ignition YAMAHA YZ250F 2001 Manuale duso (in Italian)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Dimensioni: 24.86 MB

Page 24 of 656

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS

AND WIRING DIAGRAM

.......................... 6-1

MAP-CONTROLLED CDI UNIT

................ 6-2

IGNITION SYSTEM

................................... 6-3

THROTTLE POSITION

SENSOR SYSTEM

................................... 6-7

CHAPTER 7

TUNING

ENGINE

..................................................... 7-1

CHASSIS

................................................ 7-11

Page 39 of 656

GEN

INFO

1 - 8

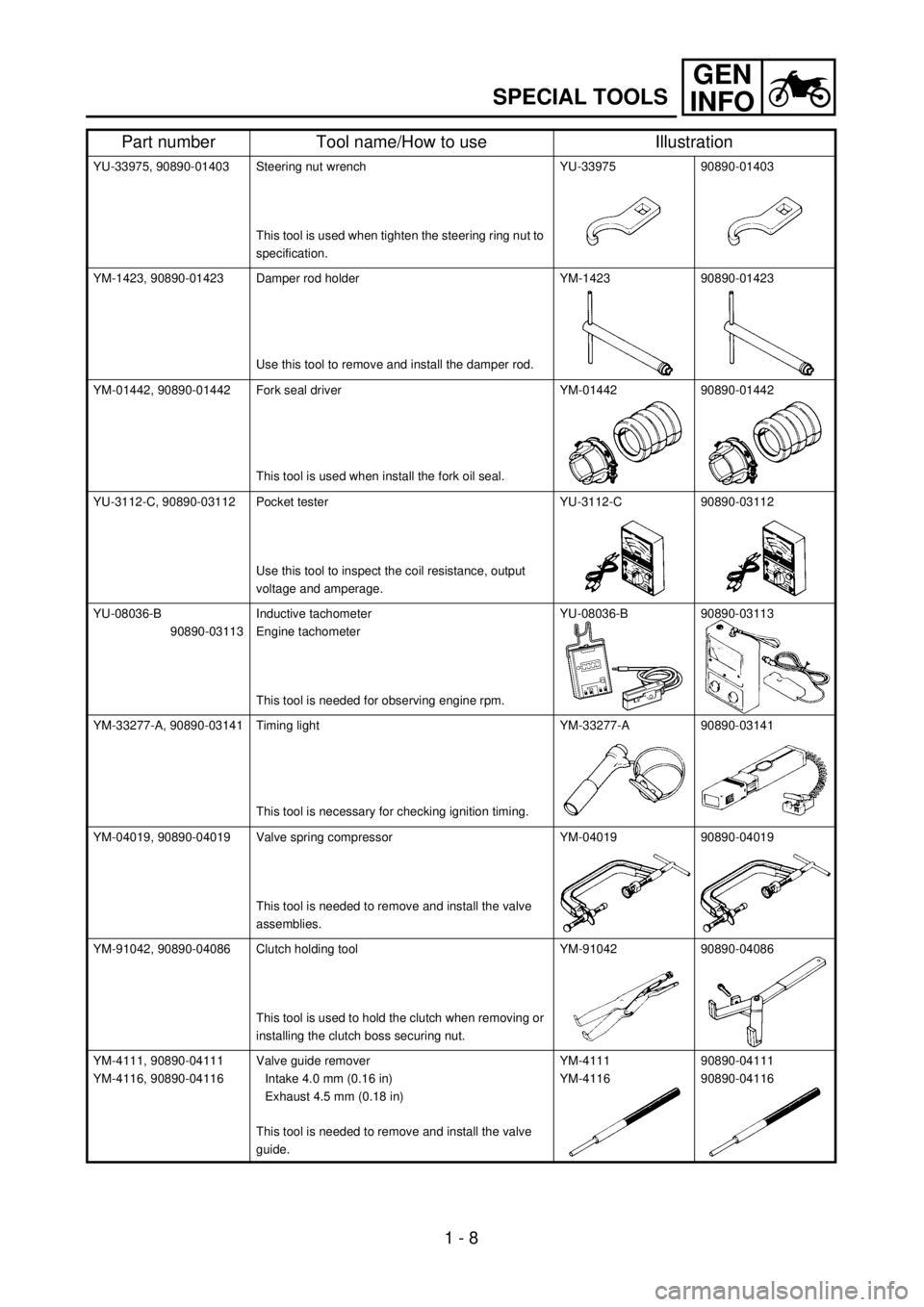

SPECIAL TOOLS

YU-33975, 90890-01403 Steering nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-1423, 90890-01423 Damper rod holder

Use this tool to remove and install the damper rod.YM-1423 90890-01423

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.YM-01442 90890-01442

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YU-08036-B

90890-03113Inductive tachometer

Engine tachometer

This tool is needed for observing engine rpm.YU-08036-B 90890-03113

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-04019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-04019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4111, 90890-04111

YM-4116, 90890-04116Valve guide remover

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

This tool is needed to remove and install the valve

guide.YM-4111

YM-411690890-04111

90890-04116

Part number Tool name/How to use Illustration

Page 40 of 656

GEN

INFO

1 - 9

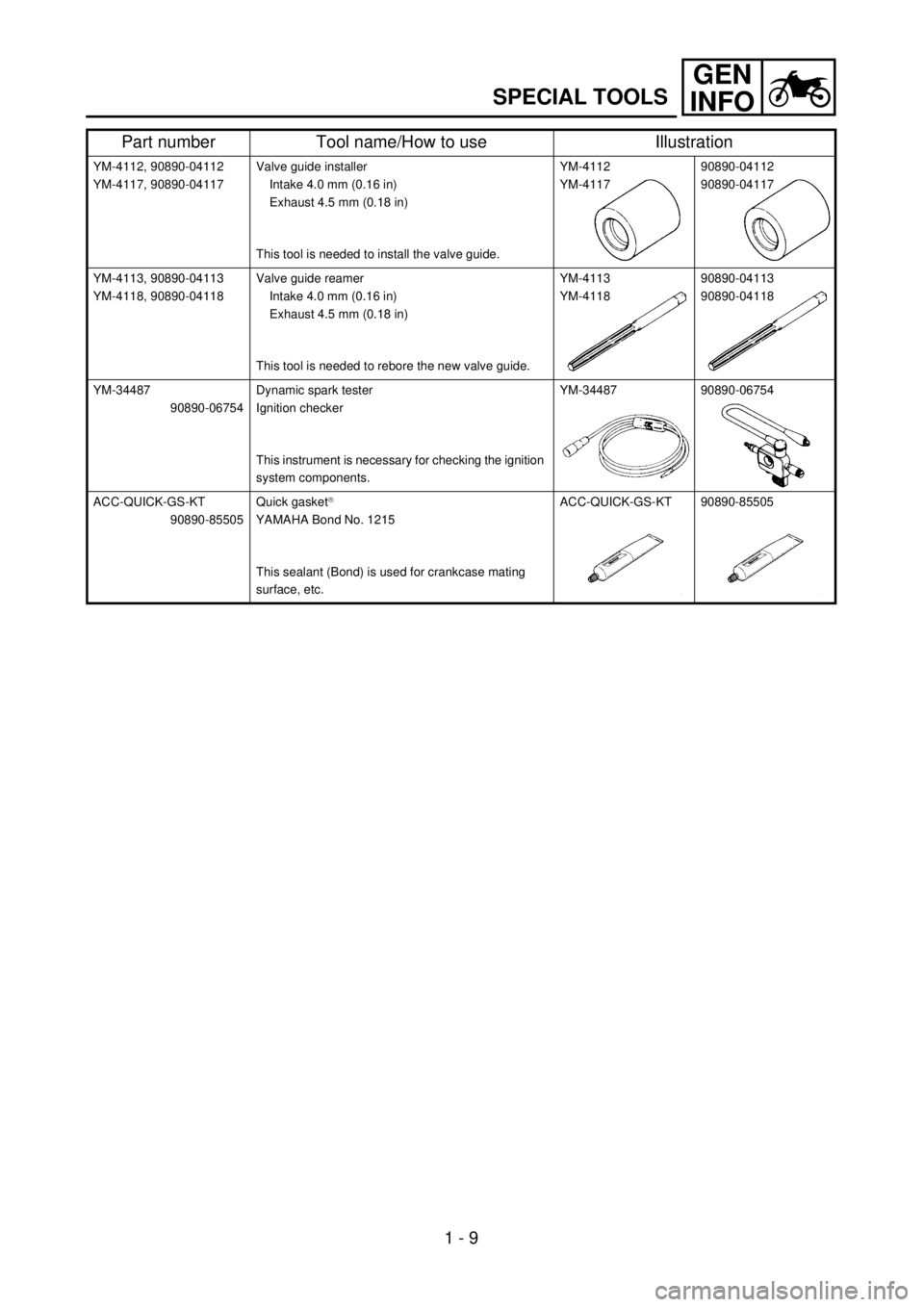

SPECIAL TOOLS

YM-4112, 90890-04112

YM-4117, 90890-04117Valve guide installer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

This tool is needed to install the valve guide.YM-4112

YM-411790890-04112

90890-04117

YM-4113, 90890-04113

YM-4118, 90890-04118Valve guide reamer

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

This tool is needed to rebore the new valve guide.YM-4113

YM-411890890-04113

90890-04118

YM-34487

90890-06754Dynamic spark tester

Ignition checker

This instrument is necessary for checking the ignition

system components.YM-34487 90890-06754

ACC-QUICK-GS-KT

90890-85505Quick gasket

â

YAMAHA Bond No. 1215

This sealant (Bond) is used for crankcase mating

surface, etc.ACC-QUICK-GS-KT 90890-85505

Part number Tool name/How to use Illustration

Page 76 of 656

SPEC

2 - 3

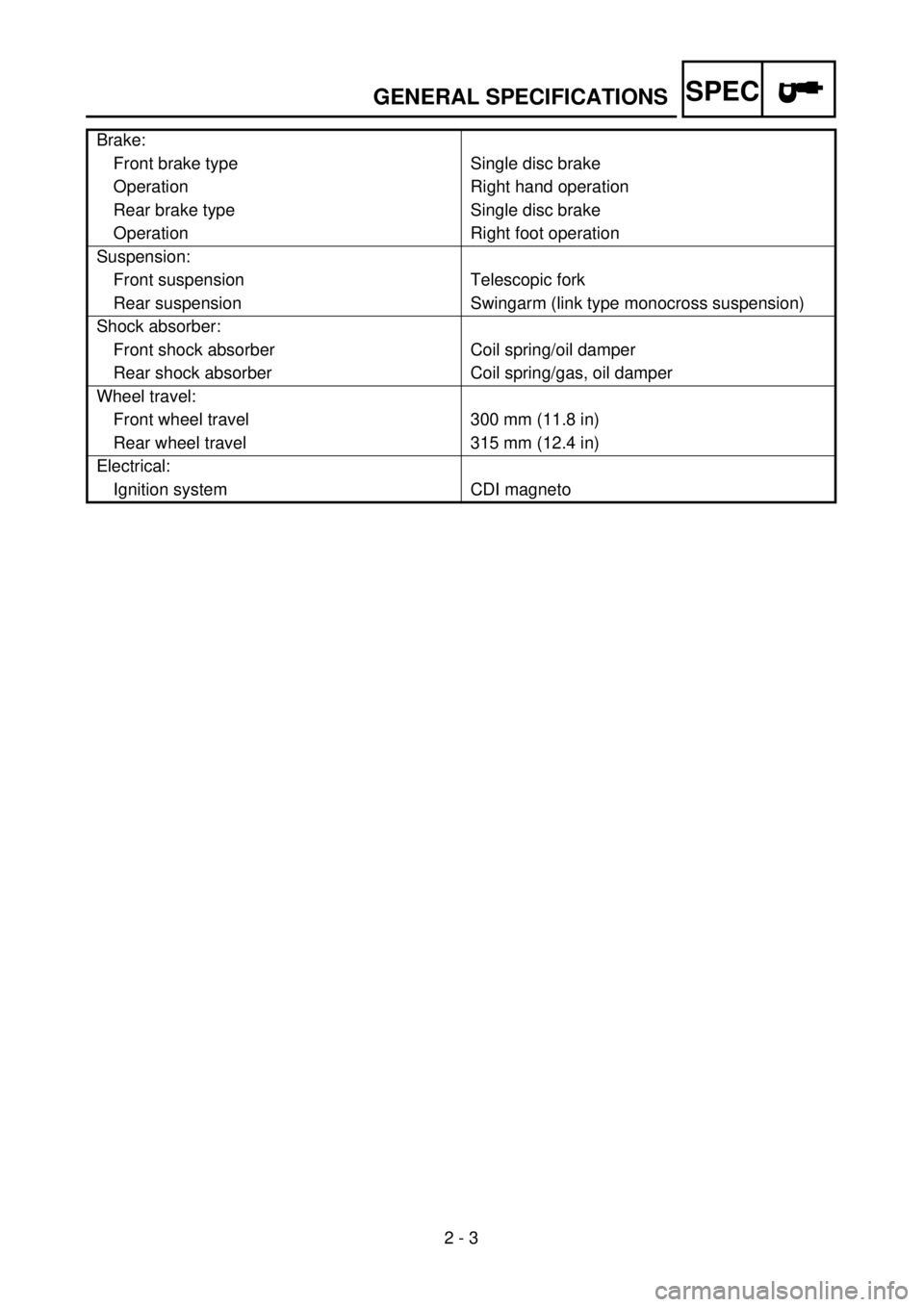

GENERAL SPECIFICATIONS

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 315 mm (12.4 in)

Electrical:

Ignition system CDI magneto

Page 89 of 656

SPEC

2 - 16

MAINTENANCE SPECIFICATIONS

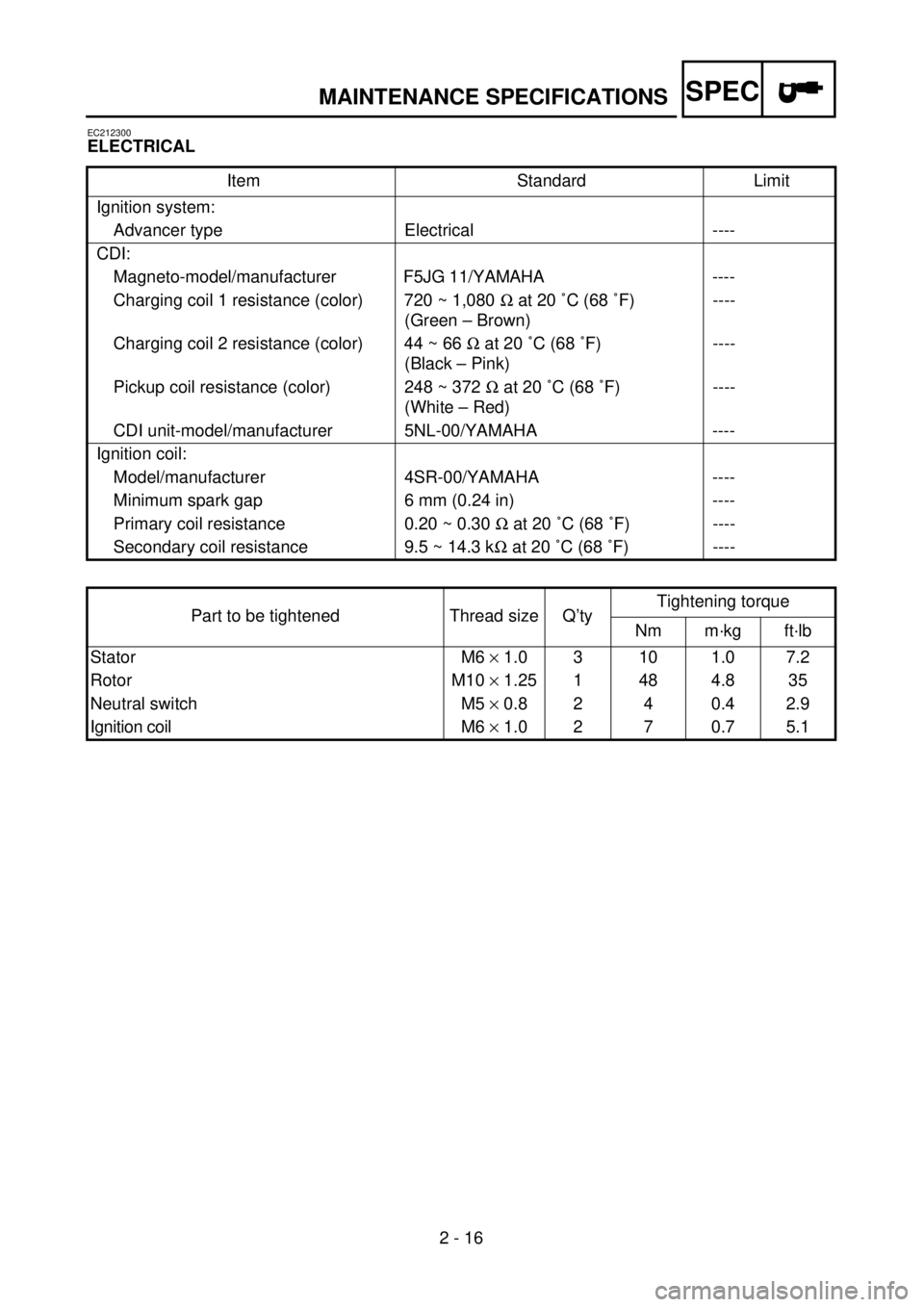

EC212300

ELECTRICAL

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI:

Magneto-model/manufacturer F5JG 11/YAMAHA----

Charging coil 1 resistance (color) 720 ~ 1,080 W at 20 ˚C (68 ˚F)

(Green – Brown)----

Charging coil 2 resistance (color) 44 ~ 66 W at 20 ˚C (68 ˚F)

(Black – Pink)----

Pickup coil resistance (color) 248 ~ 372 W at 20 ˚C (68 ˚F)

(White – Red)----

CDI unit-model/manufacturer 5NL-00/YAMAHA ----

Ignition coil:

Model/manufacturer 4SR-00/YAMAHA ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.20 ~ 0.30 W at 20 ˚C (68 ˚F) ----

Secondary coil resistance 9.5 ~ 14.3 kW at 20 ˚C (68 ˚F) ----

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Stator M6 ´ 1.0 3 10 1.0 7.2

Rotor M10 ´ 1.25 1 48 4.8 35

Neutral switch M5 ´ 0.8 2 4 0.4 2.9

Ignition coil M6 ´ 1.0 2 7 0.7 5.1

Page 142 of 656

2 - 18

SPEC

CABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1

Hose guide

2

Brake hose

3

Fuel tank breather hose

4

Engine stop switch lead

5

Oil tank breather hose

6

Sub-wire harness

7

Neutral switch lead

8

Cable guide

9

Cylinder head breather hose

0

CDI magneto lead

A

Radiator breather hose

B

Carburetor breather hose

C

Carburetor overflow hose

D

Ignition coil lead

E

CDI unit lead

Pass the fuel tank breather hose

between the handlebar and ten-

sion bar, then insert its end into

the hole of the number plate.

õ

Fasten the engine stop switch

lead and ignition coil lead of the

sub-wire harness.

‚

Fasten the sub-wire harness

and engine stop switch lead.

Fasten the engine stop switch

lead at its protecting tube.

ë

Fasten the sub-wire harness

and engine stop switch leads.

ä

Pass the sub-wire harness

between upper engine brackets.

ì

Fasten the sub-wire harness.

í

Fasten the throttle position sen-

sor lead.

î

Pass the carburetor breather

hose and overflow hose

between the connecting rod and

cross tube (frame).

é

Fasten the neutral switch lead

on the oil hose.

ï

Pass the clutch cable through

the cable guide.

ð

Fasten the cylinder head

breather hose and neutral switch

lead.

ñ

Fasten the neutral switch lead.

Page 144 of 656

2 - 19

SPEC

CABLE ROUTING DIAGRAM

÷

Pass the cylinder head

breather hose through the hose

guide.

ö

Fasten the neutral switch lead

and CDI magneto lead.

¯

Pass the clutch cable on the

inside the cylinder head

breather hose.

¸

Pass the clutch cable in front of

the radiator mounting boss.

Î

Fit the brake hose into the

guides on the protector.

å

Pass the carburetor breather

hoses and overflow hose so

that all there hoses do not con-

tact the rear shock absorber.

ê

Fasten the ground lead

together with the ignition coil.

æ

Do not allow the engine stop

switch leads to slacken

between the two clamps.

è

Pass the clutch cable through

the cable guides.

Ã

Position each lead at the lower

left of the main tube (frame).

Page 146 of 656

2 - 20

SPEC

1

Spark plug lead

2

Ignition coil

3

CDI unit

4

CDI unit band

5

Throttle cable (return)

6

Throttle cable (pull)

7

Cable guide

8

CDI unit lead

9

CDI unit stay

0

Radiator breather hose

A

Radiator hose 4

Pass the CDI unit lead

between the radiator hose and

radiator mounting boss.

õ

Pass the throttle cables

through cable guide.

‚

Pass the throttle cables under

the radiator mounting boss.

ë

Insert the CDI unit band over

the CDI unit stay (frame) as far

as possible.

ä

Pass the radiator breather

hose in front of the radiator

mounting rear boss and at the

left of the chassis. And then,

pass it between the radiator

hose 4 and down tube (frame)

and between the engine and

lower engine guard.

CABLE ROUTING DIAGRAM

Page 164 of 656

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

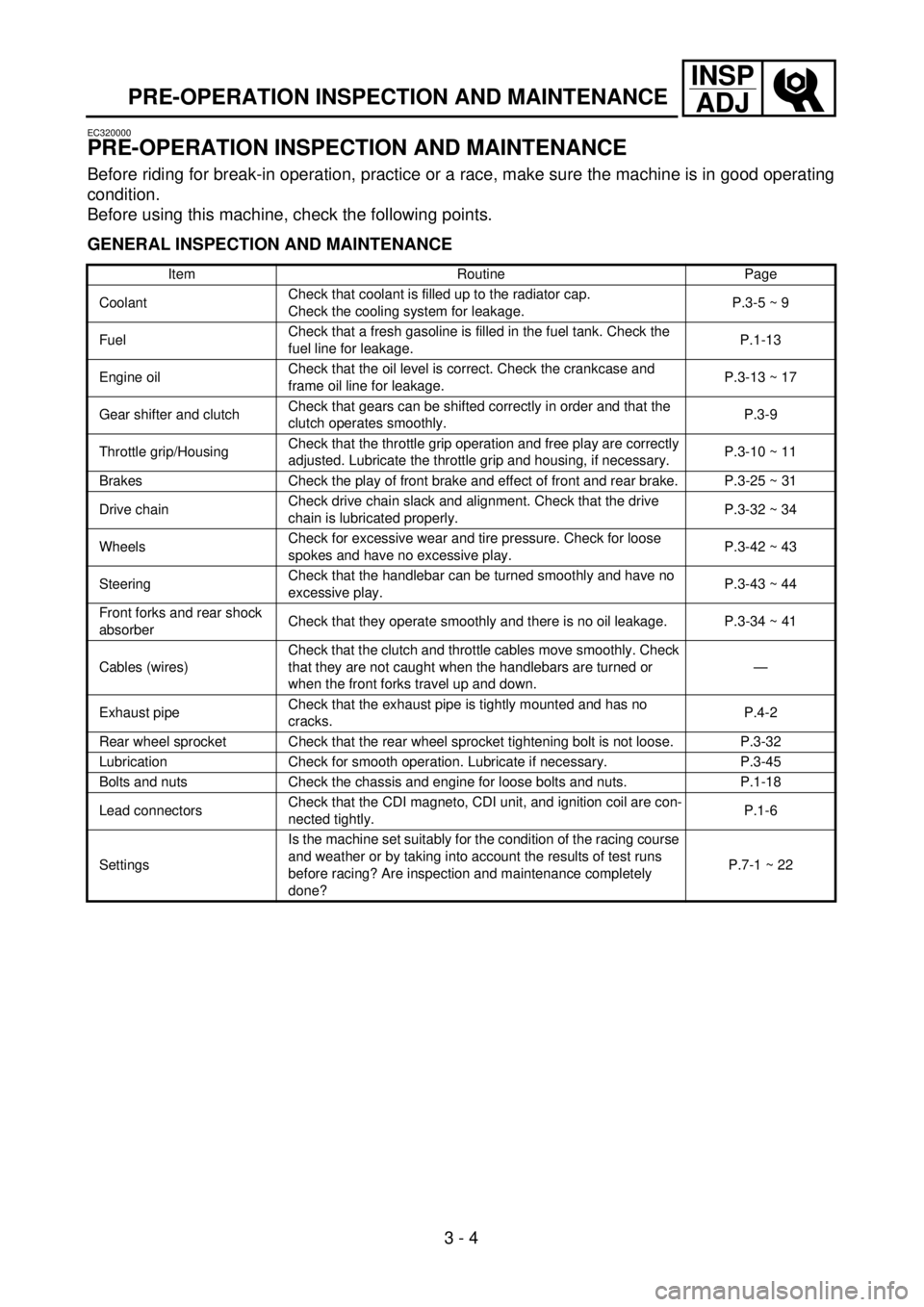

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-13

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-25 ~ 31

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-32 ~ 34

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-42 ~ 43

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-43 ~ 44

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-34 ~ 41

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-2

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-32

Lubrication Check for smooth operation. Lubricate if necessary. P.3-45

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-18

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 22

Page 254 of 656

3 - 47

INSP

ADJ

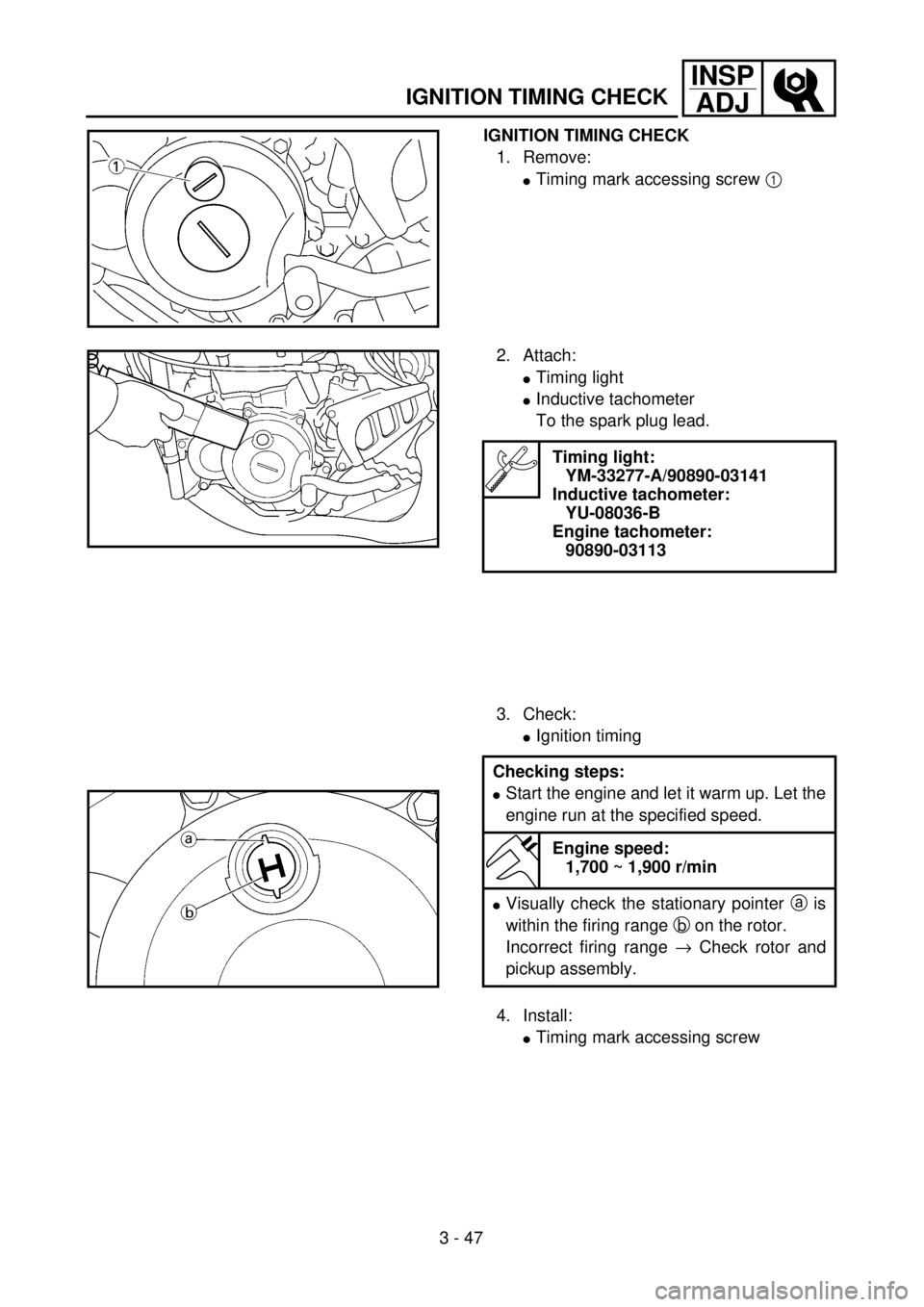

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

lTiming mark accessing screw 1

2. Attach:

lTiming light

lInductive tachometer

To the spark plug lead.

3. Check:

lIgnition timing

Timing light:

YM-33277-A/90890-03141

Inductive tachometer:

YU-08036-B

Engine tachometer:

90890-03113

Checking steps:

lStart the engine and let it warm up. Let the

engine run at the specified speed.

Engine speed:

1,700 ~ 1,900 r/min

lVisually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range ® Check rotor and

pickup assembly.

4. Install:

lTiming mark accessing screw