clutch YAMAHA YZ250F 2006 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ250F, Model: YAMAHA YZ250F 2006Pages: 674, PDF Size: 21.07 MB

Page 142 of 674

2 - 18

SPECCABLE ROUTING DIAGRAM

EC240000

CABLE ROUTING DIAGRAM

1Fuel tank breather hose

2Radiator hose 1

3Cylinder head breather hose

4Radiator hose 4

5Clutch cable

6Throttle position sensor lead

7Fuel hose

8Hot starter cable

9Carburetor breather hose

0Carburetor overflow hose

AConnector coverÈInsert the end of the fuel tank

breather hose into the hole in

the steering stem.

ÉPass the cylinder head

breather hose on the outside of

the radiator hose 1 and on the

inside of the radiator pipe (radi-

ator hose 4).

ÊPass the clutch cable through

the cable guides.

ËPass the clutch cable in front of

the radiator mounting boss.ÌPass the fuel hose between the

hot starter cable and throttle

position sensor lead.

ÍPass the carburetor breather

hoses and overflow hose so

that all there hoses do not con-

tact the rear shock absorber.

ÎInstall the connector cover so

that it does not come in

between the radiator hose 1

and radiator.

B A

99

0

Í

B

A

8

3A2Î

7

Ì

ËÉ

1

È

6

5

4

Ê

Page 144 of 674

2 - 19

SPECCABLE ROUTING DIAGRAM

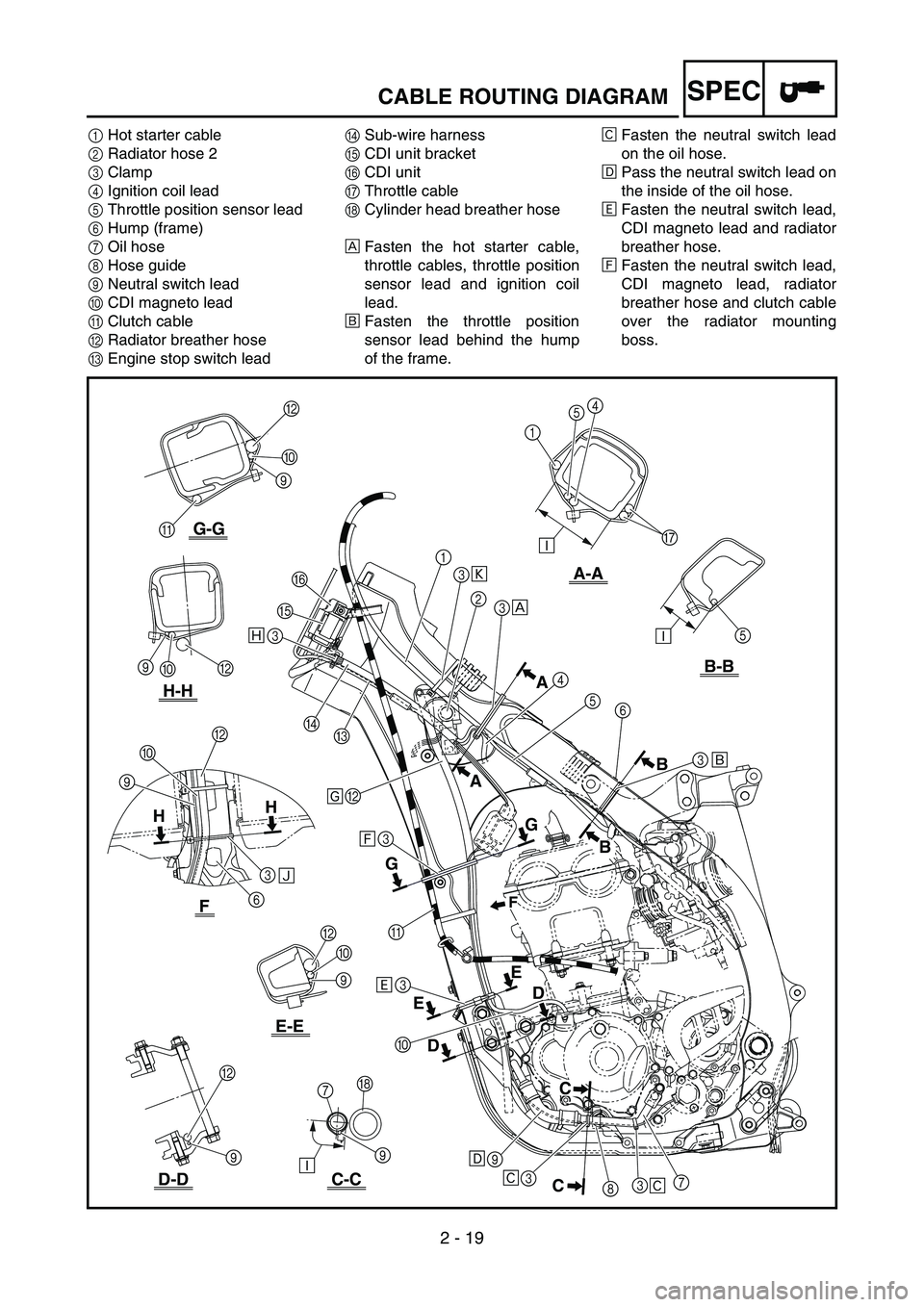

1Hot starter cable

2Radiator hose 2

3Clamp

4Ignition coil lead

5Throttle position sensor lead

6Hump (frame)

7Oil hose

8Hose guide

9Neutral switch lead

0CDI magneto lead

AClutch cable

BRadiator breather hose

CEngine stop switch leadDSub-wire harness

ECDI unit bracket

FCDI unit

GThrottle cable

HCylinder head breather hose

ÈFasten the hot starter cable,

throttle cables, throttle position

sensor lead and ignition coil

lead.

ÉFasten the throttle position

sensor lead behind the hump

of the frame.ÊFasten the neutral switch lead

on the oil hose.

ËPass the neutral switch lead on

the inside of the oil hose.

ÌFasten the neutral switch lead,

CDI magneto lead and radiator

breather hose.

ÍFasten the neutral switch lead,

CDI magneto lead, radiator

breather hose and clutch cable

over the radiator mounting

boss.

5Ð

Ð

B-B

C-C

E-E

H-H

G-G

D-D

A-A

G

4

5

1

7H

Ð B

B

0

9 F

3

Ñ

6 90F

È

9

CC

C E HH

GA

AB

E

7

3

8 3 9

Ê Ê

Ë

F

E

3

D

C

B

3

A

3

Ì Í Î Ï

1

2

3

4

5

6

3

B

0

9

A

0É

B

B 0 9

9

D

G

B

D

Ò 3

Page 152 of 674

2 - 23

SPECCABLE ROUTING DIAGRAM

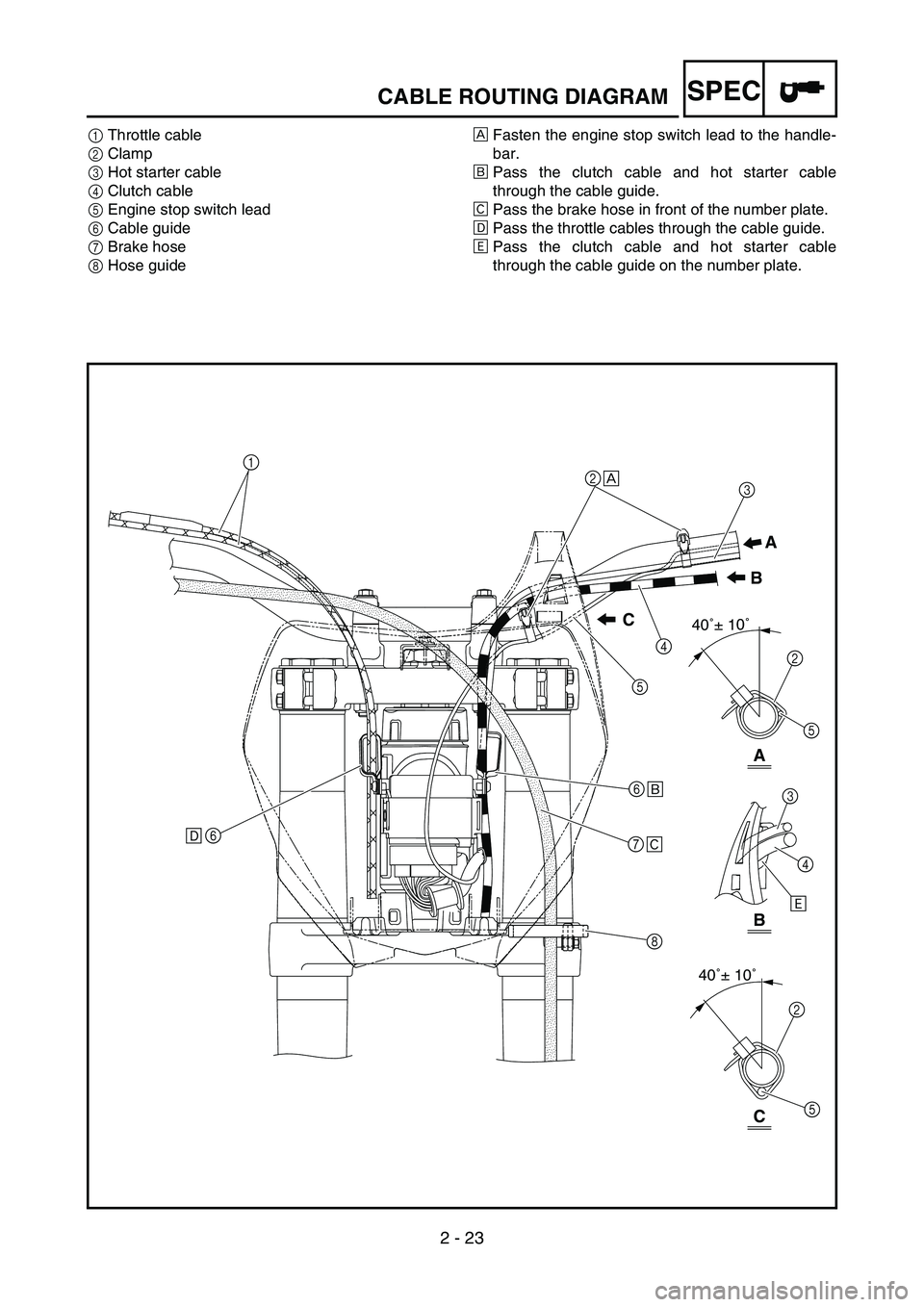

1Throttle cable

2Clamp

3Hot starter cable

4Clutch cable

5Engine stop switch lead

6Cable guide

7Brake hose

8Hose guideÈFasten the engine stop switch lead to the handle-

bar.

ÉPass the clutch cable and hot starter cable

through the cable guide.

ÊPass the brake hose in front of the number plate.

ËPass the throttle cables through the cable guide.

ÌPass the clutch cable and hot starter cable

through the cable guide on the number plate.

A

B

C

A

B

C40˚± 10˚

40˚± 10˚

2

È3

2

5

4

2

3

5

6

Ë1

4

5

7

Ê

6

É

Ì

8

Page 154 of 674

3 - 1

INSP

ADJ

MAINTENANCE INTERVALS

EC300000

REGULAR INSPECTION AND ADJUSTMENTS

MAINTENANCE INTERVALS

The following schedule is intended as a general guide to maintenance and lubrication. Bear in mind

that such factors as weather, terrain, geographical location, and individual usage will alter the

required maintenance and lubrication intervals. If you are a doubt as to what intervals to follow in

maintaining and lubricating your machine, consult your Yamaha dealer.

ItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

ENGINE OIL

Replace

Inspect

OIL FILTER ELEMENT, OIL STRAINER

Clean

VALVES

The engine must be cold.

Check the valve seats

and valve stems for wear. Check the valve clearances

Inspect

Replace

VALVE SPRINGS

Check the free length and

the tilt. Inspect

Replace

VALVE LIFTERS

Check for scratches and

wear. Inspect

Replace

CAMSHAFTS Inspect the camshaft sur-

face.

Inspect the decompres-

sion system. Inspect

Replace

TIMING CHAIN SPROCKETS, TIMING

CHAIN

Check for wear on the

teeth and for damage. Inspect

Replace

PISTON

Inspect

Inspect crack

Inspect carbon deposits

and eliminate them. Clean

Replace

PISTON RING

InspectCheck ring end gap

Replace

PISTON PIN

Inspect

Replace

CYLINDER HEAD Inspect carbon deposits

and eliminate them.

Change gasket Inspect and clean

CYLINDER

Inspect and clean

Inspect score marks

Inspect wear

Replace

CLUTCH

Inspect housing, friction

plate, clutch plate and

spring Inspect and adjust

Replace

TRANSMISSION

Inspect

Replace bearing

Page 156 of 674

3 - 3

INSP

ADJ

MAINTENANCE INTERVALS

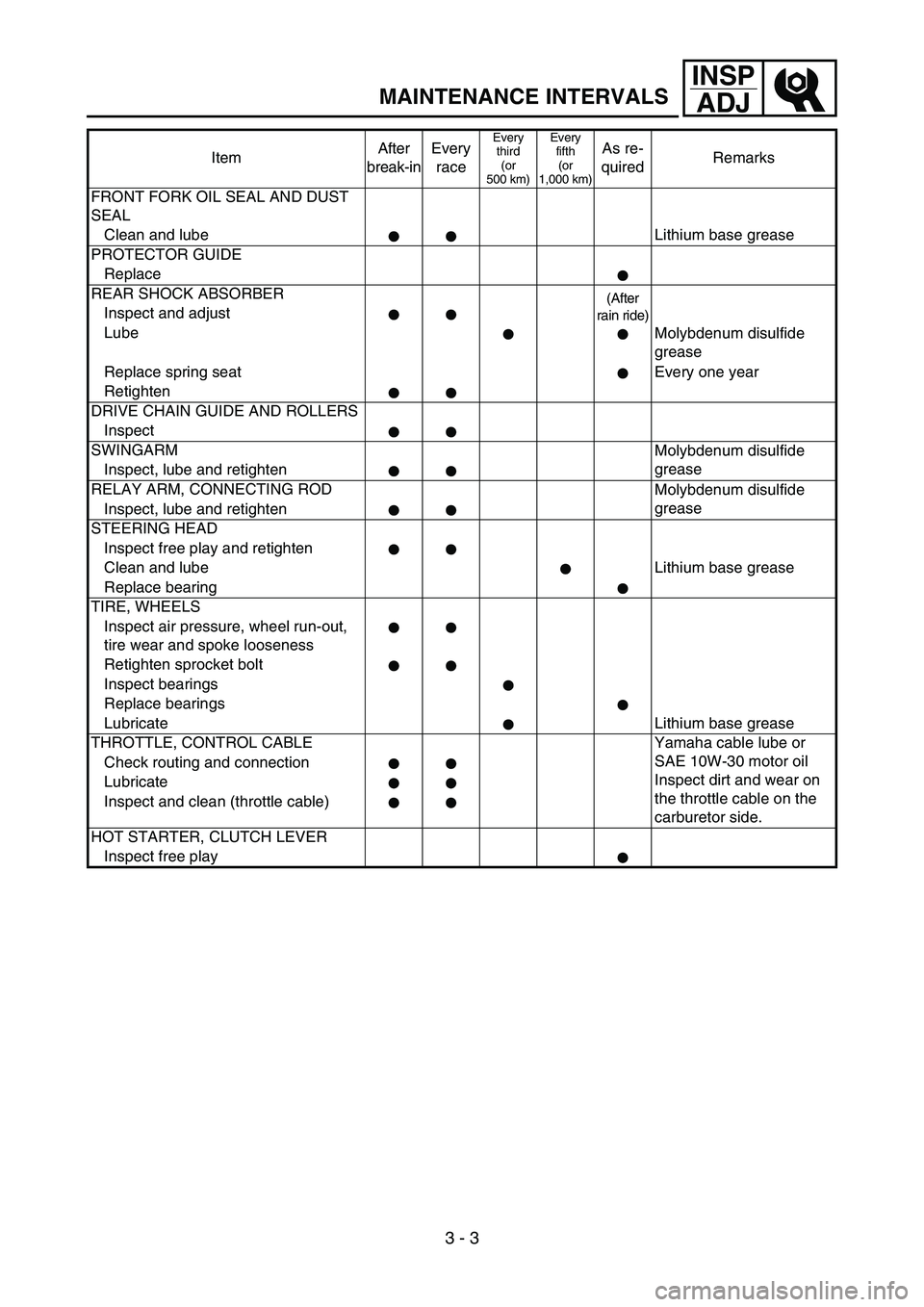

FRONT FORK OIL SEAL AND DUST

SEAL

Clean and lube Lithium base grease

PROTECTOR GUIDE

Replace

REAR SHOCK ABSORBER

(After

rain ride)

Inspect and adjust

Lube

Molybdenum disulfide

grease

Replace spring seat Every one year

Retighten

DRIVE CHAIN GUIDE AND ROLLERS

Inspect

SWINGARM

Molybdenum disulfide

grease

Inspect, lube and retighten

RELAY ARM, CONNECTING ROD

Molybdenum disulfide

grease

Inspect, lube and retighten

STEERING HEAD

Inspect free play and retighten

Clean and lube Lithium base grease

Replace bearing

TIRE, WHEELS

Inspect air pressure, wheel run-out,

tire wear and spoke looseness

Retighten sprocket bolt

Inspect bearings

Replace bearings

Lubricate Lithium base grease

THROTTLE, CONTROL CABLE Yamaha cable lube or

SAE 10W-30 motor oil

Inspect dirt and wear on

the throttle cable on the

carburetor side. Check routing and connection

Lubricate

Inspect and clean (throttle cable)

HOT STARTER, CLUTCH LEVER

Inspect free playItemAfter

break-inEvery

race

Every

third

(or

500 km)Every

fifth

(or

1,000 km)As re-

quiredRemarks

Page 166 of 674

3 - 4

INSP

ADJ

PRE-OPERATION INSPECTION AND MAINTENANCE

EC320000

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

GENERAL INSPECTION AND MAINTENANCE

Item Routine Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.P.3-5 ~ 9

FuelCheck that a fresh gasoline is filled in the fuel tank. Check the

fuel line for leakage.P.1-13

Engine oilCheck that the oil level is correct. Check the crankcase and oil

line for leakage.P.3-13 ~ 17

Gear shifter and clutchCheck that gears can be shifted correctly in order and that the

clutch operates smoothly.P.3-9 ~ 10

Throttle grip/HousingCheck that the throttle grip operation and free play are correctly

adjusted. Lubricate the throttle grip and housing, if necessary.P.3-10 ~ 11

Brakes Check the play of front brake and effect of front and rear brake. P.3-23 ~ 29

Drive chainCheck drive chain slack and alignment. Check that the drive

chain is lubricated properly.P.3-30 ~ 32

WheelsCheck for excessive wear and tire pressure. Check for loose

spokes and have no excessive play.P.3-40 ~ 41

SteeringCheck that the handlebar can be turned smoothly and have no

excessive play.P.3-41 ~ 43

Front forks and rear shock

absorberCheck that they operate smoothly and there is no oil leakage. P.3-32 ~ 39

Cables (wires)Check that the clutch and throttle cables move smoothly. Check

that they are not caught when the handlebars are turned or

when the front forks travel up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and has no

cracks.P.4-3 ~ 5

Rear wheel sprocket Check that the rear wheel sprocket tightening bolt is not loose. P.3-30

Lubrication Check for smooth operation. Lubricate if necessary. P.3-44

Bolts and nuts Check the chassis and engine for loose bolts and nuts. P.1-18

Lead connectorsCheck that the CDI magneto, CDI unit, and ignition coil are con-

nected tightly.P.1-6

SettingsIs the machine set suitably for the condition of the racing course

and weather or by taking into account the results of test runs

before racing? Are inspection and maintenance completely

done?P.7-1 ~ 21

Page 178 of 674

3 - 9

INSP

ADJ

CLUTCH ADJUSTMENT

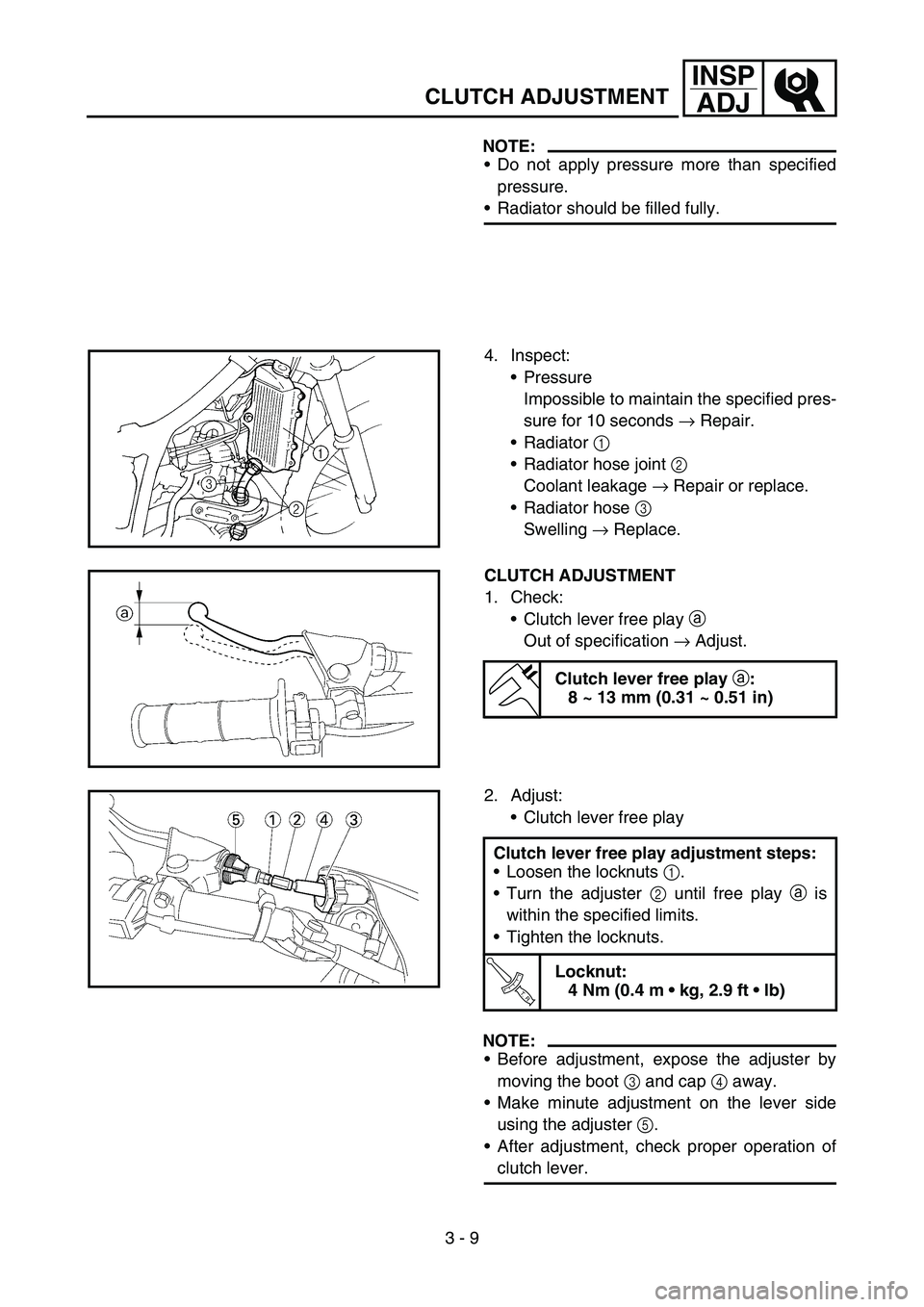

NOTE:

Do not apply pressure more than specified

pressure.

Radiator should be filled fully.

4. Inspect:

Pressure

Impossible to maintain the specified pres-

sure for 10 seconds → Repair.

Radiator 1

Radiator hose joint 2

Coolant leakage → Repair or replace.

Radiator hose 3

Swelling → Replace.

CLUTCH ADJUSTMENT

1. Check:

Clutch lever free play a

Out of specification → Adjust.

Clutch lever free play

a:

8 ~ 13 mm (0.31 ~ 0.51 in)

2. Adjust:

Clutch lever free play

NOTE:

Before adjustment, expose the adjuster by

moving the boot 3 and cap 4 away.

Make minute adjustment on the lever side

using the adjuster 5.

After adjustment, check proper operation of

clutch lever. Clutch lever free play adjustment steps:

Loosen the locknuts 1.

Turn the adjuster 2 until free play a is

within the specified limits.

Tighten the locknuts.

T R..

Locknut:

4 Nm (0.4 m kg, 2.9 ft lb)

Page 188 of 674

3 - 14

INSP

ADJ

ENGINE OIL LEVEL INSPECTION

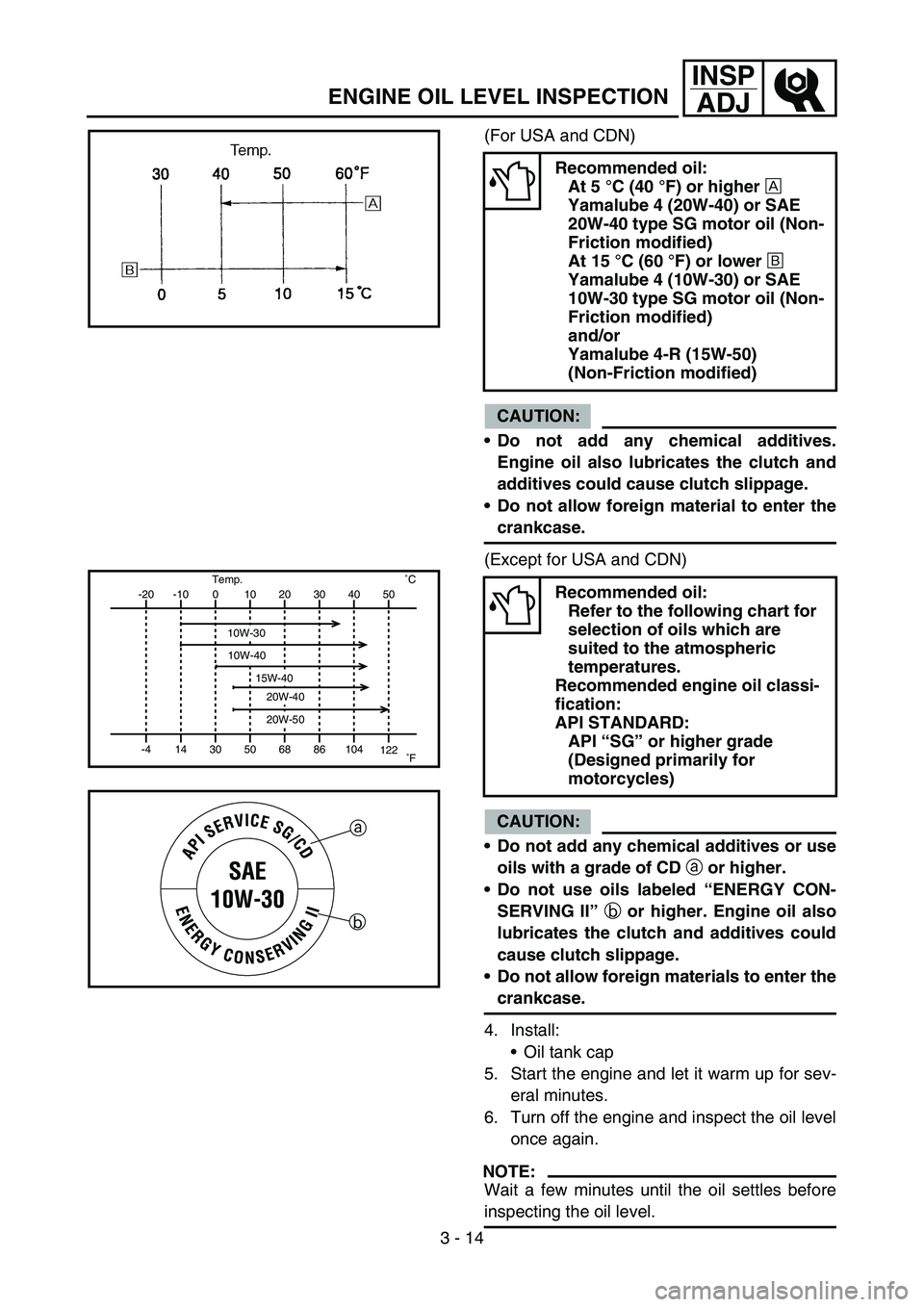

(For USA and CDN)

CAUTION:

Do not add any chemical additives.

Engine oil also lubricates the clutch and

additives could cause clutch slippage.

Do not allow foreign material to enter the

crankcase.

(Except for USA and CDN)

CAUTION:

Do not add any chemical additives or use

oils with a grade of CD

a or higher.

Do not use oils labeled “ENERGY CON-

SERVING II”

b or higher. Engine oil also

lubricates the clutch and additives could

cause clutch slippage.

Do not allow foreign materials to enter the

crankcase.

4. Install:

Oil tank cap

5. Start the engine and let it warm up for sev-

eral minutes.

6. Turn off the engine and inspect the oil level

once again.

NOTE:

Wait a few minutes until the oil settles before

inspecting the oil level.

Recommended oil:

At 5 °C (40 °F) or higher

È

Yamalube 4 (20W-40) or SAE

20W-40 type SG motor oil (Non-

Friction modified)

At 15 °C (60 °F) or lower

É

Yamalube 4 (10W-30) or SAE

10W-30 type SG motor oil (Non-

Friction modified)

and/or

Yamalube 4-R (15W-50)

(Non-Friction modified)

Recommended oil:

Refer to the following chart for

selection of oils which are

suited to the atmospheric

temperatures.

Recommended engine oil classi-

fication:

API STANDARD:

API “SG” or higher grade

(Designed primarily for

motorcycles)-20

-4-10

140

3010

5020

6830

8640 50

104

122 ˚CTemp.

˚F

10W-30

10W-40

20W-40

20W-50

15W-40

a

b

Page 250 of 674

3 - 44

INSP

ADJ

LUBRICATION

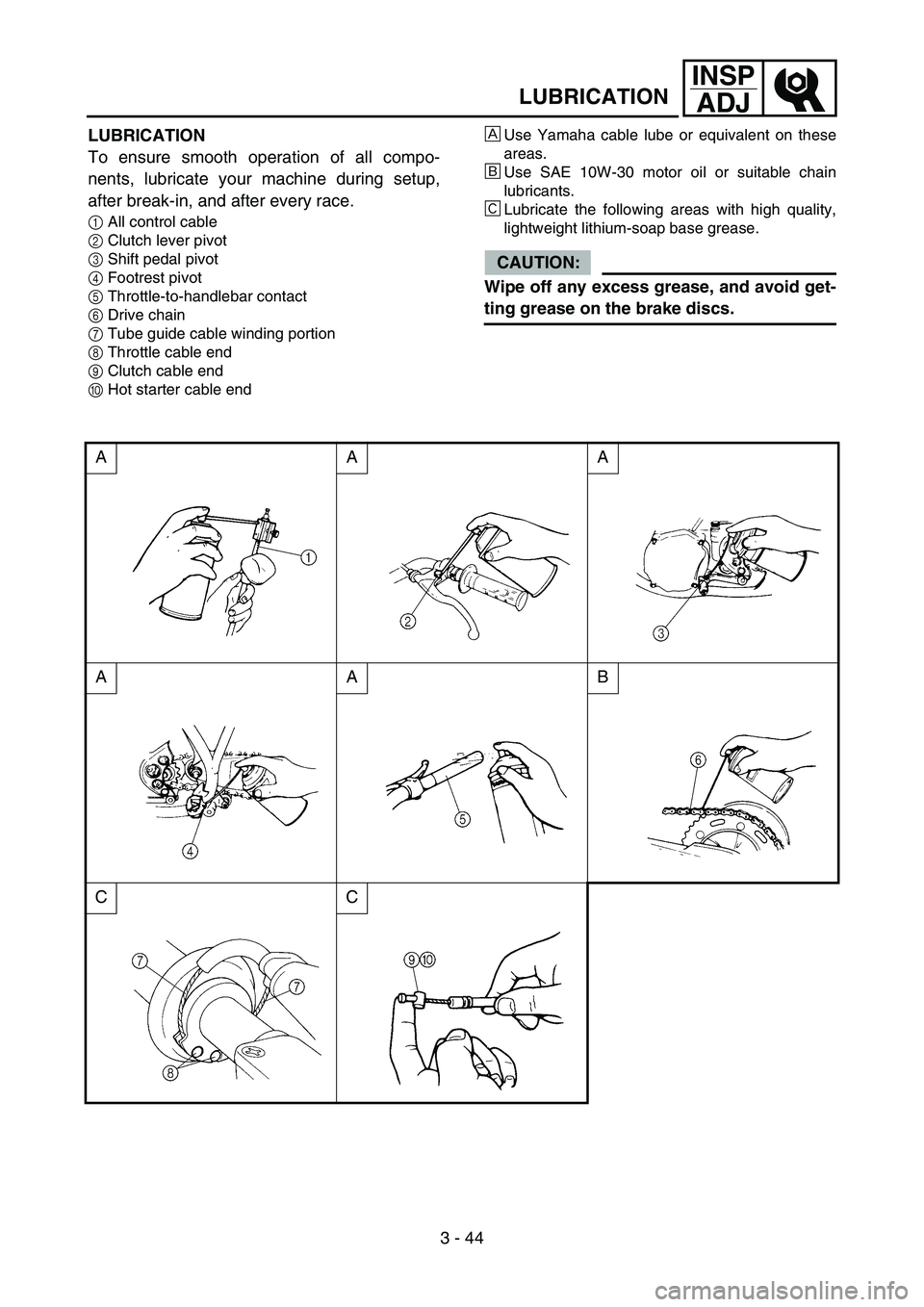

LUBRICATION

To ensure smooth operation of all compo-

nents, lubricate your machine during setup,

after break-in, and after every race.

1All control cable

2Clutch lever pivot

3Shift pedal pivot

4Footrest pivot

5Throttle-to-handlebar contact

6Drive chain

7Tube guide cable winding portion

8Throttle cable end

9Clutch cable end

0Hot starter cable end

ÈUse Yamaha cable lube or equivalent on these

areas.

ÉUse SAE 10W-30 motor oil or suitable chain

lubricants.

ÊLubricate the following areas with high quality,

lightweight lithium-soap base grease.

CAUTION:

Wipe off any excess grease, and avoid get-

ting grease on the brake discs.

AAA

AAB

CC

Page 258 of 674

4 - 2

ENG

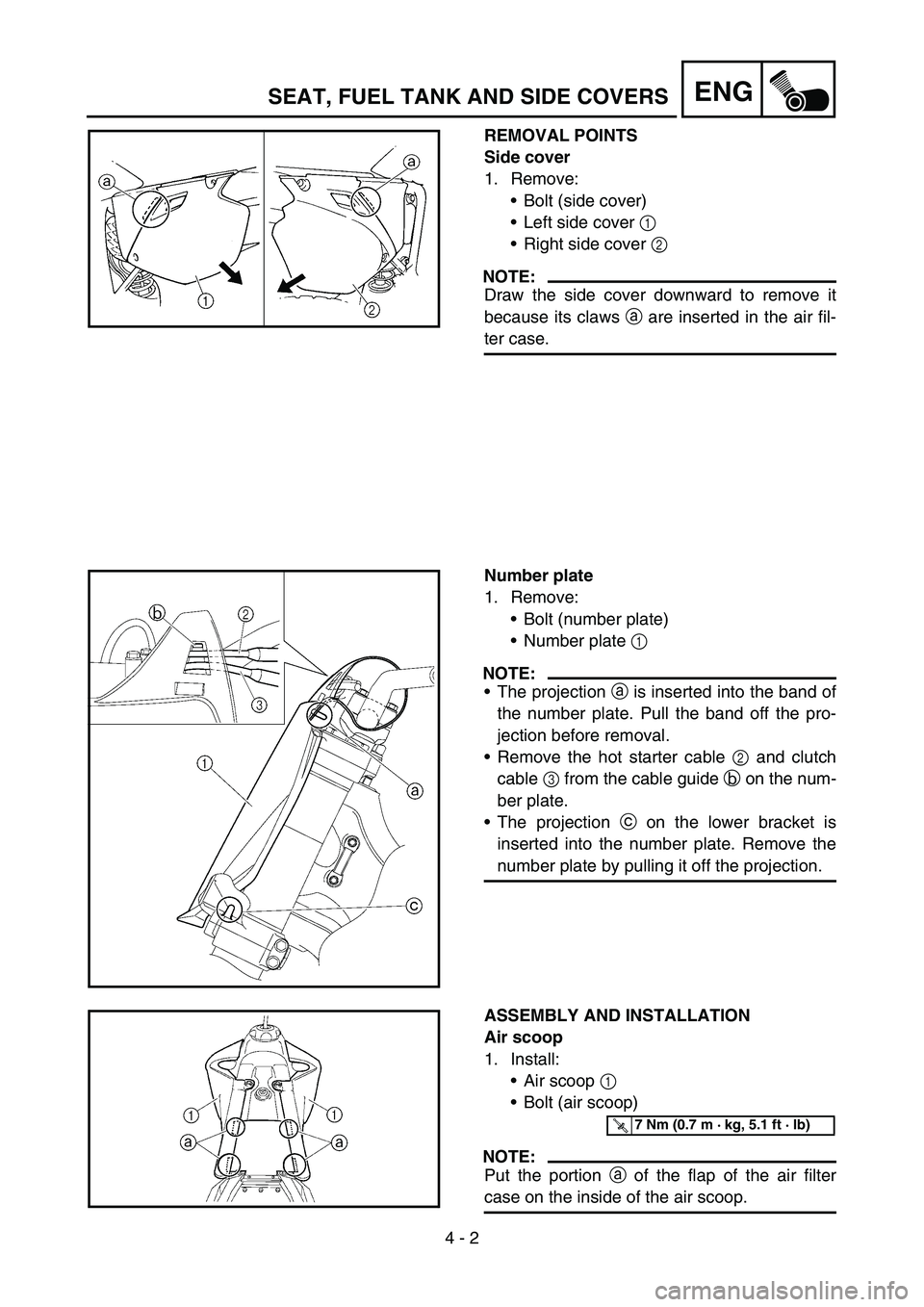

REMOVAL POINTS

Side cover

1. Remove:

Bolt (side cover)

Left side cover 1

Right side cover 2

NOTE:

Draw the side cover downward to remove it

because its claws a are inserted in the air fil-

ter case.

Number plate

1. Remove:

Bolt (number plate)

Number plate 1

NOTE:

The projection a is inserted into the band of

the number plate. Pull the band off the pro-

jection before removal.

Remove the hot starter cable 2 and clutch

cable 3 from the cable guide b on the num-

ber plate.

The projection c on the lower bracket is

inserted into the number plate. Remove the

number plate by pulling it off the projection.

ASSEMBLY AND INSTALLATION

Air scoop

1. Install:

Air scoop 1

Bolt (air scoop)

NOTE:

Put the portion a of the flap of the air filter

case on the inside of the air scoop.

T R..7 Nm (0.7 m · kg, 5.1 ft · lb)

SEAT, FUEL TANK AND SIDE COVERS