oil YAMAHA YZ250F 2001 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2001, Model line: YZ250F, Model: YAMAHA YZ250F 2001Pages: 656, PDF Size: 24.86 MB

Page 418 of 656

4 - 82

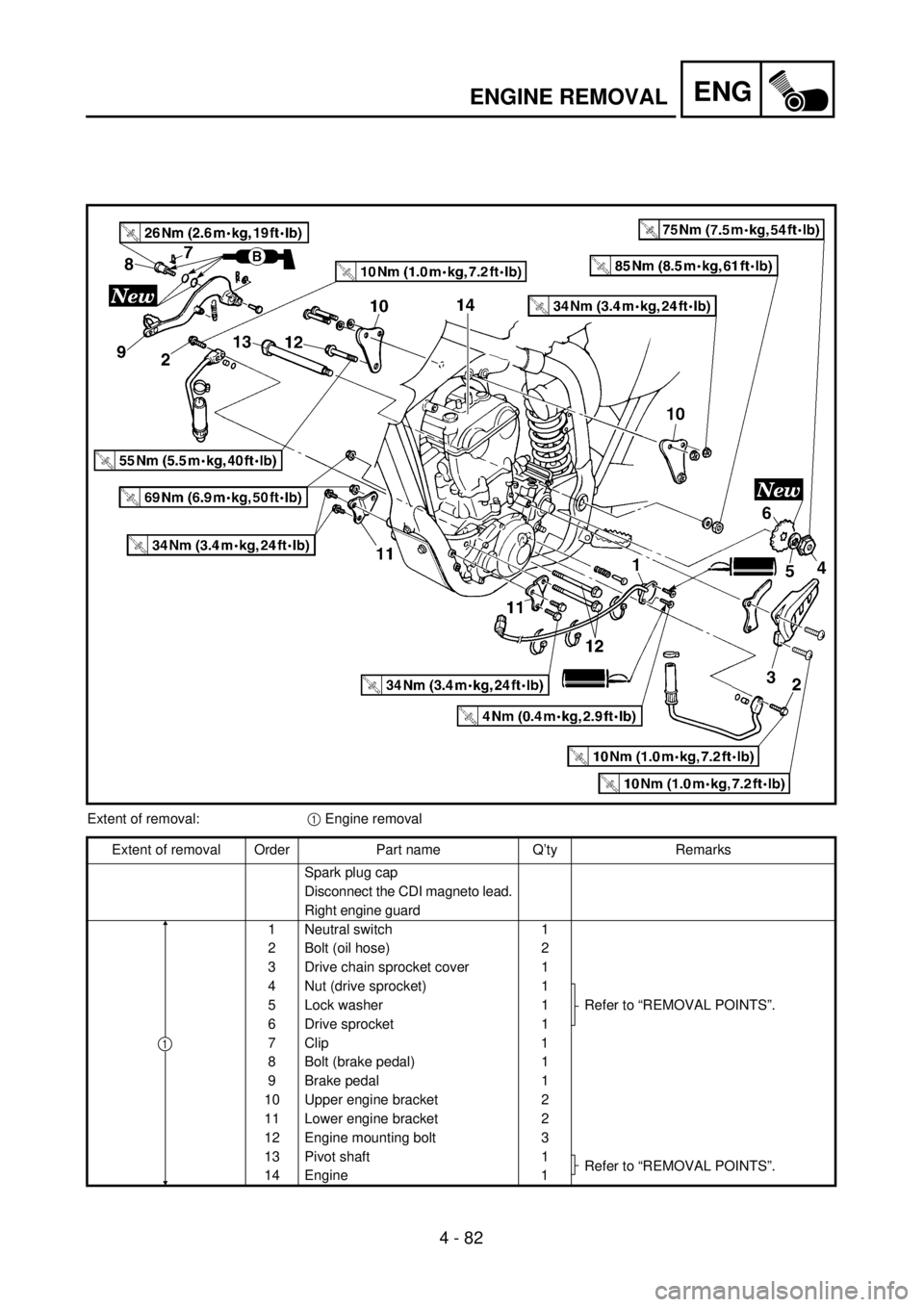

ENGENGINE REMOVAL

Extent of removal:1 Engine removal

Extent of removal Order Part name Q’ty Remarks

Spark plug cap

Disconnect the CDI magneto lead.

Right engine guard

1 Neutral switch 1

2 Bolt (oil hose) 2

3 Drive chain sprocket cover 1

4 Nut (drive sprocket) 1

Refer to “REMOVAL POINTS”. 5 Lock washer 1

6 Drive sprocket 1

7 Clip 1

8 Bolt (brake pedal) 1

9 Brake pedal 1

10 Upper engine bracket 2

11 Lower engine bracket 2

12 Engine mounting bolt 3

13 Pivot shaft 1

Refer to “REMOVAL POINTS”.

14Engine

1

1

Page 424 of 656

4 - 85

ENGENGINE REMOVAL

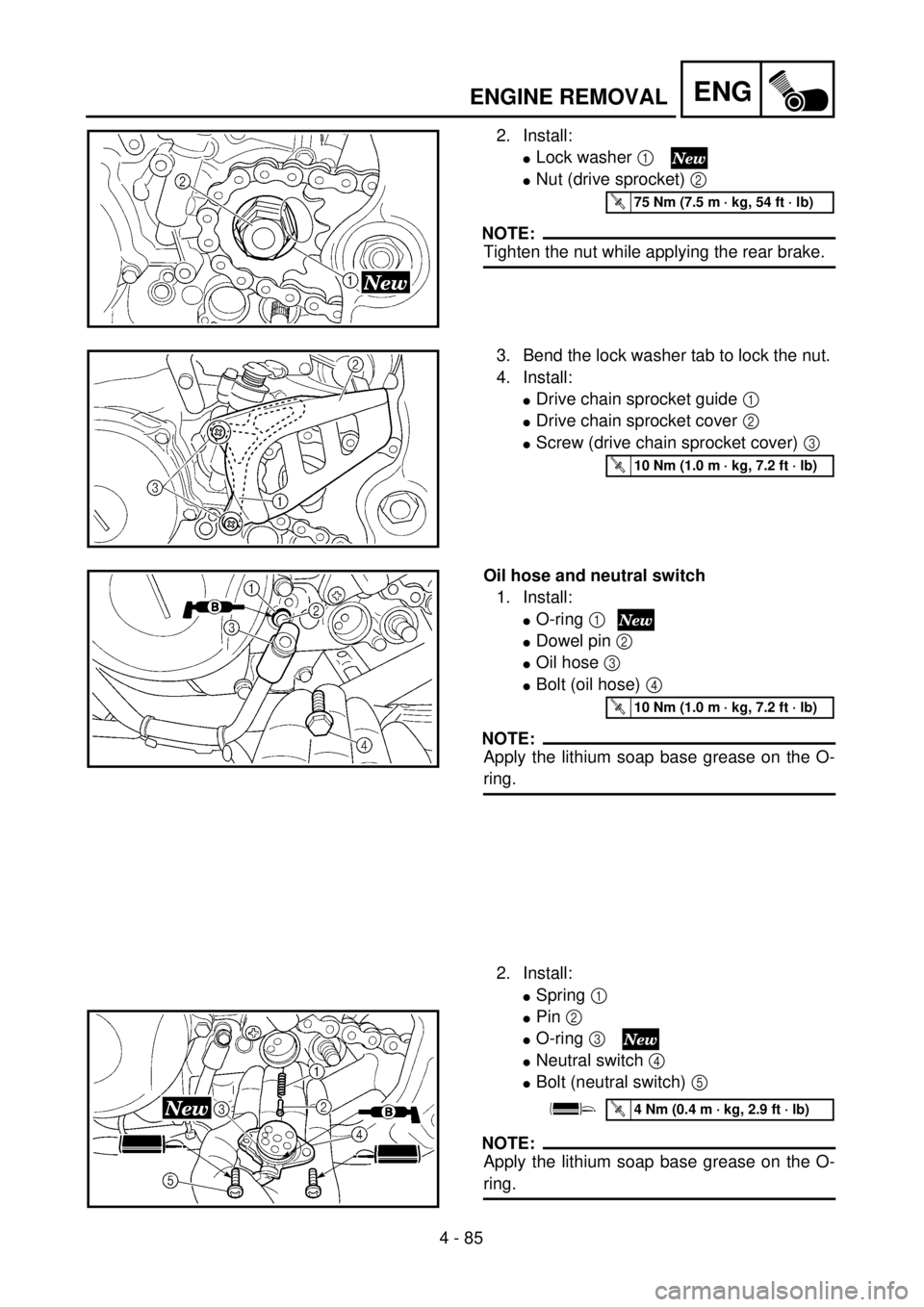

2. Install:

lLock washer 1

lNut (drive sprocket) 2

NOTE:

Tighten the nut while applying the rear brake.

T R..75 Nm (7.5 m · kg, 54 ft · lb)

3. Bend the lock washer tab to lock the nut.

4. Install:

lDrive chain sprocket guide 1

lDrive chain sprocket cover 2

lScrew (drive chain sprocket cover) 3

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Oil hose and neutral switch

1. Install:

lO-ring 1

lDowel pin 2

lOil hose 3

lBolt (oil hose) 4

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

lSpring 1

lPin 2

lO-ring 3

lNeutral switch 4

lBolt (neutral switch) 5

NOTE:

Apply the lithium soap base grease on the O-

ring.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

T R..4 Nm (0.4 m · kg, 2.9 ft · lb)

Page 426 of 656

4 - 86

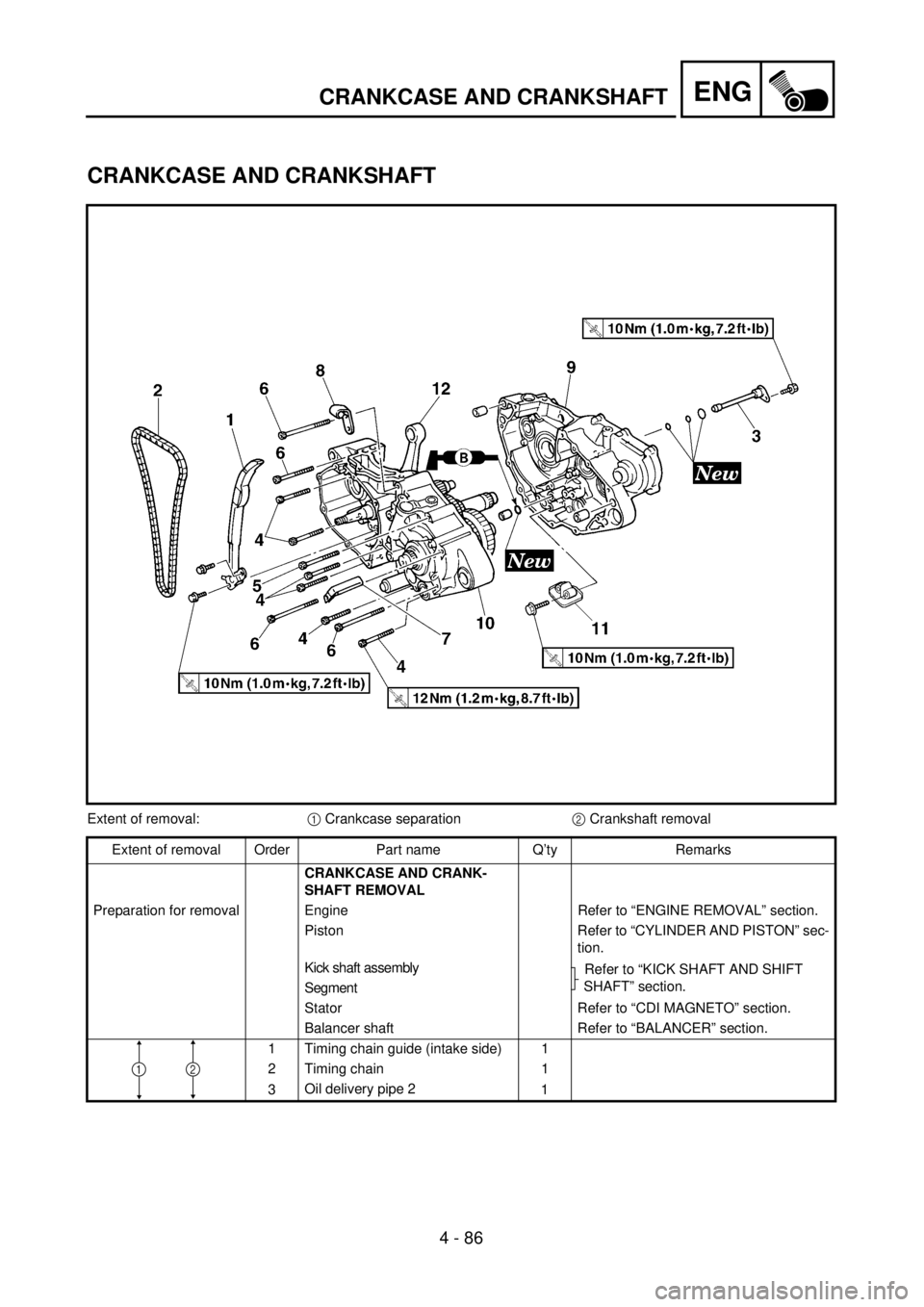

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE AND CRANKSHAFT

Extent of removal:1 Crankcase separation2 Crankshaft removal

Extent of removal Order Part name Q’ty Remarks

CRANKCASE AND CRANK-

SHAFT REMOVAL

Preparation for removal Engine Refer to “ENGINE REMOVAL” section.

Piston Refer to “CYLINDER AND PISTON” sec-

tion.

Kick shaft assembly

Refer to “KICK SHAFT AND SHIFT

SHAFT” section.

Segment

Stator Refer to “CDI MAGNETO” section.

Balancer shaft Refer to “BALANCER” section.

1 Timing chain guide (intake side) 1

2 Timing chain 1

3Oil delivery pipe 2

1

21

Page 428 of 656

![YAMAHA YZ250F 2001 Notices Demploi (in French) 4 - 87

ENGCRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

4 Bolt [L = 45 mm (1.77 in)] 6

Refer to “REMOVAL POINTS”. 5 Bolt [L = 55 mm (2.17 in)] 1

6 Bolt [L = 70 mm (2.76 YAMAHA YZ250F 2001 Notices Demploi (in French) 4 - 87

ENGCRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

4 Bolt [L = 45 mm (1.77 in)] 6

Refer to “REMOVAL POINTS”. 5 Bolt [L = 55 mm (2.17 in)] 1

6 Bolt [L = 70 mm (2.76](/img/51/53962/w960_53962-427.png)

4 - 87

ENGCRANKCASE AND CRANKSHAFT

Extent of removal Order Part name Q’ty Remarks

4 Bolt [L = 45 mm (1.77 in)] 6

Refer to “REMOVAL POINTS”. 5 Bolt [L = 55 mm (2.17 in)] 1

6 Bolt [L = 70 mm (2.76 in)] 4

7 Hose guide 1

8 Clutch cable holder 1

9 Right crankcase 1

10 Left crankcase 1

11 Oil strainer 1

12 Crankshaft 1 Use special tool.

Refer to “REMOVAL POINTS”.

2

1

Page 430 of 656

4 - 88

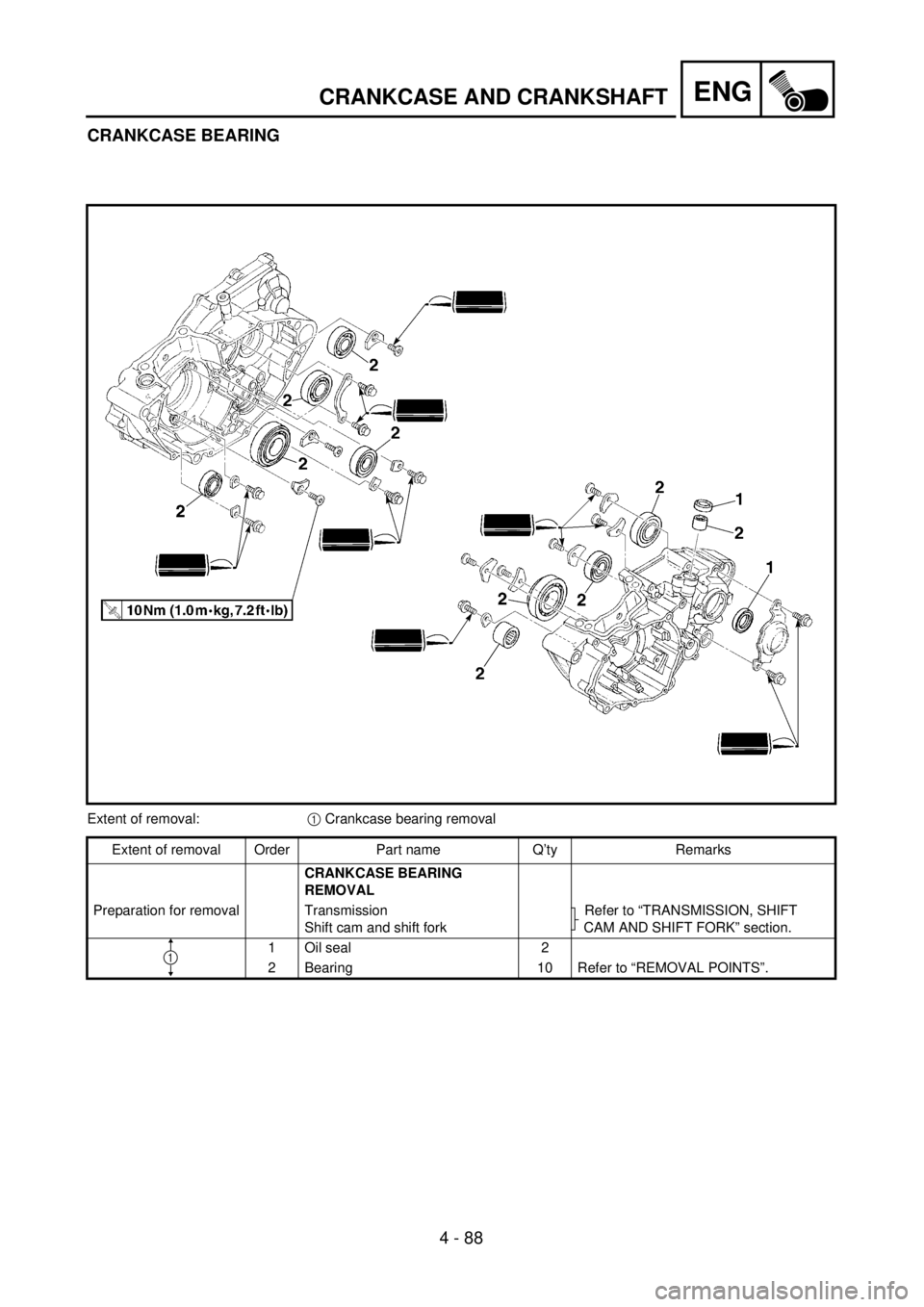

ENGCRANKCASE AND CRANKSHAFT

CRANKCASE BEARING

Extent of removal:1 Crankcase bearing removal

Extent of removal Order Part name Q’ty Remarks

CRANKCASE BEARING

REMOVAL

Preparation for removal Transmission

Shift cam and shift forkRefer to “TRANSMISSION, SHIFT

CAM AND SHIFT FORK” section.

1 Oil seal 2

2 Bearing 10 Refer to “REMOVAL POINTS”.

1

Page 434 of 656

4 - 90

ENGCRANKCASE AND CRANKSHAFT

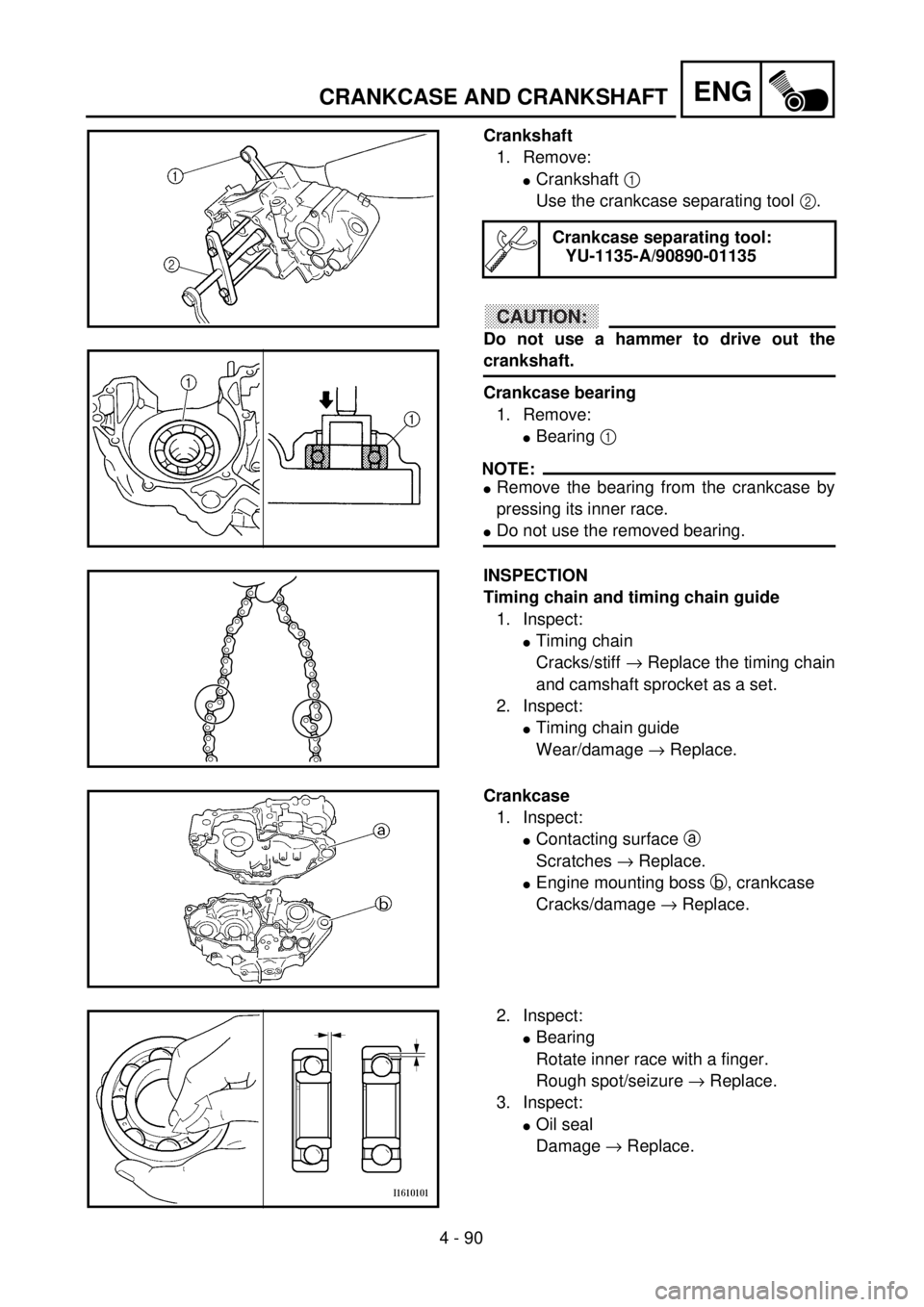

Crankshaft

1. Remove:

lCrankshaft 1

Use the crankcase separating tool 2.

CAUTION:

Do not use a hammer to drive out the

crankshaft.

Crankcase bearing

1. Remove:

lBearing 1

NOTE:

lRemove the bearing from the crankcase by

pressing its inner race.

lDo not use the removed bearing.

Crankcase separating tool:

YU-1135-A/90890-01135

INSPECTION

Timing chain and timing chain guide

1. Inspect:

lTiming chain

Cracks/stiff ® Replace the timing chain

and camshaft sprocket as a set.

2. Inspect:

lTiming chain guide

Wear/damage ® Replace.

Crankcase

1. Inspect:

lContacting surface a

Scratches ® Replace.

lEngine mounting boss b, crankcase

Cracks/damage ® Replace.

2. Inspect:

lBearing

Rotate inner race with a finger.

Rough spot/seizure ® Replace.

3. Inspect:

lOil seal

Damage ® Replace.

Page 436 of 656

4 - 91

ENGCRANKCASE AND CRANKSHAFT

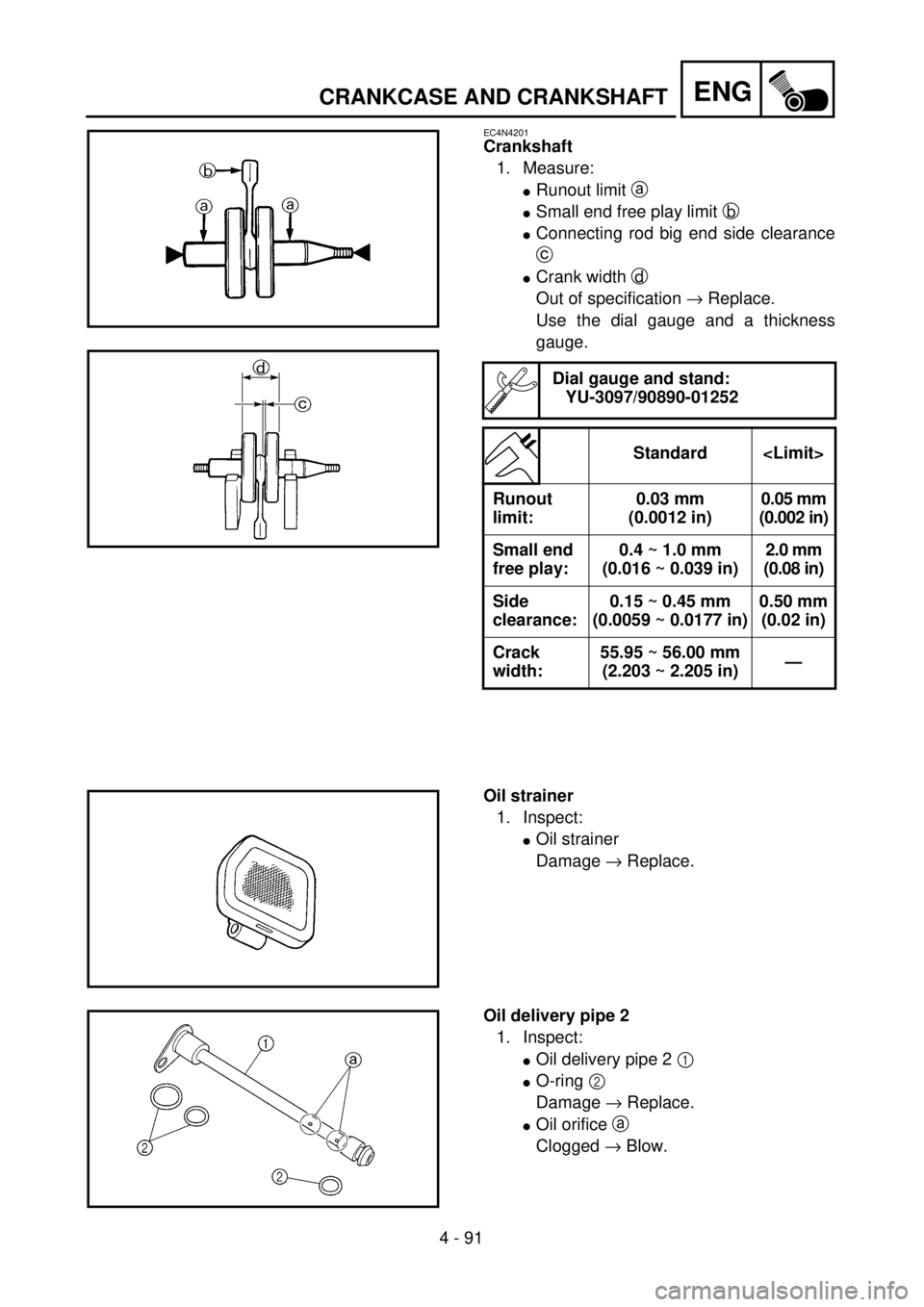

EC4N4201

Crankshaft

1. Measure:

lRunout limit a

lSmall end free play limit b

lConnecting rod big end side clearance

c

lCrank width d

Out of specification ® Replace.

Use the dial gauge and a thickness

gauge.

Dial gauge and stand:

YU-3097/90890-01252

Standard

Runout

limit:0.03 mm

(0.0012 in)0.05 mm

(0.002 in)

Small end

free play:0.4 ~ 1.0 mm

(0.016 ~ 0.039 in)2.0 mm

(0.08 in)

Side

clearance:0.15 ~ 0.45 mm

(0.0059 ~ 0.0177 in)0.50 mm

(0.02 in)

Crack

width:55.95 ~ 56.00 mm

(2.203 ~ 2.205 in)—

Oil strainer

1. Inspect:

lOil strainer

Damage ® Replace.

Oil delivery pipe 2

1. Inspect:

lOil delivery pipe 2 1

lO-ring 2

Damage ® Replace.

lOil orifice a

Clogged ® Blow.

Page 440 of 656

4 - 93

ENGCRANKCASE AND CRANKSHAFT

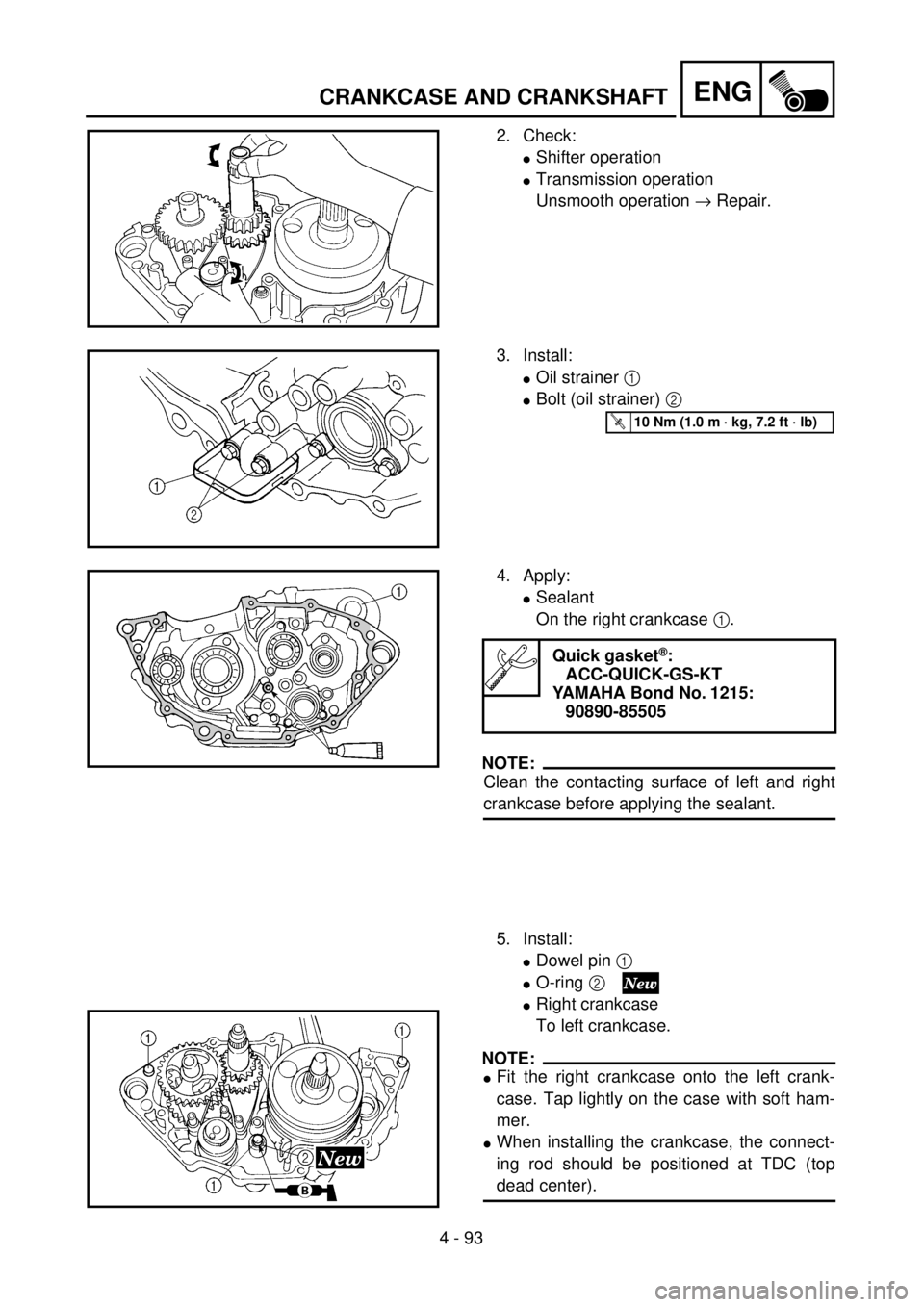

2. Check:

lShifter operation

lTransmission operation

Unsmooth operation ® Repair.

3. Install:

lOil strainer 1

lBolt (oil strainer) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

4. Apply:

lSealant

On the right crankcase 1.

NOTE:

Clean the contacting surface of left and right

crankcase before applying the sealant.

5. Install:

lDowel pin 1

lO-ring 2

lRight crankcase

To left crankcase.

NOTE:

lFit the right crankcase onto the left crank-

case. Tap lightly on the case with soft ham-

mer.

lWhen installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505

Page 442 of 656

4 - 94

ENGCRANKCASE AND CRANKSHAFT

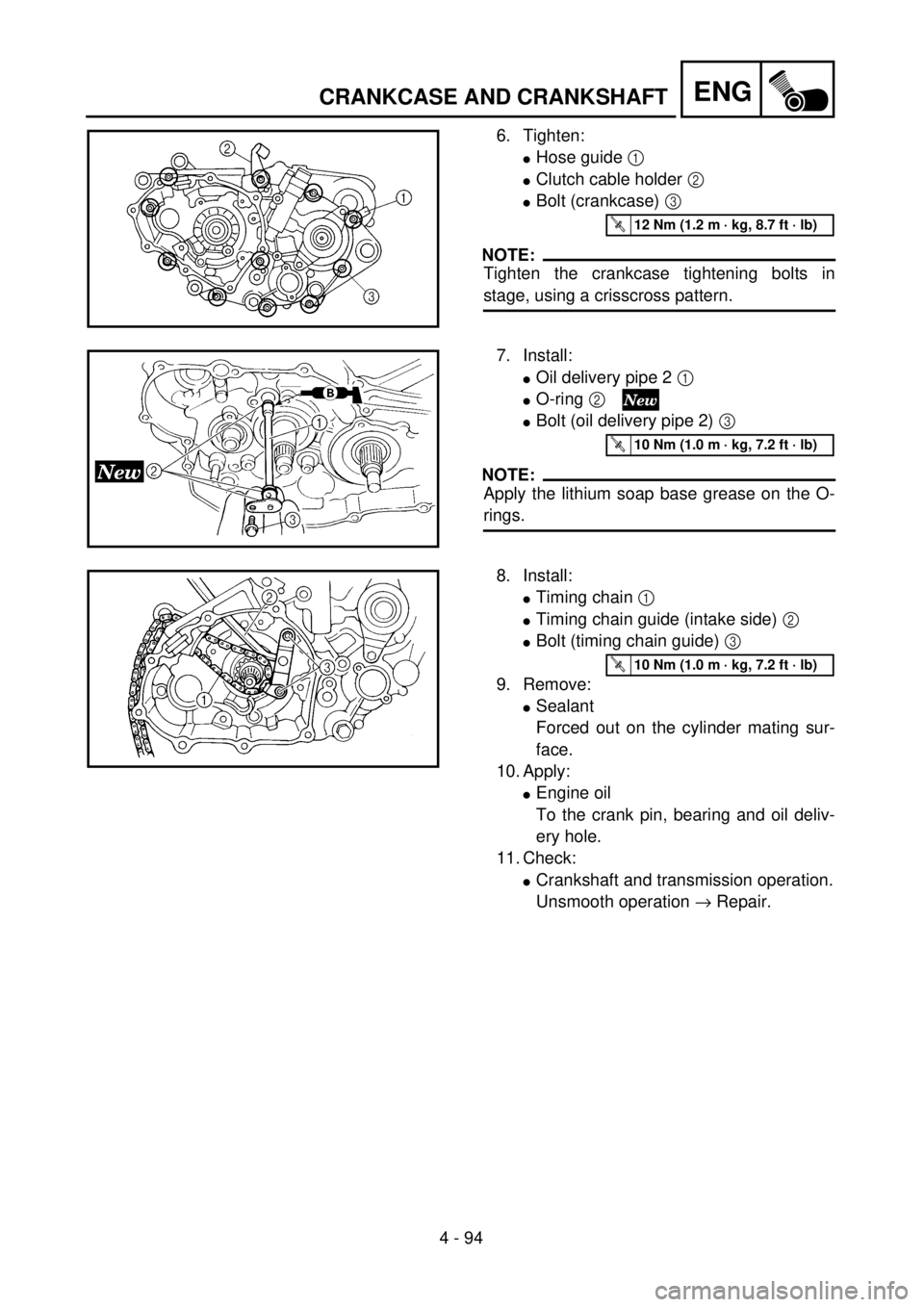

6. Tighten:

lHose guide 1

lClutch cable holder 2

lBolt (crankcase) 3

NOTE:

Tighten the crankcase tightening bolts in

stage, using a crisscross pattern.

T R..12 Nm (1.2 m · kg, 8.7 ft · lb)

7. Install:

lOil delivery pipe 2 1

lO-ring 2

lBolt (oil delivery pipe 2) 3

NOTE:

Apply the lithium soap base grease on the O-

rings.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

8. Install:

lTiming chain 1

lTiming chain guide (intake side) 2

lBolt (timing chain guide) 3

9. Remove:

lSealant

Forced out on the cylinder mating sur-

face.

10. Apply:

lEngine oil

To the crank pin, bearing and oil deliv-

ery hole.

11. Check:

lCrankshaft and transmission operation.

Unsmooth operation ® Repair.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 448 of 656

4 - 97

ENGTRANSMISSION, SHIFT CAM AND SHIFT FORK

EC4H4810

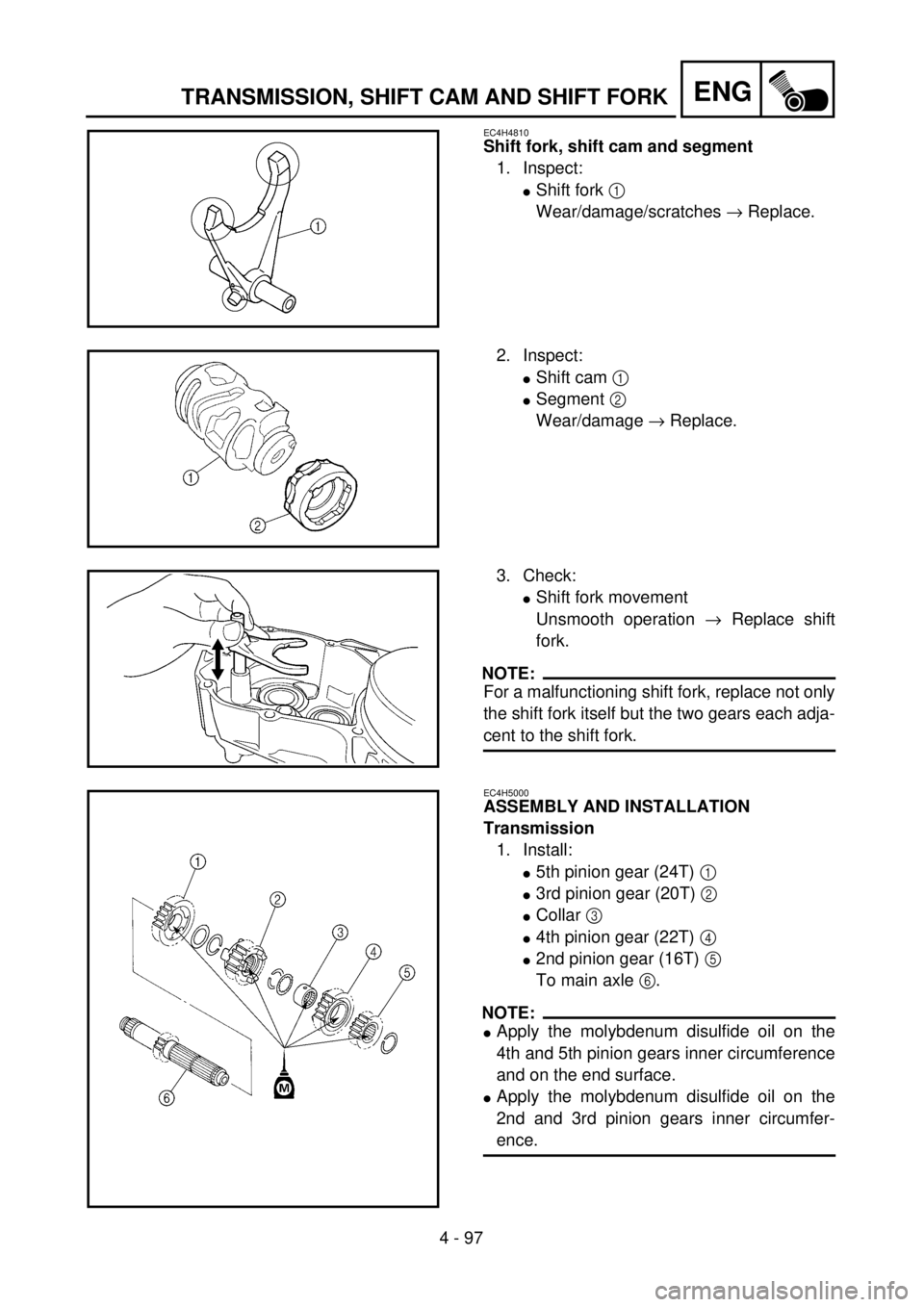

Shift fork, shift cam and segment

1. Inspect:

lShift fork 1

Wear/damage/scratches ® Replace.

2. Inspect:

lShift cam 1

lSegment 2

Wear/damage ® Replace.

3. Check:

lShift fork movement

Unsmooth operation ® Replace shift

fork.

NOTE:

For a malfunctioning shift fork, replace not only

the shift fork itself but the two gears each adja-

cent to the shift fork.

EC4H5000

ASSEMBLY AND INSTALLATION

Transmission

1. Install:

l5th pinion gear (24T) 1

l3rd pinion gear (20T) 2

lCollar 3

l4th pinion gear (22T) 4

l2nd pinion gear (16T) 5

To main axle 6.

NOTE:

lApply the molybdenum disulfide oil on the

4th and 5th pinion gears inner circumference

and on the end surface.

lApply the molybdenum disulfide oil on the

2nd and 3rd pinion gears inner circumfer-

ence.