steering YAMAHA YZ250F 2005 Notices Demploi (in French)

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 22 of 668

CHAPTER 4

ENGINE

SEAT, FUEL TANK

AND SIDE COVERS ..................................4-1

EXHAUST PIPE AND SILENCER .............4-3

RADIATOR ................................................4-5

CARBURETOR ..........................................4-8

CAMSHAFTS ...........................................4-21

CYLINDER HEAD ....................................4-30

VALVES AND VALVE SPRINGS ............4-33

CYLINDER AND PISTON ........................4-42

CLUTCH ...................................................4-49

OIL FILTER ELEMENT, WATER PUMP

AND RIGHT CRANKCASE COVER .......4-56

BALANCER .............................................4-63

OIL PUMP ................................................4-66

KICK SHAFT AND SHIFT SHAFT ..........4-71

CDI MAGNETO ........................................4-78

ENGINE REMOVAL .................................4-82

CRANKCASE AND CRANKSHAFT ........4-87

TRANSMISSION, SHIFT CAM

AND SHIFT FORK ...................................4-96

CHAPTER 5

CHASSIS

FRONT WHEEL AND REAR WHEEL .......5-1

FRONT BRAKE AND REAR BRAKE .....5-10

FRONT FORK ..........................................5-26

HANDLEBAR ...........................................5-42

STEERING ...............................................5-48

SWINGARM .............................................5-53

REAR SHOCK ABSORBER ....................5-61

Page 28 of 668

1 - 2

GEN

INFO

MACHINE IDENTIFICATION

EC120001

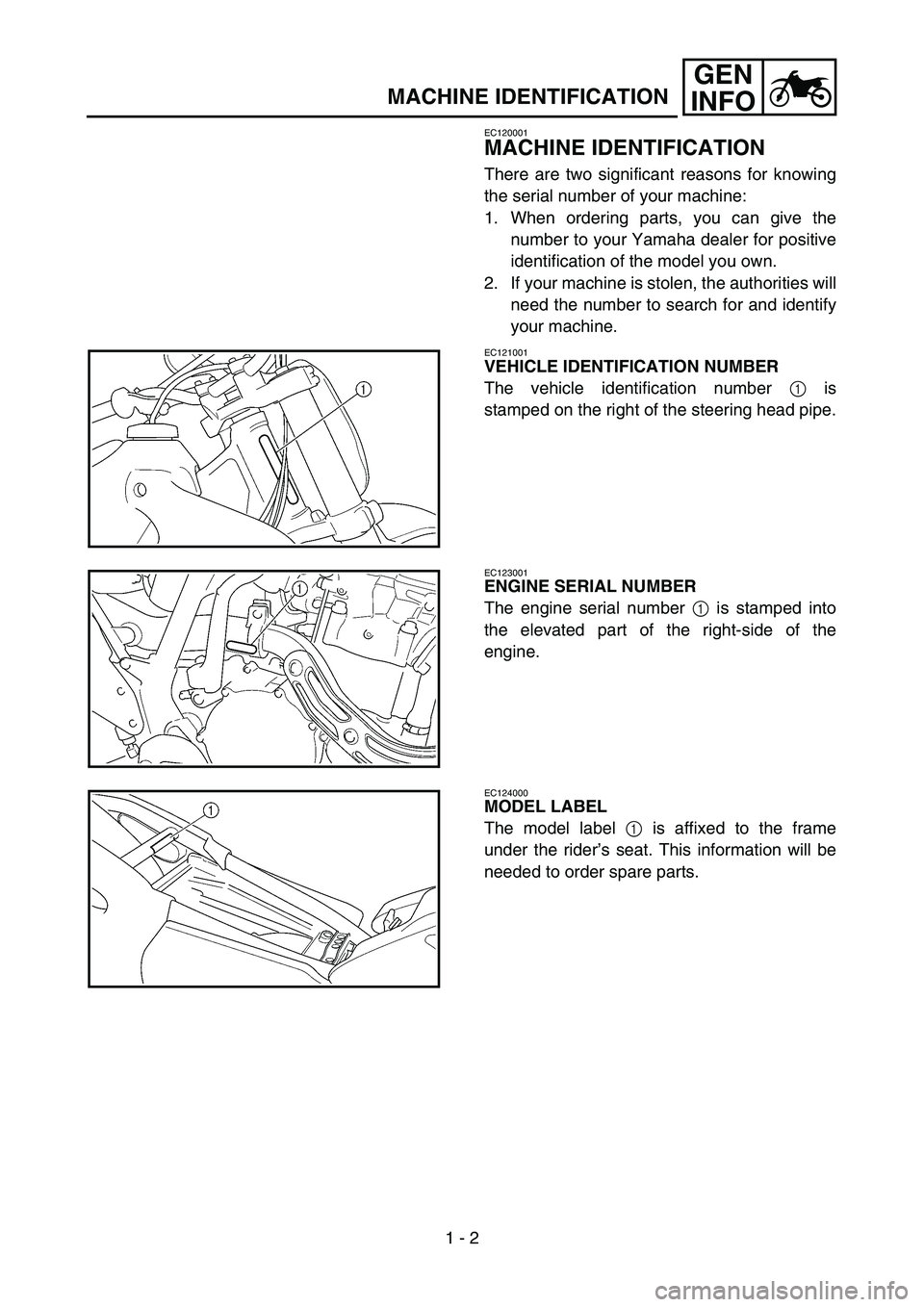

MACHINE IDENTIFICATION

There are two significant reasons for knowing

the serial number of your machine:

1. When ordering parts, you can give the

number to your Yamaha dealer for positive

identification of the model you own.

2. If your machine is stolen, the authorities will

need the number to search for and identify

your machine.

EC121001

VEHICLE IDENTIFICATION NUMBER

The vehicle identification number 1 is

stamped on the right of the steering head pipe.

EC123001

ENGINE SERIAL NUMBER

The engine serial number 1 is stamped into

the elevated part of the right-side of the

engine.

EC124000

MODEL LABEL

The model label 1 is affixed to the frame

under the rider’s seat. This information will be

needed to order spare parts.

Page 39 of 668

GEN

INFO

1 - 8

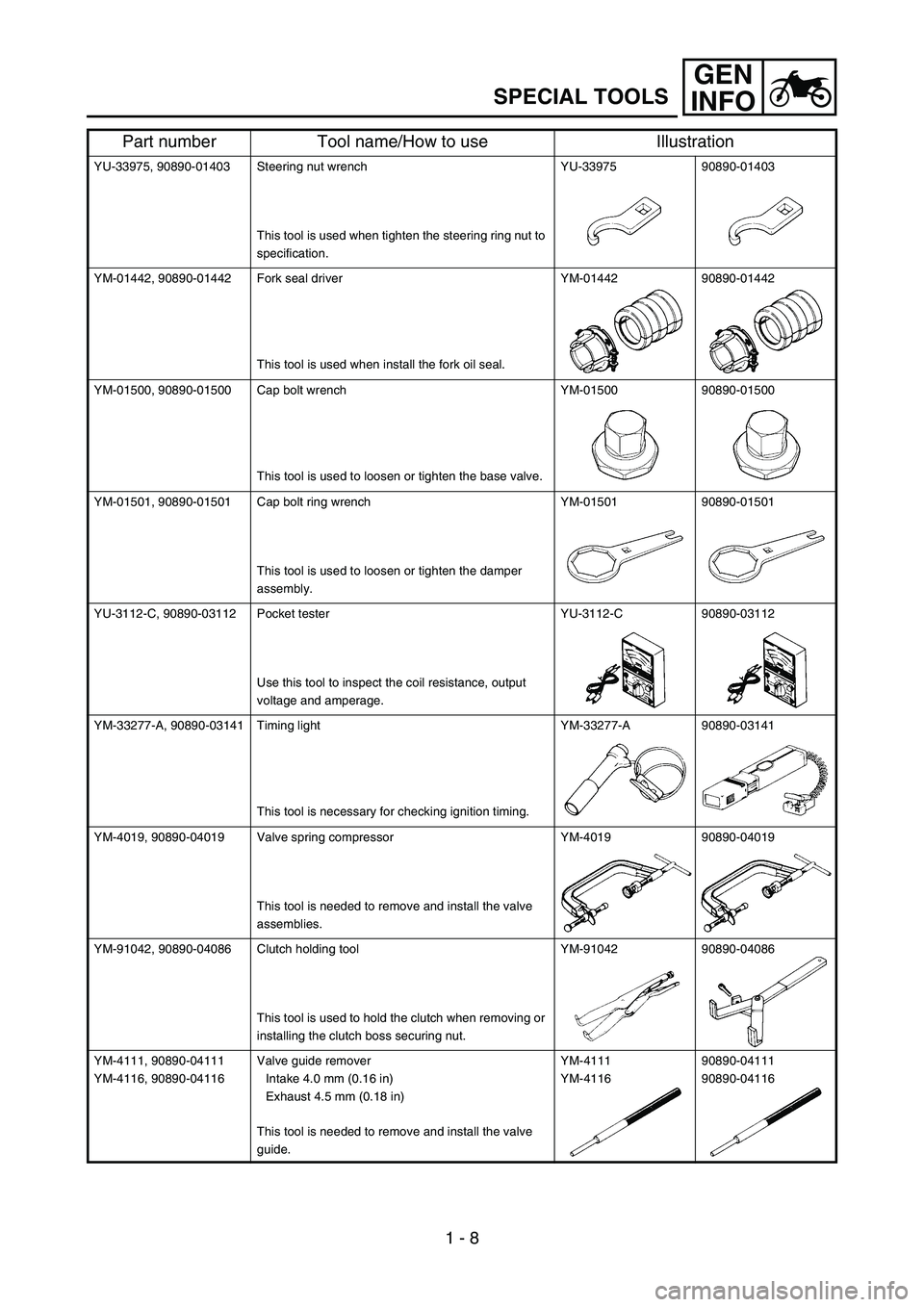

SPECIAL TOOLS

YU-33975, 90890-01403 Steering nut wrench

This tool is used when tighten the steering ring nut to

specification.YU-33975 90890-01403

YM-01442, 90890-01442 Fork seal driver

This tool is used when install the fork oil seal.YM-01442 90890-01442

YM-01500, 90890-01500 Cap bolt wrench

This tool is used to loosen or tighten the base valve.YM-01500 90890-01500

YM-01501, 90890-01501 Cap bolt ring wrench

This tool is used to loosen or tighten the damper

assembly.YM-01501 90890-01501

YU-3112-C, 90890-03112 Pocket tester

Use this tool to inspect the coil resistance, output

voltage and amperage.YU-3112-C 90890-03112

YM-33277-A, 90890-03141 Timing light

This tool is necessary for checking ignition timing.YM-33277-A 90890-03141

YM-4019, 90890-04019 Valve spring compressor

This tool is needed to remove and install the valve

assemblies.YM-4019 90890-04019

YM-91042, 90890-04086 Clutch holding tool

This tool is used to hold the clutch when removing or

installing the clutch boss securing nut.YM-91042 90890-04086

YM-4111, 90890-04111

YM-4116, 90890-04116Valve guide remover

Intake 4.0 mm (0.16 in)

Exhaust 4.5 mm (0.18 in)

This tool is needed to remove and install the valve

guide.YM-4111

YM-411690890-04111

90890-04116

Part number Tool name/How to use Illustration

Page 66 of 668

GEN

INFO

1 - 18

TORQUE-CHECK POINTS

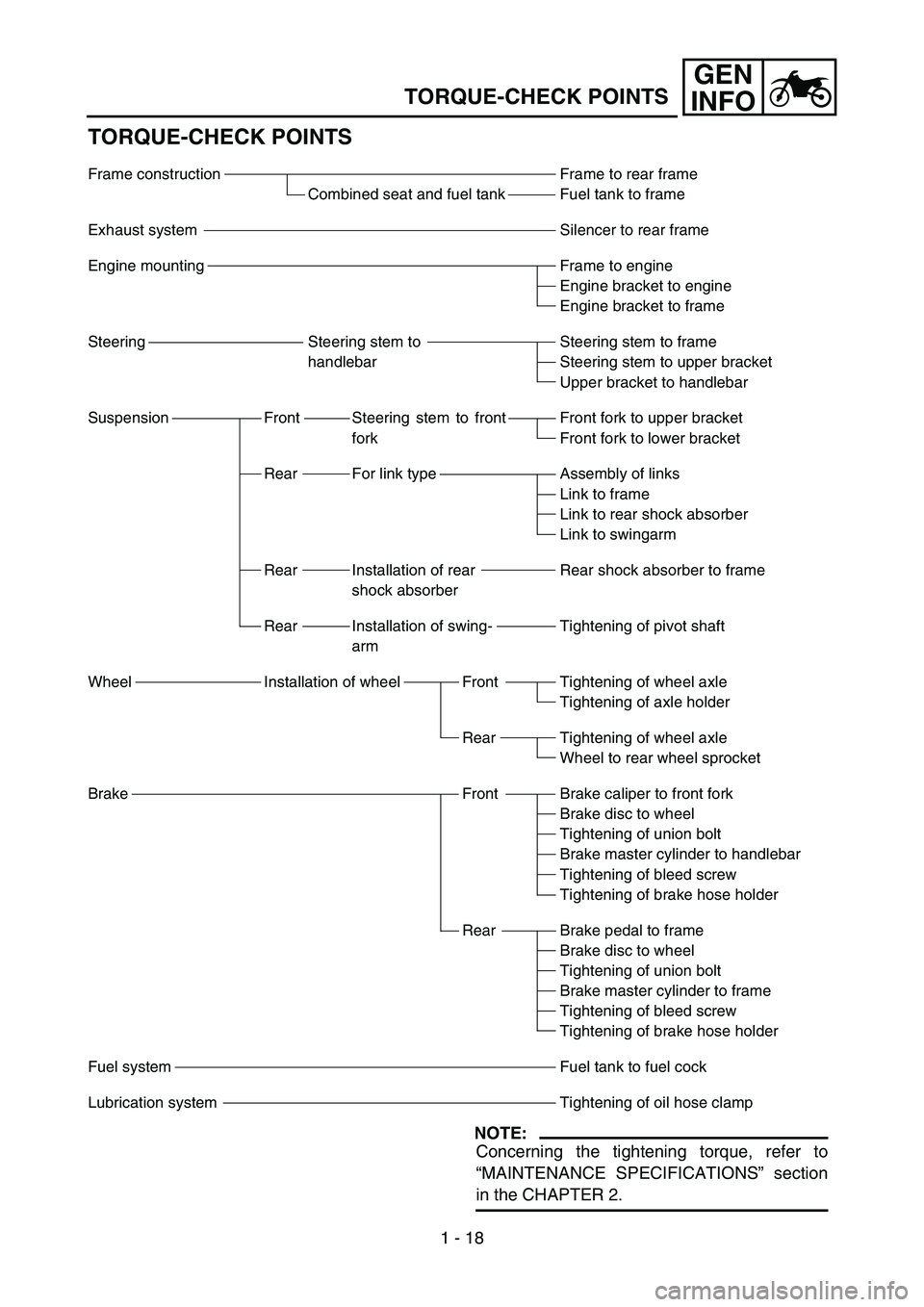

TORQUE-CHECK POINTS

Frame construction

Combined seat and fuel tank

Exhaust system

Engine mounting

Steering Steering stem to

handlebar

Suspension Front Steering stem to front

fork

Rear For link type

Rear Installation of rear

shock absorber

Rear Installation of swing-

arm

Wheel Installation of wheel Front

Rear

Brake Front

Rear

Fuel system

Lubrication systemFrame to rear frame

Fuel tank to frame

Silencer to rear frame

Frame to engine

Engine bracket to engine

Engine bracket to frame

Steering stem to frame

Steering stem to upper bracket

Upper bracket to handlebar

Front fork to upper bracket

Front fork to lower bracket

Assembly of links

Link to frame

Link to rear shock absorber

Link to swingarm

Rear shock absorber to frame

Tightening of pivot shaft

Tightening of wheel axle

Tightening of axle holder

Tightening of wheel axle

Wheel to rear wheel sprocket

Brake caliper to front fork

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to handlebar

Tightening of bleed screw

Tightening of brake hose holder

Brake pedal to frame

Brake disc to wheel

Tightening of union bolt

Brake master cylinder to frame

Tightening of bleed screw

Tightening of brake hose holder

Fuel tank to fuel cock

Tightening of oil hose clamp

NOTE:

Concerning the tightening torque, refer to

“MAINTENANCE SPECIFICATIONS” section

in the CHAPTER 2.

Page 85 of 668

SPEC

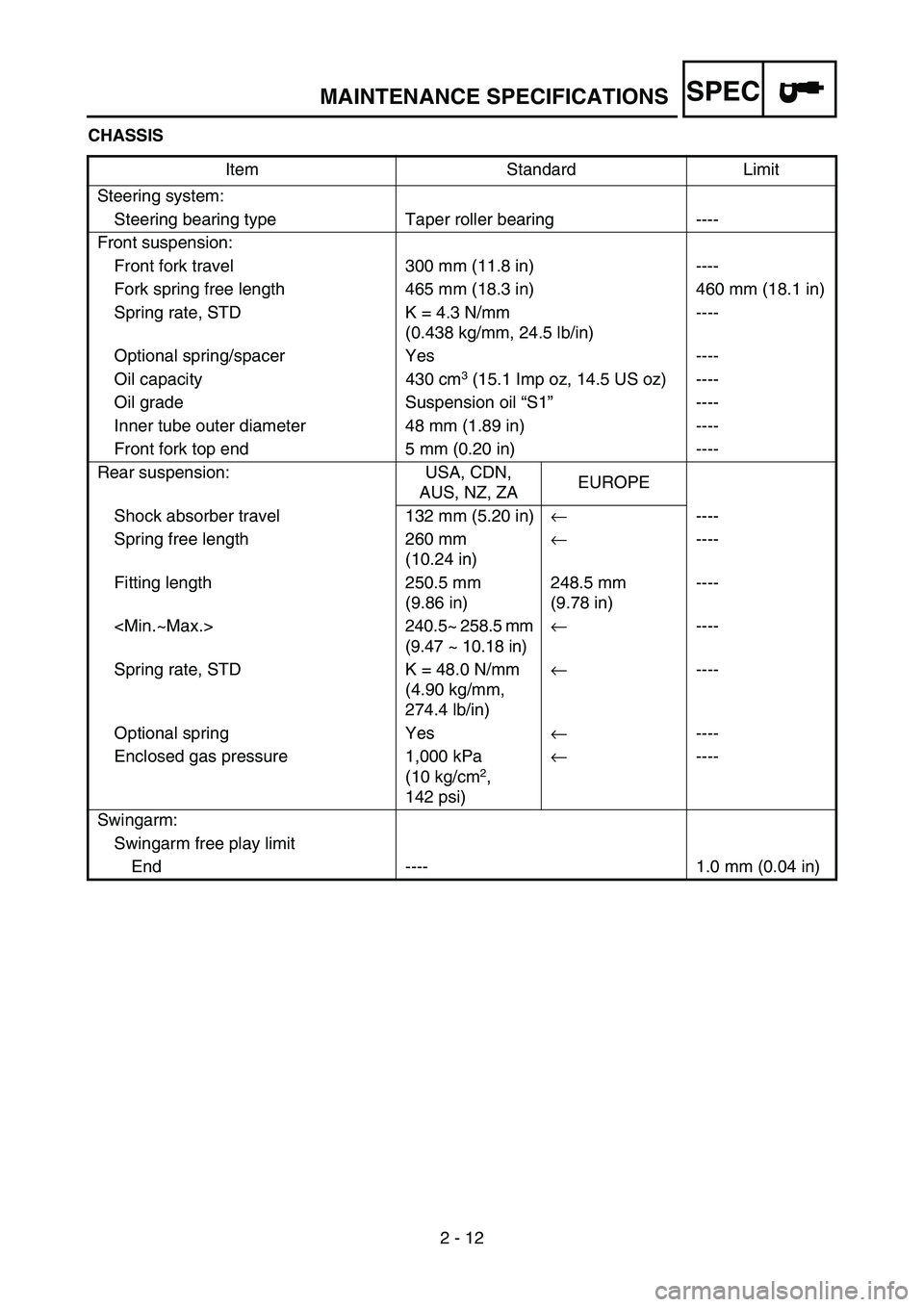

2 - 12 CHASSIS

Item Standard Limit

Steering system:

Steering bearing type Taper roller bearing ----

Front suspension:

Front fork travel 300 mm (11.8 in) ----

Fork spring free length 465 mm (18.3 in) 460 mm (18.1 in)

Spring rate, STD K = 4.3 N/mm

(0.438 kg/mm, 24.5 lb/in)----

Optional spring/spacer Yes ----

Oil capacity 430 cm

3 (15.1 Imp oz, 14.5 US oz) ----

Oil grade Suspension oil “S1”----

Inner tube outer diameter 48 mm (1.89 in) ----

Front fork top end 5 mm (0.20 in) ----

Rear suspension: USA, CDN,

AUS, NZ, ZAEUROPE

Shock absorber travel 132 mm (5.20 in)← ----

Spring free length 260 mm

(10.24 in)← ----

Fitting length 250.5 mm

(9.86 in)248.5 mm

(9.78 in)----

(9.47 ~ 10.18 in)← ----

Spring rate, STD K = 48.0 N/mm

(4.90 kg/mm,

274.4 lb/in)←----

Optional spring Yes← ----

Enclosed gas pressure 1,000 kPa

(10 kg/cm

2,

142 psi)← ----

Swingarm:

Swingarm free play limit

End ---- 1.0 mm (0.04 in)

MAINTENANCE SPECIFICATIONS

Page 87 of 668

SPEC

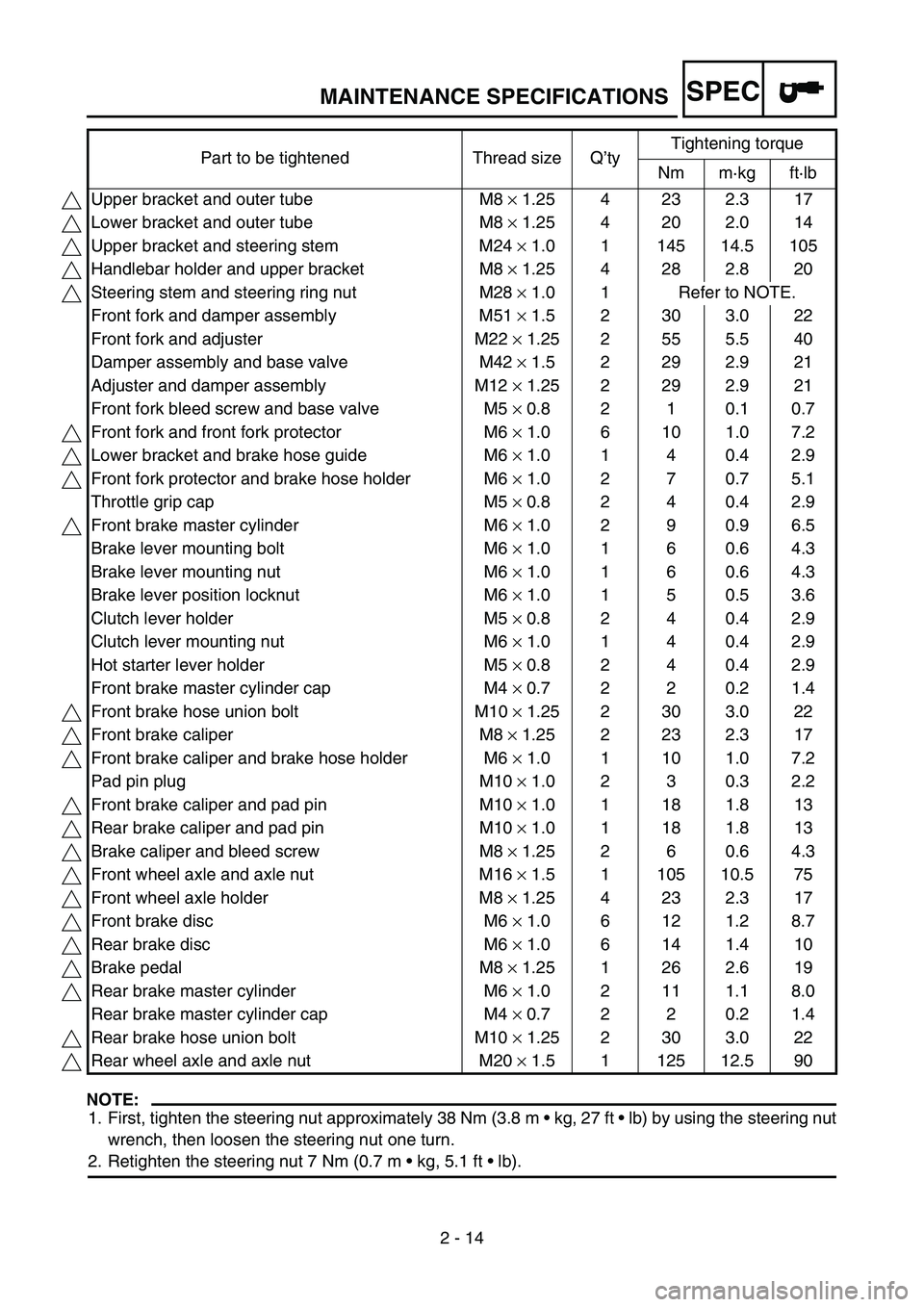

2 - 14

NOTE:

1. First, tighten the steering nut approximately 38 Nm (3.8 m kg, 27 ft lb) by using the steering nut

wrench, then loosen the steering nut one turn.

2. Retighten the steering nut 7 Nm (0.7 m kg, 5.1 ft lb). Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Upper bracket and outer tube M8 × 1.25 4 23 2.3 17

Lower bracket and outer tube M8 × 1.25 4 20 2.0 14

Upper bracket and steering stem M24 × 1.0 1 145 14.5 105

Handlebar holder and upper bracket M8 × 1.25 4 28 2.8 20

Steering stem and steering ring nut M28 × 1.0 1 Refer to NOTE.

Front fork and damper assembly M51 × 1.5 2 30 3.0 22

Front fork and adjuster M22 × 1.25 2 55 5.5 40

Damper assembly and base valve M42 × 1.5 2 29 2.9 21

Adjuster and damper assembly M12 × 1.25 2 29 2.9 21

Front fork bleed screw and base valve M5 × 0.8 2 1 0.1 0.7

Front fork and front fork protector M6 × 1.0 6 10 1.0 7.2

Lower bracket and brake hose guide M6 × 1.0 1 4 0.4 2.9

Front fork protector and brake hose holder M6 × 1.0 2 7 0.7 5.1

Throttle grip cap M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder M6 × 1.0 2 9 0.9 6.5

Brake lever mounting bolt M6 × 1.0 1 6 0.6 4.3

Brake lever mounting nut M6 × 1.0 1 6 0.6 4.3

Brake lever position locknut M6 × 1.0 1 5 0.5 3.6

Clutch lever holder M5 × 0.8 2 4 0.4 2.9

Clutch lever mounting nut M6 × 1.0 1 4 0.4 2.9

Hot starter lever holder M5 × 0.8 2 4 0.4 2.9

Front brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Front brake hose union bolt M10 × 1.25 2 30 3.0 22

Front brake caliper M8 × 1.25 2 23 2.3 17

Front brake caliper and brake hose holder M6 × 1.0 1 10 1.0 7.2

Pad pin plug M10 × 1.0 2 3 0.3 2.2

Front brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Rear brake caliper and pad pin M10 × 1.0 1 18 1.8 13

Brake caliper and bleed screw M8 × 1.25 2 6 0.6 4.3

Front wheel axle and axle nut M16 × 1.5 1 105 10.5 75

Front wheel axle holder M8 × 1.25 4 23 2.3 17

Front brake disc M6 × 1.0 6 12 1.2 8.7

Rear brake disc M6 × 1.0 6 14 1.4 10

Brake pedal M8 × 1.25 1 26 2.6 19

Rear brake master cylinder M6 × 1.0 2 11 1.1 8.0

Rear brake master cylinder cap M4 × 0.7 2 2 0.2 1.4

Rear brake hose union bolt M10 × 1.25 2 30 3.0 22

Rear wheel axle and axle nut M20 × 1.5 1 125 12.5 90

MAINTENANCE SPECIFICATIONS

Page 142 of 668

2 - 18

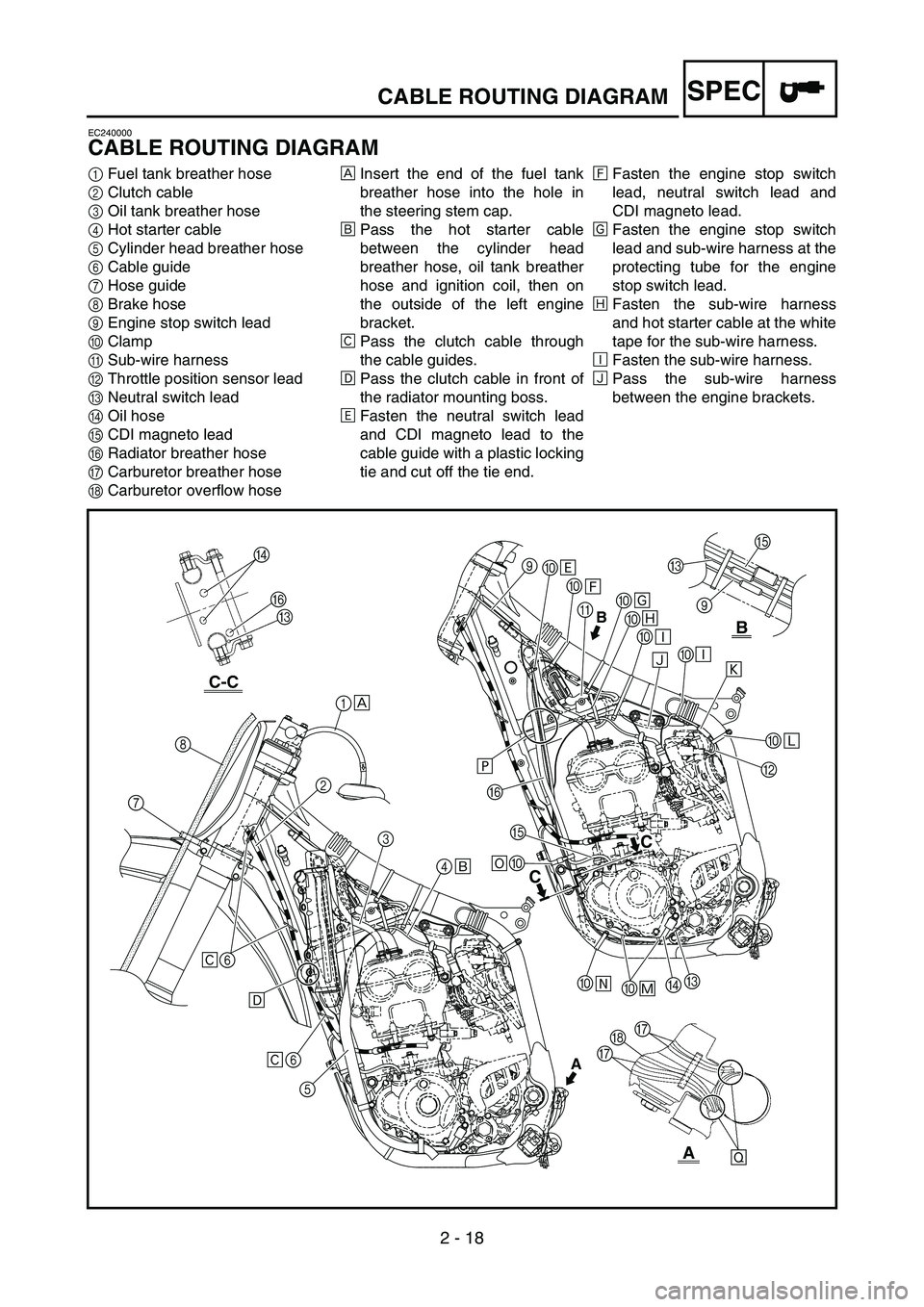

SPECCABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1Fuel tank breather hose

2Clutch cable

3Oil tank breather hose

4Hot starter cable

5Cylinder head breather hose

6Cable guide

7Hose guide

8Brake hose

9Engine stop switch lead

0Clamp

ASub-wire harness

BThrottle position sensor lead

CNeutral switch lead

DOil hose

ECDI magneto lead

FRadiator breather hose

GCarburetor breather hose

HCarburetor overflow hoseÈInsert the end of the fuel tank

breather hose into the hole in

the steering stem cap.

ÉPass the hot starter cable

between the cylinder head

breather hose, oil tank breather

hose and ignition coil, then on

the outside of the left engine

bracket.

ÊPass the clutch cable through

the cable guides.

ËPass the clutch cable in front of

the radiator mounting boss.

ÌFasten the neutral switch lead

and CDI magneto lead to the

cable guide with a plastic locking

tie and cut off the tie end.ÍFasten the engine stop switch

lead, neutral switch lead and

CDI magneto lead.

ÎFasten the engine stop switch

lead and sub-wire harness at the

protecting tube for the engine

stop switch lead.

ÏFasten the sub-wire harness

and hot starter cable at the white

tape for the sub-wire harness.

ÐFasten the sub-wire harness.

ÑPass the sub-wire harness

between the engine brackets.

B

E

C

9

B

C

C

9

0

0

A

0

0

0

0

B 0 Ì

Í

Î

Ï

Ð

Ð

Ñ

Ò

Ó

C

D

0 0 0E F

Ô Õ Ö ×

1

2

3

4

5 6 6 8

7

Ê

Ê ËÈ

É

AGG

H

Ø

D

F

C

Page 154 of 668

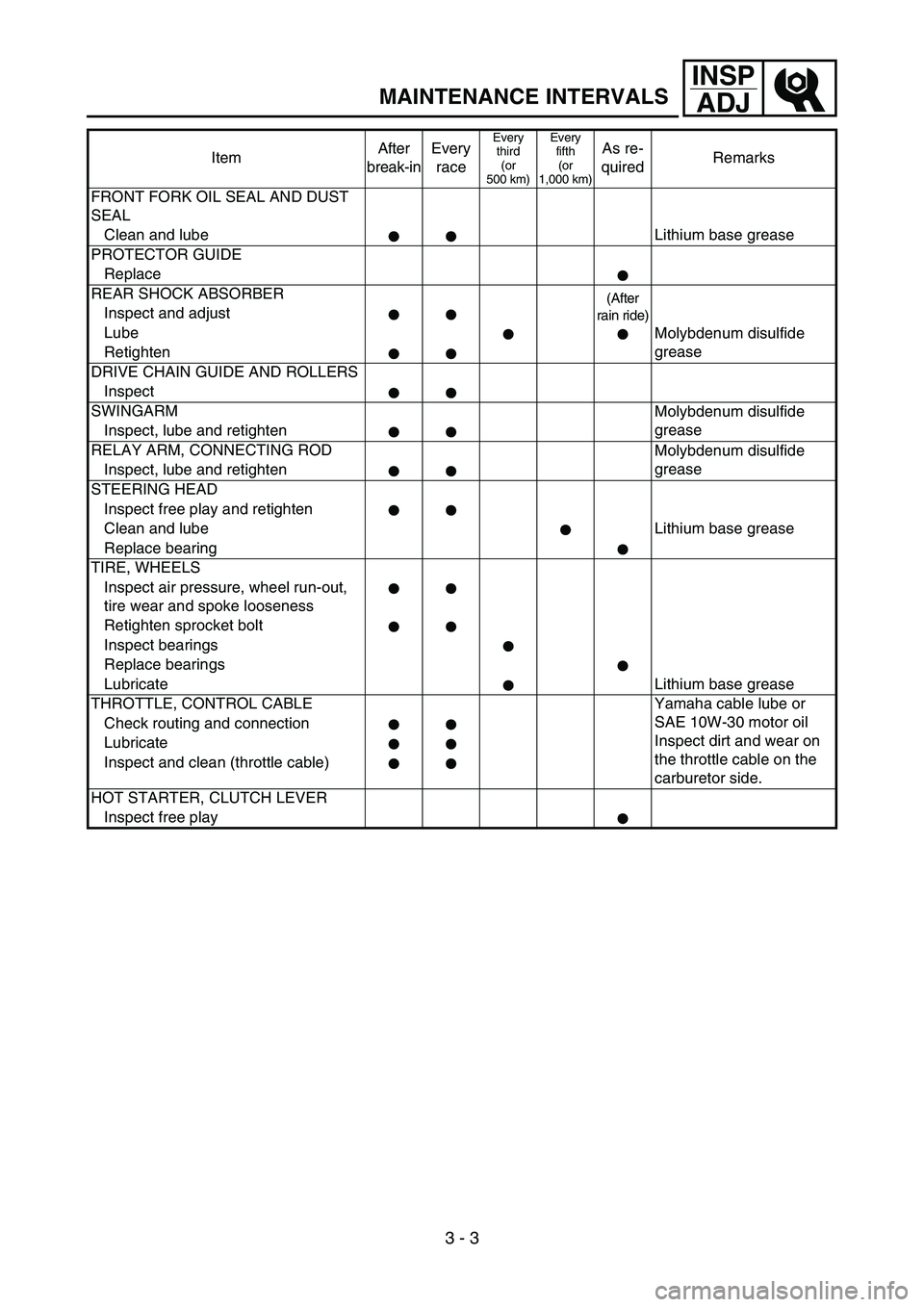

3 - 3

INSP

ADJ

MAINTENANCE INTERVALS

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube Lithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

(After

rain ride)

Inspect and adjust

Lube

Molybdenum disulfide

grease

Retighten

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

SWINGARM

Molybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD

Molybdenum disulfide

grease

Inspect, lube and retighten

STEERING HEAD

Inspect free play and retighten

Clean and lube Lithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate Lithium base grease

THROTTLE, CONTROL CABLE Yamaha cable lube or

SAE 10W-30 motor oil

Inspect dirt and wear on

the throttle cable on the

carburetor side. Check routing and connection

Lubricate

Inspect and clean (throttle cable)

HOT STARTER, CLUTCH LEVER

Inspect free playItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 164 of 668

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

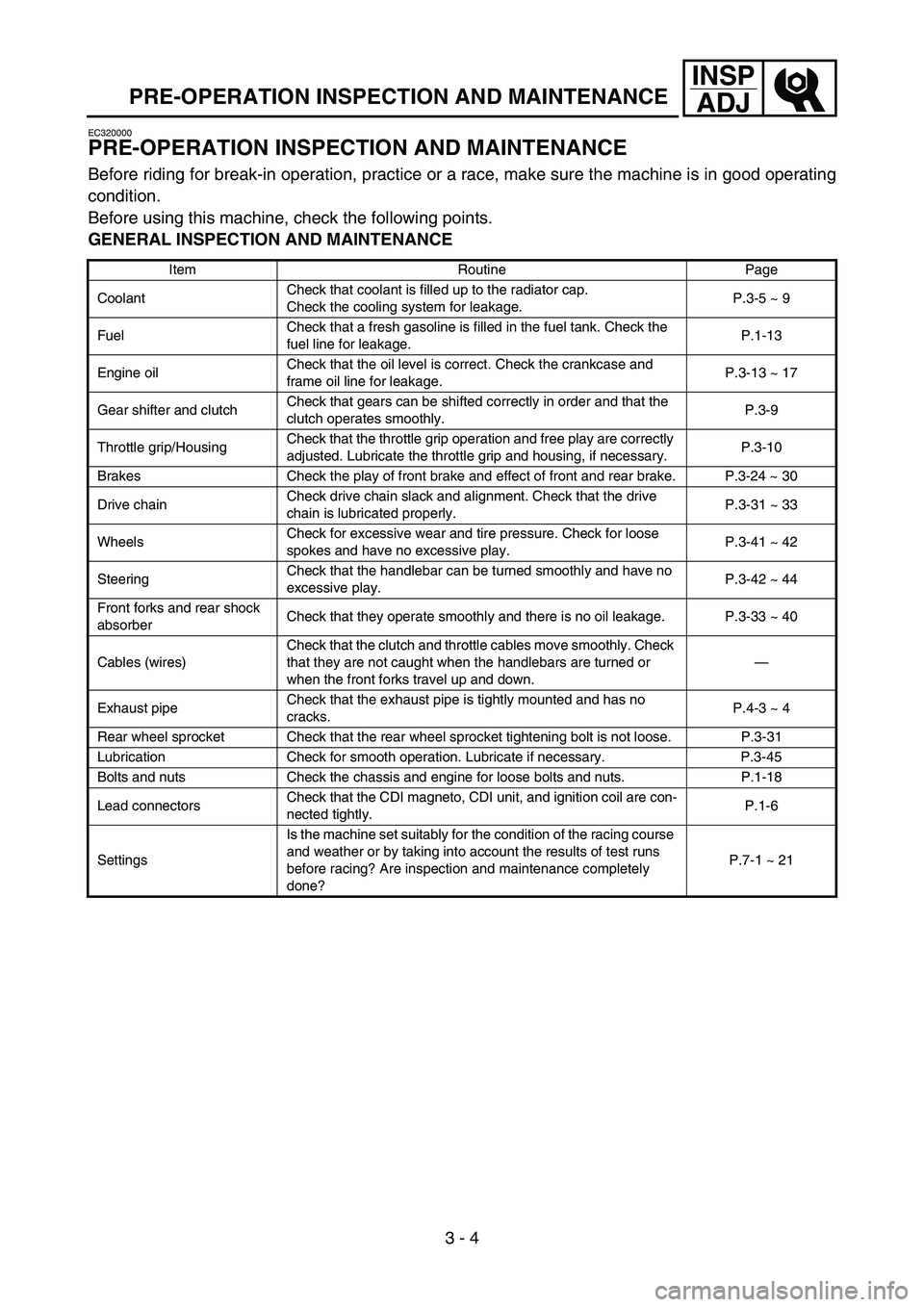

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-13

Engine oilCheck that the oil level is correct. Check the crankcase and

frame oil line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10

Brakes Check the play of front brake and effect of front and rear brake. P.3-24 ~ 30

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-31 ~ 33

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-41 ~ 42

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-42 ~ 44

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-33 ~ 40

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-3 ~ 4

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-31

Lubrication Check for smooth operation. Lubricate if necessary. P.3-45

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-18

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 21

Page 244 of 668

3 - 42

INSP

ADJ

STEERING HEAD INSPECTION AND ADJUSTMENT

2. Inspect:

Bearing free play

Exist play → Replace.

EC36U013

STEERING HEAD INSPECTION AND

ADJUSTMENT

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Check:

Steering stem

Grasp the bottom of the forks and gently

rock the fork assembly back and forth.

Free play → Adjust steering head.

3. Check:

Steering smooth action

Turn the handlebar lock to lock.

Unsmooth action → Adjust steering ring

nut.

4. Adjust:

Steering ring nut

Steering ring nut adjustment steps:

Remove the number plate.

Remove the handlebar and handlebar

upper bracket.

Loosen the steering ring nut 1 using the

steering nut wrench 2.

Steering nut wrench:

YU-33975/90890-01403