engine YAMAHA YZ250F 2005 Workshop Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2005, Model line: YZ250F, Model: YAMAHA YZ250F 2005Pages: 668, PDF Size: 15.74 MB

Page 254 of 668

3 - 47

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw 1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “ENGINE IDLING SPEED

ADJUSTMENT” section.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing mark accessing screw

Page 256 of 668

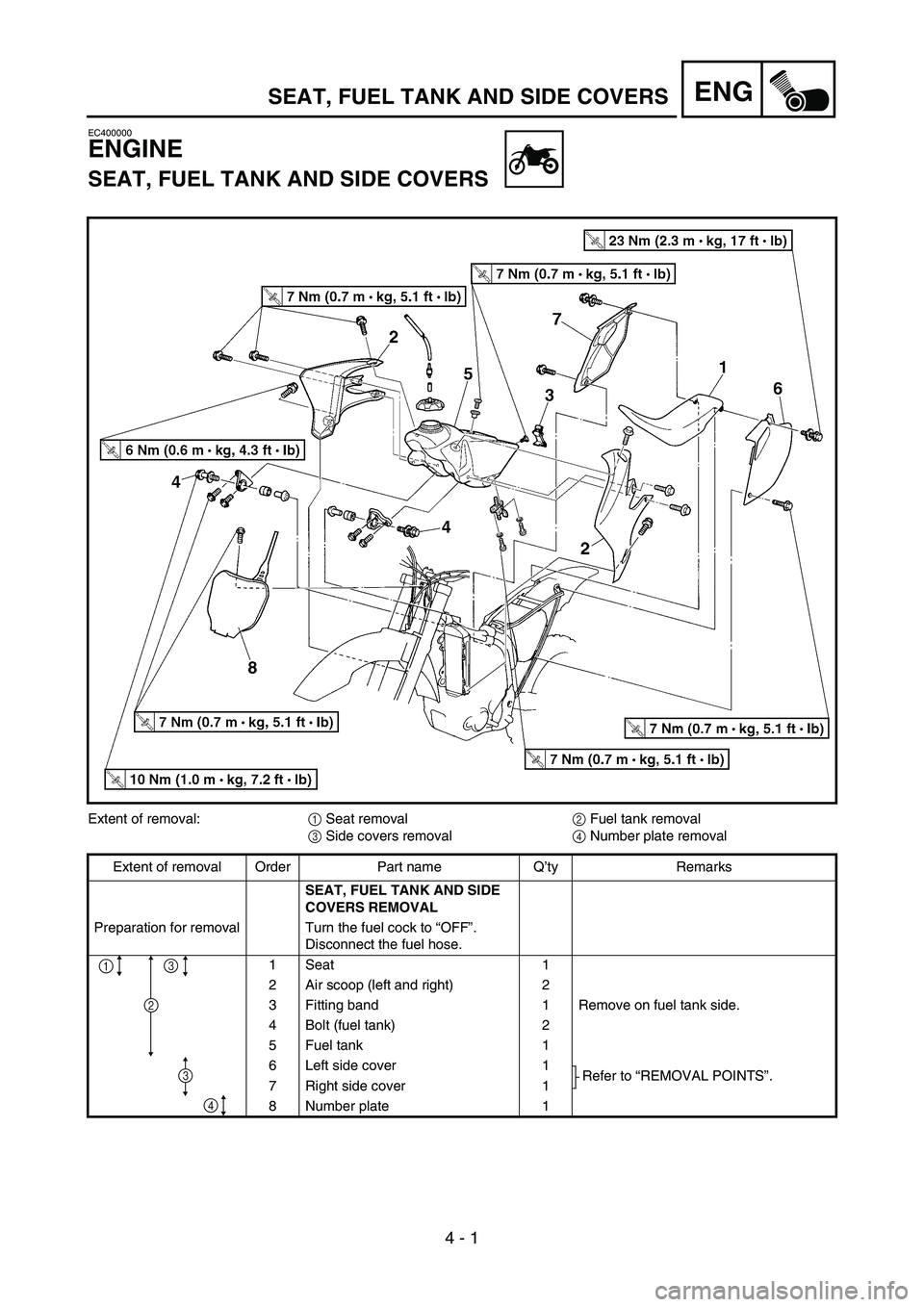

4 - 1

ENG

EC400000

ENGINE

SEAT, FUEL TANK AND SIDE COVERS

Extent of removal:

1 Seat removal

2 Fuel tank removal

3 Side covers removal

4 Number plate removal

Extent of removal Order Part name Q’ty Remarks

SEAT, FUEL TANK AND SIDE

COVERS REMOVAL

Preparation for removal Turn the fuel cock to “OFF”.

Disconnect the fuel hose.

1Seat 1

2 Air scoop (left and right) 2

3 Fitting band 1 Remove on fuel tank side.

4 Bolt (fuel tank) 2

5 Fuel tank 1

6 Left side cover 1

Refer to “REMOVAL POINTS”.

7 Right side cover 1

8 Number plate 1

4

2

1

3

3

SEAT, FUEL TANK AND SIDE COVERS

4

Page 266 of 668

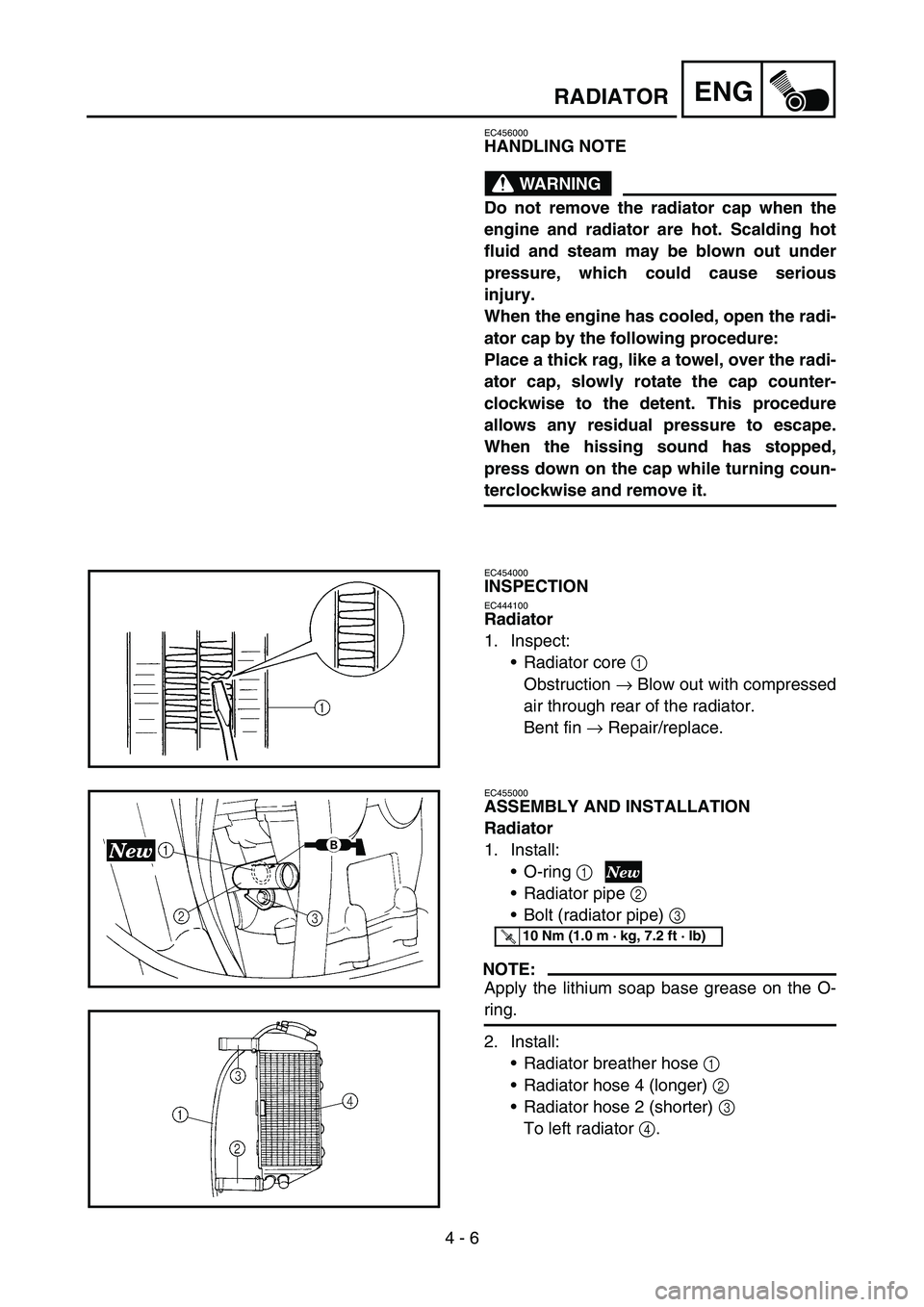

4 - 6

ENGRADIATOR

EC456000

HANDLING NOTE

WARNING

Do not remove the radiator cap when the

engine and radiator are hot. Scalding hot

fluid and steam may be blown out under

pressure, which could cause serious

injury.

When the engine has cooled, open the radi-

ator cap by the following procedure:

Place a thick rag, like a towel, over the radi-

ator cap, slowly rotate the cap counter-

clockwise to the detent. This procedure

allows any residual pressure to escape.

When the hissing sound has stopped,

press down on the cap while turning coun-

terclockwise and remove it.

EC454000

INSPECTION

EC444100

Radiator

1. Inspect:

Radiator core 1

Obstruction → Blow out with compressed

air through rear of the radiator.

Bent fin → Repair/replace.

EC455000

ASSEMBLY AND INSTALLATION

Radiator

1. Install:

O-ring 1

Radiator pipe 2

Bolt (radiator pipe) 3

NOTE:

Apply the lithium soap base grease on the O-

ring.

2. Install:

Radiator breather hose 1

Radiator hose 4 (longer) 2

Radiator hose 2 (shorter) 3

To left radiator 4.

T R..10 Nm (1.0 m · kg, 7.2 ft · lb)

Page 276 of 668

4 - 11

ENGCARBURETOR

HANDLING NOTE

CAUTION:

Do not loosen the screws (throttle position

sensor)

1 except when changing the throt-

tle position sensor due to failure because it

will cause a drop in engine performance.

1

REMOVAL POINTS

Pilot screw

1. Remove:

Pilot screw 1

NOTE:

To optimize the fuel flow at a small throttle

opening, each machine’s pilot screw has been

individually set at the factory. Before removing

the pilot screw, turn it in fully and count the

number of turns. Record this number as the

factory-set number of turns out.

INSPECTION

Carburetor

1. Inspect:

Carburetor body

Contamination → Clean.

NOTE:

Use a petroleum based solvent for cleaning.

Blow out all passages and jets with com-

pressed air.

Never use a wire.

Page 306 of 668

4 - 26

ENGCAMSHAFTS

Decompression system

1. Check:

Decompression system

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

Exhaust camshaft 1

Intake camshaft 2 Checking steps:

Check that the decompression mecha-

nism cam 1 moves smoothly.

Check that the decompression mecha-

nism cam lever pin 2 projects from the

camshaft.

Installation steps:

Turn the crankshaft counterclockwise with

a wrench.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Squeezing the decompression lever

allows the crankshaft to be turned easily.

Align the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

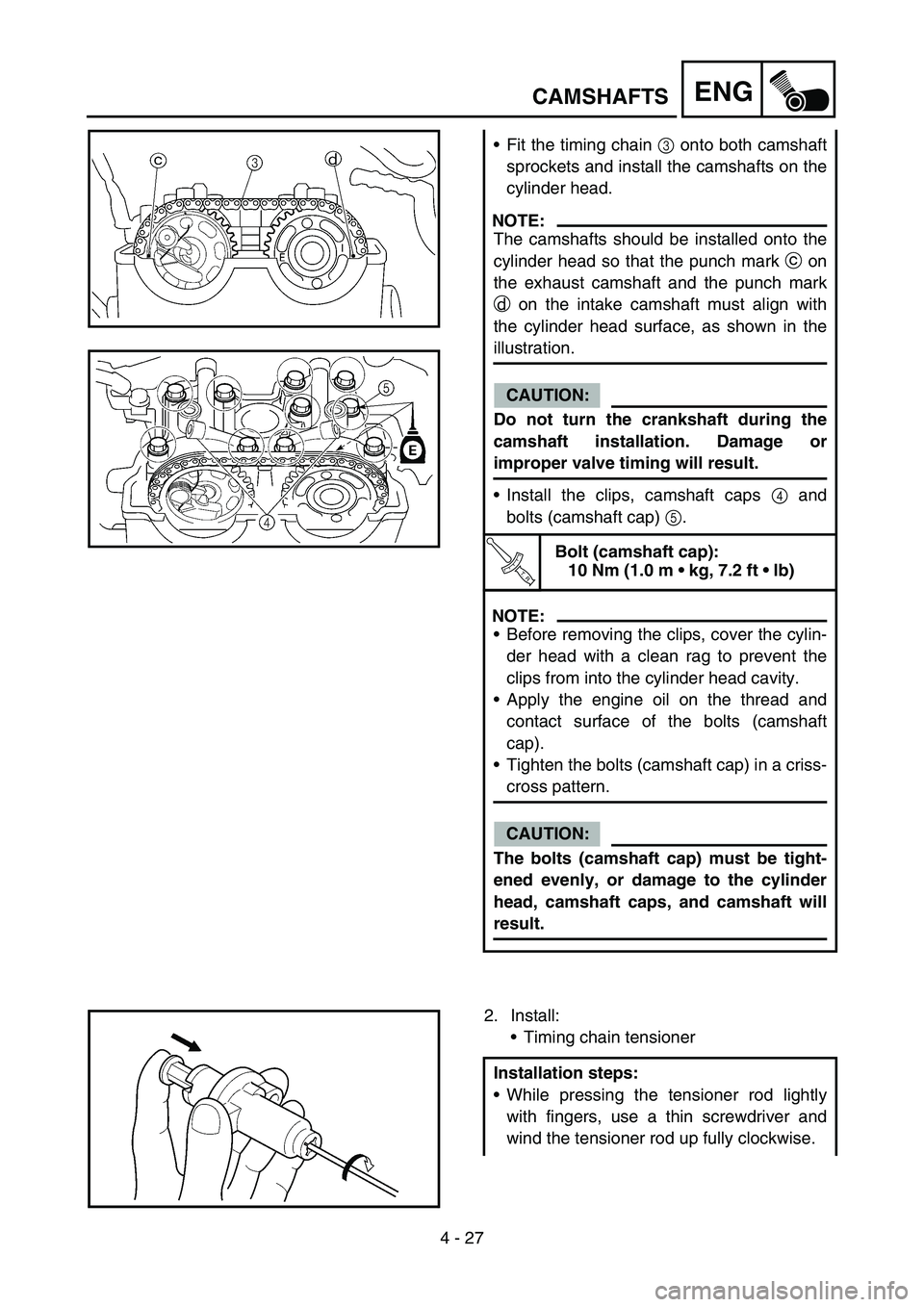

Page 308 of 668

4 - 27

ENGCAMSHAFTS

Fit the timing chain 3 onto both camshaft

sprockets and install the camshafts on the

cylinder head.

NOTE:

The camshafts should be installed onto the

cylinder head so that the punch mark c on

the exhaust camshaft and the punch mark

d on the intake camshaft must align with

the cylinder head surface, as shown in the

illustration.

CAUTION:

Do not turn the crankshaft during the

camshaft installation. Damage or

improper valve timing will result.

Install the clips, camshaft caps 4 and

bolts (camshaft cap) 5.

T R..

Bolt (camshaft cap):

10 Nm (1.0 m kg, 7.2 ft lb)

NOTE:

Before removing the clips, cover the cylin-

der head with a clean rag to prevent the

clips from into the cylinder head cavity.

Apply the engine oil on the thread and

contact surface of the bolts (camshaft

cap).

Tighten the bolts (camshaft cap) in a criss-

cross pattern.

CAUTION:

The bolts (camshaft cap) must be tight-

ened evenly, or damage to the cylinder

head, camshaft caps, and camshaft will

result.

2. Install:

Timing chain tensioner

Installation steps:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver and

wind the tensioner rod up fully clockwise.

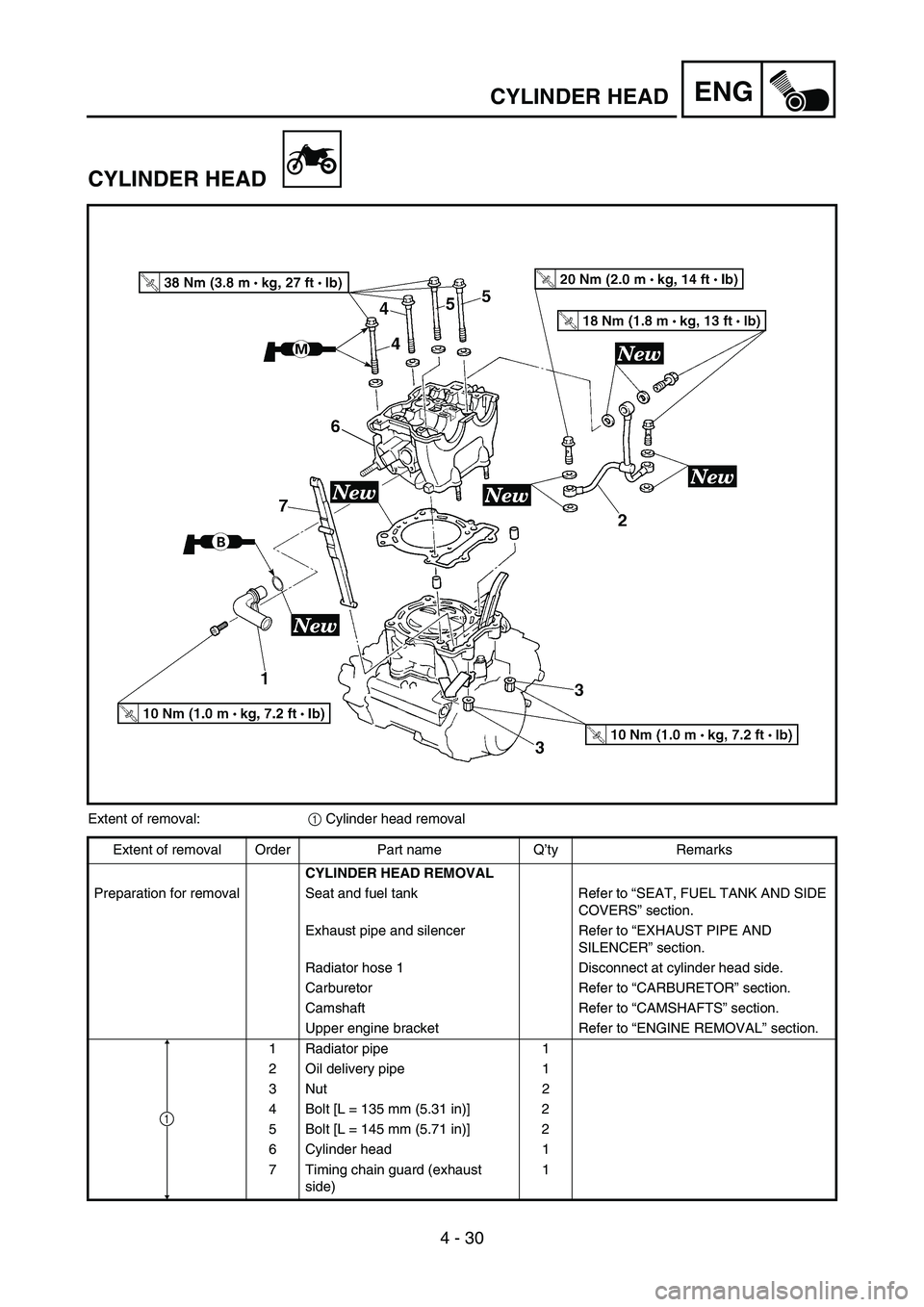

Page 314 of 668

4 - 30

ENGCYLINDER HEAD

CYLINDER HEAD

Extent of removal:

1 Cylinder head removal

Extent of removal Order Part name Q’ty Remarks

CYLINDER HEAD REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Radiator hose 1 Disconnect at cylinder head side.

Carburetor Refer to “CARBURETOR” section.

Camshaft Refer to “CAMSHAFTS” section.

Upper engine bracket Refer to “ENGINE REMOVAL” section.

1 Radiator pipe 1

2 Oil delivery pipe 1

3Nut 2

4 Bolt [L = 135 mm (5.31 in)] 2

5 Bolt [L = 145 mm (5.71 in)] 2

6 Cylinder head 1

7 Timing chain guard (exhaust

side)1

1

Page 336 of 668

4 - 41

ENGVALVES AND VALVE SPRINGS

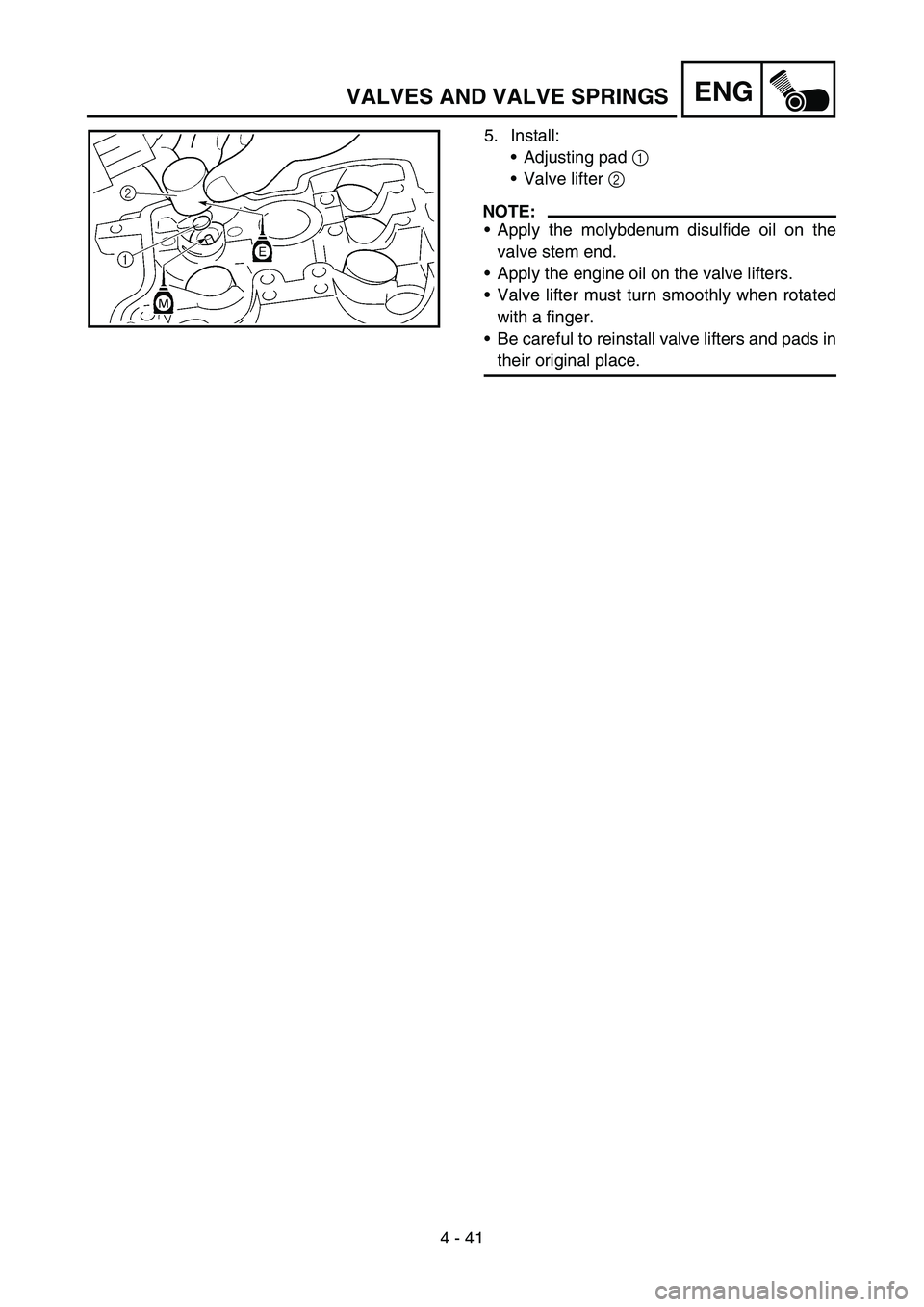

5. Install:

Adjusting pad 1

Valve lifter 2

NOTE:

Apply the molybdenum disulfide oil on the

valve stem end.

Apply the engine oil on the valve lifters.

Valve lifter must turn smoothly when rotated

with a finger.

Be careful to reinstall valve lifters and pads in

their original place.

Page 346 of 668

4 - 46

ENGCYLINDER AND PISTON

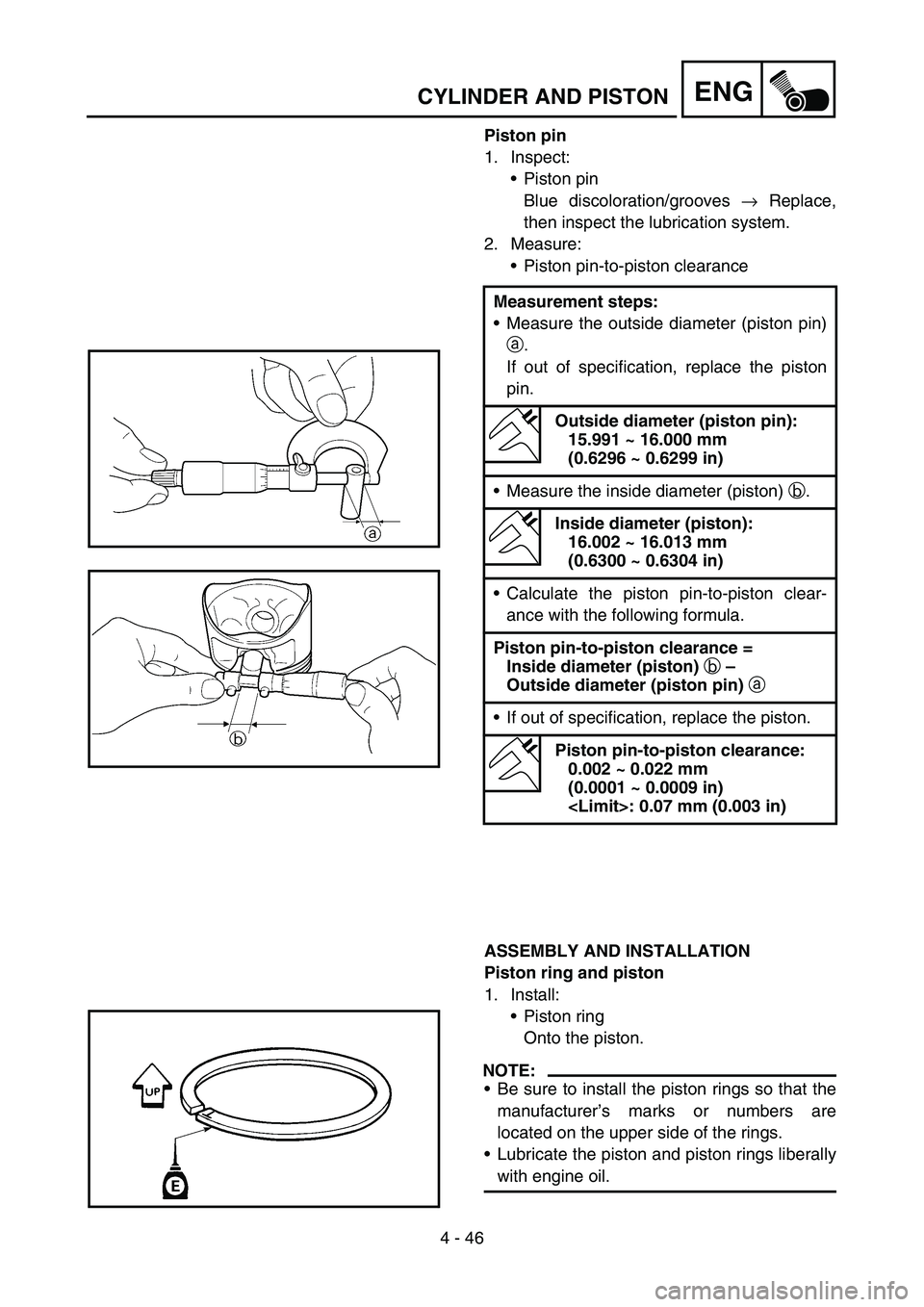

Piston pin

1. Inspect:

Piston pin

Blue discoloration/grooves → Replace,

then inspect the lubrication system.

2. Measure:

Piston pin-to-piston clearance

ASSEMBLY AND INSTALLATION

Piston ring and piston

1. Install:

Piston ring

Onto the piston.

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers are

located on the upper side of the rings.

Lubricate the piston and piston rings liberally

with engine oil. Measurement steps:

Measure the outside diameter (piston pin)

a.

If out of specification, replace the piston

pin.

Outside diameter (piston pin):

15.991 ~ 16.000 mm

(0.6296 ~ 0.6299 in)

Measure the inside diameter (piston) b.

Inside diameter (piston):

16.002 ~ 16.013 mm

(0.6300 ~ 0.6304 in)

Calculate the piston pin-to-piston clear-

ance with the following formula.

Piston pin-to-piston clearance =

Inside diameter (piston)

b –

Outside diameter (piston pin)

a

If out of specification, replace the piston.

Piston pin-to-piston clearance:

0.002 ~ 0.022 mm

(0.0001 ~ 0.0009 in)

Page 348 of 668

4 - 47

ENGCYLINDER AND PISTON

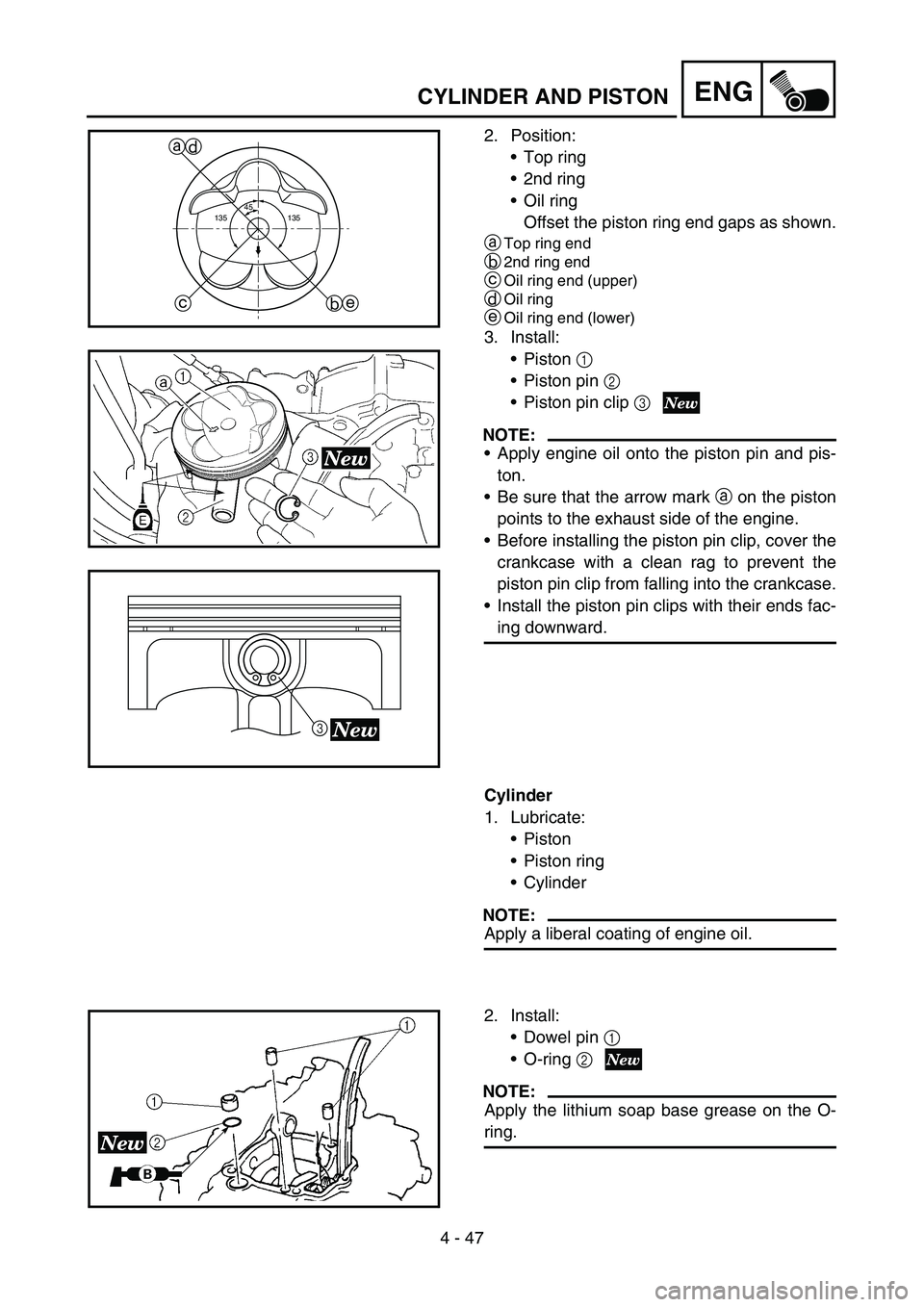

2. Position:

Top ring

2nd ring

Oil ring

Offset the piston ring end gaps as shown.

a

Top ring end

b2nd ring end

cOil ring end (upper)

dOil ring

eOil ring end (lower)

3. Install:

Piston 1

Piston pin 2

Piston pin clip 3

NOTE:

Apply engine oil onto the piston pin and pis-

ton.

Be sure that the arrow mark a on the piston

points to the exhaust side of the engine.

Before installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

Install the piston pin clips with their ends fac-

ing downward.

45

135 135

a

b ced

3

Cylinder

1. Lubricate:

Piston

Piston ring

Cylinder

NOTE:

Apply a liberal coating of engine oil.

2. Install:

Dowel pin 1

O-ring 2

NOTE:

Apply the lithium soap base grease on the O-

ring.