ECU YAMAHA YZ250F 2011 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2011, Model line: YZ250F, Model: YAMAHA YZ250F 2011Pages: 196, PDF Size: 14.15 MB

Page 170 of 196

5-33

SWINGARM

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE BEARING

1. Remove:• Bearing "1"

Remove the bearing by pressing its

outer race.

CHECKING THE SWINGARM

1. Inspect:• Bearing "1"

• Bushing "2"

Free play exists/unsmooth revolu-

tion/rust →Replace bearing and

bushing as a set.

2. Inspect: • Oil seal "3"Damage →Replace.

CHECKING THE RELAY ARM

1. Inspect: • Bearing "1"

•Collar "2"

Free play exists/unsmooth revolu-

tion/rust → Replace bearing and

collar as a set.

2. Inspect: • Oil seal "3"Damage →Replace. CHECKING THE CONNECTING

ROD

1. Inspect:

•Bearing "1"

• Collar "2"Free play exists/unsmooth revolu-

tion/rust →Replace bearing and

collar as a set.

2. Inspect: • Oil seal "3"

Damage →Replace.

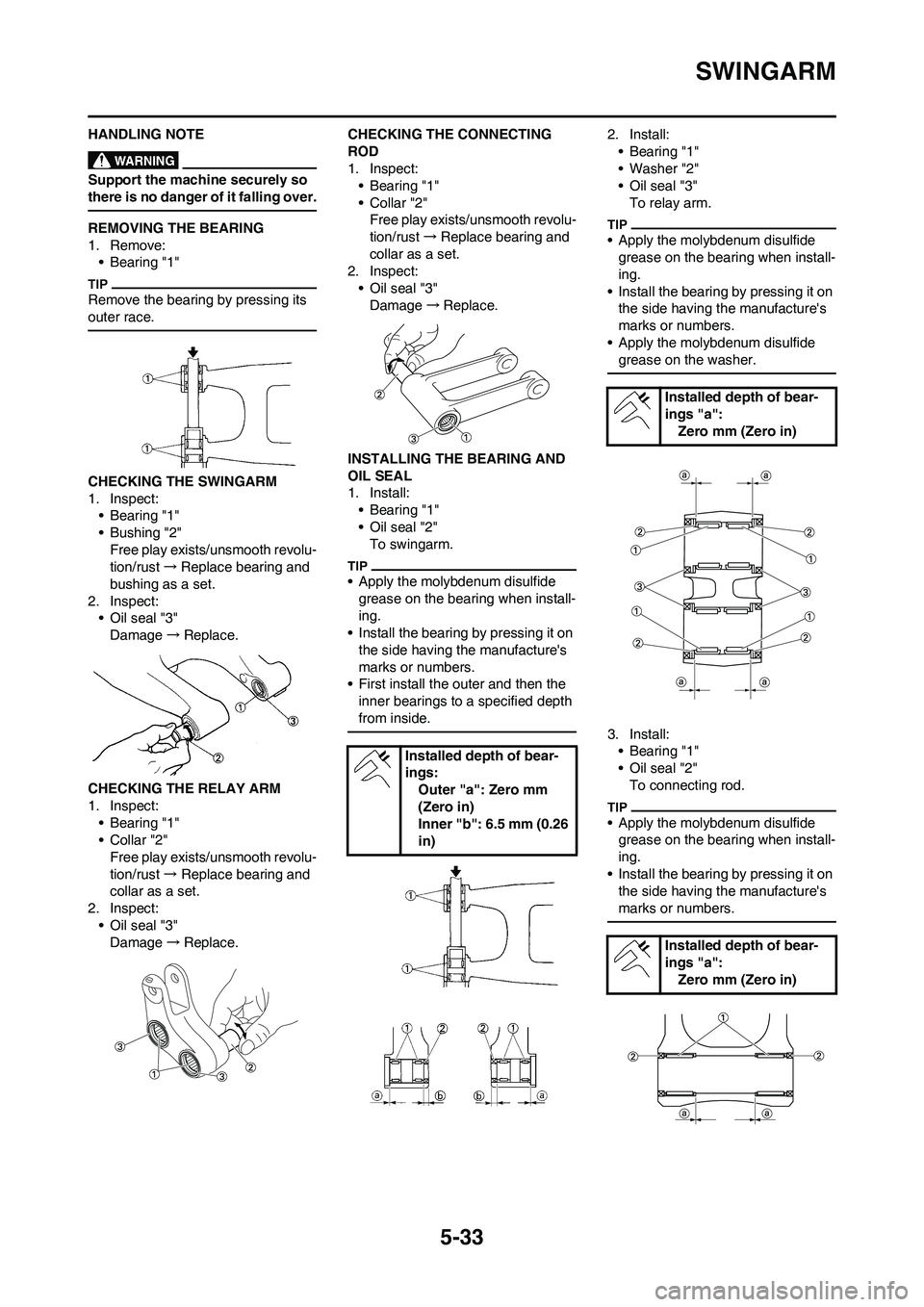

INSTALLING THE BEARING AND

OIL SEAL

1. Install: •Bearing "1"

• Oil seal "2"To swingarm.

• Apply the molybdenum disulfide

grease on the bearing when install-

ing.

• Install the bearing by pressing it on

the side having the manufacture's

marks or numbers.

• First install the outer and then the

inner bearings to a specified depth

from inside.

2. Install: • Bearing "1"

• Washer "2"

• Oil seal "3"To relay arm.

• Apply the molybdenum disulfide grease on the bearing when install-

ing.

• Install the bearing by pressing it on the side having the manufacture's

marks or numbers.

• Apply the molybdenum disulfide grease on the washer.

3. Install:• Bearing "1"

• Oil seal "2"To connecting rod.

• Apply the molybdenum disulfide grease on the bearing when install-

ing.

• Install the bearing by pressing it on the side having the manufacture's

marks or numbers.

Installed depth of bear-

ings:

Outer "a": Zero mm

(Zero in)

Inner "b": 6.5 mm (0.26

in)

Installed depth of bear-

ings "a": Zero mm (Zero in)

Installed depth of bear-

ings "a": Zero mm (Zero in)

Page 174 of 196

5-37

REAR SHOCK ABSORBER

HANDLING NOTE

• Support the machine securely so

there is no danger of it falling

over.

• This rear shock absorber is pro-

vided with a separate type tank

filled with high-pressure nitro-

gen gas. To prevent the danger

of explosion, read and under-

stand the following information

before handling the shock ab-

sorber. The manufacturer can

not be held responsible for prop-

erty damage or personal injury

that may result from improper

handling.

• Never tamper or attempt to dis-

assemble the cylinder or the

tank.

• Never throw the rear shock ab-

sorber into an open flame or

other high heat. The rear shock

absorber may explode as a re-

sult of nitrogen gas expansion

and/ or damage to the hose.

• Be careful not to damage any

part of the gas tank. A damaged

gas tank will impair the damp-

ing performance or cause a

malfunction.

• Take care not to scratch the

contact surface of the piston

rod with the cylinder; or oil

could leak out.

• Never attempt to remove the

plug at the bottom of the nitro-

gen gas tank. It is very danger-

ous to remove the plug.

• When scrapping the rear shock

absorber, follow the instruc-

tions on disposal.

NOTES ON DISPOSAL (YAMAHA

DEALERS ONLY)

Before disposing the rear shock ab-

sorber, be sure to extract the nitrogen

gas from valve "1". Wear eye protec-

tion to prevent eye damage from es-

caping gas and/or metal chips.

To dispose of a damaged or worn-

out rear shock absorber, take the

unit to your Yamaha dealer for this

disposal procedure.

REMOVING THE BEARING

1. Remove:

• Stopper ring (upper bearing) "1"

Press in the bearing while pressing its

outer race and remove the stopper

ring.

2. Remove:

• Upper bearing "1"

Remove the bearing by pressing its

outer race.

3. Remove:

• Lower bearing "1"

Remove the bearing by pressing its

outer race.

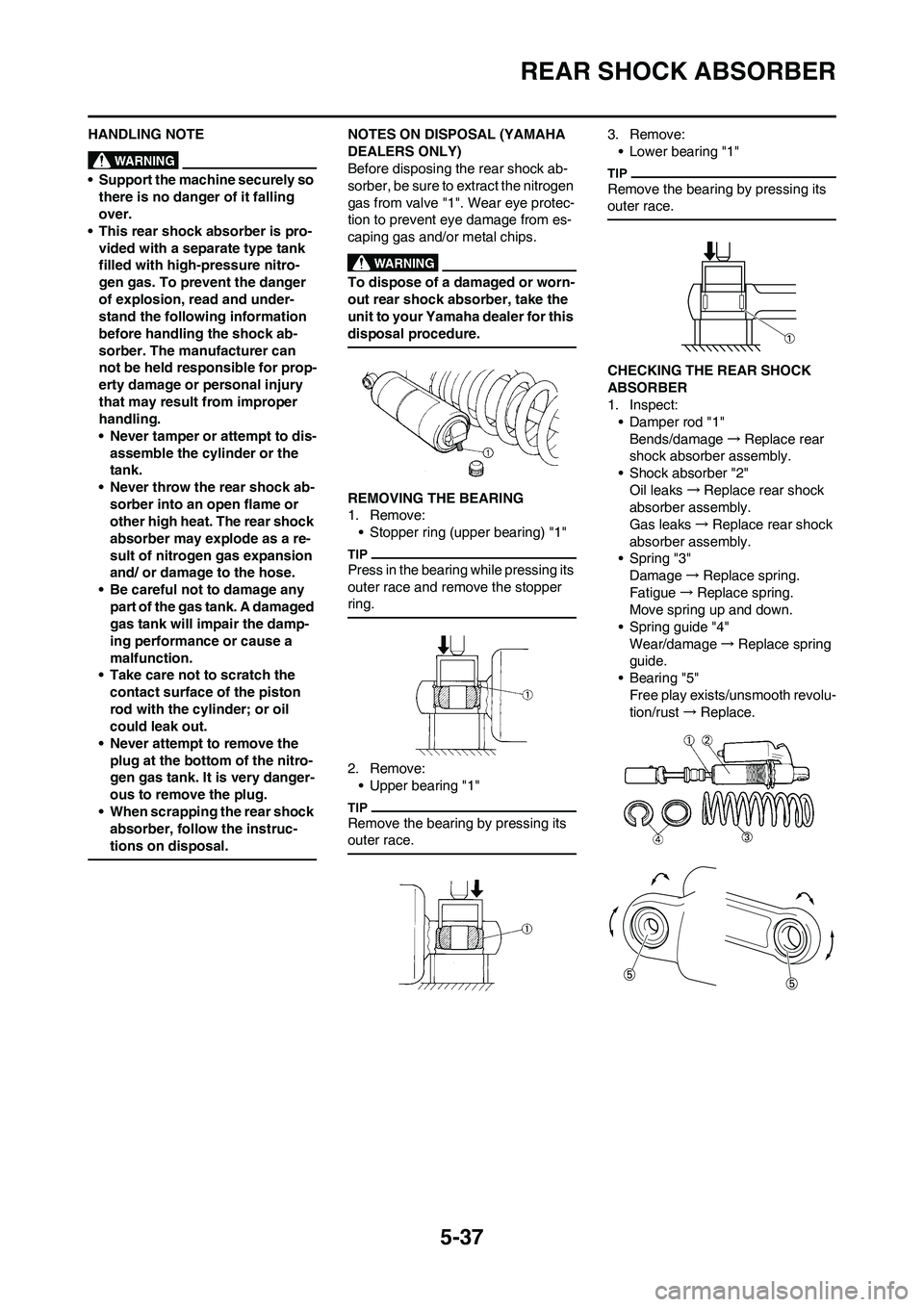

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Damper rod "1"

Bends/damage→Replace rear

shock absorber assembly.

• Shock absorber "2"

Oil leaks→Replace rear shock

absorber assembly.

Gas leaks→Replace rear shock

absorber assembly.

• Spring "3"

Damage→Replace spring.

Fatigue→Replace spring.

Move spring up and down.

• Spring guide "4"

Wear/damage→Replace spring

guide.

• Bearing "5"

Free play exists/unsmooth revolu-

tion/rust →Replace.