Electrical YAMAHA YZ250F 2006 Owners Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2006, Model line: YZ250F, Model: YAMAHA YZ250F 2006Pages: 674, PDF Size: 21.07 MB

Page 12 of 674

EC080000

HOW TO USE

THIS MANUAL

EC081000

PARTICULARLY IMPORTANT

INFORMATION

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS

INVOLVED!

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting

or repairing the machine.

A CAUTION indicates special precautions that

must be taken to avoid damage to the

machine.

NOTE:

A NOTE provides key information to make pro-

cedures easier or clearer.

WA R N I N G

CAUTION:

EC082000

FINDING THE REQUIRED PAGE

1. This manual consists of seven chapters;

“General information”, “Specifications”,

“Regular inspection and adjustments”,

“Engine”, “Chassis”, “Electrical” and “Tun-

ing”.

2. The table of contents is at the beginning of

the manual. Look over the general layout of

the book before finding then required chap-

ter and item.

Bend the book at its edge, as shown, to

find the required fore edge symbol mark

and go to a page for required item and

description.

Page 16 of 674

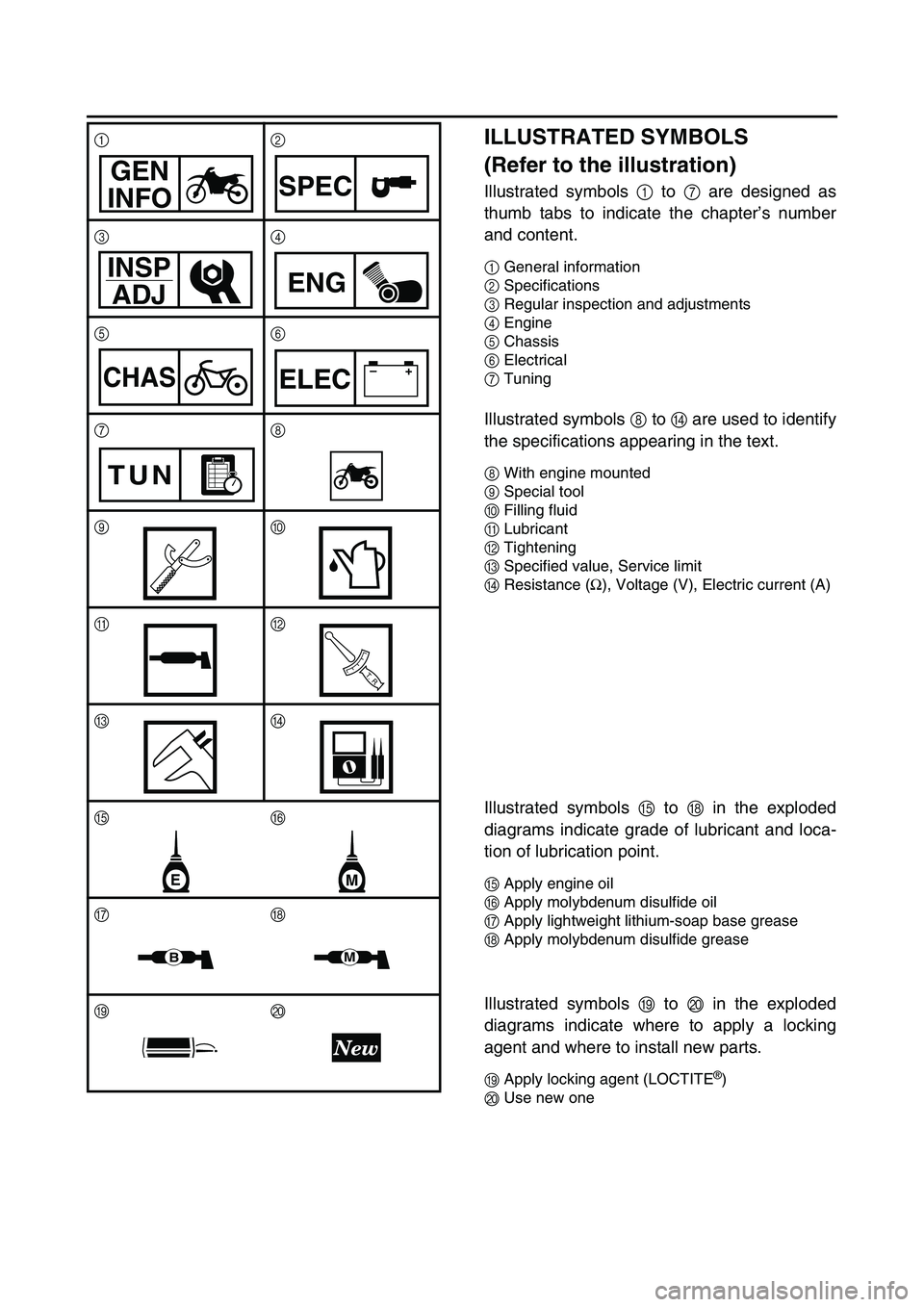

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 7 are designed as

thumb tabs to indicate the chapter’s number

and content.

1General information

2Specifications

3Regular inspection and adjustments

4Engine

5Chassis

6Electrical

7Tuning

Illustrated symbols 8 to D are used to identify

the specifications appearing in the text.

8With engine mounted

9Special tool

0Filling fluid

ALubricant

BTightening

CSpecified value, Service limit

DResistance (

Ω), Voltage (V), Electric current (A)

Illustrated symbols E to H in the exploded

diagrams indicate grade of lubricant and loca-

tion of lubrication point.

EApply engine oil

FApply molybdenum disulfide oil

GApply lightweight lithium-soap base grease

HApply molybdenum disulfide grease

Illustrated symbols I to J in the exploded

diagrams indicate where to apply a locking

agent and where to install new parts.

IApply locking agent (LOCTITE®)

JUse new one 12

34

56

78

90

AB

CD

EF

GH

IJ

GEN

INFOSPEC

INSP

ADJ

ENG

CHAS–+ELEC

TUN

T R..

EM

BM

Page 18 of 674

EC090010

INDEX

GENERAL INFORMATION

SPECIFICATIONS

REGULAR INSPECTION AND ADJUSTMENTS

ENGINE

CHASSIS

ELECTRICAL

TUNING

Page 20 of 674

EC0A0000

CONTENTS

CHAPTER 1

GENERAL INFORMATION

DESCRIPTION

............................................1-1

MACHINE IDENTIFICATION

......................1-2

IMPORTANT INFORMATION

.....................1-3

CHECKING OF CONNECTION

..................1-6

SPECIAL TOOLS

.......................................1-7

CONTROL FUNCTIONS

...........................1-10

FUEL

.........................................................1-13

STARTING AND BREAK-IN

.....................1-14

TORQUE-CHECK POINTS

.......................1-18

CLEANING AND STORAGE

....................1-19

CHAPTER 2

SPECIFICATIONS

GENERAL SPECIFICATIONS

....................2-1

MAINTENANCE SPECIFICATIONS

...........2-4

GENERAL TORQUE

SPECIFICATIONS

....................................2-17

DEFINITION OF UNITS

............................2-17

CABLE ROUTING DIAGRAM

..................2-18

CHAPTER 3

REGULAR INSPECTION AND

ADJUSTMENTS

MAINTENANCE INTERVALS

....................3-1

PRE-OPERATION INSPECTION

AND MAINTENANCE

.................................3-4

ENGINE

.......................................................3-5

CHASSIS

..................................................3-23

ELECTRICAL

............................................3-45

Page 24 of 674

CHAPTER 6

ELECTRICAL

ELECTRICAL COMPONENTS

AND WIRING DIAGRAM............................6-1

MAP-CONTROLLED CDI UNIT..................6-2

IGNITION SYSTEM.....................................6-3

THROTTLE POSITION SENSOR

SYSTEM......................................................6-7

CHAPTER 7

TUNING

ENGINE.......................................................7-1

CHASSIS..................................................7-11

Page 76 of 674

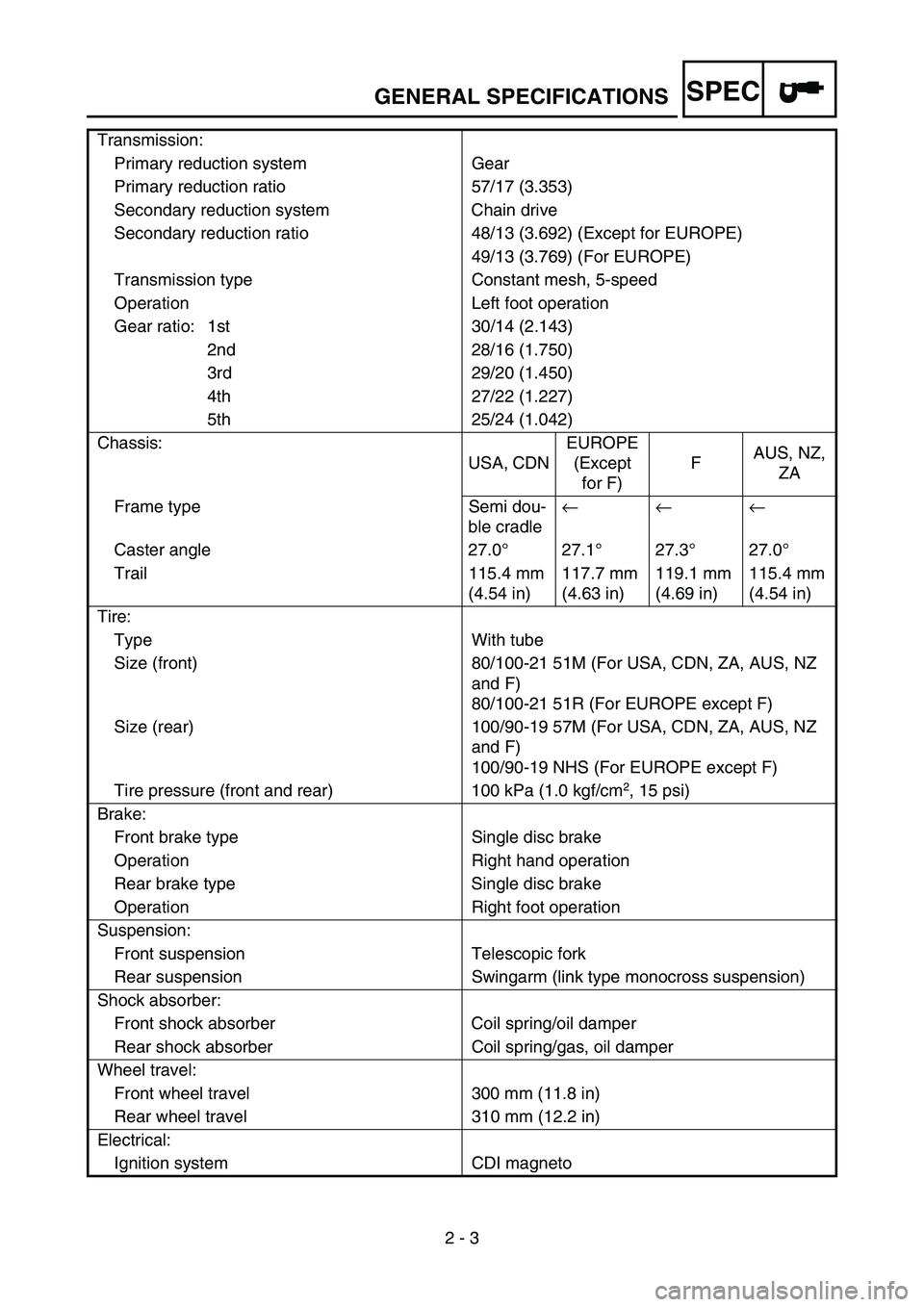

SPEC

2 - 3 Transmission:

Primary reduction system Gear

Primary reduction ratio 57/17 (3.353)

Secondary reduction system Chain drive

Secondary reduction ratio 48/13 (3.692) (Except for EUROPE)

49/13 (3.769) (For EUROPE)

Transmission type Constant mesh, 5-speed

Operation Left foot operation

Gear ratio: 1st 30/14 (2.143)

2nd 28/16 (1.750)

3rd 29/20 (1.450)

4th 27/22 (1.227)

5th 25/24 (1.042)

Chassis:

USA, CDNEUROPE

(Except

for F)FAUS, NZ,

ZA

Frame type Semi dou-

ble cradle← ← ←

Caster angle 27.0°27.1°27.3°27.0°

Trail 115.4 mm

(4.54 in)117.7 mm

(4.63 in)119.1 mm

(4.69 in)115.4 mm

(4.54 in)

Tire:

Type With tube

Size (front) 80/100-21 51M (For USA, CDN, ZA, AUS, NZ

and F)

80/100-21 51R (For EUROPE except F)

Size (rear) 100/90-19 57M (For USA, CDN, ZA, AUS, NZ

and F)

100/90-19 NHS (For EUROPE except F)

Tire pressure (front and rear) 100 kPa (1.0 kgf/cm

2, 15 psi)

Brake:

Front brake type Single disc brake

Operation Right hand operation

Rear brake type Single disc brake

Operation Right foot operation

Suspension:

Front suspension Telescopic fork

Rear suspension Swingarm (link type monocross suspension)

Shock absorber:

Front shock absorber Coil spring/oil damper

Rear shock absorber Coil spring/gas, oil damper

Wheel travel:

Front wheel travel 300 mm (11.8 in)

Rear wheel travel 310 mm (12.2 in)

Electrical:

Ignition system CDI magneto

GENERAL SPECIFICATIONS

Page 89 of 674

SPEC

2 - 16

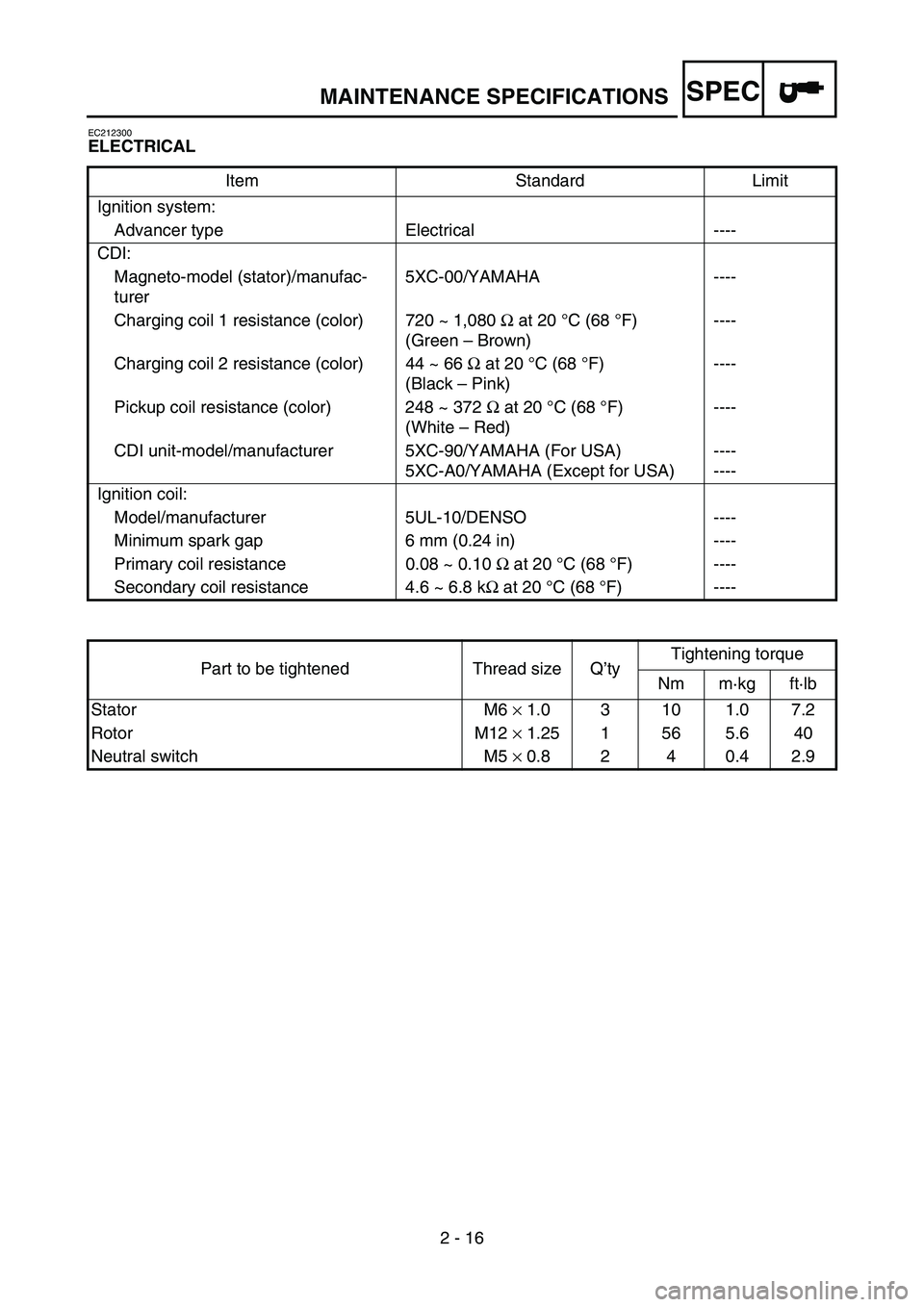

EC212300

ELECTRICAL

Item Standard Limit

Ignition system:

Advancer type Electrical ----

CDI:

Magneto-model (stator)/manufac-

turer5XC-00/YAMAHA ----

Charging coil 1 resistance (color) 720 ~ 1,080 Ω at 20 °C (68 °F)

(Green – Brown)----

Charging coil 2 resistance (color) 44 ~ 66 Ω at 20°C (68 °F)

(Black – Pink)----

Pickup coil resistance (color) 248 ~ 372 Ω at 20°C (68 °F)

(White – Red)----

CDI unit-model/manufacturer 5XC-90/YAMAHA (For USA)

5XC-A0/YAMAHA (Except for USA)----

----

Ignition coil:

Model/manufacturer 5UL-10/DENSO ----

Minimum spark gap 6 mm (0.24 in) ----

Primary coil resistance 0.08 ~ 0.10 Ω at 20 °C (68 °F) ----

Secondary coil resistance 4.6 ~ 6.8 kΩ at 20 °C (68 °F) ----

Part to be tightened Thread size Q’tyTightening torque

Nm m·kg ft·lb

Stator M6 × 1.0 3 10 1.0 7.2

Rotor M12 × 1.25 1 56 5.6 40

Neutral switch M5 × 0.8 2 4 0.4 2.9

MAINTENANCE SPECIFICATIONS

Page 252 of 674

3 - 45

INSP

ADJ

ELECTRICAL/SPARK PLUG INSPECTION

EC370000

ELECTRICAL

EC371001

SPARK PLUG INSPECTION

1. Remove:

Spark plug

2. Inspect:

Electrode 1

Wear/damage → Replace.

Insulator color 2

Normal condition is a medium to light tan

color.

Distinctly different color → Check the

engine condition.

NOTE:

When the engine runs for many hours at low

speeds, the spark plug insulator will become

sooty, even if the engine and carburetor are in

good operating condition.

3. Measure:

Plug gap a

Use a wire gauge or thickness gauge.

Out of specification → Regap.

4. Clean the plug with a spark plug cleaner if

necessary.

Spark plug gap:

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

5. Tighten:

Spark plug

NOTE:

Before installing a spark plug, clean the gas-

ket surface and plug surface.

Finger-tighten a the spark plug before torqu-

ing to specification b.

T R..13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 596 of 674

6 - 1

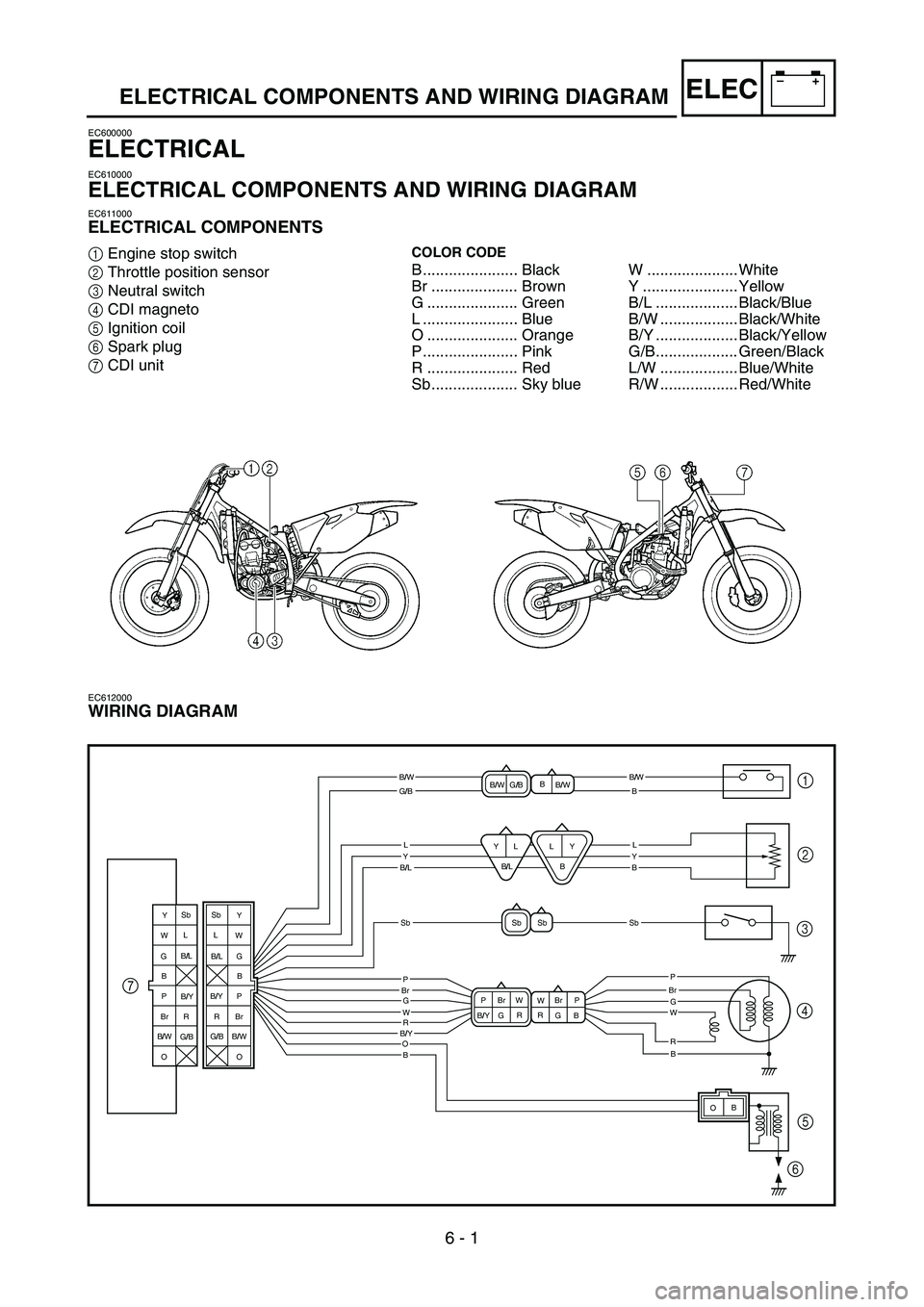

–+ELECELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC600000

ELECTRICAL

EC610000

ELECTRICAL COMPONENTS AND WIRING DIAGRAM

EC611000

ELECTRICAL COMPONENTS

1Engine stop switch

2Throttle position sensor

3Neutral switch

4CDI magneto

5Ignition coil

6Spark plug

7CDI unitCOLOR CODE

B ...................... Black

Br .................... Brown

G ..................... Green

L ...................... Blue

O ..................... Orange

P ...................... Pink

R ..................... Red

Sb.................... Sky blue

EC612000

WIRING DIAGRAM

71

5

62

3

4

B/WB/W

B/L

B/Y

SbSb

G/B

LYLY

P

B

B

B

B

G

O

WR

P

GW

R PP

B Br W

W

B/YGBr

G RR

OB Sb Sb Y

Y

WY

W

GG

B

PP

Br BrR R

OL

B SbY LL

B/L B/WB/W G/B

B B

B/L L Sb

B/L

G/B

G/BB/Y

B/Y

B/W

O B/W

BrBr

W ..................... White

Y ...................... Yellow

B/L ................... Black/Blue

B/W .................. Black/White

B/Y ................... Black/Yellow

G/B................... Green/Black

L/W .................. Blue/White

R/W .................. Red/White

Page 610 of 674

6 - 6

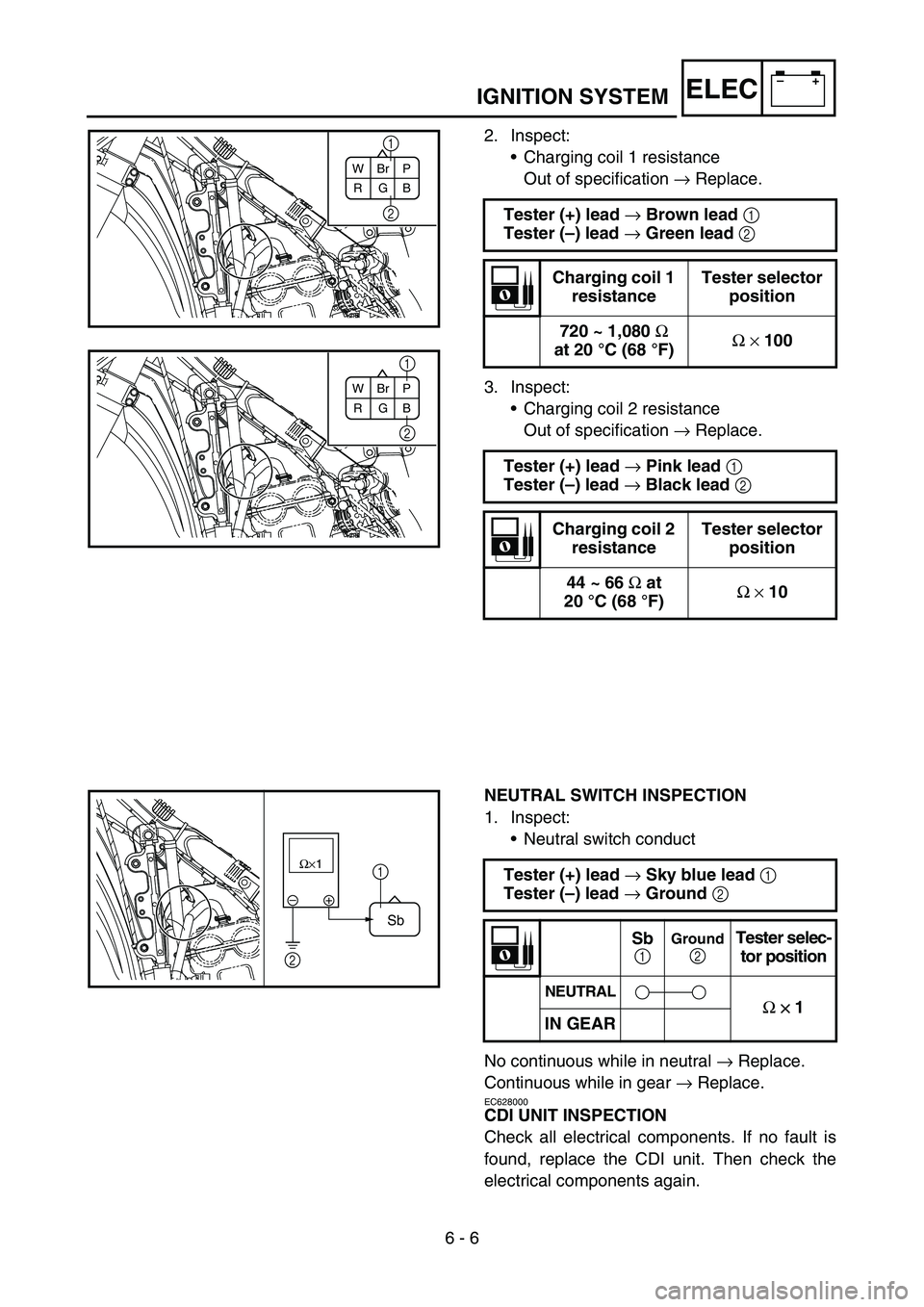

–+ELECIGNITION SYSTEM

2. Inspect:

•Charging coil 1 resistance

Out of specification → Replace.

3. Inspect:

•Charging coil 2 resistance

Out of specification → Replace. Tester (+) lead

→ Brown lead

1

Tester (–) lead

→ Green lead

2

Charging coil 1

resistanceTester selector

position

720 ~ 1,080

Ω

at 20 °C (68 °F)Ω

× 100

Tester (+) lead

→ Pink lead

1

Tester (–) lead

→ Black lead

2

Charging coil 2

resistanceTester selector

position

44 ~ 66

Ω at

20 °C (68 °F)Ω

× 10

W

RBr

GP

B

2 1

2

1

W

RBr

GP

B

NEUTRAL SWITCH INSPECTION

1. Inspect:

•Neutral switch conduct

No continuous while in neutral → Replace.

Continuous while in gear → Replace.

EC628000

CDI UNIT INSPECTION

Check all electrical components. If no fault is

found, replace the CDI unit. Then check the

electrical components again.Tester (+) lead

→ Sky blue lead

1

Tester (–) lead

→ Ground

2

Sb

1 Ground

2

Tester selec-

tor position

NEUTRAL

Ω

×

×× × 1

IN GEAR

–+ Ω×1

1

2

Sb