid and steam

may be blown out under pressure, which

could cause serious injury.

When the engine has cooled, place a thick

towel over the radiator cap, slowly rotate

the cap counterclockwise to the detent.

This procedure allows any residual pres-

sure to escape. When the hissing sound

has stopped, press down on the cap while

turning counterclockwise and remove it.

CAUTION:

Hard water or salt water is harmful to the

engine parts. You may use distilled water, if

you can’t get soft water.

1. Place the machine on a level place, and

hold it in an upright position.

2. Remove:

lRadiator cap

3. Check:

lCoolant level a

Coolant level low ® Add coolant.

1Radiator

1a

ENGINE/COOLANT LEVEL INSPECTION

Page 180 of 656

3 - 11

INSP

ADJTHROTTLE LUBRICATION/

DECOMPRESSION ADJUSTMENT

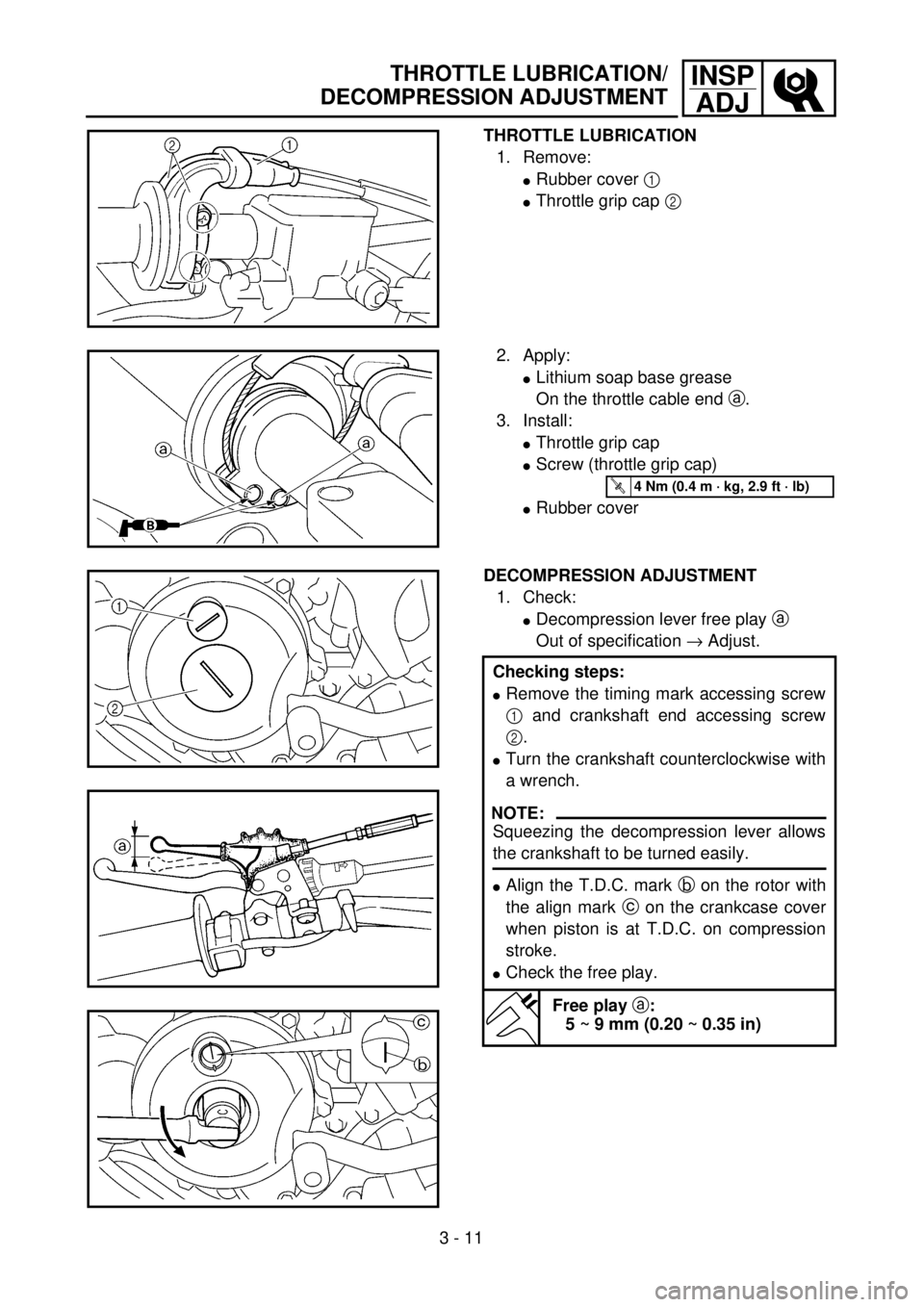

THROTTLE LUBRICATION

1. Remove:

lRubber cover 1

lThrottle grip cap 2

2. Apply:

lLithium soap base grease

On the throttle cable end a.

3. Install:

lThrottle grip cap

lScrew (throttle grip cap)

lRubber cover

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

DECOMPRESSION ADJUSTMENT

1. Check:

lDecompression lever free play a

Out of specification ® Adjust.

Checking steps:

lRemove the timing mark accessing screw

1 and crankshaft end accessing screw

2.

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark b on the rotor with

the align mark c on the crankcase cover

when piston is at T.D.C. on compression

stroke.

lCheck the free play.

Free play a:

5 ~ 9 mm (0.20 ~ 0.35 in)

Page 200 of 656

3 - 21

INSP

ADJ

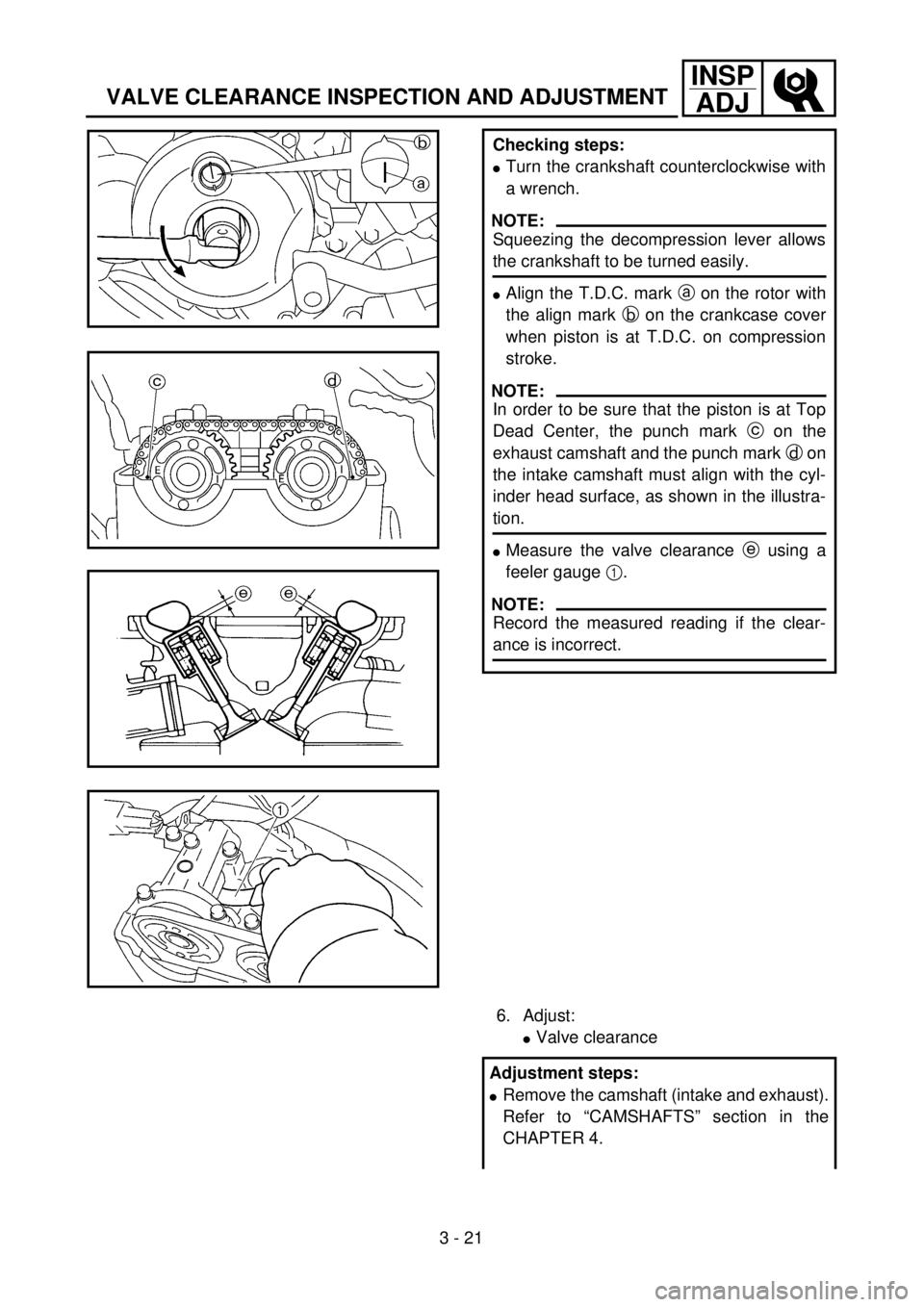

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

Checking steps:

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

NOTE:

In order to be sure that the piston is at Top

Dead Center, the punch mark c on the

exhaust camshaft and the punch mark d on

the intake camshaft must align with the cyl-

inder head surface, as shown in the illustra-

tion.

lMeasure the valve clearance e using a

feeler gauge 1.

NOTE:

Record the measured reading if the clear-

ance is incorrect.

6. Adjust:

lValve clearance

Adjustment steps:

lRemove the camshaft (intake and exhaust).

Refer to “CAMSHAFTS” section in the

CHAPTER 4.

Page 228 of 656

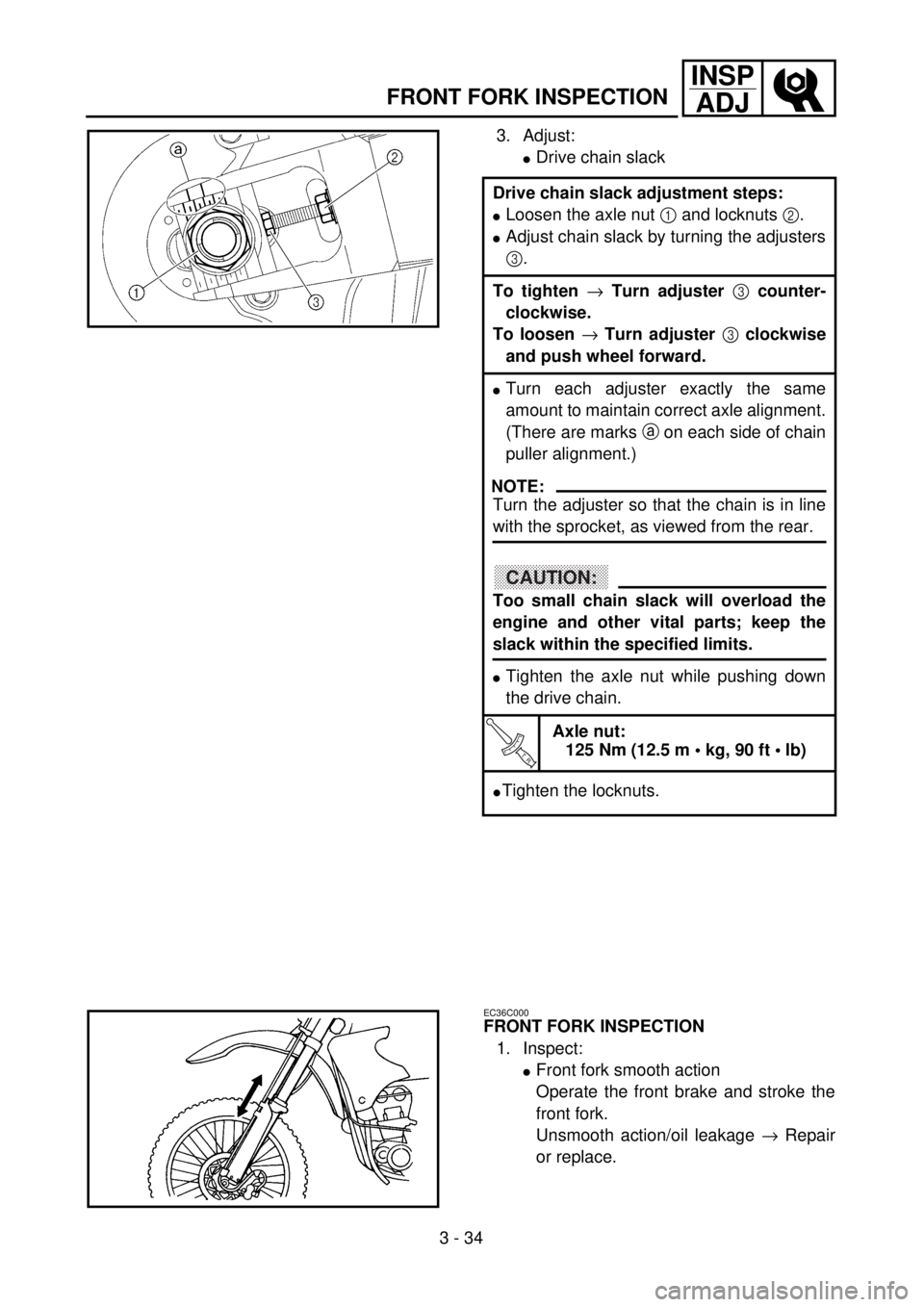

3 - 34

INSP

ADJ

FRONT FORK INSPECTION

3. Adjust:

lDrive chain slack

Drive chain slack adjustment steps:

lLoosen the axle nut 1 and locknuts 2.

lAdjust chain slack by turning the adjusters

3.

To tighten ® Turn adjuster 3 counter-

clockwise.

To loosen ® Turn adjuster 3 clockwise

and push wheel forward.

lTurn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of chain

puller alignment.)

NOTE:

Turn the adjuster so that the chain is in line

with the sprocket, as viewed from the rear.

CAUTION:

Too small chain slack will overload the

engine and other vital parts; keep the

slack within the specified limits.

lTighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

125 Nm (12.5 m • kg, 90 ft • lb)

lTighten the locknuts.

EC36C000

FRONT FORK INSPECTION

1. Inspect:

lFront fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage ® Repair

or replace.

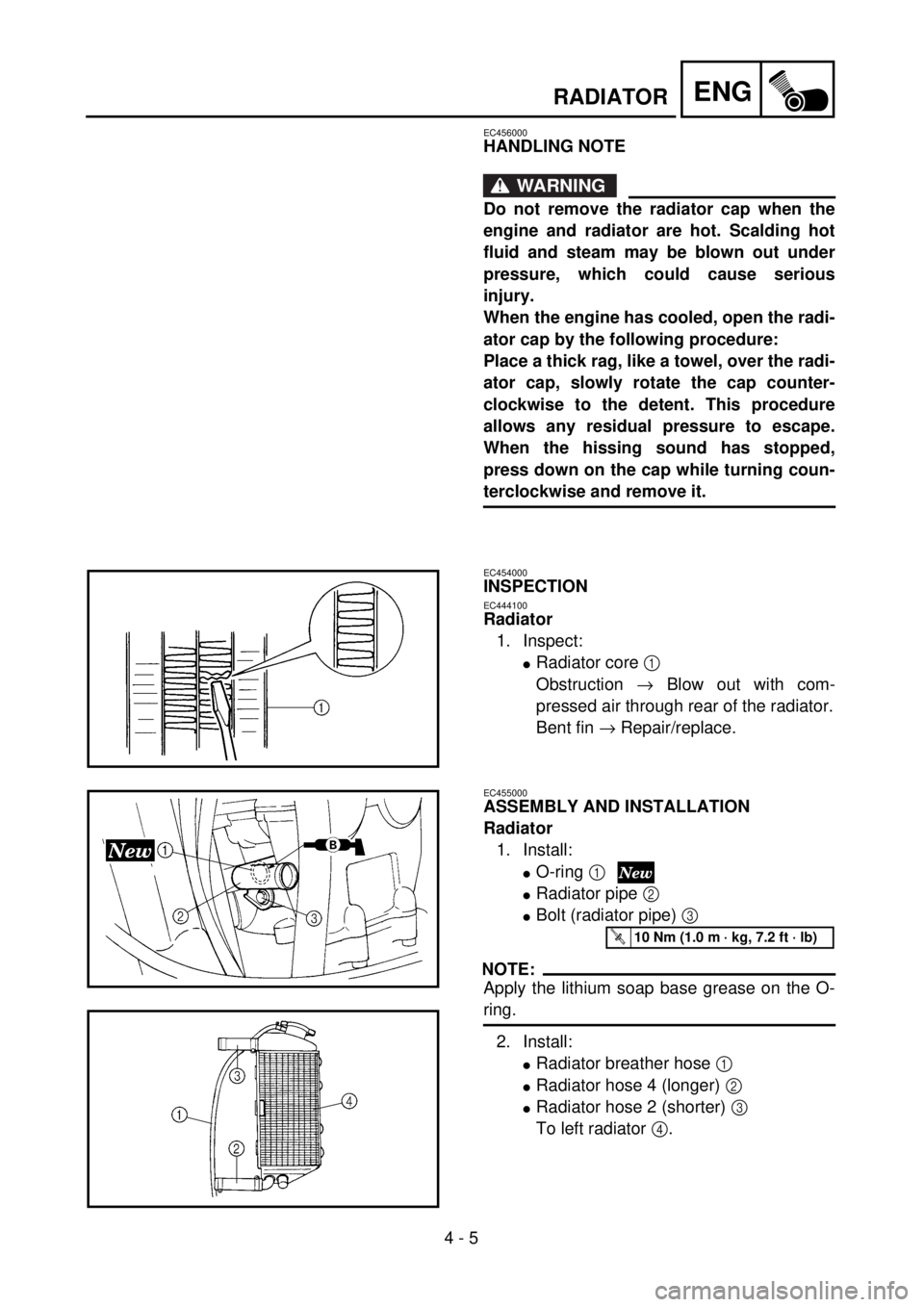

Page 264 of 656

4 - 5

ENG

RADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC454000

INSPECTION

EC444100

Radiator

1. Inspect:

l

Radiator core

1

Obstruction

®

Blow out with com-

pressed air through rear of the radiator.

Bent fin

®

Repair/replace.

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

l

O-ring

1

l

Radiator pipe

2

l

Bolt (radiator pipe)

3

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

l

Radiator breather hose

1

lRadiator hose 4 (longer) 2

lRadiator hose 2 (shorter) 3

To left radiator 4.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 296 of 656

4 - 21

ENGCAMSHAFTS

REMOVAL POINTS

Camshaft

1. Remove:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

2. Align:

lT.D.C. mark

With align mark.

Checking steps:

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

NOTE:

In order to be sure that the piston is at Top

Dead Center, the punch mark c on the

exhaust camshaft and the punch mark d on

the intake camshaft must align with the cyl-

inder head surface, as shown in the illustra-

tion.

3. Remove:

lTiming chain tensioner cap bolt 1

lTiming chain tensioner 2

lGasket

4. Remove:

lBolt (camshaft cap) 1

lCamshaft cap 2

lClip

NOTE:

Remove the bolts (camshaft cap) in a criss-

cross pattern, working from the outside in.

CAUTION:

The bolts (camshaft cap) must be removed

evenly to prevent damage to the cylinder

head, camshafts or camshaft caps.

Page 302 of 656

4 - 24

ENGCAMSHAFTS

Timing chain tensioner

1. Check:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully

clockwise.

lWhen releasing the screwdriver by

pressing lightly with fingers, make sure

that the tensioner rod will come out

smoothly.

lIf not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

lExhaust camshaft 1

lIntake camshaft 2

Installation steps:

lTurn the crankshaft counterclockwise with

a wrench.

NOTE:

Squeezing the decompression lever allows

the crankshaft to be turned easily.

lAlign the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

lFit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the punch mark c on

the exhaust camshaft and the punch mark

d on the intake camshaft must align with

the cylinder head surface, as shown in the

illustration.

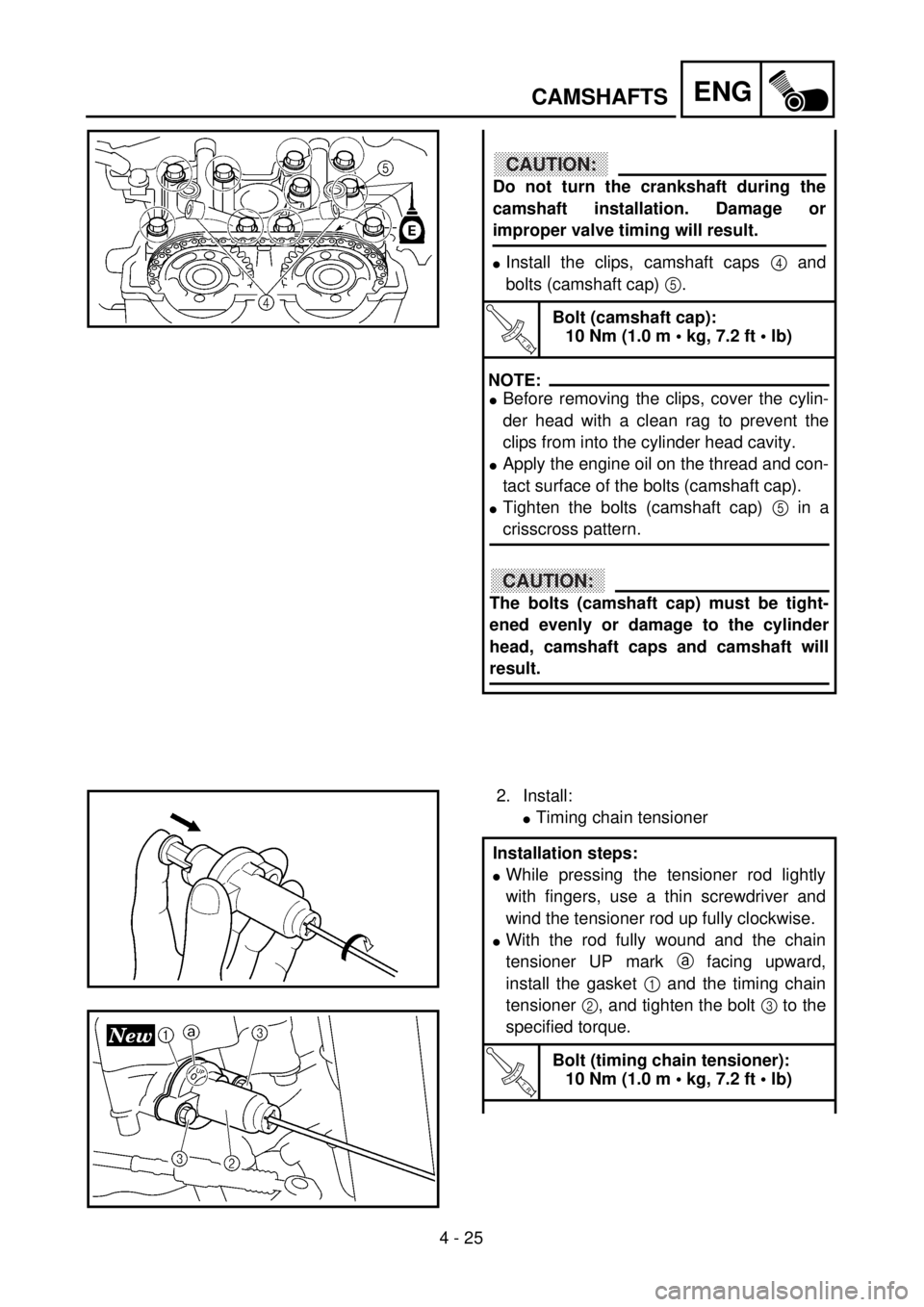

Page 304 of 656

4 - 25

ENGCAMSHAFTS

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

lInstall the clips, camshaft caps 4 and

bolts (camshaft cap) 5.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m • kg, 7.2 ft • lb)

NOTE:

lBefore removing the clips, cover the cylin-

der head with a clean rag to prevent the

clips from into the cylinder head cavity.

lApply the engine oil on the thread and con-

tact surface of the bolts (camshaft cap).

lTighten the bolts (camshaft cap) 5 in a

crisscross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly or damage to the cylinder

head, camshaft caps and camshaft will

result.

2. Install:

lTiming chain tensioner

Installation steps:

lWhile pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

lWith the rod fully wound and the chain

tensioner UP mark a facing upward,

install the gasket 1 and the timing chain

tensioner 2, and tighten the bolt 3 to the

specified torque.

T R..

Bolt (timing chain tensioner):

10 Nm (1.0 m • kg, 7.2 ft • lb)

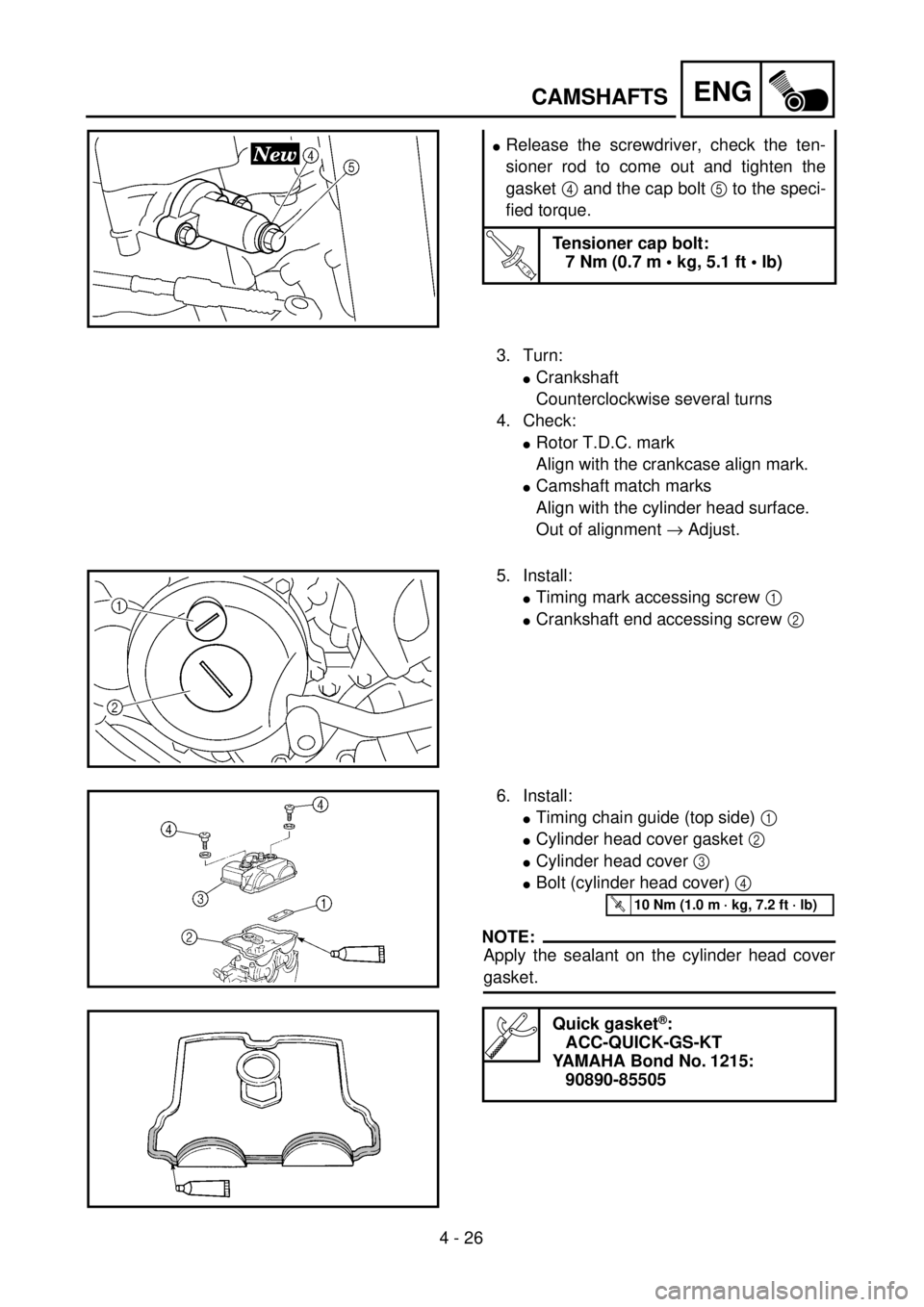

Page 306 of 656

4 - 26

ENG

lRelease the screwdriver, check the ten-

sioner rod to come out and tighten the

gasket 4 and the cap bolt 5 to the speci-

fied torque.

T R..

Tensioner cap bolt:

7 Nm (0.7 m • kg, 5.1 ft • lb)

3. Turn:

lCrankshaft

Counterclockwise several turns

4. Check:

lRotor T.D.C. mark

Align with the crankcase align mark.

lCamshaft match marks

Align with the cylinder head surface.

Out of alignment ® Adjust.

5. Install:

lTiming mark accessing screw 1

lCrankshaft end accessing screw 2

6. Install:

lTiming chain guide (top side) 1

lCylinder head cover gasket 2

lCylinder head cover 3

lBolt (cylinder head cover) 4

NOTE:

Apply the sealant on the cylinder head cover

gasket.

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

CAMSHAFTS