light YAMAHA YZ250F 2005 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 252 of 668

3 - 46

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode 1

Wear/damage → Replace.

Insulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color → Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

4. Clean the plug with a spark plug cleaner if

necessary.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

5. Tighten:

Spark plug

NOTE:

Before installing a spark plug, clean the gas-

ket surface and plug surface.

Finger-tighten a the spark plug before torqu-

ing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 254 of 668

3 - 47

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw 1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “ENGINE IDLING SPEED

ADJUSTMENT” section.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing mark accessing screw

Page 288 of 668

4 - 17

ENGCARBURETOR

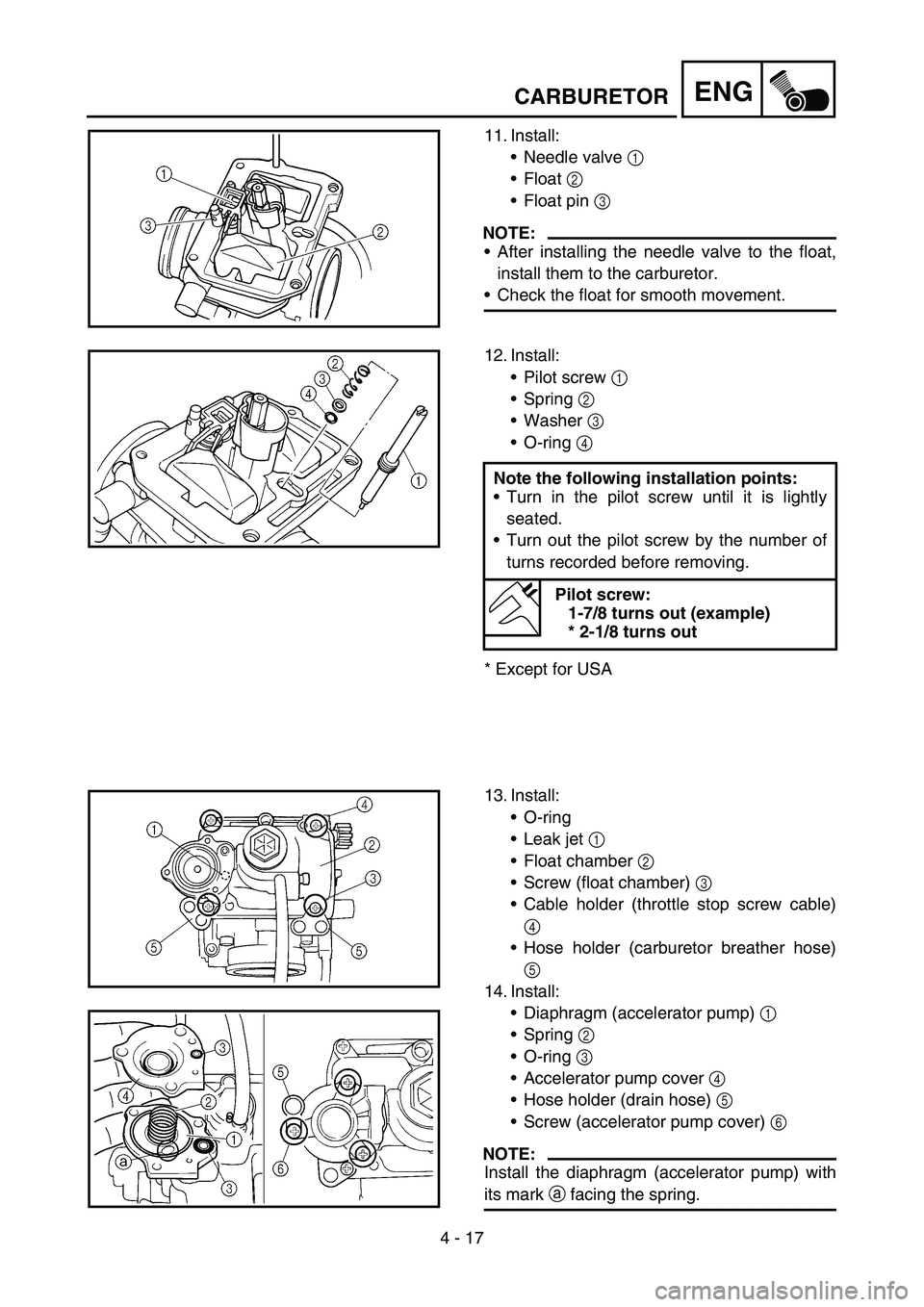

11. Install:

Needle valve 1

Float 2

Float pin 3

NOTE:

After installing the needle valve to the float,

install them to the carburetor.

Check the float for smooth movement.

12. Install:

Pilot screw 1

Spring 2

Washer 3

O-ring 4

* Except for USANote the following installation points:

Turn in the pilot screw until it is lightly

seated.

Turn out the pilot screw by the number of

turns recorded before removing.

Pilot screw:

1-7/8 turns out (example)

* 2-1/8 turns out

13. Install:

O-ring

Leak jet 1

Float chamber 2

Screw (float chamber) 3

Cable holder (throttle stop screw cable)

4

Hose holder (carburetor breather hose)

5

14. Install:

Diaphragm (accelerator pump) 1

Spring 2

O-ring 3

Accelerator pump cover 4

Hose holder (drain hose) 5

Screw (accelerator pump cover) 6

NOTE:

Install the diaphragm (accelerator pump) with

its mark a facing the spring.

Page 292 of 668

4 - 19

ENGCARBURETOR

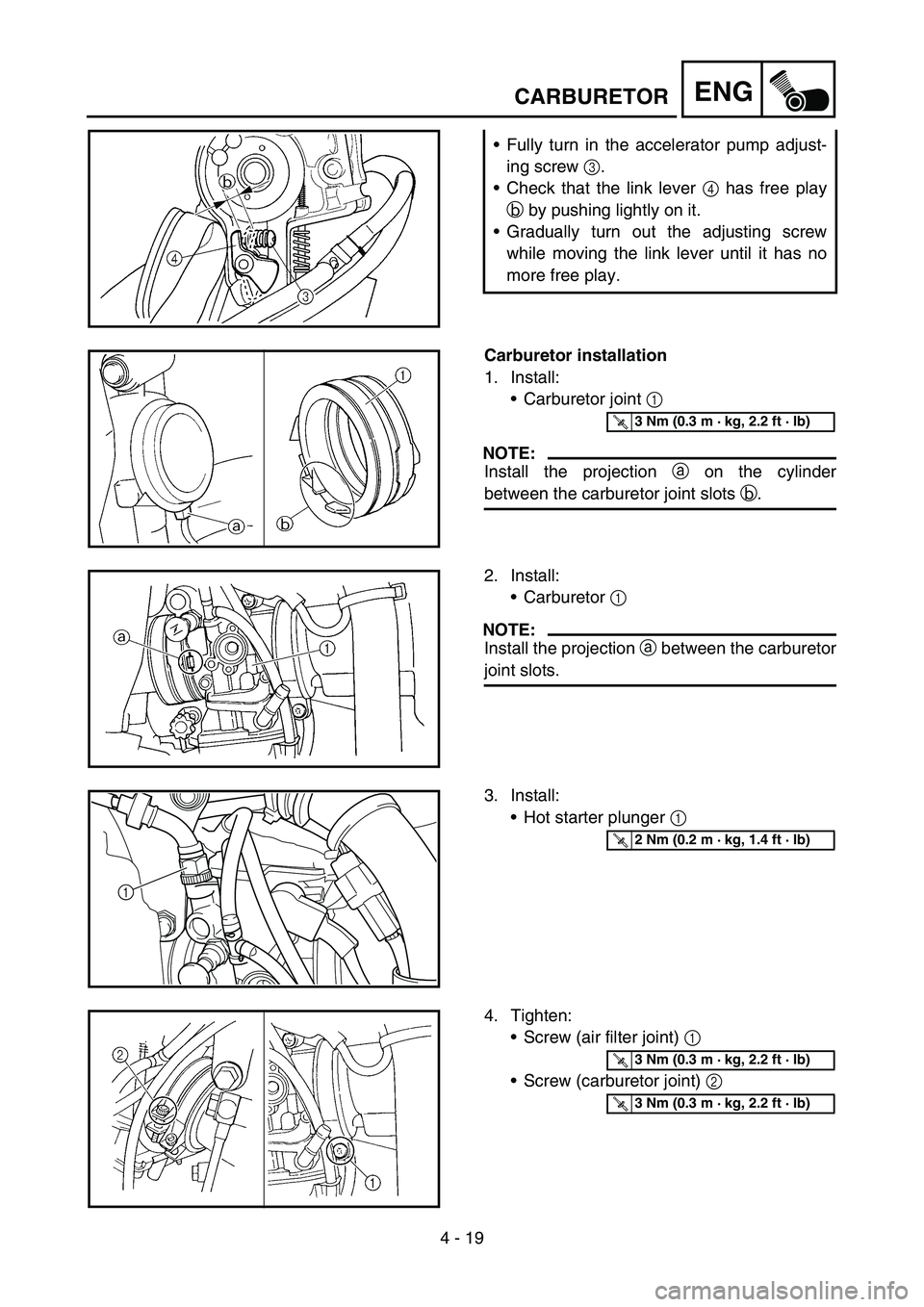

Fully turn in the accelerator pump adjust-

ing screw 3.

Check that the link lever 4 has free play

b by pushing lightly on it.

Gradually turn out the adjusting screw

while moving the link lever until it has no

more free play.

Carburetor installation

1. Install:

Carburetor joint 1

NOTE:

Install the projection a on the cylinder

between the carburetor joint slots b.

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

2. Install:

Carburetor 1

NOTE:

Install the projection a between the carburetor

joint slots.

3. Install:

Hot starter plunger 1

1

T R..2 Nm (0.2 m · kg, 1.4 ft · lb)

4. Tighten:

Screw (air filter joint) 1

Screw (carburetor joint) 2

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

T R..3 Nm (0.3 m · kg, 2.2 ft · lb)

Page 306 of 668

4 - 26

ENGCAMSHAFTS

Decompression system

1. Check:

Decompression system

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

Exhaust camshaft 1

Intake camshaft 2 Checking steps:

Check that the decompression mecha-

nism cam 1 moves smoothly.

Check that the decompression mecha-

nism cam lever pin 2 projects from the

camshaft.

Installation steps:

Turn the crankshaft counterclockwise with

a wrench.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Squeezing the decompression lever

allows the crankshaft to be turned easily.

Align the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

Page 308 of 668

4 - 27

ENGCAMSHAFTS

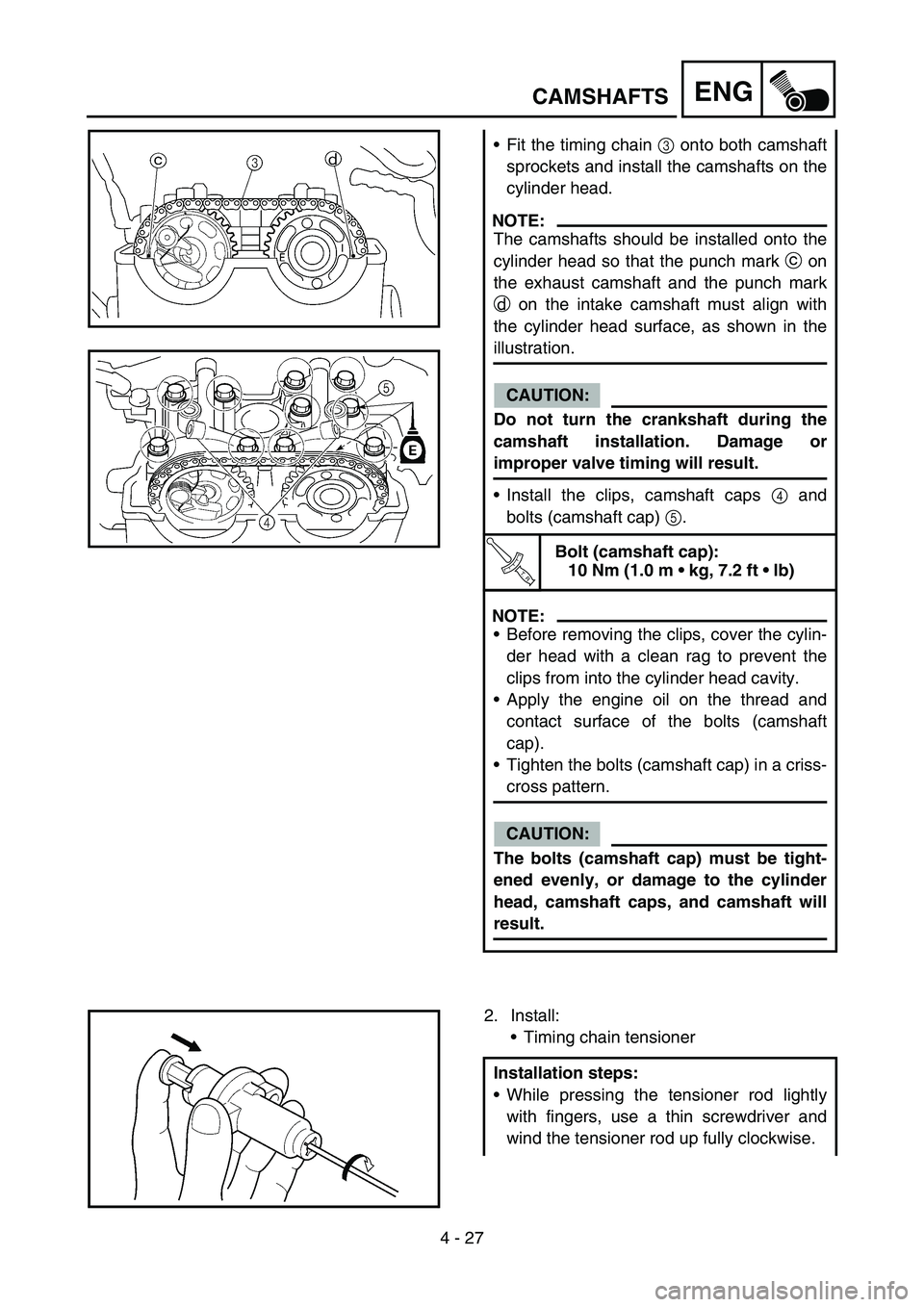

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the punch mark c on

the exhaust camshaft and the punch mark

d on the intake camshaft must align with

the cylinder head surface, as shown in the

illustration.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips, camshaft caps 4 and

bolts (camshaft cap) 5.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Before removing the clips, cover the cylin-

der head with a clean rag to prevent the

clips from into the cylinder head cavity.

Apply the engine oil on the thread and

contact surface of the bolts (camshaft

cap).

Tighten the bolts (camshaft cap) in a criss-

cross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

Page 330 of 668

4 - 38

ENGVALVES AND VALVE SPRINGS

9. Lap:

Valve face

Valve seat

NOTE:

After refacing the valve seat or replacing the

valve and valve guide, the valve seat and

valve face should be lapped.

Lapping steps:

Apply a coarse lapping compound to the

valve face.

CAUTION:

Do not let the compound enter the gap

between the valve stem and the guide.

Apply molybdenum disulfide oil to the

valve stem.

Install the valve into the cylinder head.

Turn the valve until the valve face and

valve seat are evenly polished, then clean

off all of the compound.

NOTE:

For best lapping results, lightly tap the valve

seat while rotating the valve back and forth

between your hands.

Apply a fine lapping compound to the

valve face and repeat the above steps.

NOTE:

After every lapping operation be sure to

clean off all of the compound from the valve

face and valve seat.

Apply Mechanic’s blueing dye (Dykem) to

the valve face.

Install the valve into the cylinder head.

Press the valve through the valve guide

and onto the valve seat to make a clear

pattern.

Measure the valve seat width again. If the

valve seat width is out of specification,

reface and relap the valve seat.

Page 334 of 668

4 - 40

ENGVALVES AND VALVE SPRINGS

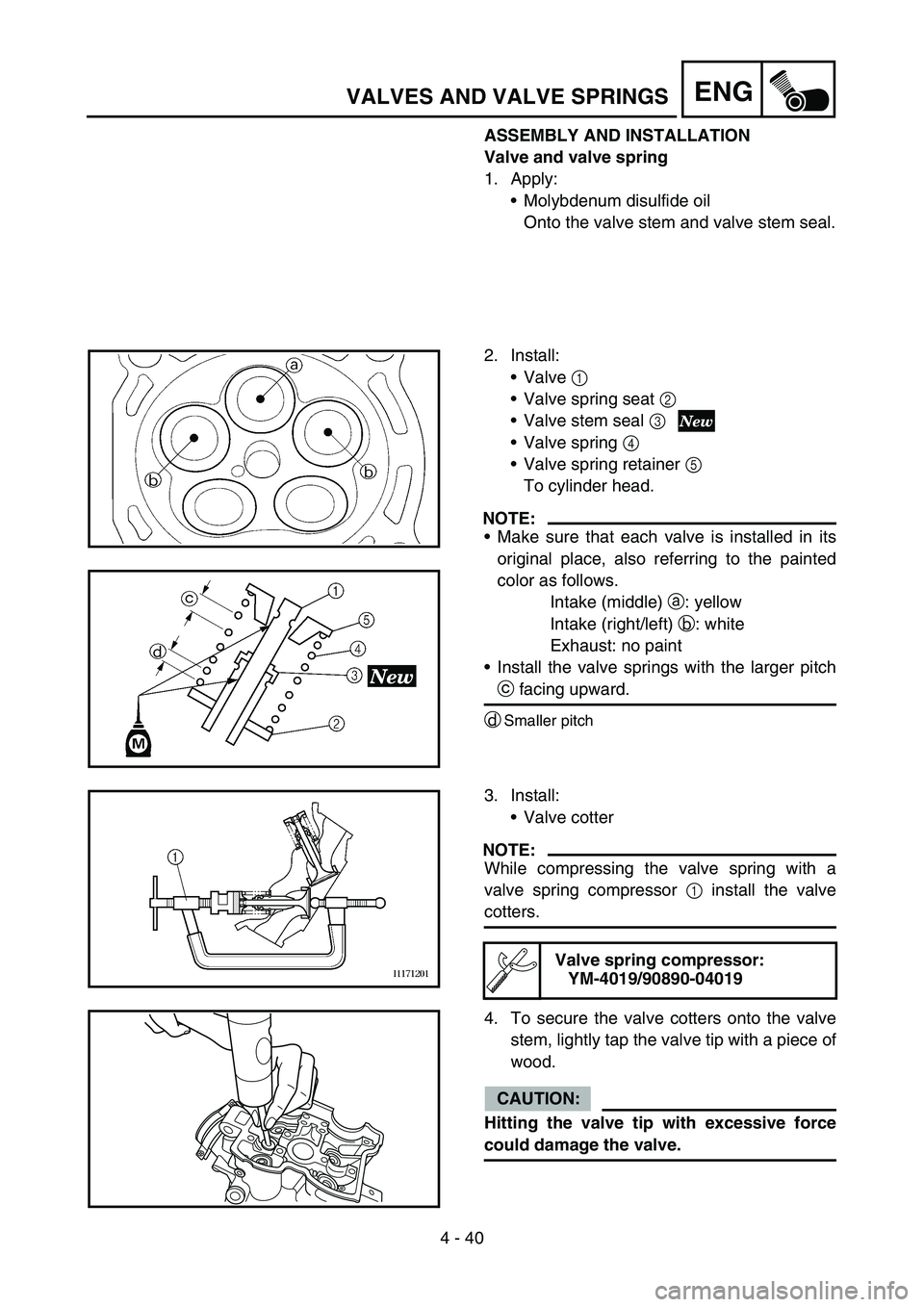

ASSEMBLY AND INSTALLATION

Valve and valve spring

1. Apply:

Molybdenum disulfide oil

Onto the valve stem and valve stem seal.

2. Install:

Valve 1

Valve spring seat 2

Valve stem seal 3

Valve spring 4

Valve spring retainer 5

To cylinder head.

NOTE:

Make sure that each valve is installed in its

original place, also referring to the painted

color as follows.

Intake (middle) a: yellow

Intake (right/left) b: white

Exhaust: no paint

Install the valve springs with the larger pitch

c facing upward.

d

Smaller pitch

3. Install:

Valve cotter

NOTE:

While compressing the valve spring with a

valve spring compressor 1 install the valve

cotters.

4. To secure the valve cotters onto the valve

stem, lightly tap the valve tip with a piece of

wood.

CAUTION:

Hitting the valve tip with excessive force

could damage the valve.

Valve spring compressor:

YM-4019/90890-04019

Page 434 of 668

4 - 90

ENGCRANKCASE AND CRANKSHAFT

REMOVAL POINTS

Crankcase

1. Separate:

Right crankcase

Left crankcase

Separation steps:

Remove the crankcase bolts 1, hose

guide 2 and clutch cable holder 3.

NOTE:

Loosen each bolt 1/4 of a turn at a time and

after all the bolts are loosened, remove

them.

Remove the right crankcase 4.

NOTE:

Place the crankcase with its left side

downward and split it by inserting a screw-

driver tip into the splitting slit a in the

crankcase.

Lift the right crankcase horizontally while

lightly patting the case splitting slit and

engine mounting boss using a soft ham-

mer, and leave the crankshaft and trans-

mission with the left crankcase.

CAUTION:

Use soft hammer to tap on the case half.

Tap only on reinforced portions of case.

Do not tap on gasket mating surface.

Work slowly and carefully. Make sure the

case halves separate evenly. If one end

“hangs up”, take pressure off the push

screw, realign, and start over. If the

cases do not separate, check for a

remaining case screw or fitting. Do not

force.

Remove the dowel pins and O-ring.

a

4

Page 442 of 668

4 - 94

ENGCRANKCASE AND CRANKSHAFT

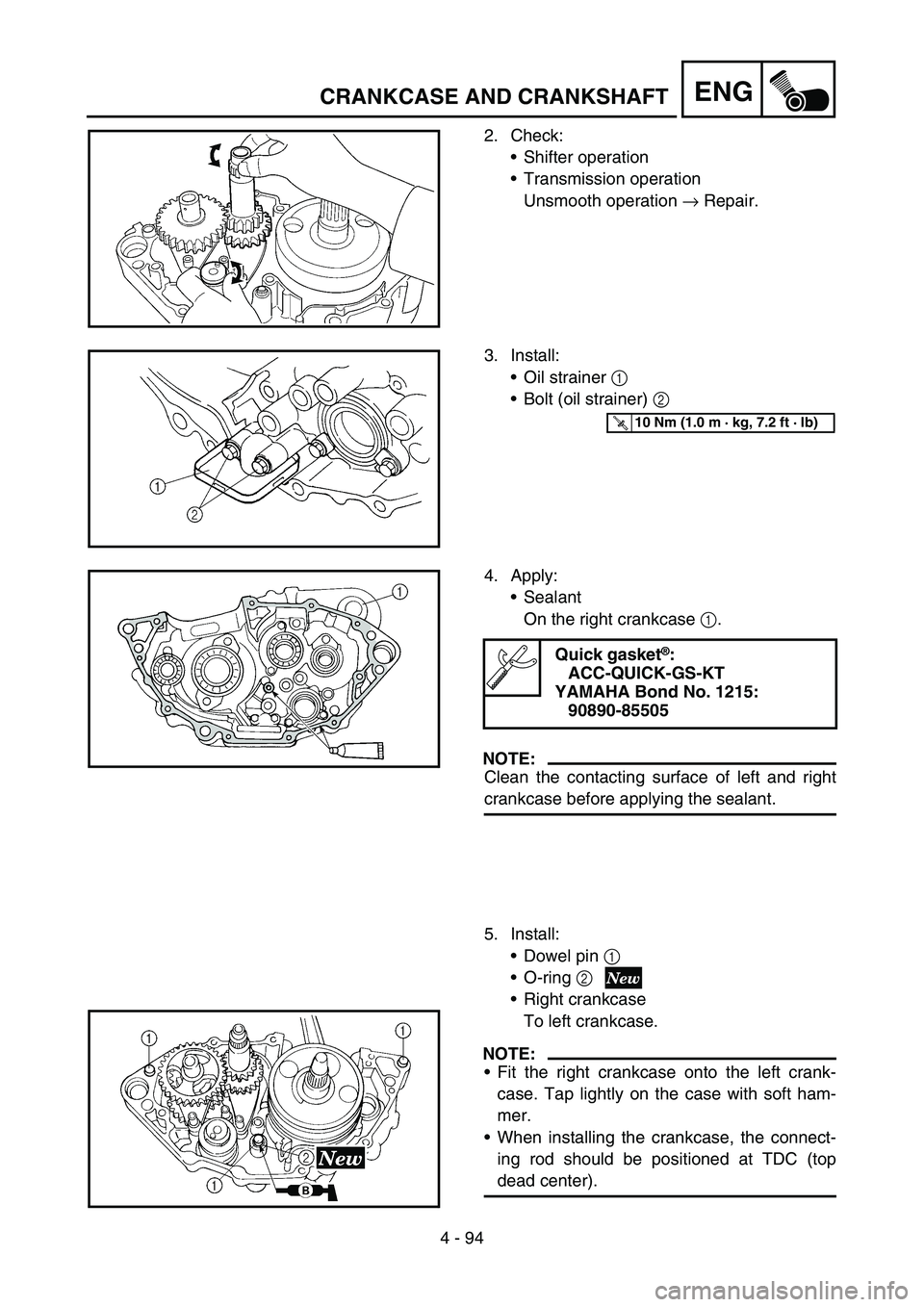

2. Check:

Shifter operation

Transmission operation

Unsmooth operation → Repair.

3. Install:

Oil strainer 1

Bolt (oil strainer) 2

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

4. Apply:

Sealant

On the right crankcase 1.

NOTE:

Clean the contacting surface of left and right

crankcase before applying the sealant.

5. Install:

Dowel pin 1

O-ring 2

Right crankcase

To left crankcase.

NOTE:

Fit the right crankcase onto the left crank-

case. Tap lightly on the case with soft ham-

mer.

When installing the crankcase, the connect-

ing rod should be positioned at TDC (top

dead center).

Quick gasket®:

ACC-QUICK-GS-KT

YAMAHA Bond No. 1215:

90890-85505