YAMAHA YZ250F 2012 Owners Manual

Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ250F, Model: YAMAHA YZ250F 2012Pages: 198, PDF Size: 11.78 MB

Page 161 of 198

5-22

FRONT FORK

26. Loosen:

• Rebound damping adjuster "1"

• Loosen the rebound damping ad-

juster finger tight.

• Record the set position of the ad-

juster (the amount of turning out the

fully turned in position).

27. Install:

• Push rod "1"

• Copper washer "2"

• Adjuster "3"

To damper assembly "4".

• While compressing the inner tube

"5", set the cap bolt ring wrench "7"

between the inner tube and locknut

"6".

• Fully finger tighten the adjuster onto

the damper assembly.

28. Inspect:

• Gap "a" between the adjuster "1"

and locknut "2".

Out of specification → Retighten

and readjust the locknut.

If the adjuster is installed out of spec-

ification, proper damping force can-

not be obtained.

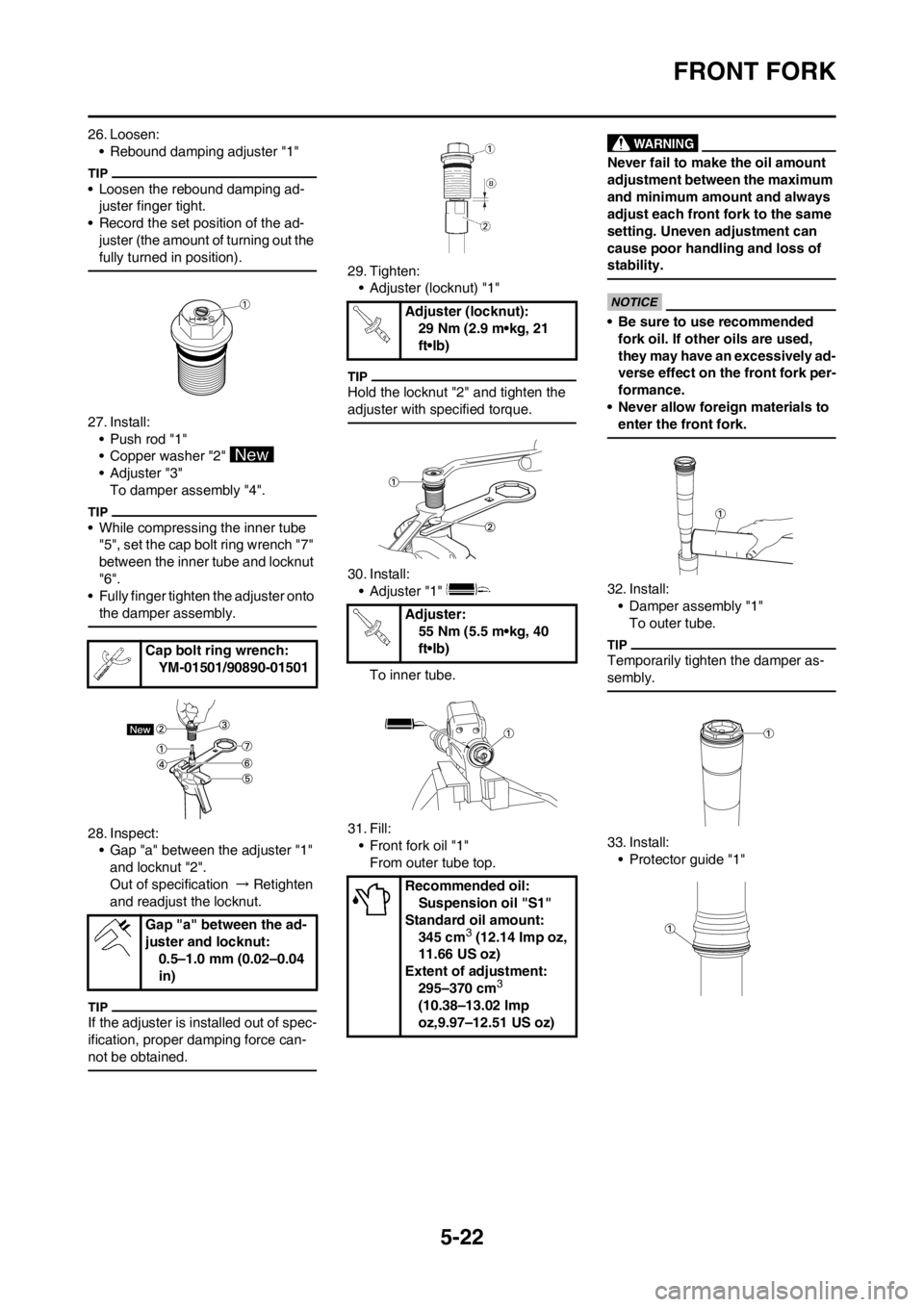

29. Tighten:

• Adjuster (locknut) "1"

Hold the locknut "2" and tighten the

adjuster with specified torque.

30. Install:

• Adjuster "1"

To inner tube.

31. Fill:

• Front fork oil "1"

From outer tube top.

Never fail to make the oil amount

adjustment between the maximum

and minimum amount and always

adjust each front fork to the same

setting. Uneven adjustment can

cause poor handling and loss of

stability.

• Be sure to use recommended

fork oil. If other oils are used,

they may have an excessively ad-

verse effect on the front fork per-

formance.

• Never allow foreign materials to

enter the front fork.

32. Install:

• Damper assembly "1"

To outer tube.

Temporarily tighten the damper as-

sembly.

33. Install:

• Protector guide "1" Cap bolt ring wrench:

YM-01501/90890-01501

Gap "a" between the ad-

juster and locknut:

0.5–1.0 mm (0.02–0.04

in)

Adjuster (locknut):

29 Nm (2.9 m•kg, 21

ft•lb)

Adjuster:

55 Nm (5.5 m•kg, 40

ft•lb)

Recommended oil:

Suspension oil "S1"

Standard oil amount:

345 cm

3 (12.14 Imp oz,

11.66 US oz)

Extent of adjustment:

295–370 cm

3

(10.38–13.02 Imp

oz,9.97–12.51 US oz)

Page 162 of 198

5-23

FRONT FORK

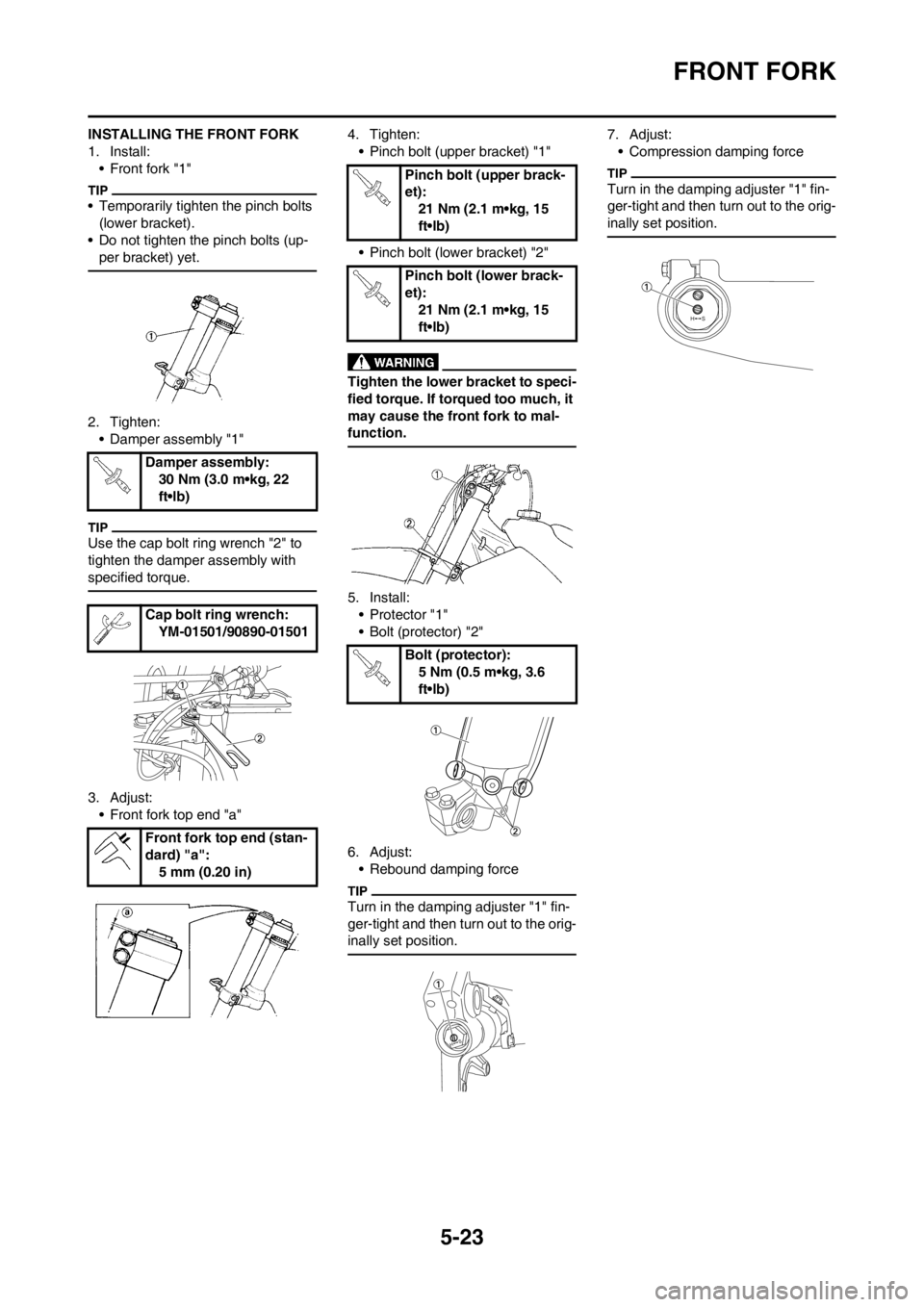

INSTALLING THE FRONT FORK

1. Install:

• Front fork "1"

• Temporarily tighten the pinch bolts

(lower bracket).

• Do not tighten the pinch bolts (up-

per bracket) yet.

2. Tighten:

• Damper assembly "1"

Use the cap bolt ring wrench "2" to

tighten the damper assembly with

specified torque.

3. Adjust:

• Front fork top end "a"4. Tighten:

• Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If torqued too much, it

may cause the front fork to mal-

function.

5. Install:

• Protector "1"

• Bolt (protector) "2"

6. Adjust:

• Rebound damping force

Turn in the damping adjuster "1" fin-

ger-tight and then turn out to the orig-

inally set position.

7. Adjust:

• Compression damping force

Turn in the damping adjuster "1" fin-

ger-tight and then turn out to the orig-

inally set position.

Damper assembly:

30 Nm (3.0 m•kg, 22

ft•lb)

Cap bolt ring wrench:

YM-01501/90890-01501

Front fork top end (stan-

dard) "a":

5 mm (0.20 in)

Pinch bolt (upper brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Bolt (protector):

5 Nm (0.5 m•kg, 3.6

ft•lb)

Page 163 of 198

5-24

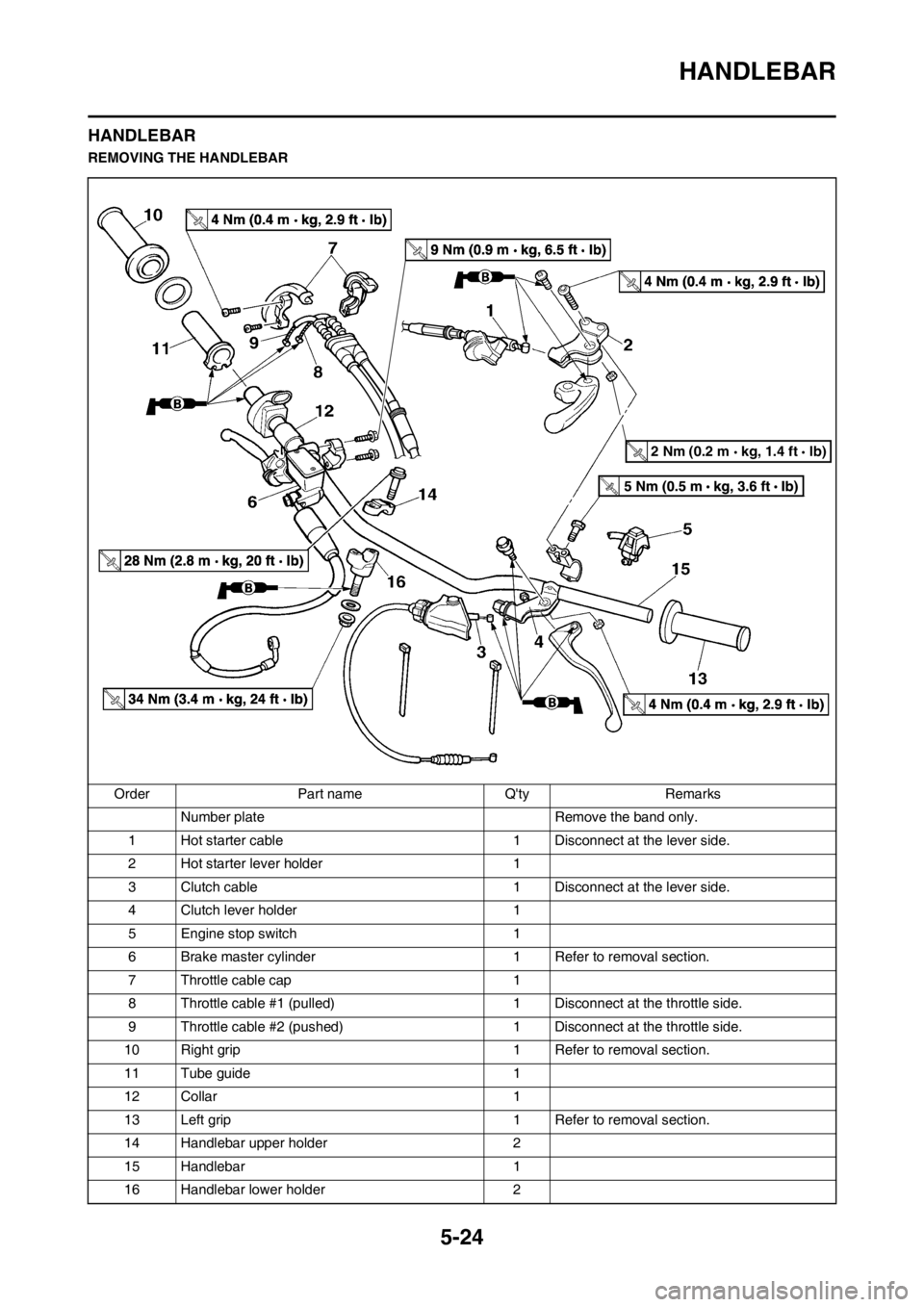

HANDLEBAR

HANDLEBAR

REMOVING THE HANDLEBAR

Order Part name Q'ty Remarks

Number plate Remove the band only.

1 Hot starter cable 1 Disconnect at the lever side.

2 Hot starter lever holder 1

3 Clutch cable 1 Disconnect at the lever side.

4 Clutch lever holder 1

5 Engine stop switch 1

6 Brake master cylinder 1 Refer to removal section.

7 Throttle cable cap 1

8 Throttle cable #1 (pulled) 1 Disconnect at the throttle side.

9 Throttle cable #2 (pushed) 1 Disconnect at the throttle side.

10 Right grip 1 Refer to removal section.

11 Tube guide 1

12 Collar 1

13 Left grip 1 Refer to removal section.

14 Handlebar upper holder 2

15 Handlebar 1

16 Handlebar lower holder 2

2 Nm (0.2 m kg, 1.4 ft lb)

Page 164 of 198

5-25

HANDLEBAR

REMOVING THE BRAKE MASTER

CYLINDER

1. Remove:

• Brake master cylinder bracket "1"

• Brake master cylinder "2"

• Do not let the brake master cylin-

der hang on the brake hose.

• Keep the brake master cylinder

cap side horizontal to prevent air

from coming in.

REMOVING THE GRIP

1. Remove:

•Grip "1"

Blow in air between the handlebar or

tube guide and the grip. Then remove

the grip which has become loose.

CHECKING THE HANDLEBAR

1. Inspect:

• Handlebar "1"

Bends/cracks/damage→Re-

place.

Do not attempt to straighten a bent

handlebar as this may dangerous-

ly weaken the handlebar.

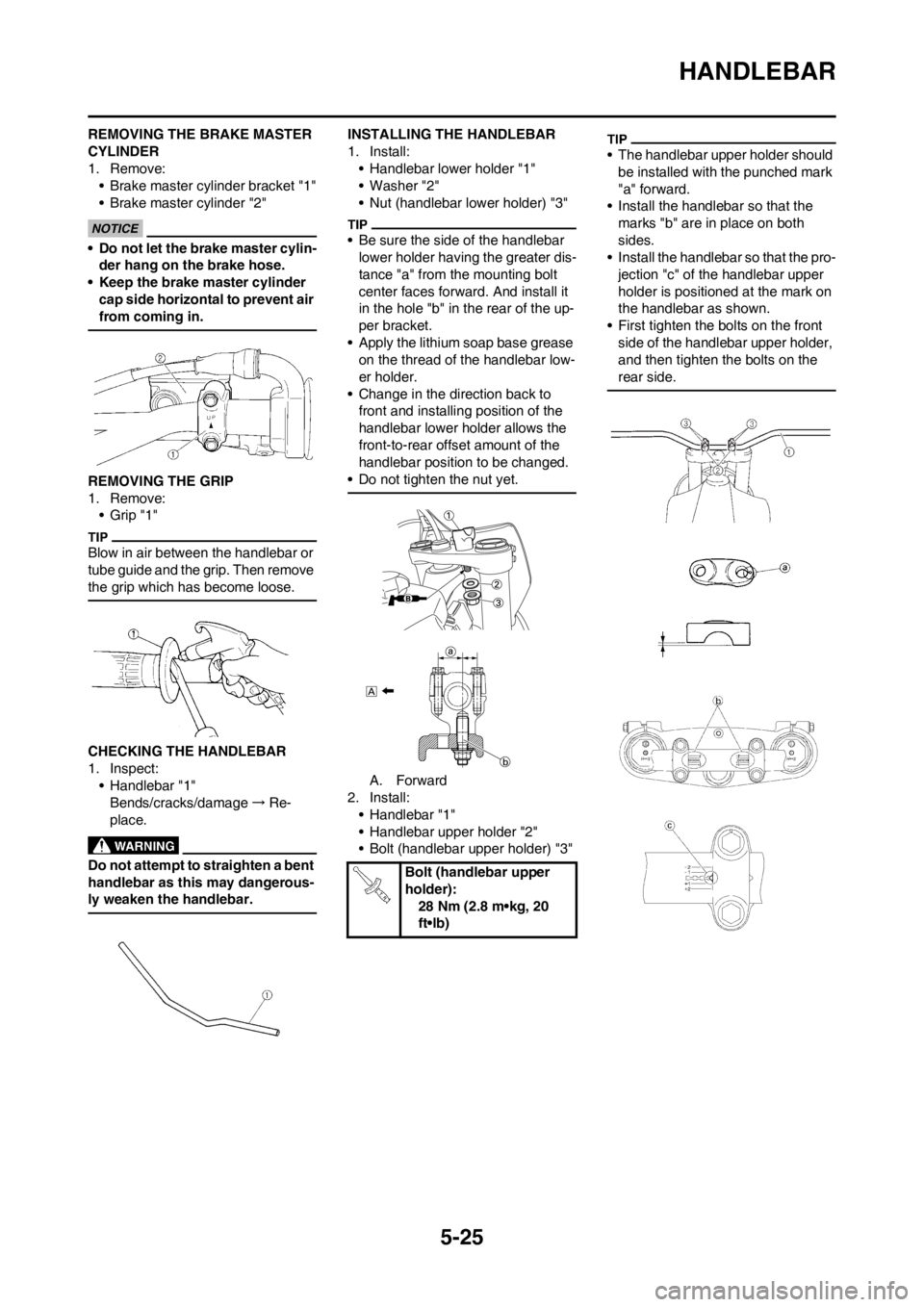

INSTALLING THE HANDLEBAR

1. Install:

• Handlebar lower holder "1"

• Washer "2"

• Nut (handlebar lower holder) "3"

• Be sure the side of the handlebar

lower holder having the greater dis-

tance "a" from the mounting bolt

center faces forward. And install it

in the hole "b" in the rear of the up-

per bracket.

• Apply the lithium soap base grease

on the thread of the handlebar low-

er holder.

• Change in the direction back to

front and installing position of the

handlebar lower holder allows the

front-to-rear offset amount of the

handlebar position to be changed.

• Do not tighten the nut yet.

A. Forward

2. Install:

• Handlebar "1"

• Handlebar upper holder "2"

• Bolt (handlebar upper holder) "3"

• The handlebar upper holder should

be installed with the punched mark

"a" forward.

• Install the handlebar so that the

marks "b" are in place on both

sides.

• Install the handlebar so that the pro-

jection "c" of the handlebar upper

holder is positioned at the mark on

the handlebar as shown.

• First tighten the bolts on the front

side of the handlebar upper holder,

and then tighten the bolts on the

rear side.

Bolt (handlebar upper

holder):

28 Nm (2.8 m•kg, 20

ft•lb)

Page 165 of 198

5-26

HANDLEBAR

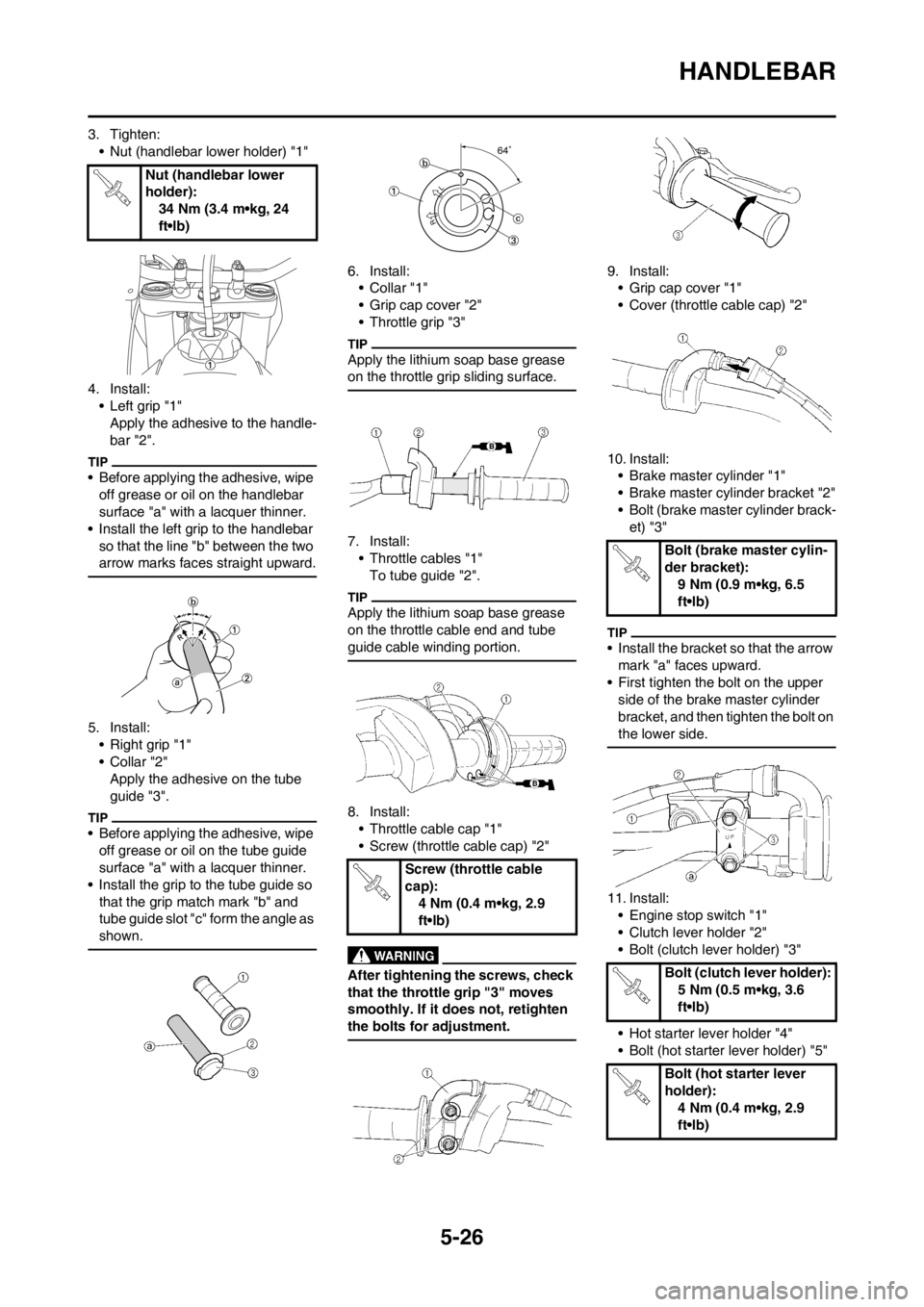

3. Tighten:

• Nut (handlebar lower holder) "1"

4. Install:

• Left grip "1"

Apply the adhesive to the handle-

bar "2".

• Before applying the adhesive, wipe

off grease or oil on the handlebar

surface "a" with a lacquer thinner.

• Install the left grip to the handlebar

so that the line "b" between the two

arrow marks faces straight upward.

5. Install:

• Right grip "1"

•Collar "2"

Apply the adhesive on the tube

guide "3".

• Before applying the adhesive, wipe

off grease or oil on the tube guide

surface "a" with a lacquer thinner.

• Install the grip to the tube guide so

that the grip match mark "b" and

tube guide slot "c" form the angle as

shown.

6. Install:

• Collar "1"

• Grip cap cover "2"

• Throttle grip "3"

Apply the lithium soap base grease

on the throttle grip sliding surface.

7. Install:

• Throttle cables "1"

To tube guide "2".

Apply the lithium soap base grease

on the throttle cable end and tube

guide cable winding portion.

8. Install:

• Throttle cable cap "1"

• Screw (throttle cable cap) "2"

After tightening the screws, check

that the throttle grip "3" moves

smoothly. If it does not, retighten

the bolts for adjustment.

9. Install:

• Grip cap cover "1"

• Cover (throttle cable cap) "2"

10. Install:

• Brake master cylinder "1"

• Brake master cylinder bracket "2"

• Bolt (brake master cylinder brack-

et) "3"

• Install the bracket so that the arrow

mark "a" faces upward.

• First tighten the bolt on the upper

side of the brake master cylinder

bracket, and then tighten the bolt on

the lower side.

11. Install:

• Engine stop switch "1"

• Clutch lever holder "2"

• Bolt (clutch lever holder) "3"

• Hot starter lever holder "4"

• Bolt (hot starter lever holder) "5" Nut (handlebar lower

holder):

34 Nm (3.4 m•kg, 24

ft•lb)

Screw (throttle cable

cap):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Bolt (brake master cylin-

der bracket):

9 Nm (0.9 m•kg, 6.5

ft•lb)

Bolt (clutch lever holder):

5 Nm (0.5 m•kg, 3.6

ft•lb)

Bolt (hot starter lever

holder):

4 Nm (0.4 m•kg, 2.9

ft•lb)

Page 166 of 198

5-27

HANDLEBAR

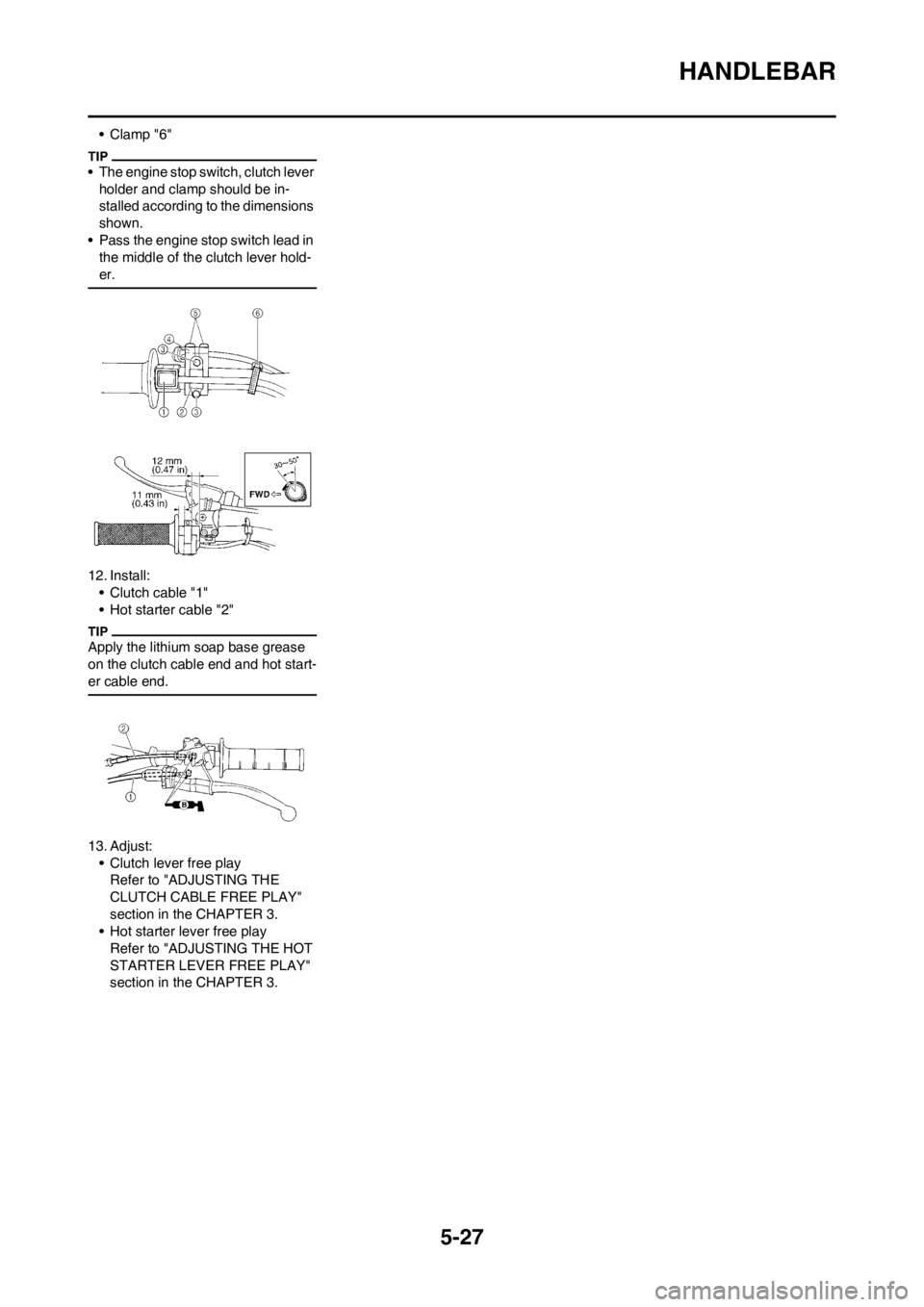

• Clamp "6"

• The engine stop switch, clutch lever

holder and clamp should be in-

stalled according to the dimensions

shown.

• Pass the engine stop switch lead in

the middle of the clutch lever hold-

er.

12. Install:

• Clutch cable "1"

• Hot starter cable "2"

Apply the lithium soap base grease

on the clutch cable end and hot start-

er cable end.

13. Adjust:

• Clutch lever free play

Refer to "ADJUSTING THE

CLUTCH CABLE FREE PLAY"

section in the CHAPTER 3.

• Hot starter lever free play

Refer to "ADJUSTING THE HOT

STARTER LEVER FREE PLAY"

section in the CHAPTER 3.

Page 167 of 198

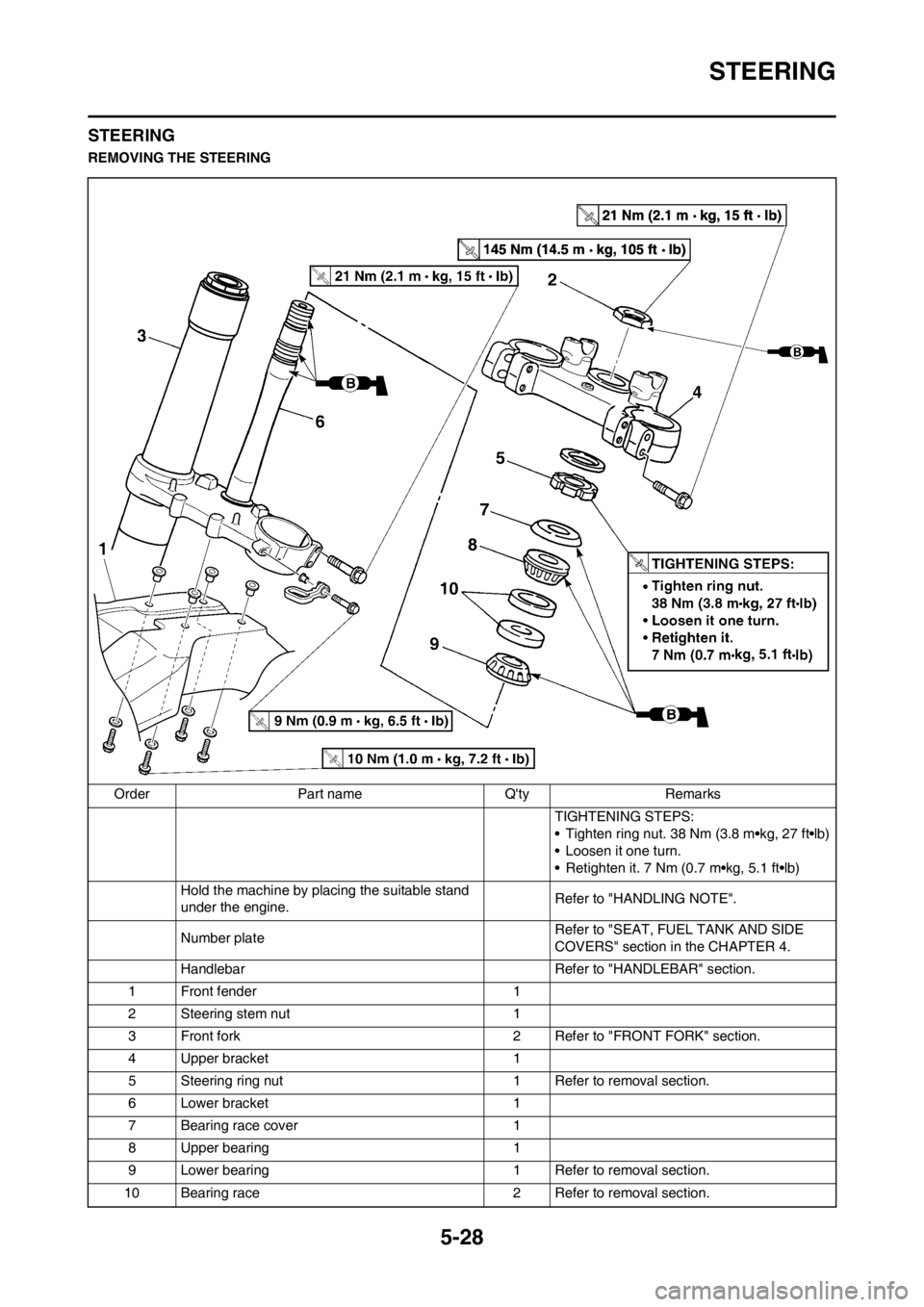

5-28

STEERING

STEERING

REMOVING THE STEERING

Order Part name Q'ty Remarks

TIGHTENING STEPS:

• Tighten ring nut. 38 Nm (3.8 m•kg, 27 ft•lb)

• Loosen it one turn.

• Retighten it. 7 Nm (0.7 m•kg, 5.1 ft•lb)

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Number plateRefer to "SEAT, FUEL TANK AND SIDE

COVERS" section in the CHAPTER 4.

Handlebar Refer to "HANDLEBAR" section.

1 Front fender 1

2 Steering stem nut 1

3 Front fork 2 Refer to "FRONT FORK" section.

4 Upper bracket 1

5 Steering ring nut 1 Refer to removal section.

6 Lower bracket 1

7 Bearing race cover 1

8 Upper bearing 1

9 Lower bearing 1 Refer to removal section.

10 Bearing race 2 Refer to removal section.

Page 168 of 198

5-29

STEERING

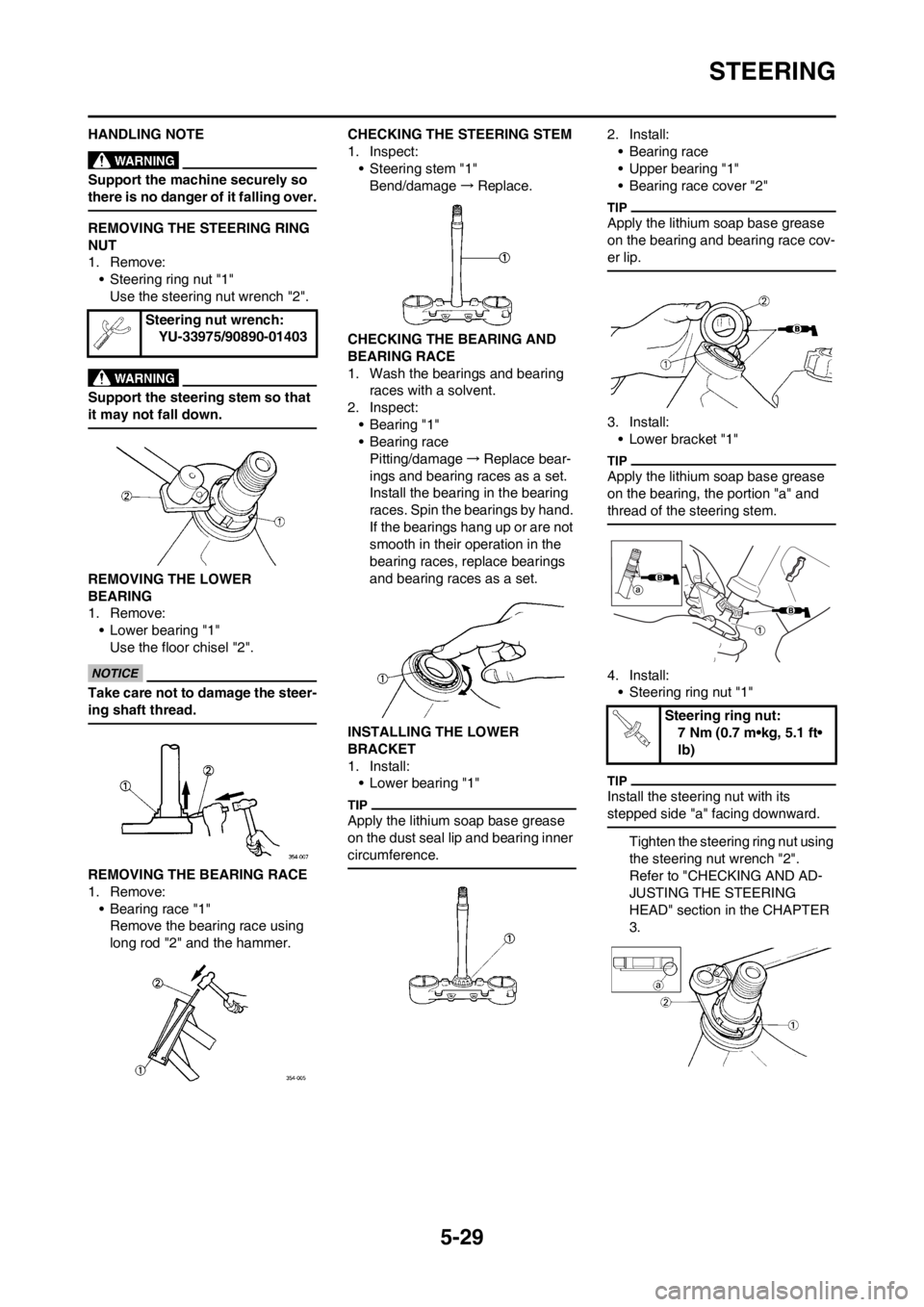

HANDLING NOTE

Support the machine securely so

there is no danger of it falling over.

REMOVING THE STEERING RING

NUT

1. Remove:

• Steering ring nut "1"

Use the steering nut wrench "2".

Support the steering stem so that

it may not fall down.

REMOVING THE LOWER

BEARING

1. Remove:

• Lower bearing "1"

Use the floor chisel "2".

Take care not to damage the steer-

ing shaft thread.

REMOVING THE BEARING RACE

1. Remove:

• Bearing race "1"

Remove the bearing race using

long rod "2" and the hammer.CHECKING THE STEERING STEM

1. Inspect:

• Steering stem "1"

Bend/damage→Replace.

CHECKING THE BEARING AND

BEARING RACE

1. Wash the bearings and bearing

races with a solvent.

2. Inspect:

•Bearing "1"

• Bearing race

Pitting/damage→Replace bear-

ings and bearing races as a set.

Install the bearing in the bearing

races. Spin the bearings by hand.

If the bearings hang up or are not

smooth in their operation in the

bearing races, replace bearings

and bearing races as a set.

INSTALLING THE LOWER

BRACKET

1. Install:

• Lower bearing "1"

Apply the lithium soap base grease

on the dust seal lip and bearing inner

circumference.

2. Install:

• Bearing race

• Upper bearing "1"

• Bearing race cover "2"

Apply the lithium soap base grease

on the bearing and bearing race cov-

er lip.

3. Install:

• Lower bracket "1"

Apply the lithium soap base grease

on the bearing, the portion "a" and

thread of the steering stem.

4. Install:

• Steering ring nut "1"

Install the steering nut with its

stepped side "a" facing downward.

Tighten the steering ring nut using

the steering nut wrench "2".

Refer to "CHECKING AND AD-

JUSTING THE STEERING

HEAD" section in the CHAPTER

3. Steering nut wrench:

YU-33975/90890-01403

Steering ring nut:

7 Nm (0.7 m•kg, 5.1 ft•

lb)

Page 169 of 198

5-30

STEERING

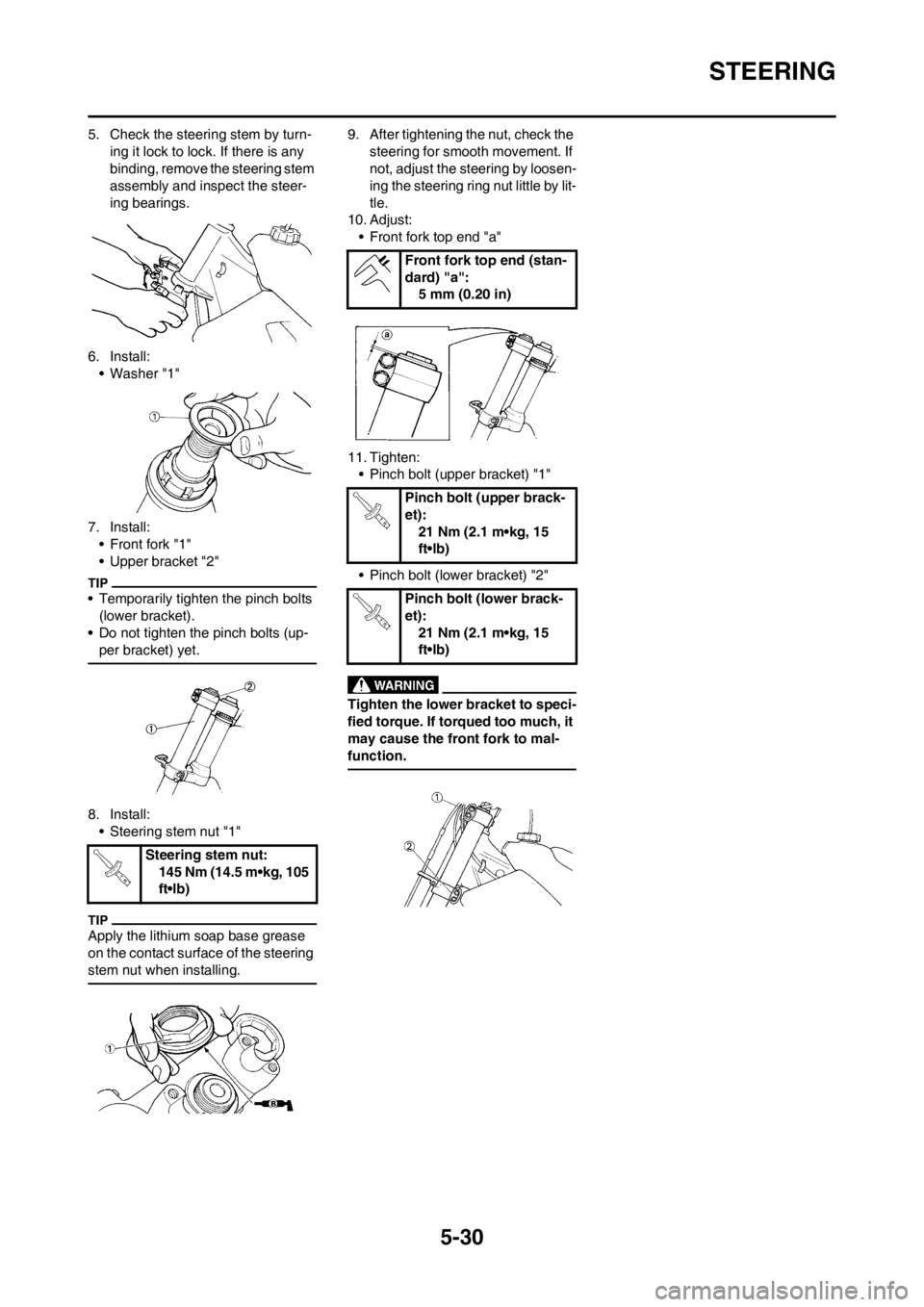

5. Check the steering stem by turn-

ing it lock to lock. If there is any

binding, remove the steering stem

assembly and inspect the steer-

ing bearings.

6. Install:

• Washer "1"

7. Install:

• Front fork "1"

• Upper bracket "2"

• Temporarily tighten the pinch bolts

(lower bracket).

• Do not tighten the pinch bolts (up-

per bracket) yet.

8. Install:

• Steering stem nut "1"

Apply the lithium soap base grease

on the contact surface of the steering

stem nut when installing.

9. After tightening the nut, check the

steering for smooth movement. If

not, adjust the steering by loosen-

ing the steering ring nut little by lit-

tle.

10. Adjust:

• Front fork top end "a"

11. Tighten:

• Pinch bolt (upper bracket) "1"

• Pinch bolt (lower bracket) "2"

Tighten the lower bracket to speci-

fied torque. If torqued too much, it

may cause the front fork to mal-

function.

Steering stem nut:

145 Nm (14.5 m•kg, 105

ft•lb)

Front fork top end (stan-

dard) "a":

5 mm (0.20 in)

Pinch bolt (upper brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Pinch bolt (lower brack-

et):

21 Nm (2.1 m•kg, 15

ft•lb)

Page 170 of 198

5-31

SWINGARM

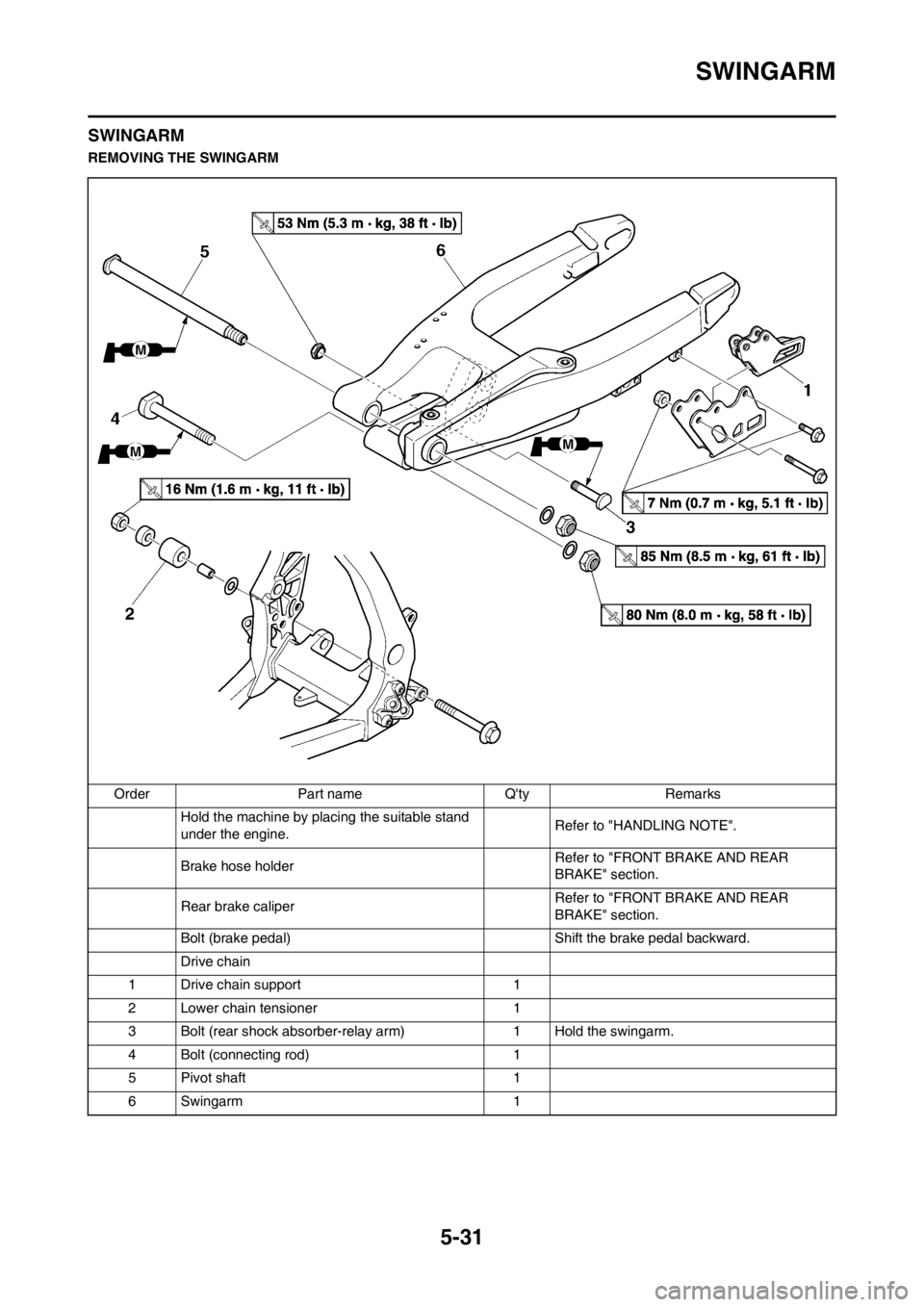

SWINGARM

REMOVING THE SWINGARM

Order Part name Q'ty Remarks

Hold the machine by placing the suitable stand

under the engine.Refer to "HANDLING NOTE".

Brake hose holder Refer to "FRONT BRAKE AND REAR

BRAKE" section.

Rear brake caliperRefer to "FRONT BRAKE AND REAR

BRAKE" section.

Bolt (brake pedal) Shift the brake pedal backward.

Drive chain

1 Drive chain support 1

2 Lower chain tensioner 1

3 Bolt (rear shock absorber-relay arm) 1 Hold the swingarm.

4 Bolt (connecting rod) 1

5 Pivot shaft 1

6 Swingarm 1