engine YAMAHA YZ250F 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ250F, Model: YAMAHA YZ250F 2006Pages: 674, PDF Size: 21.07 MB

Page 626 of 674

7 - 2

TUN

CAUTION:

The carburetor is extremely sensitive to

foreign matter (dirt, sand, water, etc.).

During installation, do not allow foreign

matter to get into the carburetor.

Always handle the carburetor and its

components carefully. Even slight

scratches, bends or damage to carburetor

parts may prevent the carburetor from

functioning correctly. Carefully perform

all servicing with the appropriate tools

and without applying excessive force.

When the engine is stopped or when

riding at no load, do not open and close

the throttle unnecessarily. Otherwise, too

much fuel may be discharged, starting

may become difficult or the engine may

not run well.

After installing the carburetor, check that

the throttle operates correctly and opens

and closes smoothly.

Atmospheric conditions and carburetor

settings

The air density (i.e., concentration of oxygen

in the air) determines the richness or lean-

ness of the air/fuel mixture. Therefore, refer

to the above table for mixture settings.

That is:

•Higher temperature expands the air with its

resultant reduced density.

•Higher humidity reduces the amount of oxy-

gen in the air by so much of the water vapor

in the same air.

•Lower atmospheric pressure (at a high alti-

tude) reduces the density of the air.

Air temp. HumidityAir

pressure

(altitude)Mixture Setting

High High Low (high) Richer Leaner

Low Low High (low) Leaner Richer

SETTING

Page 630 of 674

7 - 4

TUNSETTING

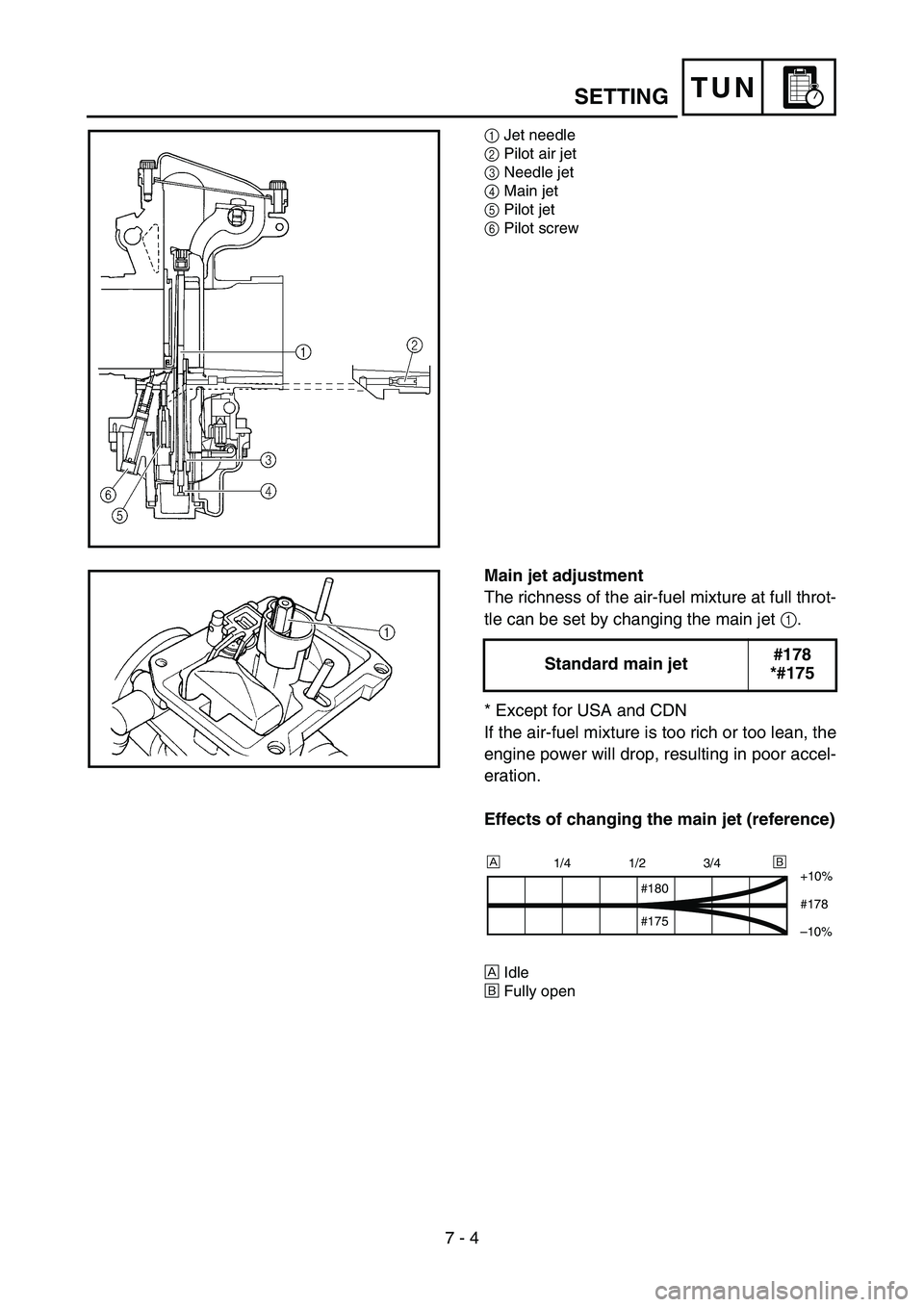

1Jet needle

2Pilot air jet

3Needle jet

4Main jet

5Pilot jet

6Pilot screw

Main jet adjustment

The richness of the air-fuel mixture at full throt-

tle can be set by changing the main jet 1

.

* Except for USA and CDN

If the air-fuel mixture is too rich or too lean, the

engine power will drop, resulting in poor accel-

eration.

Effects of changing the main jet (reference)

ÈIdle

ÉFully open

Standard main jet#178

*#175

1/4 1/2 3/4

+10%

#178

–10%

#180

#175

ÈÉ

Page 632 of 674

7 - 5

TUNSETTING

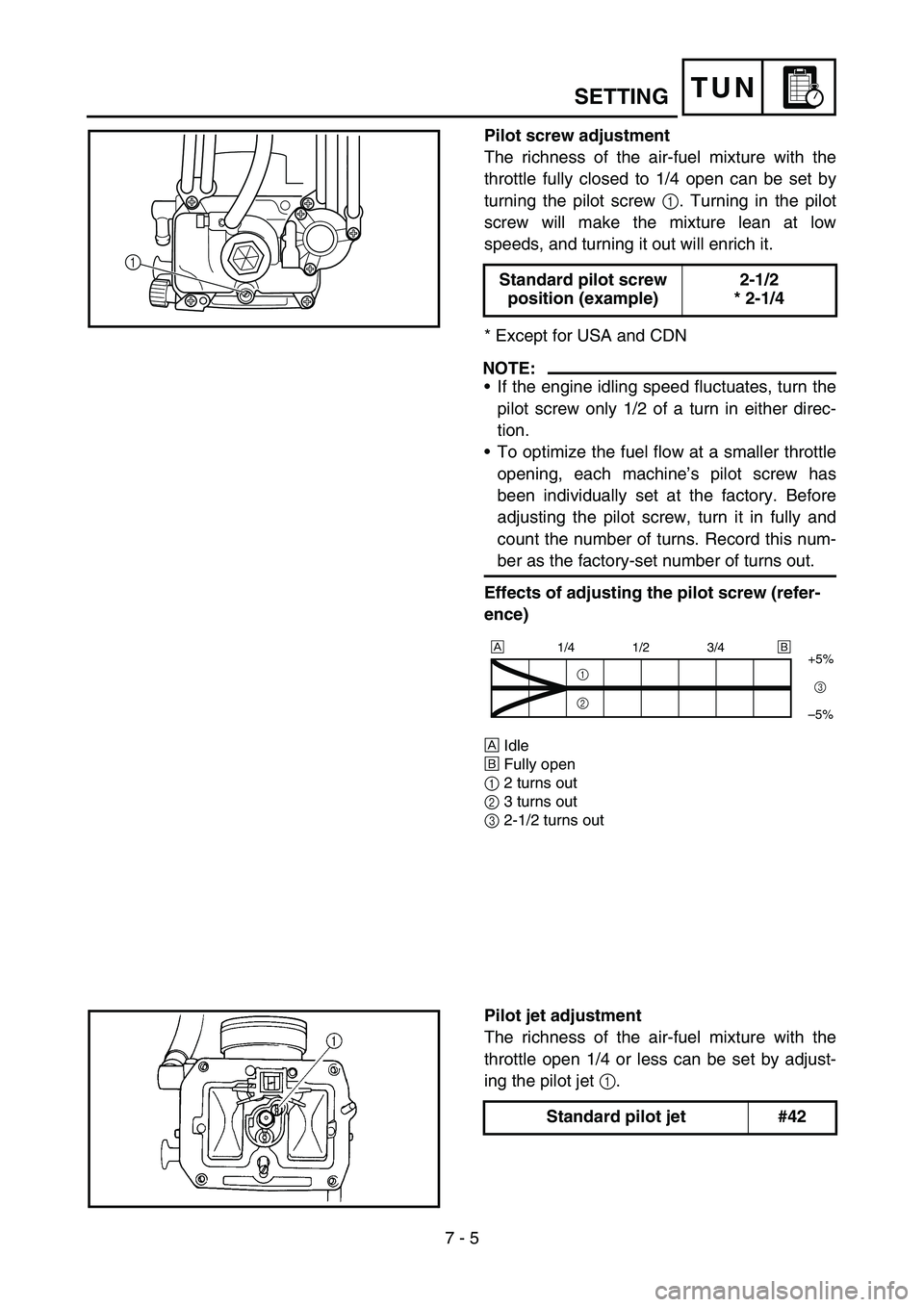

Pilot screw adjustment

The richness of the air-fuel mixture with the

throttle fully closed to 1/4 open can be set by

turning the pilot screw 1. Turning in the pilot

screw will make the mixture lean at low

speeds, and turning it out will enrich it.

* Except for USA and CDN

NOTE:

•If the engine idling speed fluctuates, turn the

pilot screw only 1/2 of a turn in either direc-

tion.

•To optimize the fuel flow at a smaller throttle

opening, each machine’s pilot screw has

been individually set at the factory. Before

adjusting the pilot screw, turn it in fully and

count the number of turns. Record this num-

ber as the factory-set number of turns out.

Effects of adjusting the pilot screw (refer-

ence)

ÈIdle

ÉFully open

12 turns out

23 turns out

32-1/2 turns out

Standard pilot screw

position (example)2-1/2

* 2-1/4

1

1/4 1/2 3/4

+5%

–5%

1

23

ÈÉ

Pilot jet adjustment

The richness of the air-fuel mixture with the

throttle open 1/4 or less can be set by adjust-

ing the pilot jet 1.

Standard pilot jet #42

Page 634 of 674

7 - 6

TUNSETTING

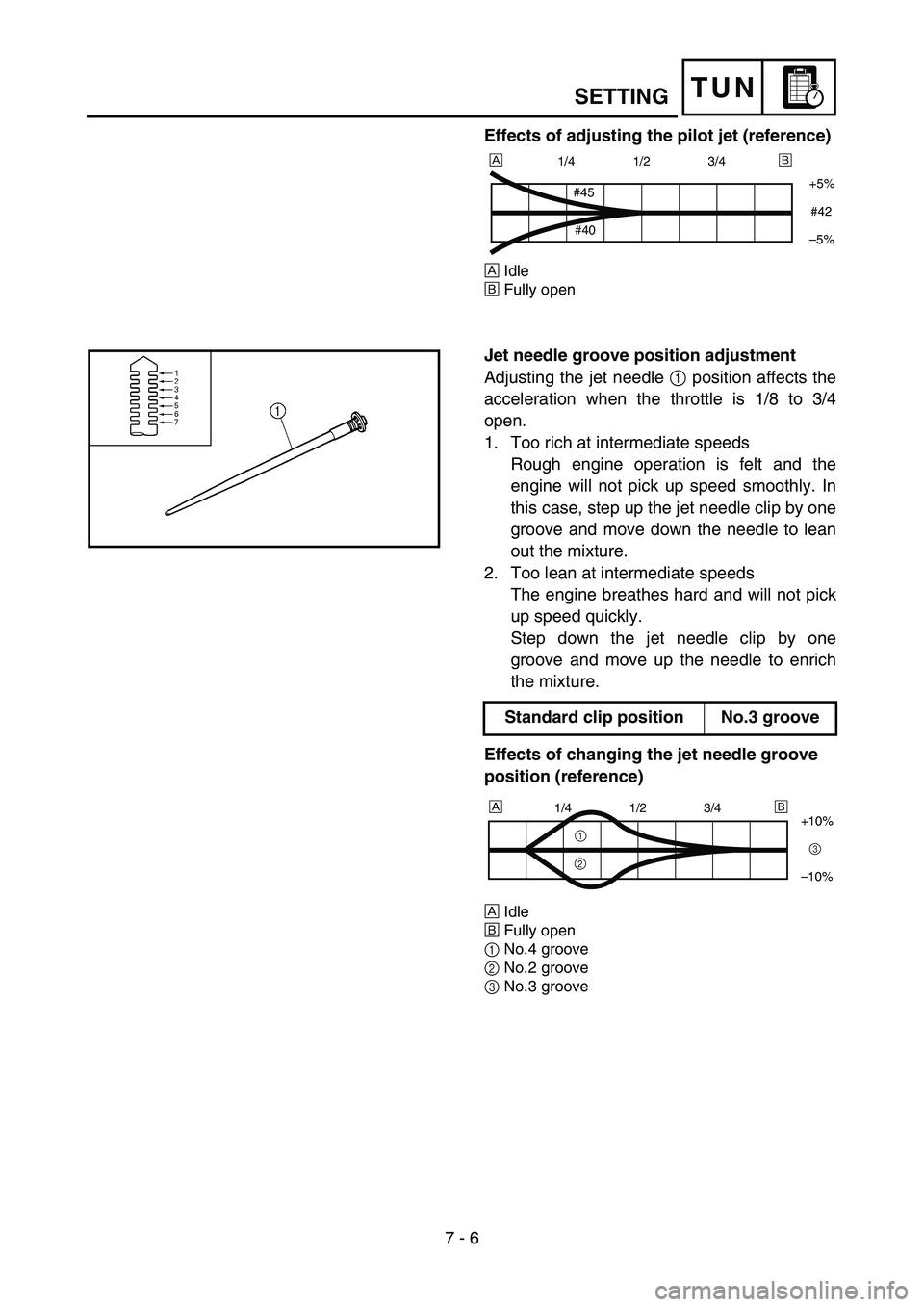

Effects of adjusting the pilot jet (reference)

ÈIdle

ÉFully open

1/4 1/2 3/4

+5%

–5%

#45

#40#42

ÈÉ

Jet needle groove position adjustment

Adjusting the jet needle 1 position affects the

acceleration when the throttle is 1/8 to 3/4

open.

1. Too rich at intermediate speeds

Rough engine operation is felt and the

engine will not pick up speed smoothly. In

this case, step up the jet needle clip by one

groove and move down the needle to lean

out the mixture.

2. Too lean at intermediate speeds

The engine breathes hard and will not pick

up speed quickly.

Step down the jet needle clip by one

groove and move up the needle to enrich

the mixture.

Effects of changing the jet needle groove

position (reference)

ÈIdle

ÉFully open

1No.4 groove

2No.2 groove

3No.3 groove

Standard clip position No.3 groove

1/4 1/2 3/4

+10%

–10%

1

23

ÈÉ

Page 638 of 674

7 - 8

TUN

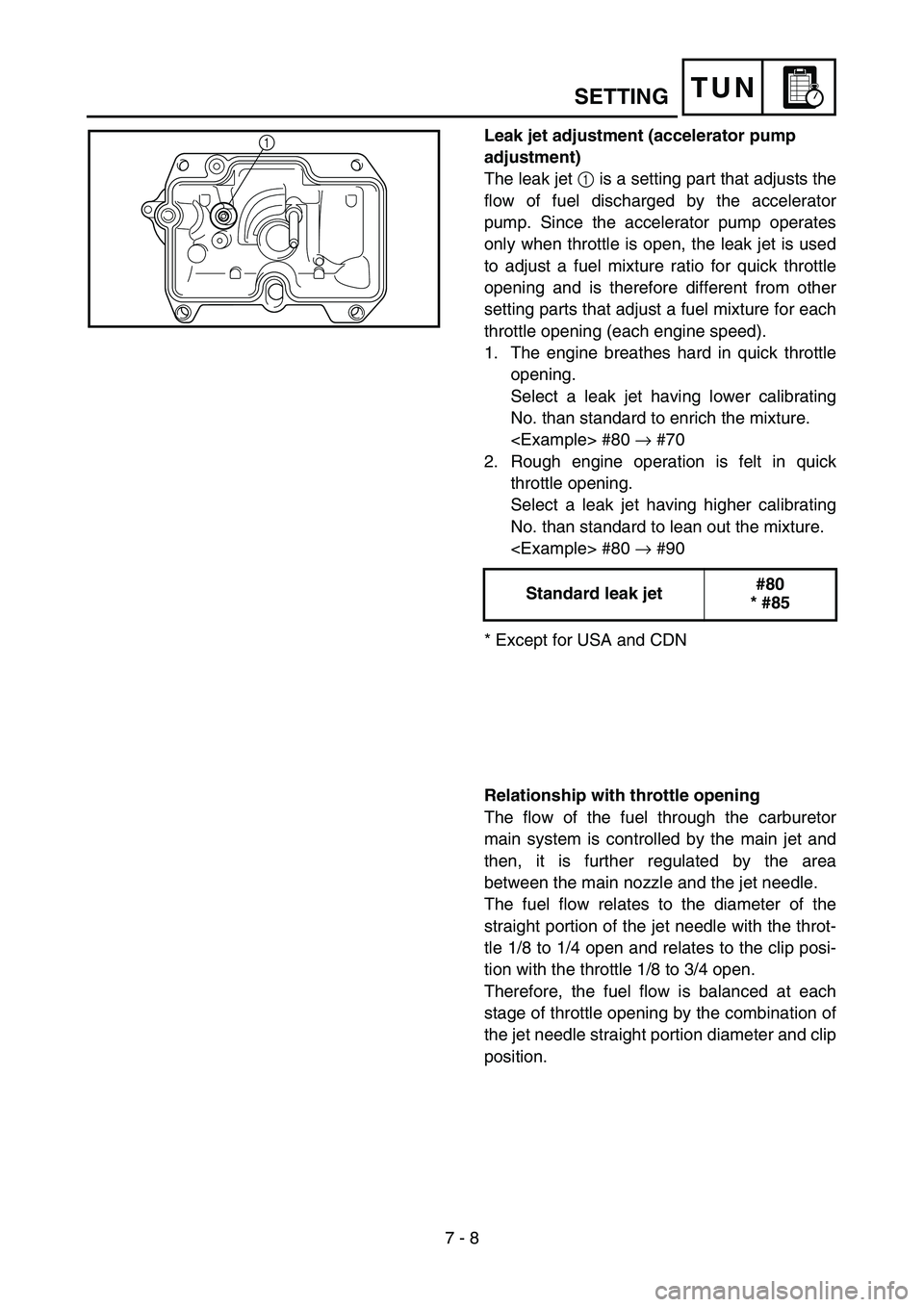

Leak jet adjustment (accelerator pump

adjustment)

The leak jet 1 is a setting part that adjusts the

flow of fuel discharged by the accelerator

pump. Since the accelerator pump operates

only when throttle is open, the leak jet is used

to adjust a fuel mixture ratio for quick throttle

opening and is therefore different from other

setting parts that adjust a fuel mixture for each

throttle opening (each engine speed).

1. The engine breathes hard in quick throttle

opening.

Select a leak jet having lower calibrating

No. than standard to enrich the mixture.

2. Rough engine operation is felt in quick

throttle opening.

Select a leak jet having higher calibrating

No. than standard to lean out the mixture.

* Except for USA and CDNStandard leak jet#80

* #851

Relationship with throttle opening

The flow of the fuel through the carburetor

main system is controlled by the main jet and

then, it is further regulated by the area

between the main nozzle and the jet needle.

The fuel flow relates to the diameter of the

straight portion of the jet needle with the throt-

tle 1/8 to 1/4 open and relates to the clip posi-

tion with the throttle 1/8 to 3/4 open.

Therefore, the fuel flow is balanced at each

stage of throttle opening by the combination of

the jet needle straight portion diameter and clip

position.

SETTING

Page 642 of 674

7 - 10

TUN

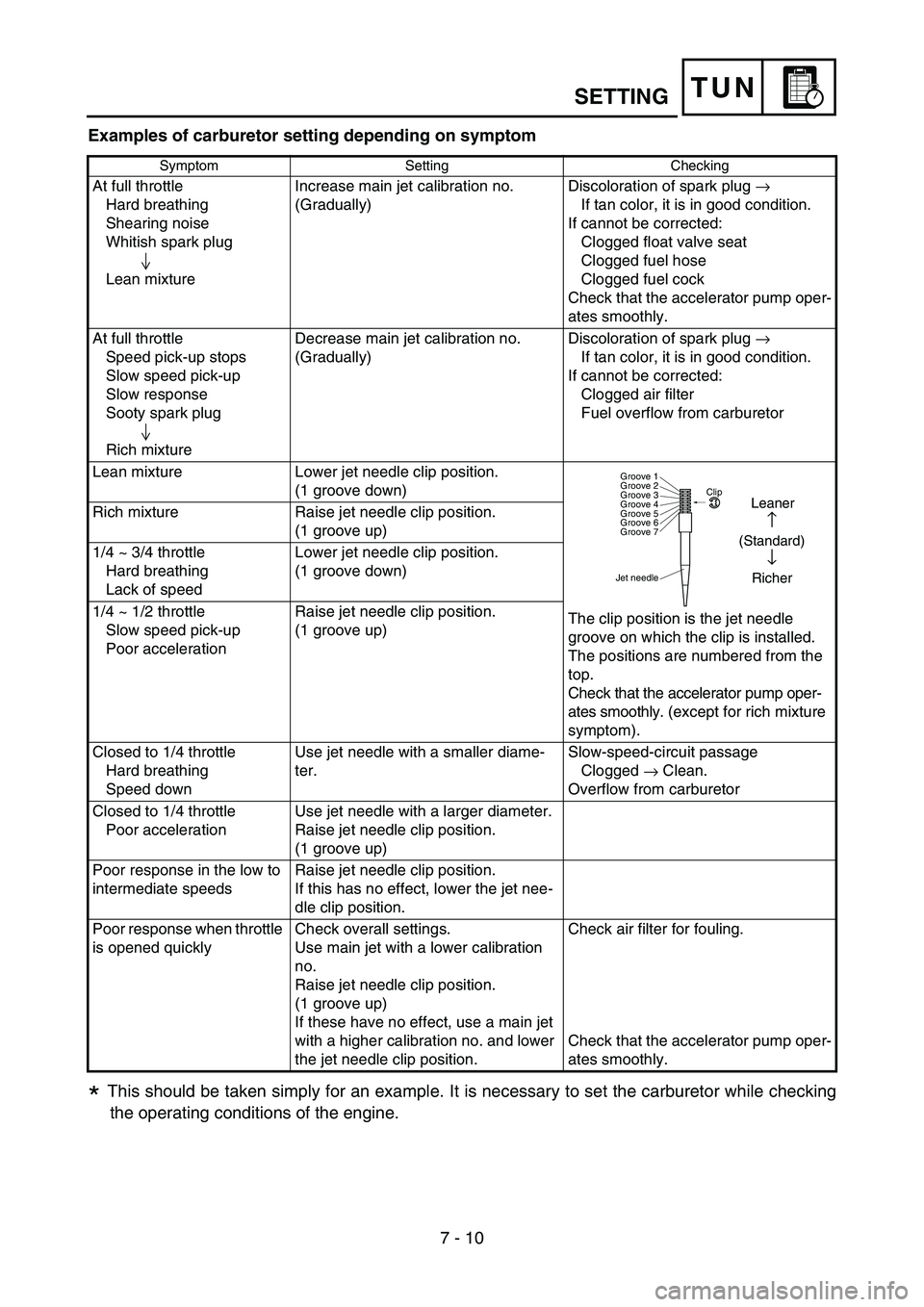

Examples of carburetor setting depending on symptom

This should be taken simply for an example. It is necessary to set the carburetor while checking

the operating conditions of the engine.

Symptom Setting Checking

At full throttle

Hard breathing

Shearing noise

Whitish spark plug

Lean mixtureIncrease main jet calibration no.

(Gradually)Discoloration of spark plug

→

If tan color, it is in good condition.

If cannot be corrected:

Clogged float valve seat

Clogged fuel hose

Clogged fuel cock

Check that the accelerator pump oper-

ates smoothly.

At full throttle

Speed pick-up stops

Slow speed pick-up

Slow response

Sooty spark plug

Rich mixtureDecrease main jet calibration no.

(Gradually)Discoloration of spark plug

→

If tan color, it is in good condition.

If cannot be corrected:

Clogged air filter

Fuel overflow from carburetor

Lean mixture Lower jet needle clip position.

(1 groove down)

The clip position is the jet needle

groove on which the clip is installed.

The positions are numbered from the

top.

Check that the accelerator pump oper-

ates smoothly. (except for rich mixture

symptom). Rich mixture Raise jet needle clip position.

(1 groove up)

1/4 ~ 3/4 throttle

Hard breathing

Lack of speedLower jet needle clip position.

(1 groove down)

1/4 ~ 1/2 throttle

Slow speed pick-up

Poor accelerationRaise jet needle clip position.

(1 groove up)

Closed to 1/4 throttle

Hard breathing

Speed downUse jet needle with a smaller diame-

ter.Slow-speed-circuit passage

Clogged

→ Clean.

Overflow from carburetor

Closed to 1/4 throttle

Poor accelerationUse jet needle with a larger diameter.

Raise jet needle clip position.

(1 groove up)

Poor response in the low to

intermediate speedsRaise jet needle clip position.

If this has no effect, lower the jet nee-

dle clip position.

Poor response when throttle

is opened quicklyCheck overall settings.

Use main jet with a lower calibration

no.

Raise jet needle clip position.

(1 groove up)

If these have no effect, use a main jet

with a higher calibration no. and lower

the jet needle clip position.Check air filter for fouling.

Check that the accelerator pump oper-

ates smoothly.

Jet needleClip

Groove 7 Groove 6

Groove 5

Groove 4

Groove 3

Groove 2

Groove 1

Leaner

↑

(Standard)

↓

Richer

*

SETTING

Page 646 of 674

7 - 11

TUN

EC720000

CHASSIS

Selection of the secondary reduction ratio

(Sprocket)

* For EUROPE

•It is generally said that the secondary gear

ratio should be reduced for a longer straight

portion of a speed course and should be

increased for a course with many corners.

Actually, however, as the speed depends on

the ground condition of the day of the race,

be sure to run through the circuit to set the

machine suitable for the entire course.

•In actuality, it is very difficult to achieve set-

tings suitable for the entire course and some

settings may be sacrificed. Thus, the settings

should be matched to the portion of the

course that has the greatest effect on the

race result. In such a case, run through the

entire course while making notes of lap times

to find the best balance; then, determine the

secondary reduction ratio.

•If a course has a long straight portion where

a machine can run at maximum speed, the

machine is generally set such that it can

develop its maximum revolutions toward the

end of the straight line, with care taken to

avoid the engine over-revving.

NOTE:

Riding technique varies from rider to rider and

the performance of a machine also vary from

machine to machine. Therefore, do not imitate

other rider’s settings from the beginning but

choose your own setting according to the level

of your riding technique.

Secondary

reduction

ratio

=Number of rear wheel sprocket teeth

Number of drive sprocket teeth

Standard secondary

reduction ratio48/13 (3.692)

* 49/13 (3.769)

SETTING

Page 656 of 674

7 - 16

TUN

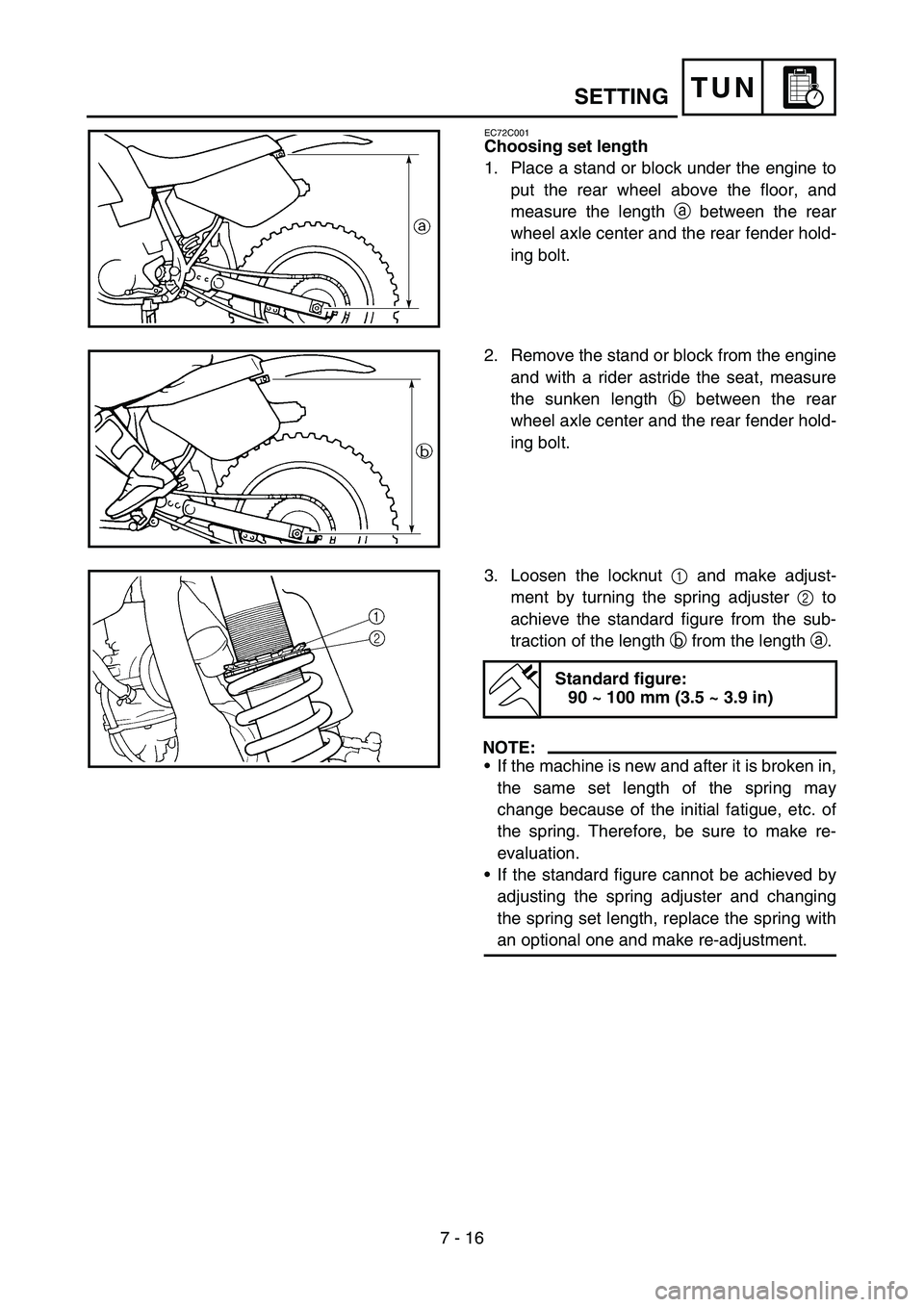

EC72C001

Choosing set length

1. Place a stand or block under the engine to

put the rear wheel above the floor, and

measure the length a between the rear

wheel axle center and the rear fender hold-

ing bolt.

2. Remove the stand or block from the engine

and with a rider astride the seat, measure

the sunken length b between the rear

wheel axle center and the rear fender hold-

ing bolt.

3. Loosen the locknut 1 and make adjust-

ment by turning the spring adjuster 2 to

achieve the standard figure from the sub-

traction of the length b from the length a.

NOTE:

•If the machine is new and after it is broken in,

the same set length of the spring may

change because of the initial fatigue, etc. of

the spring. Therefore, be sure to make re-

evaluation.

•If the standard figure cannot be achieved by

adjusting the spring adjuster and changing

the spring set length, replace the spring with

an optional one and make re-adjustment.

Standard figure:

90 ~ 100 mm (3.5 ~ 3.9 in)

SETTING