engine oil YAMAHA YZ250F 2006 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ250F, Model: YAMAHA YZ250F 2006Pages: 674, PDF Size: 21.07 MB

Page 224 of 674

3 - 31

INSP

ADJ

DRIVE CHAIN SLACK ADJUSTMENT

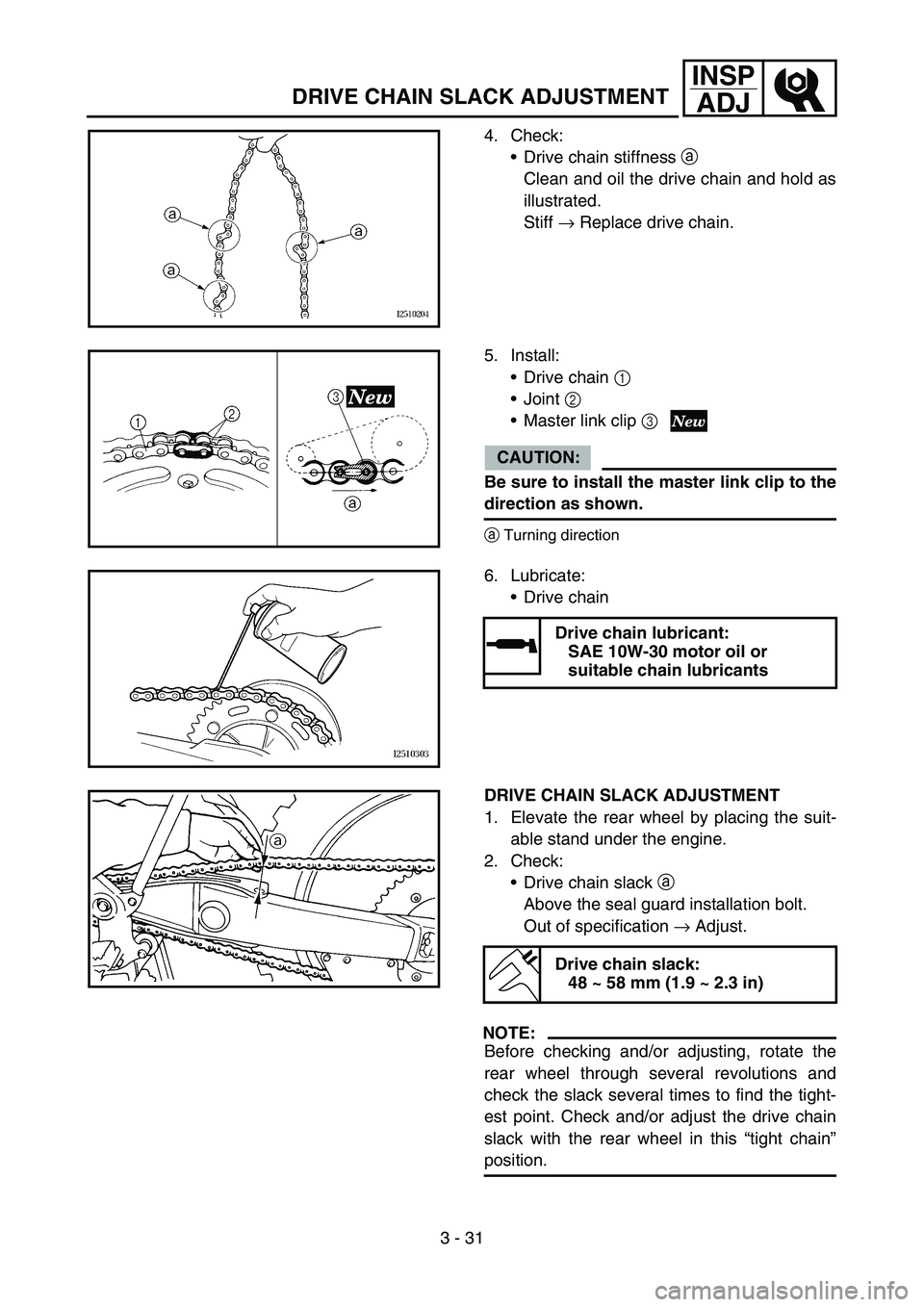

4. Check:

Drive chain stiffness a

Clean and oil the drive chain and hold as

illustrated.

Stiff → Replace drive chain.

5. Install:

Drive chain 1

Joint 2

Master link clip 3

CAUTION:

Be sure to install the master link clip to the

direction as shown.

aTurning direction

6. Lubricate:

Drive chain

Drive chain lubricant:

SAE 10W-30 motor oil or

suitable chain lubricants

DRIVE CHAIN SLACK ADJUSTMENT

1. Elevate the rear wheel by placing the suit-

able stand under the engine.

2. Check:

Drive chain slack a

Above the seal guard installation bolt.

Out of specification → Adjust.

NOTE:

Before checking and/or adjusting, rotate the

rear wheel through several revolutions and

check the slack several times to find the tight-

est point. Check and/or adjust the drive chain

slack with the rear wheel in this “tight chain”

position.

Drive chain slack:

48 ~ 58 mm (1.9 ~ 2.3 in)

Page 226 of 674

3 - 32

INSP

ADJ

FRONT FORK INSPECTION

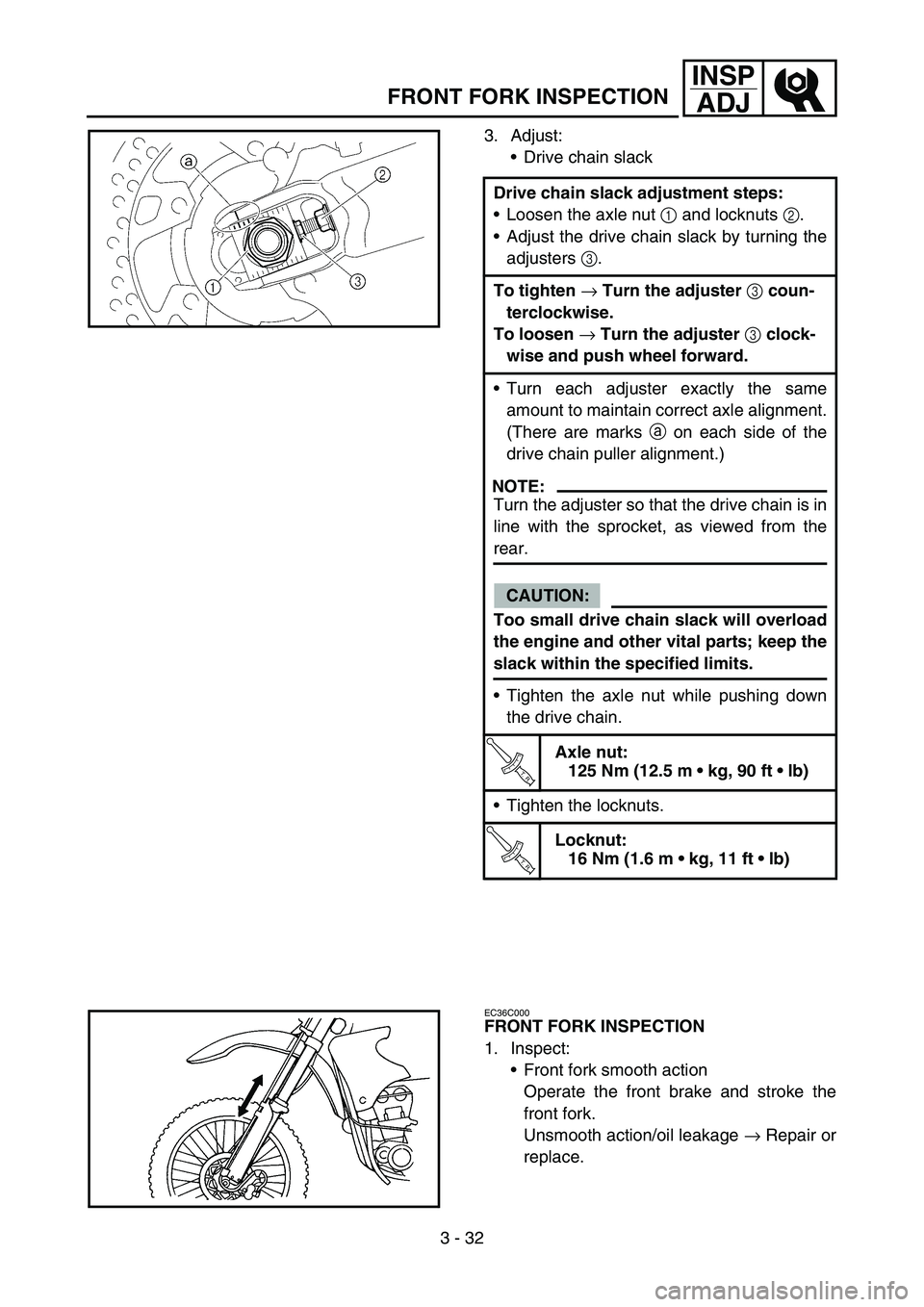

3. Adjust:

Drive chain slack

Drive chain slack adjustment steps:

Loosen the axle nut 1 and locknuts 2.

Adjust the drive chain slack by turning the

adjusters 3.

To tighten

→ Turn the adjuster

3 coun-

terclockwise.

To loosen

→ Turn the adjuster

3 clock-

wise and push wheel forward.

Turn each adjuster exactly the same

amount to maintain correct axle alignment.

(There are marks a on each side of the

drive chain puller alignment.)

NOTE:

Turn the adjuster so that the drive chain is in

line with the sprocket, as viewed from the

rear.

CAUTION:

Too small drive chain slack will overload

the engine and other vital parts; keep the

slack within the specified limits.

Tighten the axle nut while pushing down

the drive chain.

T R..

Axle nut:

125 Nm (12.5 m kg, 90 ft lb)

Tighten the locknuts.

T R..

Locknut:

16 Nm (1.6 m kg, 11 ft lb)

EC36C000

FRONT FORK INSPECTION

1. Inspect:

Front fork smooth action

Operate the front brake and stroke the

front fork.

Unsmooth action/oil leakage → Repair or

replace.

Page 228 of 674

3 - 33

INSP

ADJFRONT FORK OIL SEAL AND DUST SEAL CLEANING/

FRONT FORK INTERNAL PRESSURE RELIEVING/

FRONT FORK REBOUND DAMPING FORCE ADJUSTMENT

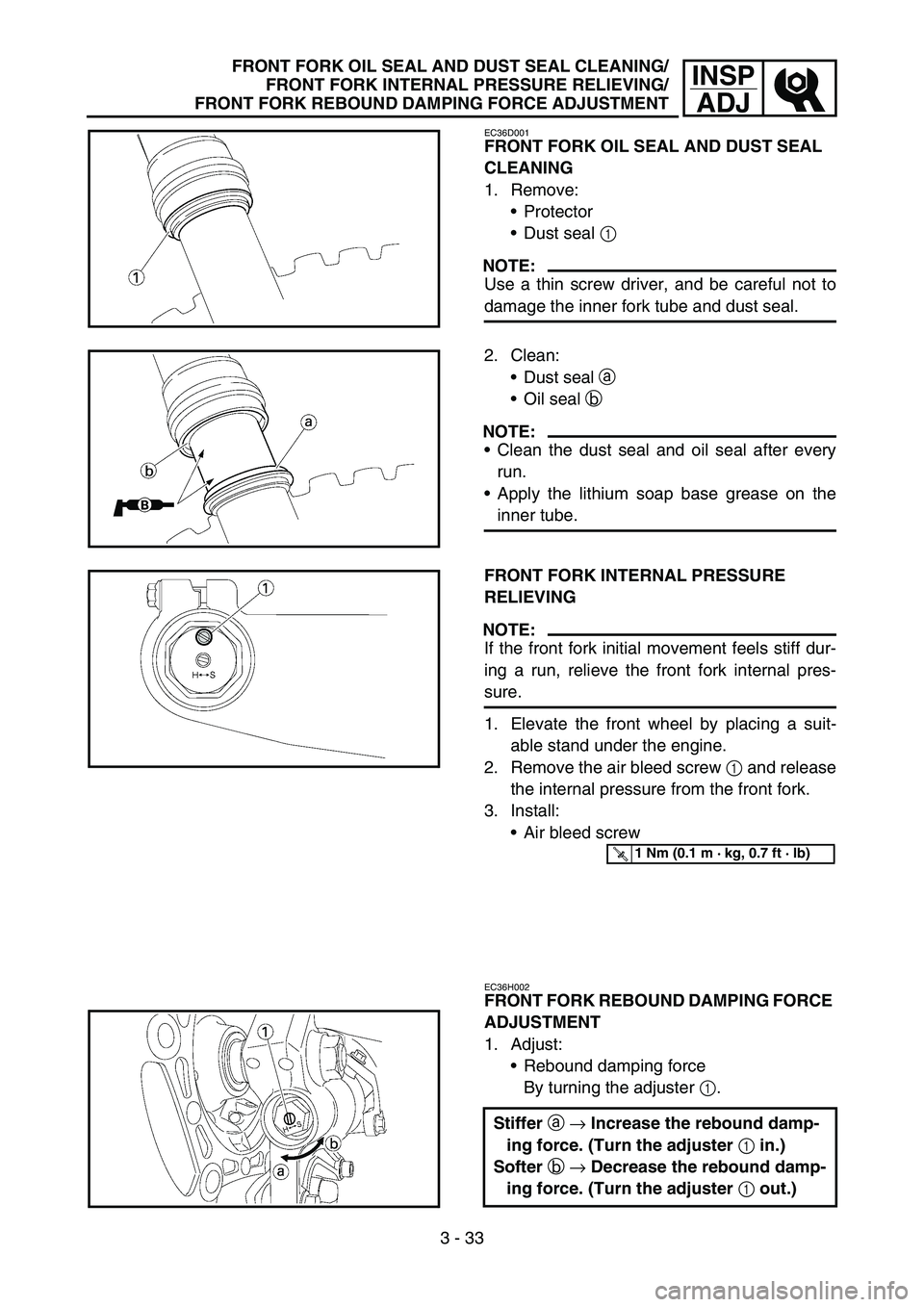

EC36D001

FRONT FORK OIL SEAL AND DUST SEAL

CLEANING

1. Remove:

Protector

Dust seal 1

NOTE:

Use a thin screw driver, and be careful not to

damage the inner fork tube and dust seal.

2. Clean:

Dust seal a

Oil seal b

NOTE:

Clean the dust seal and oil seal after every

run.

Apply the lithium soap base grease on the

inner tube.

FRONT FORK INTERNAL PRESSURE

RELIEVING

NOTE:

If the front fork initial movement feels stiff dur-

ing a run, relieve the front fork internal pres-

sure.

1. Elevate the front wheel by placing a suit-

able stand under the engine.

2. Remove the air bleed screw 1 and release

the internal pressure from the front fork.

3. Install:

Air bleed screw

EC36H002

FRONT FORK REBOUND DAMPING FORCE

ADJUSTMENT

1. Adjust:

Rebound damping force

By turning the adjuster 1.

Stiffer a → Increase the rebound damp-

ing force. (Turn the adjuster 1 in.)

Softer b → Decrease the rebound damp-

ing force. (Turn the adjuster 1 out.)

T R..1 Nm (0.1 m · kg, 0.7 ft · lb)

Page 254 of 674

3 - 46

INSP

ADJ

IGNITION TIMING CHECK

IGNITION TIMING CHECK

1. Remove:

Timing mark accessing screw 1

2. Attach:

Timing light

Inductive tachometer

To the ignition coil lead (orange lead 1).

Timing light:

YM-33277-A/90890-03141

1

3. Adjust:

Engine idling speed

Refer to “ENGINE IDLING SPEED

ADJUSTMENT” section.

4. Check:

Ignition timing

Visually check the stationary pointer a is

within the firing range b on the rotor.

Incorrect firing range → Check rotor and

pickup assembly.

5. Install:

Timing mark accessing screw

Page 308 of 674

4 - 27

ENGCAMSHAFTS

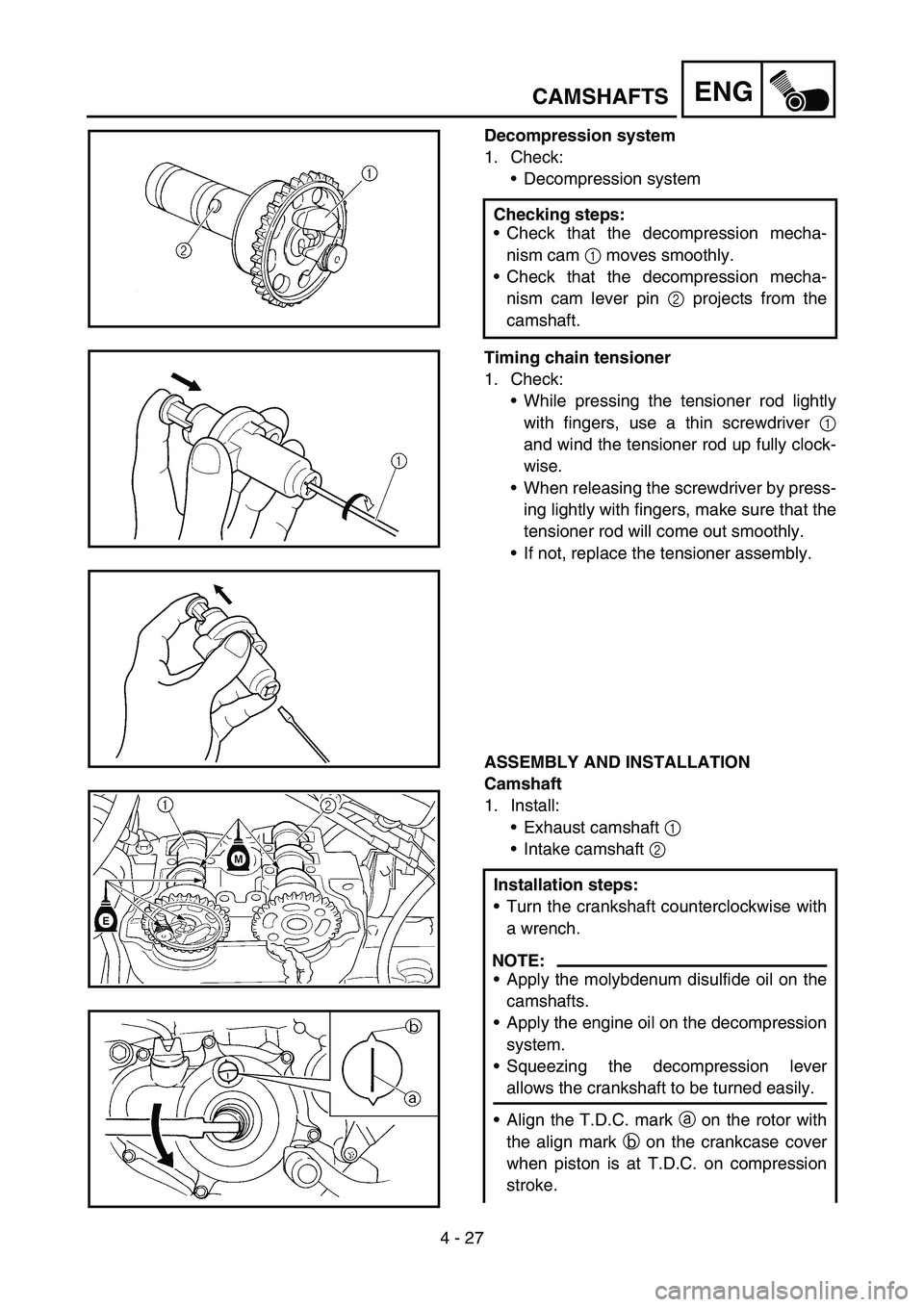

Decompression system

1. Check:

Decompression system

Timing chain tensioner

1. Check:

While pressing the tensioner rod lightly

with fingers, use a thin screwdriver 1

and wind the tensioner rod up fully clock-

wise.

When releasing the screwdriver by press-

ing lightly with fingers, make sure that the

tensioner rod will come out smoothly.

If not, replace the tensioner assembly.

ASSEMBLY AND INSTALLATION

Camshaft

1. Install:

Exhaust camshaft 1

Intake camshaft 2 Checking steps:

Check that the decompression mecha-

nism cam 1 moves smoothly.

Check that the decompression mecha-

nism cam lever pin 2 projects from the

camshaft.

Installation steps:

Turn the crankshaft counterclockwise with

a wrench.

NOTE:

Apply the molybdenum disulfide oil on the

camshafts.

Apply the engine oil on the decompression

system.

Squeezing the decompression lever

allows the crankshaft to be turned easily.

Align the T.D.C. mark a on the rotor with

the align mark b on the crankcase cover

when piston is at T.D.C. on compression

stroke.

Page 316 of 674

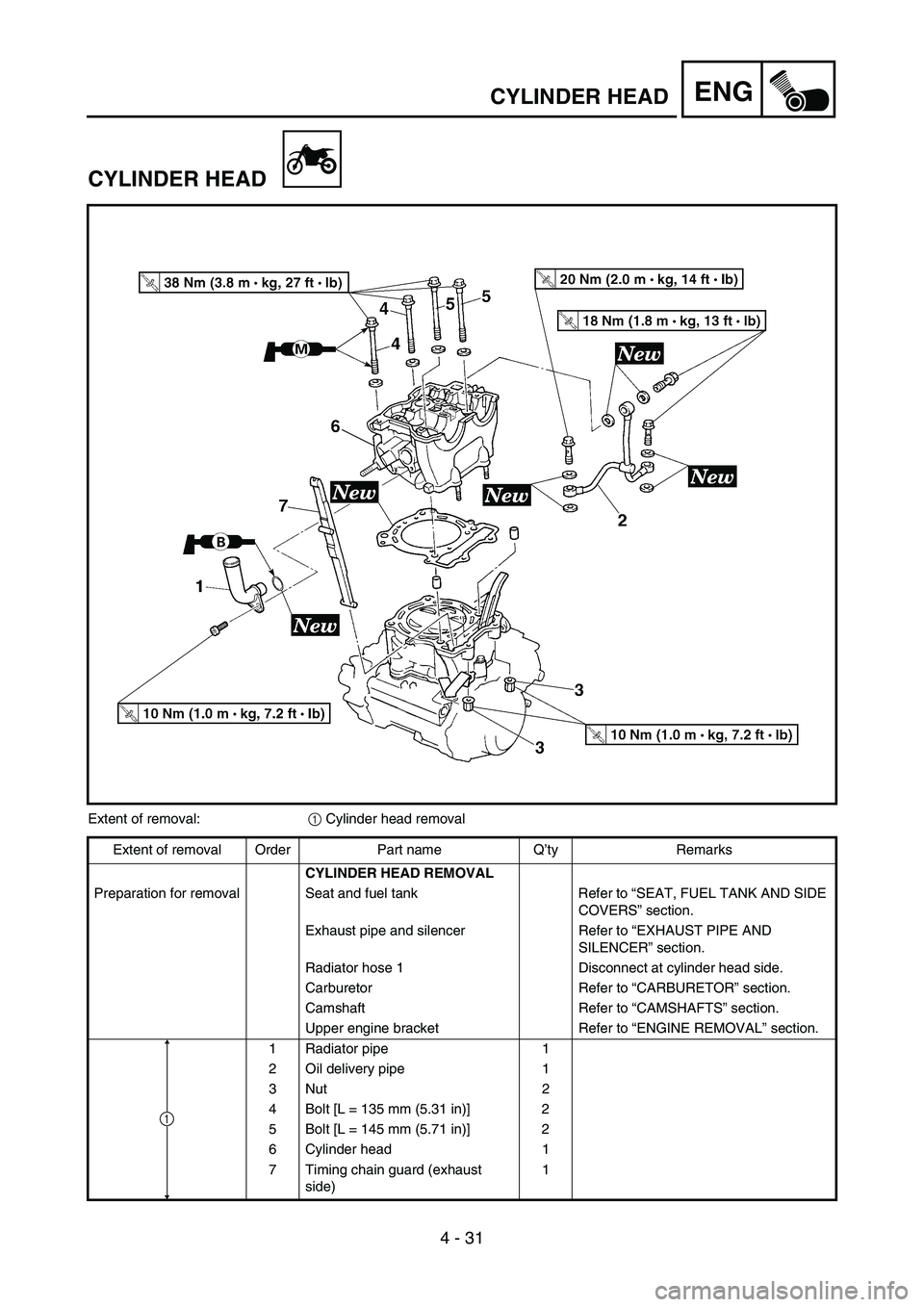

4 - 31

ENGCYLINDER HEAD

CYLINDER HEAD

Extent of removal:

1 Cylinder head removal

Extent of removal Order Part name Q’ty Remarks

CYLINDER HEAD REMOVAL

Preparation for removal Seat and fuel tank Refer to “SEAT, FUEL TANK AND SIDE

COVERS” section.

Exhaust pipe and silencer Refer to “EXHAUST PIPE AND

SILENCER” section.

Radiator hose 1 Disconnect at cylinder head side.

Carburetor Refer to “CARBURETOR” section.

Camshaft Refer to “CAMSHAFTS” section.

Upper engine bracket Refer to “ENGINE REMOVAL” section.

1 Radiator pipe 1

2 Oil delivery pipe 1

3Nut 2

4 Bolt [L = 135 mm (5.31 in)] 2

5 Bolt [L = 145 mm (5.71 in)] 2

6 Cylinder head 1

7 Timing chain guard (exhaust

side)1

1

Page 338 of 674

4 - 42

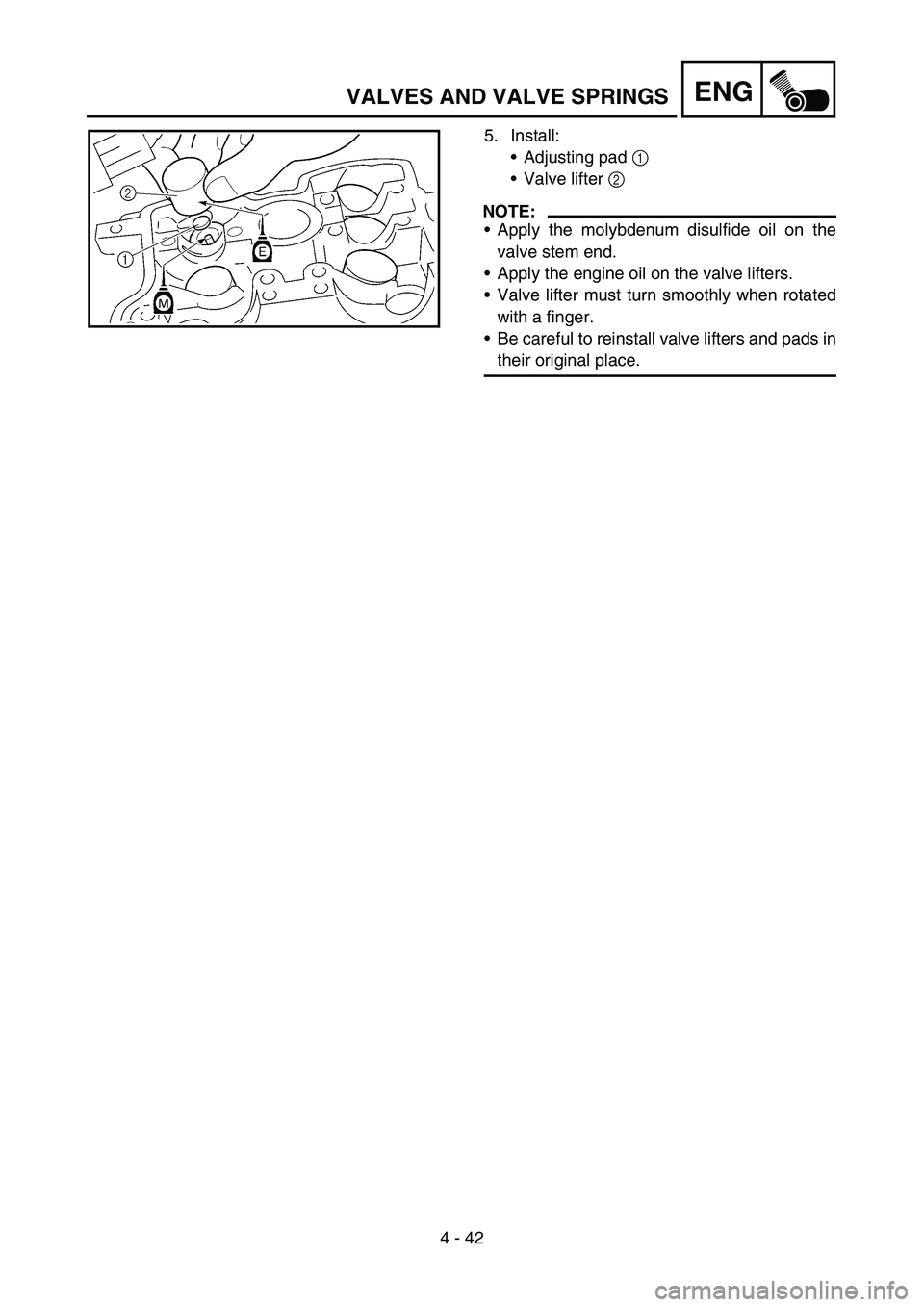

ENGVALVES AND VALVE SPRINGS

5. Install:

Adjusting pad 1

Valve lifter 2

NOTE:

Apply the molybdenum disulfide oil on the

valve stem end.

Apply the engine oil on the valve lifters.

Valve lifter must turn smoothly when rotated

with a finger.

Be careful to reinstall valve lifters and pads in

their original place.

Page 348 of 674

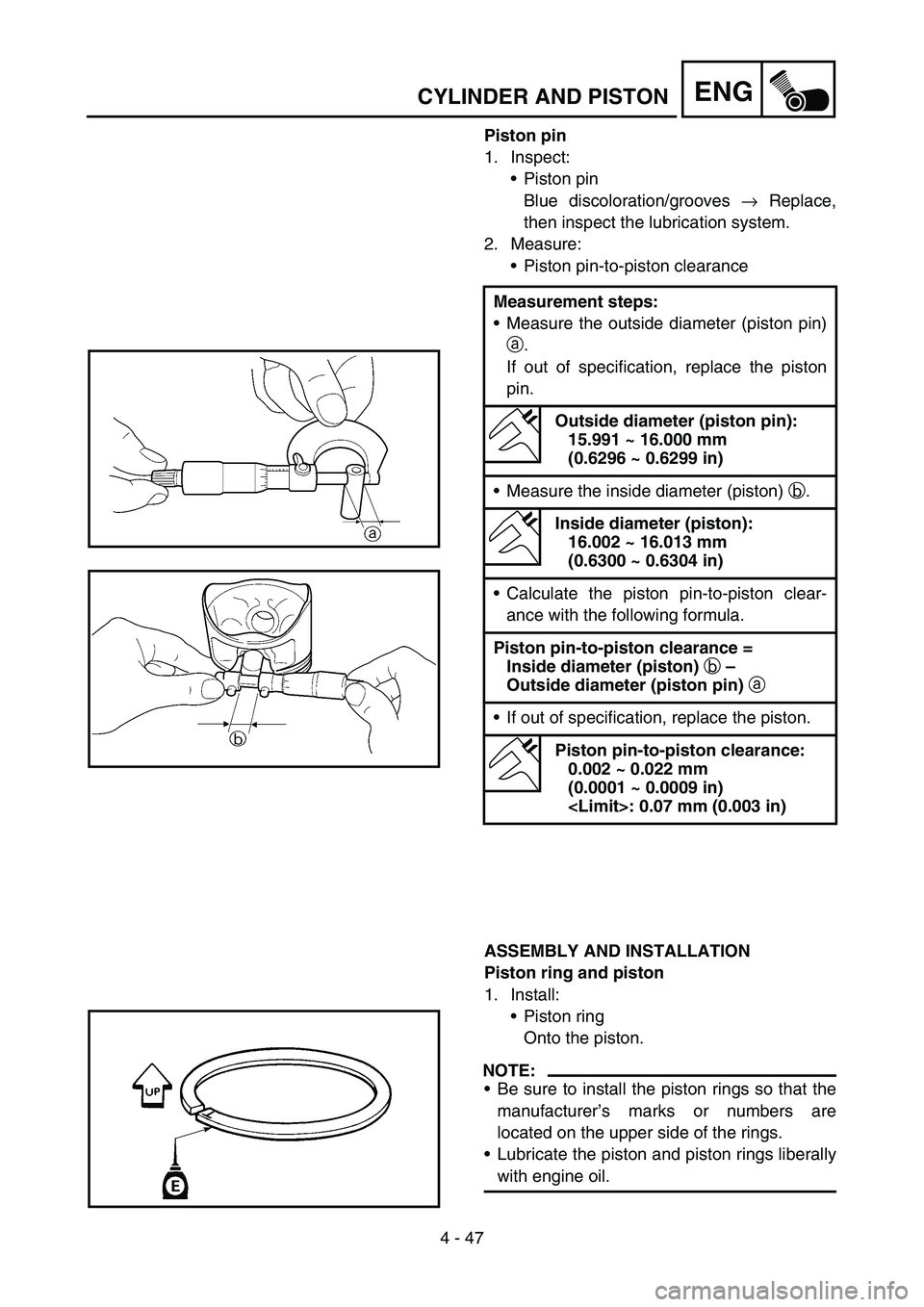

4 - 47

ENGCYLINDER AND PISTON

Piston pin

1. Inspect:

Piston pin

Blue discoloration/grooves → Replace,

then inspect the lubrication system.

2. Measure:

Piston pin-to-piston clearance

ASSEMBLY AND INSTALLATION

Piston ring and piston

1. Install:

Piston ring

Onto the piston.

NOTE:

Be sure to install the piston rings so that the

manufacturer’s marks or numbers are

located on the upper side of the rings.

Lubricate the piston and piston rings liberally

with engine oil. Measurement steps:

Measure the outside diameter (piston pin)

a.

If out of specification, replace the piston

pin.

Outside diameter (piston pin):

15.991 ~ 16.000 mm

(0.6296 ~ 0.6299 in)

Measure the inside diameter (piston) b.

Inside diameter (piston):

16.002 ~ 16.013 mm

(0.6300 ~ 0.6304 in)

Calculate the piston pin-to-piston clear-

ance with the following formula.

Piston pin-to-piston clearance =

Inside diameter (piston)

b –

Outside diameter (piston pin)

a

If out of specification, replace the piston.

Piston pin-to-piston clearance:

0.002 ~ 0.022 mm

(0.0001 ~ 0.0009 in)

Page 350 of 674

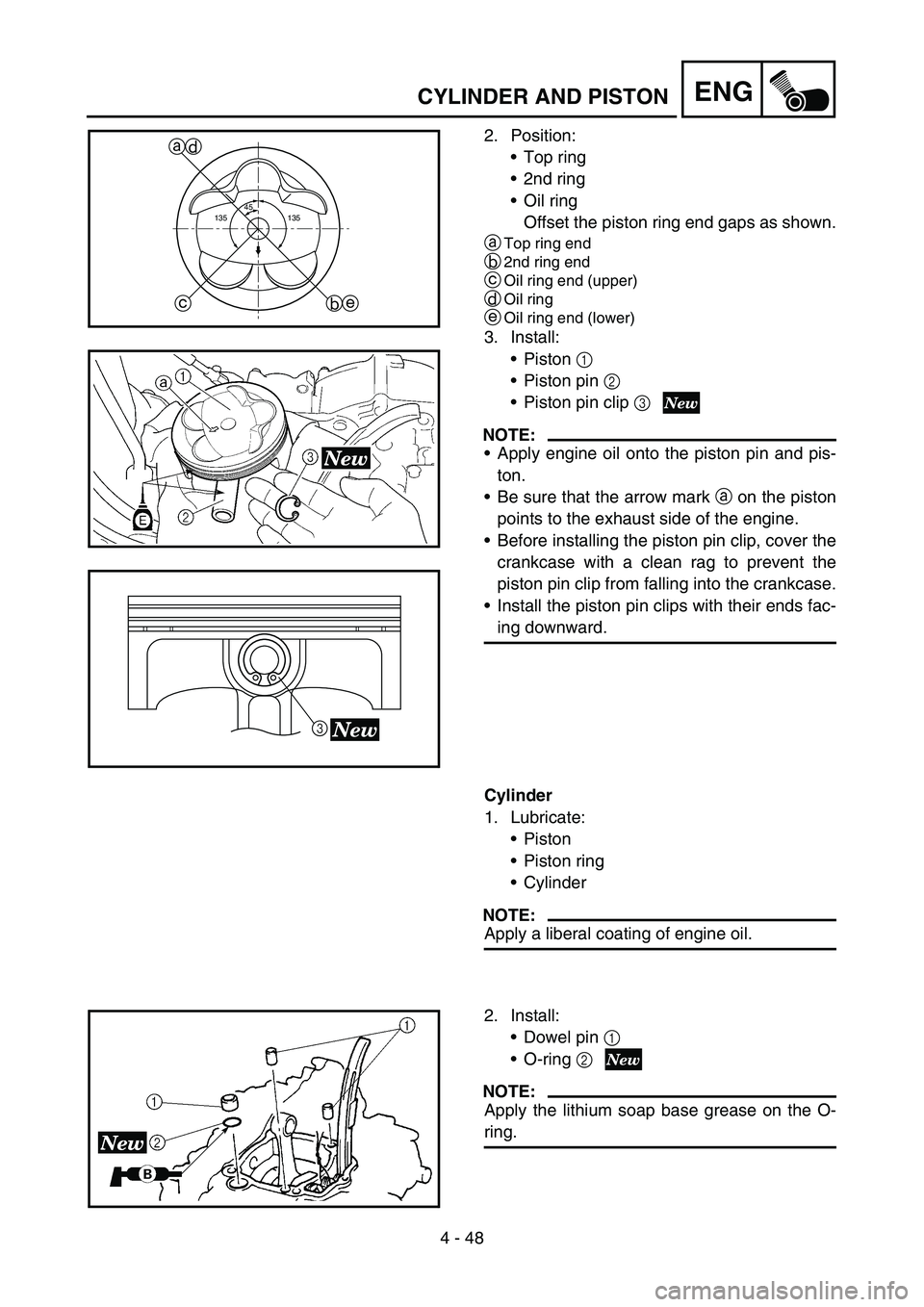

4 - 48

ENGCYLINDER AND PISTON

2. Position:

Top ring

2nd ring

Oil ring

Offset the piston ring end gaps as shown.

a

Top ring end

b2nd ring end

cOil ring end (upper)

dOil ring

eOil ring end (lower)

3. Install:

Piston 1

Piston pin 2

Piston pin clip 3

NOTE:

Apply engine oil onto the piston pin and pis-

ton.

Be sure that the arrow mark a on the piston

points to the exhaust side of the engine.

Before installing the piston pin clip, cover the

crankcase with a clean rag to prevent the

piston pin clip from falling into the crankcase.

Install the piston pin clips with their ends fac-

ing downward.

45

135 135

a

b ced

3

Cylinder

1. Lubricate:

Piston

Piston ring

Cylinder

NOTE:

Apply a liberal coating of engine oil.

2. Install:

Dowel pin 1

O-ring 2

NOTE:

Apply the lithium soap base grease on the O-

ring.

Page 354 of 674

4 - 50

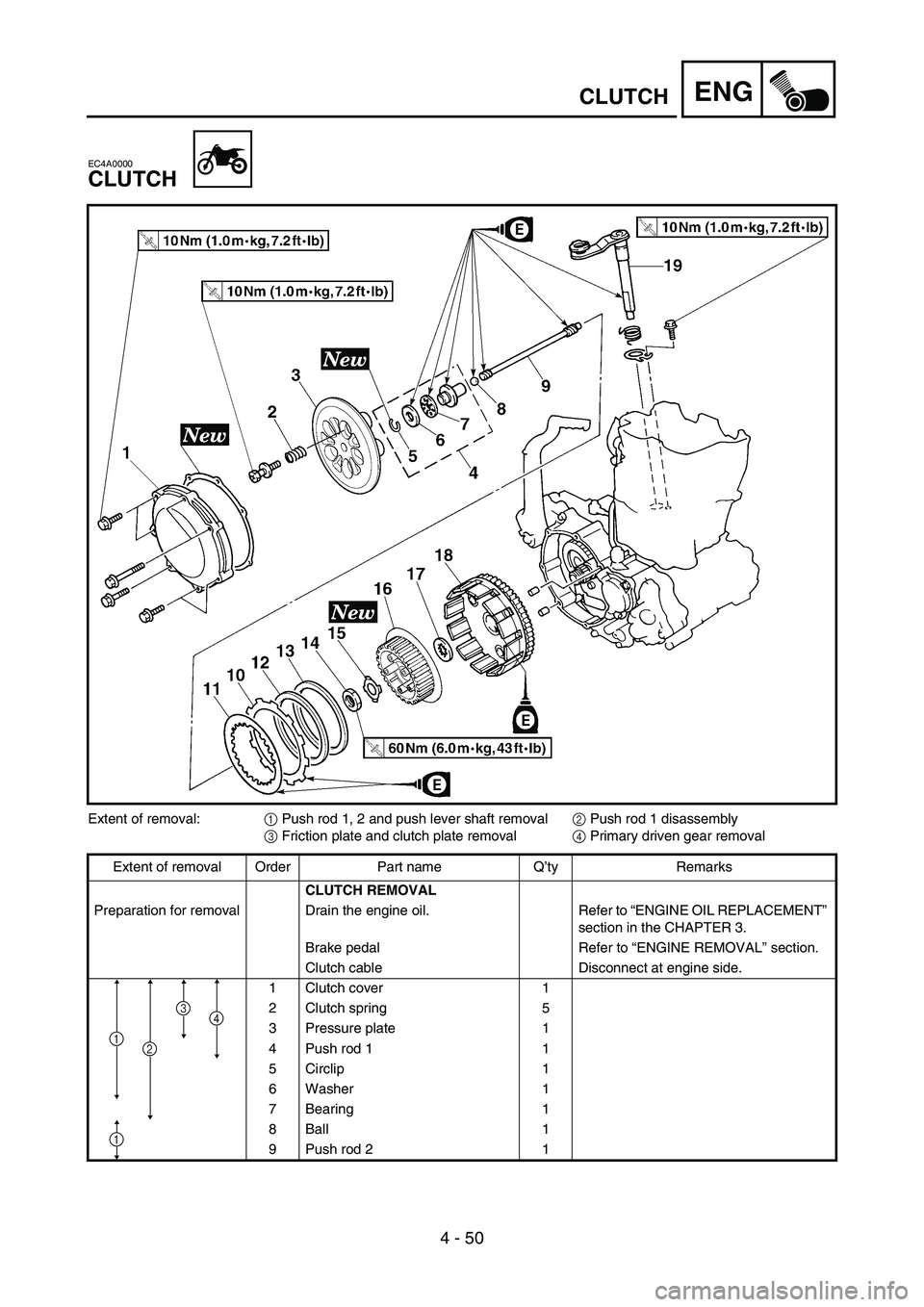

ENGCLUTCH

EC4A0000

CLUTCH

Extent of removal:

1 Push rod 1, 2 and push lever shaft removal

2 Push rod 1 disassembly

3 Friction plate and clutch plate removal

4 Primary driven gear removal

Extent of removal Order Part name Q’ty Remarks

CLUTCH REMOVAL

Preparation for removal Drain the engine oil. Refer to “ENGINE OIL REPLACEMENT”

section in the CHAPTER 3.

Brake pedal Refer to “ENGINE REMOVAL” section.

Clutch cable Disconnect at engine side.

1 Clutch cover 1

2 Clutch spring 5

3 Pressure plate 1

4 Push rod 1 1

5 Circlip 1

6 Washer 1

7 Bearing 1

8Ball 1

9 Push rod 2 1

1

4

1

3

2