check oil YAMAHA YZ250F 2012 Owner's Manual

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ250F, Model: YAMAHA YZ250F 2012Pages: 198, PDF Size: 11.78 MB

Page 69 of 198

3-19

CHASSIS

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

2. Adjust:

• Compression damping force

By turning the adjuster "1".

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Swingarm smooth action

Abnormal noise/unsmooth action

→Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage→Replace.ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Remove:

• Rear frame

3. Measure:

• Spring fitting length

The I.D. mark "a" is marked at the end

of the spring.

4. Adjust:

• Spring preload

Adjustment steps:

a. Loosen the locknut "1".

b. Loosen the adjuster "2" until there

is some clearance between the

spring and adjuster.

c. Measure the spring free length

"a".

d. Turn the adjuster "2".

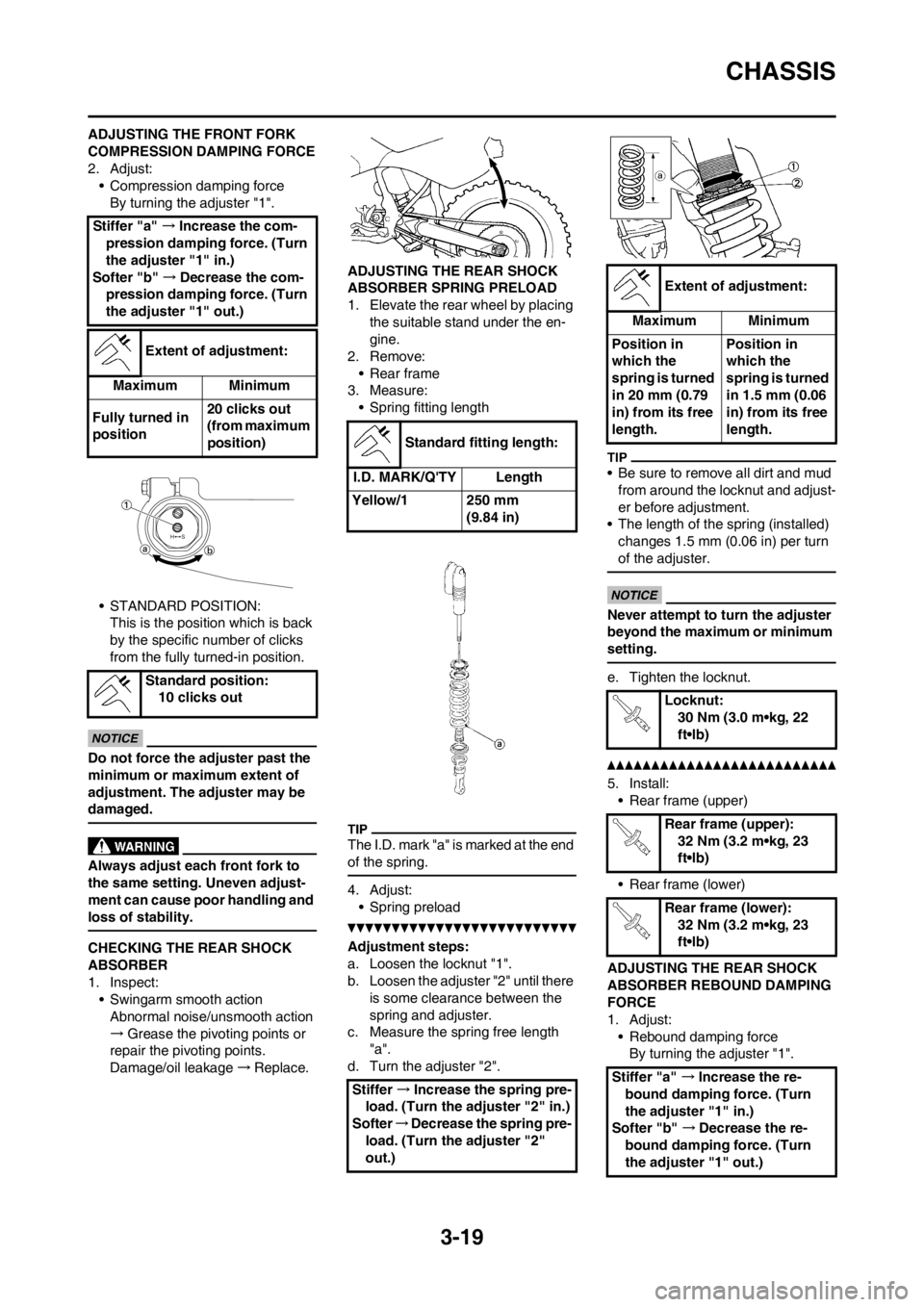

• Be sure to remove all dirt and mud

from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed)

changes 1.5 mm (0.06 in) per turn

of the adjuster.

Never attempt to turn the adjuster

beyond the maximum or minimum

setting.

e. Tighten the locknut.

5. Install:

• Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1". Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

10 clicks out

Standard fitting length:

I.D. MARK/Q'TY Length

Yellow/1 250 mm

(9.84 in)

Stiffer →Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer→Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Extent of adjustment:

Maximum Minimum

Position in

which the

spring is turned

in 20 mm (0.79

in) from its free

length.Position in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length.

Locknut:

30 Nm (3.0 m•kg, 22

ft•lb)

Rear frame (upper):

32 Nm (3.2 m•kg, 23

ft•lb)

Rear frame (lower):

32 Nm (3.2 m•kg, 23

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Page 74 of 198

3-24

ELECTRICAL

ELECTRICAL

CHECKING THE SPARK PLUG

1. Remove:

• Spark plug

2. Inspect:

• Electrode "1"

Wear/damage→Replace.

• Insulator color "2"

Normal condition is a medium to

light tan color.

Distinctly different color→Check

the engine condition.

When the engine runs for many hours

at low speeds, the spark plug insula-

tor will become sooty, even if the en-

gine and carburetor are in good

operating condition.

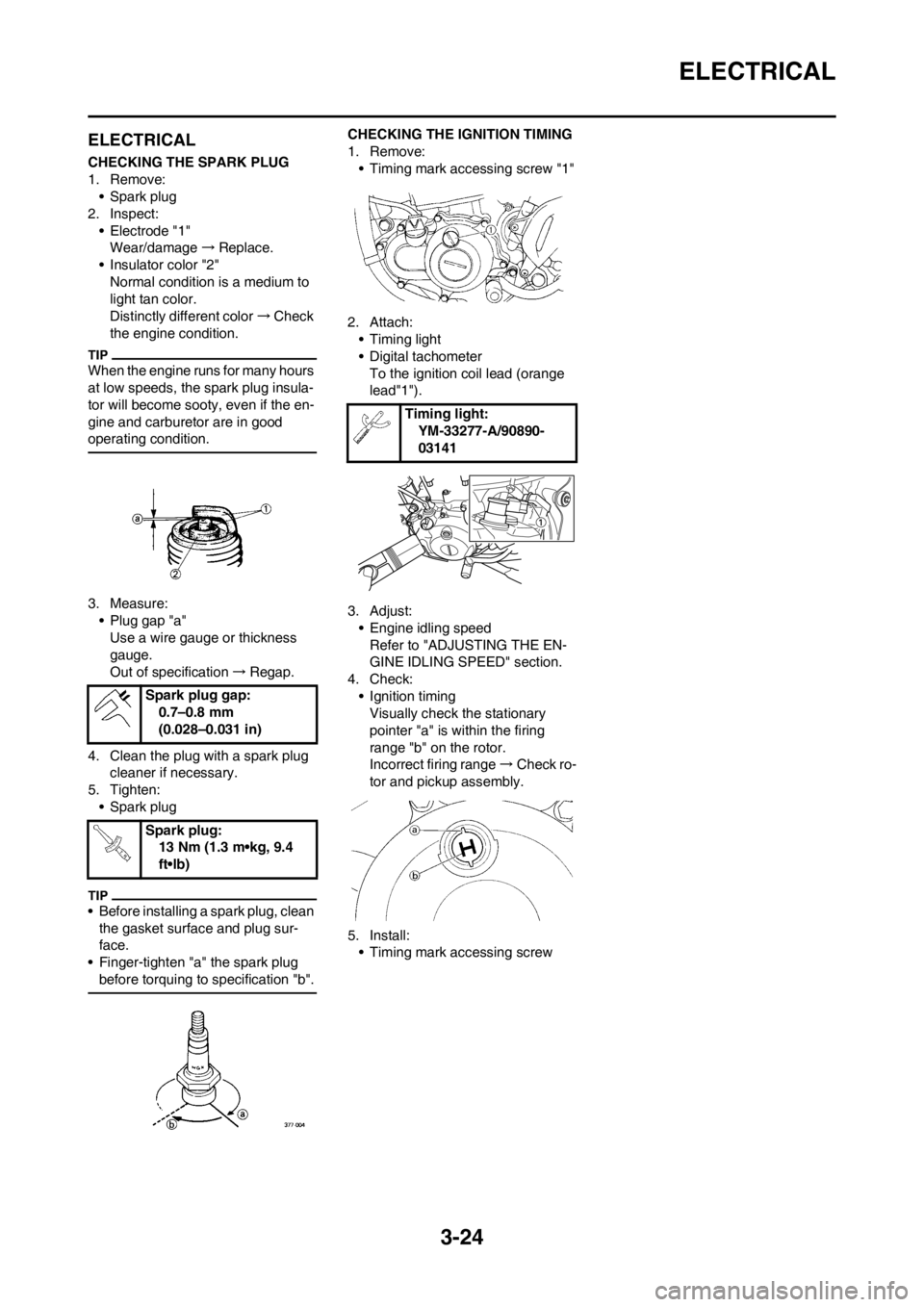

3. Measure:

• Plug gap "a"

Use a wire gauge or thickness

gauge.

Out of specification→Regap.

4. Clean the plug with a spark plug

cleaner if necessary.

5. Tighten:

• Spark plug

• Before installing a spark plug, clean

the gasket surface and plug sur-

face.

• Finger-tighten "a" the spark plug

before torquing to specification "b".

CHECKING THE IGNITION TIMING

1. Remove:

• Timing mark accessing screw "1"

2. Attach:

• Timing light

• Digital tachometer

To the ignition coil lead (orange

lead"1").

3. Adjust:

• Engine idling speed

Refer to "ADJUSTING THE EN-

GINE IDLING SPEED" section.

4. Check:

• Ignition timing

Visually check the stationary

pointer "a" is within the firing

range "b" on the rotor.

Incorrect firing range→Check ro-

tor and pickup assembly.

5. Install:

• Timing mark accessing screw Spark plug gap:

0.7–0.8 mm

(0.028–0.031 in)

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Timing light:

YM-33277-A/90890-

03141

Page 93 of 198

4-19

CAMSHAFTS

4. Measure:

• Camshaft-to-cap clearance

Out of specification→Measure

camshaft outside diameter.

Measurement steps:

a. Install the camshaft onto the cylin-

der head.

b. Position a strip of Plastigauge

®

"1" onto the camshaft.

c. Install the clip, dowel pins and

camshaft caps.

• Tighten the bolts (camshaft cap) in

a crisscross pattern from innermost

to outer caps.

• Do not turn the camshaft when

measuring clearance with the

Plastigauge

®.

d. Remove the camshaft caps and

measure the width of the Plasti-

gauge

® "1".

5. Measure:

• Camshaft outside diameter "a"

Out of specification→Replace the

camshaft.

Within specification→Replace

camshaft case and camshaft

caps as a set.CHECKING THE CAMSHAFT

SPROCKET

1. Inspect:

• Camshaft sprocket "1"

Wear/damage→Replace the

camshaft assembly and timing

chain as a set.

CHECKING THE

DECOMPRESSION SYSTEM

1. Check:

• Decompression system

Checking steps:

a. Check that the decompression

mechanism cam "1" moves

smoothly.

b. Check that the decompression

mechanism cam lever pin "2" proj-

ects from the camshaft.

CHECKING THE TIMING CHAIN

TENSIONER

1. Check:

• While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver "1" and wind the ten-

sioner rod up fully clockwise.

• When releasing the screwdriver

by pressing lightly with fingers,

make sure that the tensioner rod

will come out smoothly.

• If not, replace the tensioner as-

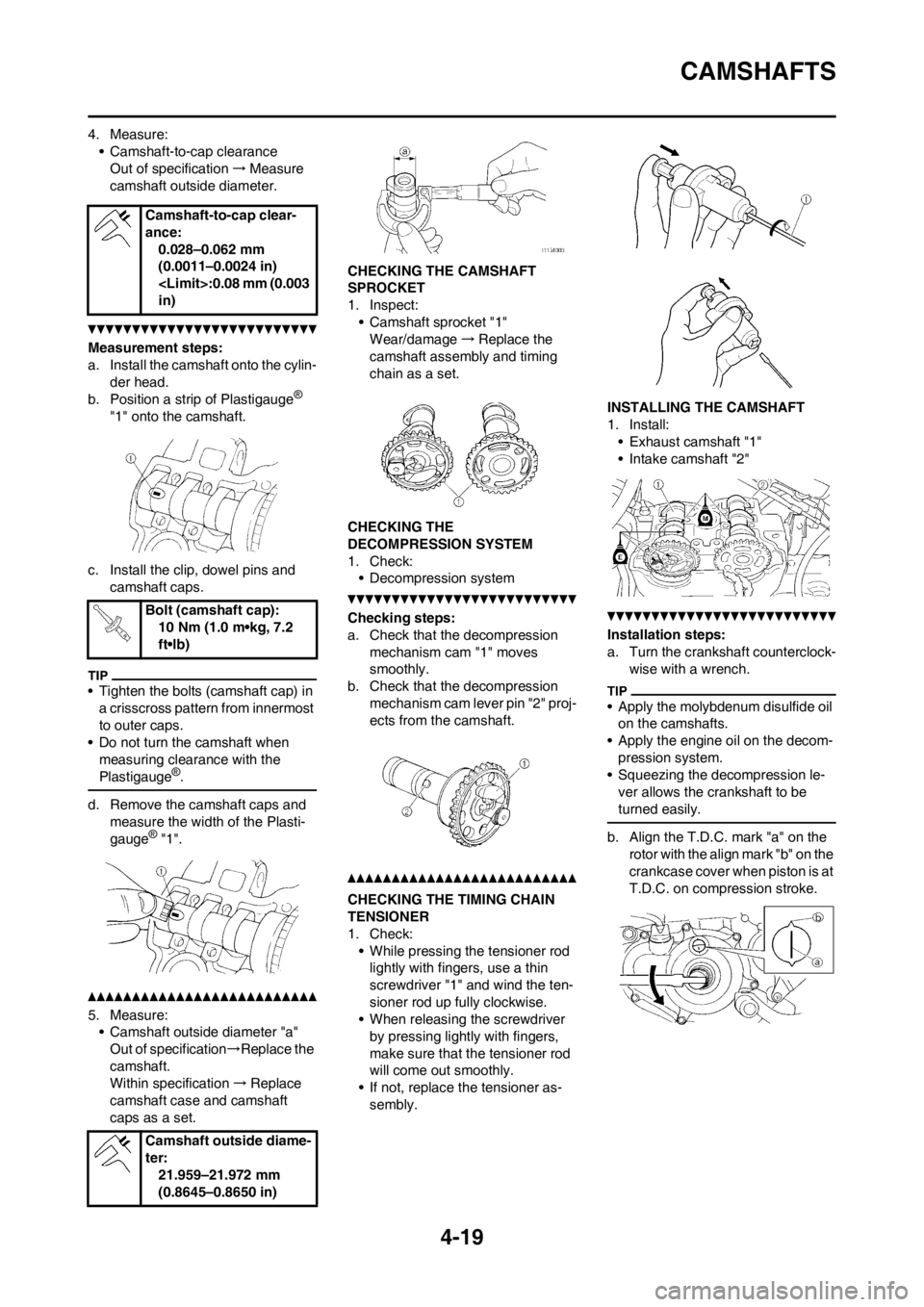

sembly.INSTALLING THE CAMSHAFT

1. Install:

• Exhaust camshaft "1"

• Intake camshaft "2"

Installation steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

• Apply the molybdenum disulfide oil

on the camshafts.

• Apply the engine oil on the decom-

pression system.

• Squeezing the decompression le-

ver allows the crankshaft to be

turned easily.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke. Camshaft-to-cap clear-

ance:

0.028–0.062 mm

(0.0011–0.0024 in)

in)

Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Camshaft outside diame-

ter:

21.959–21.972 mm

(0.8645–0.8650 in)

Page 94 of 198

4-20

CAMSHAFTS

c. Fit the timing chain "3" onto both

camshaft sprockets and install the

camshafts on the cylinder head.

The camshafts should be installed

onto the cylinder head so that the

punch mark "c" on the exhaust cam-

shaft and the punch mark "d" on the

intake camshaft must align with the

cylinder head surface, as shown in

the illustration.

Do not turn the crankshaft during

the camshaft installation. Damage

or improper valve timing will re-

sult.

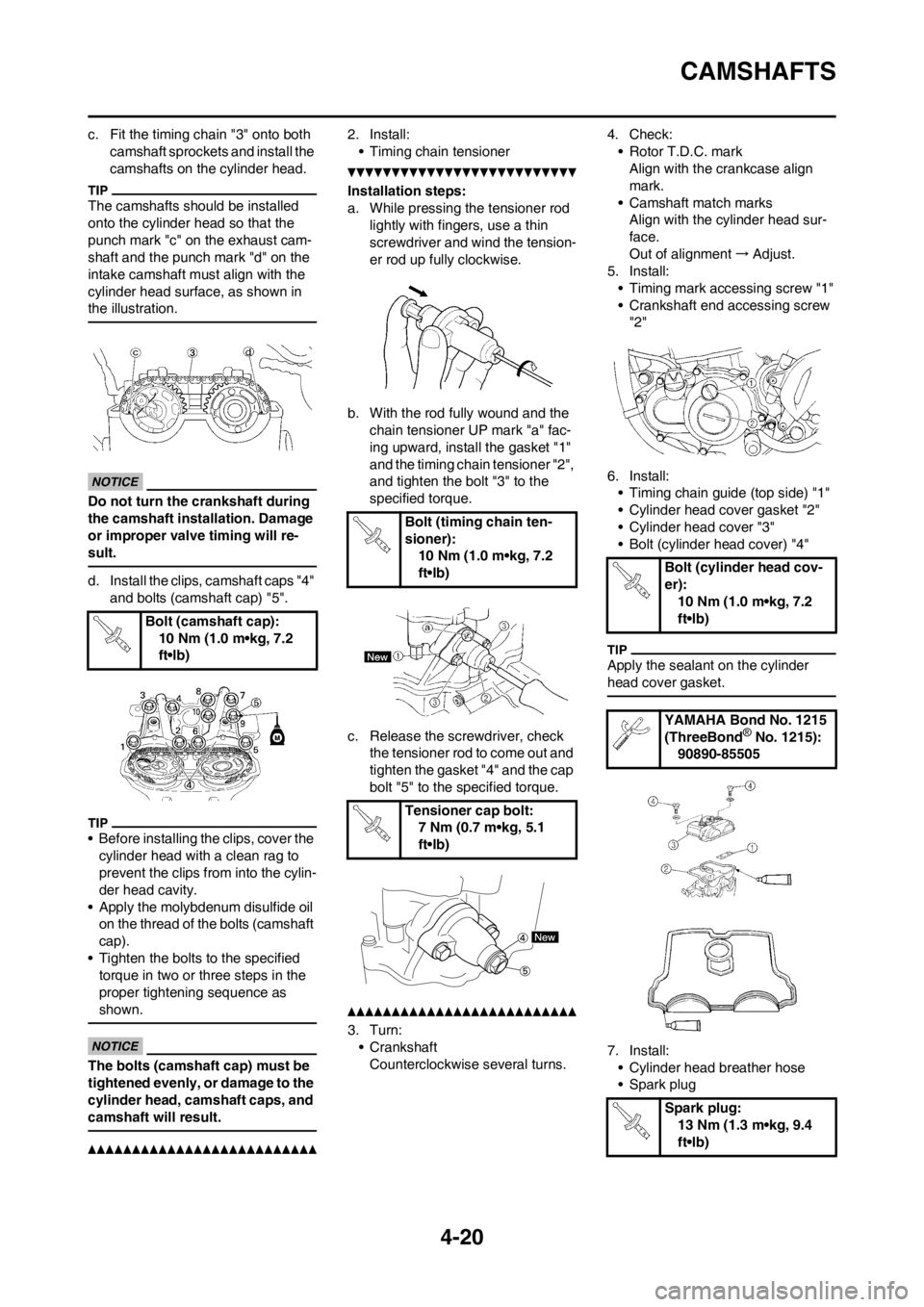

d. Install the clips, camshaft caps "4"

and bolts (camshaft cap) "5".

• Before installing the clips, cover the

cylinder head with a clean rag to

prevent the clips from into the cylin-

der head cavity.

• Apply the molybdenum disulfide oil

on the thread of the bolts (camshaft

cap).

• Tighten the bolts to the specified

torque in two or three steps in the

proper tightening sequence as

shown.

The bolts (camshaft cap) must be

tightened evenly, or damage to the

cylinder head, camshaft caps, and

camshaft will result.

2. Install:

• Timing chain tensioner

Installation steps:

a. While pressing the tensioner rod

lightly with fingers, use a thin

screwdriver and wind the tension-

er rod up fully clockwise.

b. With the rod fully wound and the

chain tensioner UP mark "a" fac-

ing upward, install the gasket "1"

and the timing chain tensioner "2",

and tighten the bolt "3" to the

specified torque.

c. Release the screwdriver, check

the tensioner rod to come out and

tighten the gasket "4" and the cap

bolt "5" to the specified torque.

3. Turn:

• Crankshaft

Counterclockwise several turns.4. Check:

• Rotor T.D.C. mark

Align with the crankcase align

mark.

• Camshaft match marks

Align with the cylinder head sur-

face.

Out of alignment→Adjust.

5. Install:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

6. Install:

• Timing chain guide (top side) "1"

• Cylinder head cover gasket "2"

• Cylinder head cover "3"

• Bolt (cylinder head cover) "4"

Apply the sealant on the cylinder

head cover gasket.

7. Install:

• Cylinder head breather hose

• Spark plug Bolt (camshaft cap):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Bolt (timing chain ten-

sioner):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Tensioner cap bolt:

7 Nm (0.7 m•kg, 5.1

ft•lb)

Bolt (cylinder head cov-

er):

10 Nm (1.0 m•kg, 7.2

ft•lb)

YAMAHA Bond No. 1215

(ThreeBond

® No. 1215):

90890-85505

Spark plug:

13 Nm (1.3 m•kg, 9.4

ft•lb)

Page 96 of 198

4-22

CYLINDER HEAD

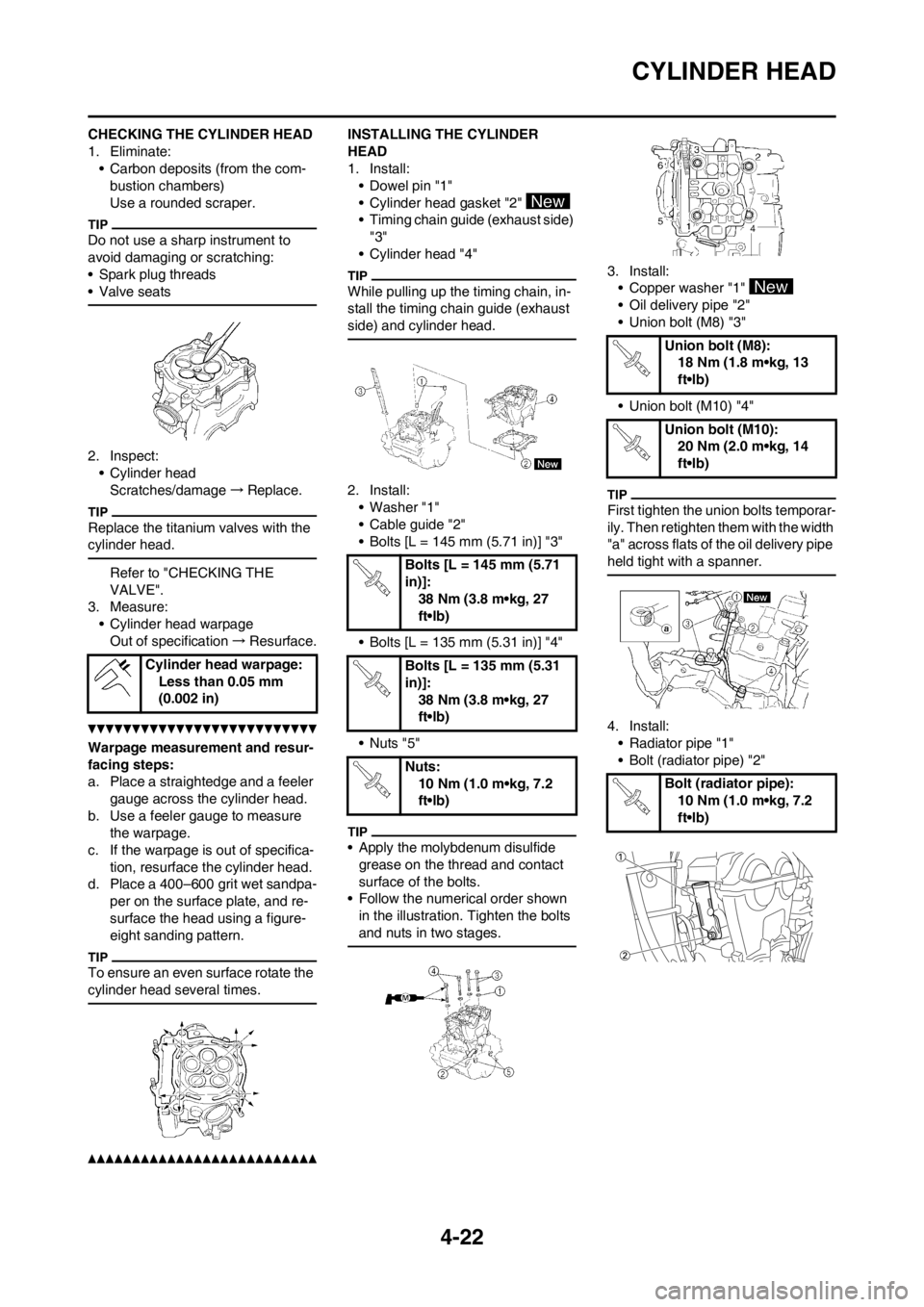

CHECKING THE CYLINDER HEAD

1. Eliminate:

• Carbon deposits (from the com-

bustion chambers)

Use a rounded scraper.

Do not use a sharp instrument to

avoid damaging or scratching:

• Spark plug threads

• Valve seats

2. Inspect:

• Cylinder head

Scratches/damage→Replace.

Replace the titanium valves with the

cylinder head.

Refer to "CHECKING THE

VALVE".

3. Measure:

• Cylinder head warpage

Out of specification→Resurface.

Warpage measurement and resur-

facing steps:

a. Place a straightedge and a feeler

gauge across the cylinder head.

b. Use a feeler gauge to measure

the warpage.

c. If the warpage is out of specifica-

tion, resurface the cylinder head.

d. Place a 400–600 grit wet sandpa-

per on the surface plate, and re-

surface the head using a figure-

eight sanding pattern.

To ensure an even surface rotate the

cylinder head several times.

INSTALLING THE CYLINDER

HEAD

1. Install:

• Dowel pin "1"

• Cylinder head gasket "2"

• Timing chain guide (exhaust side)

"3"

• Cylinder head "4"

While pulling up the timing chain, in-

stall the timing chain guide (exhaust

side) and cylinder head.

2. Install:

• Washer "1"

• Cable guide "2"

• Bolts [L = 145 mm (5.71 in)] "3"

• Bolts [L = 135 mm (5.31 in)] "4"

•Nuts "5"

• Apply the molybdenum disulfide

grease on the thread and contact

surface of the bolts.

• Follow the numerical order shown

in the illustration. Tighten the bolts

and nuts in two stages.

3. Install:

• Copper washer "1"

• Oil delivery pipe "2"

• Union bolt (M8) "3"

• Union bolt (M10) "4"

First tighten the union bolts temporar-

ily. Then retighten them with the width

"a" across flats of the oil delivery pipe

held tight with a spanner.

4. Install:

• Radiator pipe "1"

• Bolt (radiator pipe) "2" Cylinder head warpage:

Less than 0.05 mm

(0.002 in)

Bolts [L = 145 mm (5.71

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Bolts [L = 135 mm (5.31

in)]:

38 Nm (3.8 m•kg, 27

ft•lb)

Nuts:

10 Nm (1.0 m•kg, 7.2

ft•lb)

Union bolt (M8):

18 Nm (1.8 m•kg, 13

ft•lb)

Union bolt (M10):

20 Nm (2.0 m•kg, 14

ft•lb)

Bolt (radiator pipe):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 100 of 198

4-26

VALVES AND VALVE SPRINGS

h. Press the valve through the valve

guide and onto the valve seat to

make a clear pattern.

i. Measure the valve seat width

again. If the valve seat width is out

of specification, reface and relap

the valve seat.

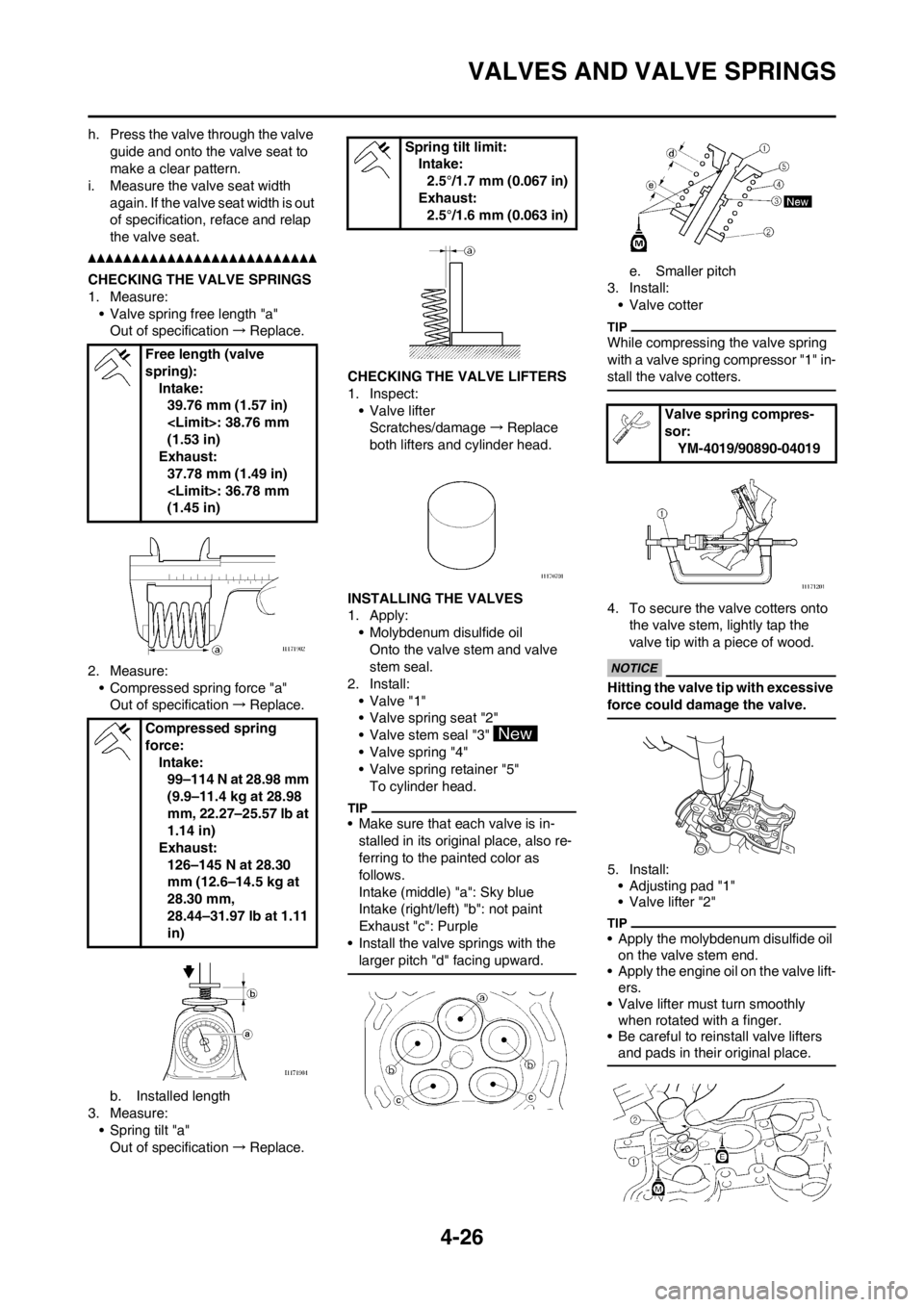

CHECKING THE VALVE SPRINGS

1. Measure:

• Valve spring free length "a"

Out of specification→Replace.

2. Measure:

• Compressed spring force "a"

Out of specification→Replace.

b. Installed length

3. Measure:

• Spring tilt "a"

Out of specification→Replace.CHECKING THE VALVE LIFTERS

1. Inspect:

• Valve lifter

Scratches/damage→Replace

both lifters and cylinder head.

INSTALLING THE VALVES

1. Apply:

• Molybdenum disulfide oil

Onto the valve stem and valve

stem seal.

2. Install:

• Valve "1"

• Valve spring seat "2"

• Valve stem seal "3"

• Valve spring "4"

• Valve spring retainer "5"

To cylinder head.

• Make sure that each valve is in-

stalled in its original place, also re-

ferring to the painted color as

follows.

Intake (middle) "a": Sky blue

Intake (right/left) "b": not paint

Exhaust "c": Purple

• Install the valve springs with the

larger pitch "d" facing upward.

e. Smaller pitch

3. Install:

• Valve cotter

While compressing the valve spring

with a valve spring compressor "1" in-

stall the valve cotters.

4. To secure the valve cotters onto

the valve stem, lightly tap the

valve tip with a piece of wood.

Hitting the valve tip with excessive

force could damage the valve.

5. Install:

• Adjusting pad "1"

• Valve lifter "2"

• Apply the molybdenum disulfide oil

on the valve stem end.

• Apply the engine oil on the valve lift-

ers.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

Free length (valve

spring):

Intake:

39.76 mm (1.57 in)

(1.53 in)

Exhaust:

37.78 mm (1.49 in)

(1.45 in)

Compressed spring

force:

Intake:

99–114 N at 28.98 mm

(9.9–11.4 kg at 28.98

mm, 22.27–25.57 lb at

1.14 in)

Exhaust:

126–145 N at 28.30

mm (12.6–14.5 kg at

28.30 mm,

28.44–31.97 lb at 1.11

in)

Spring tilt limit:

Intake:

2.5°/1.7 mm (0.067 in)

Exhaust:

2.5°/1.6 mm (0.063 in)

Valve spring compres-

sor:

YM-4019/90890-04019

Page 103 of 198

4-29

CYLINDER AND PISTON

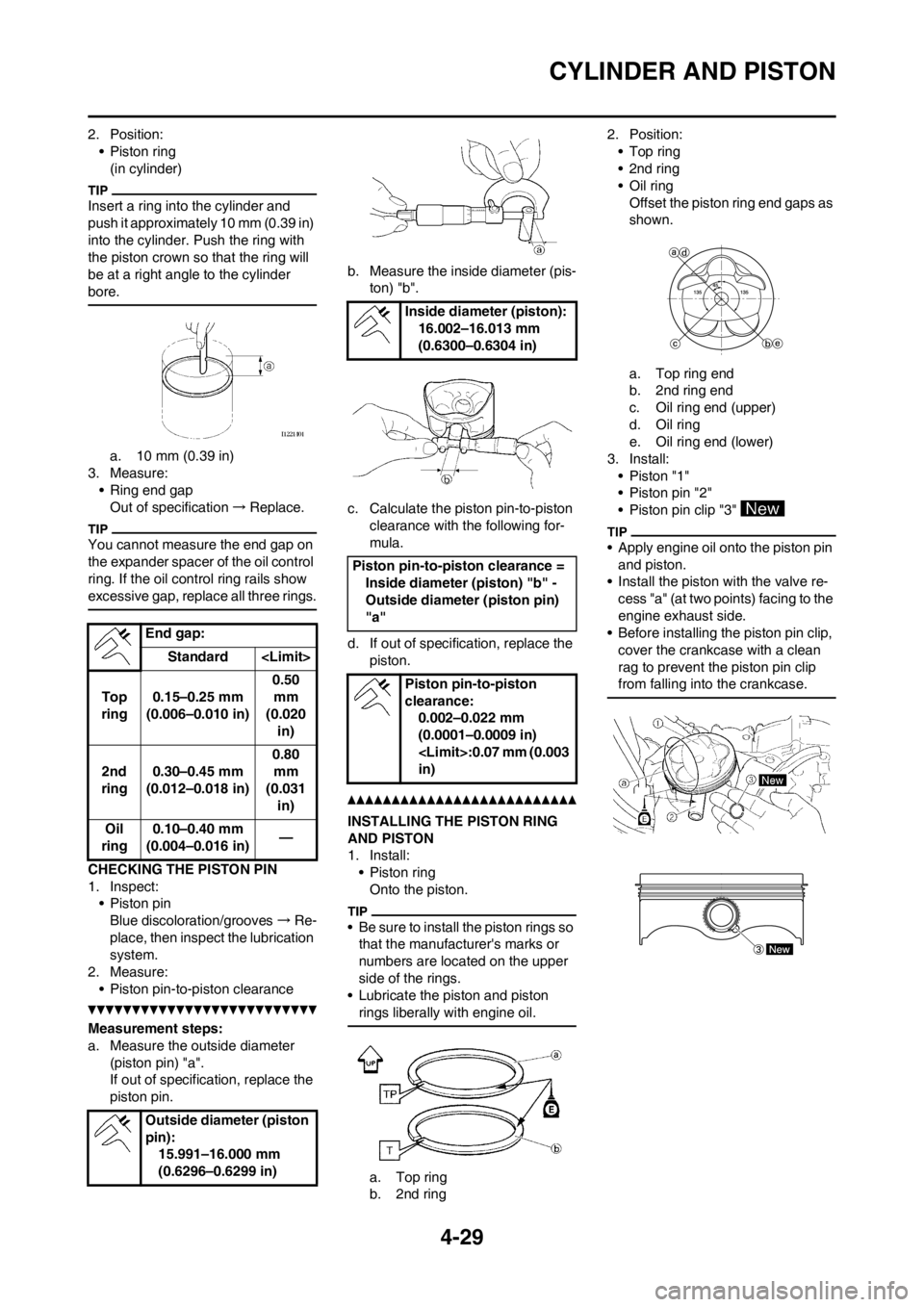

2. Position:

• Piston ring

(in cylinder)

Insert a ring into the cylinder and

push it approximately 10 mm (0.39 in)

into the cylinder. Push the ring with

the piston crown so that the ring will

be at a right angle to the cylinder

bore.

a. 10 mm (0.39 in)

3. Measure:

• Ring end gap

Out of specification→Replace.

You cannot measure the end gap on

the expander spacer of the oil control

ring. If the oil control ring rails show

excessive gap, replace all three rings.

CHECKING THE PISTON PIN

1. Inspect:

• Piston pin

Blue discoloration/grooves→Re-

place, then inspect the lubrication

system.

2. Measure:

• Piston pin-to-piston clearance

Measurement steps:

a. Measure the outside diameter

(piston pin) "a".

If out of specification, replace the

piston pin.b. Measure the inside diameter (pis-

ton) "b".

c. Calculate the piston pin-to-piston

clearance with the following for-

mula.

d. If out of specification, replace the

piston.

INSTALLING THE PISTON RING

AND PISTON

1. Install:

•Piston ring

Onto the piston.

• Be sure to install the piston rings so

that the manufacturer's marks or

numbers are located on the upper

side of the rings.

• Lubricate the piston and piston

rings liberally with engine oil.

a. Top ring

b. 2nd ring2. Position:

•Top ring

•2nd ring

•Oil ring

Offset the piston ring end gaps as

shown.

a. Top ring end

b. 2nd ring end

c. Oil ring end (upper)

d. Oil ring

e. Oil ring end (lower)

3. Install:

• Piston "1"

• Piston pin "2"

• Piston pin clip "3"

• Apply engine oil onto the piston pin

and piston.

• Install the piston with the valve re-

cess "a" (at two points) facing to the

engine exhaust side.

• Before installing the piston pin clip,

cover the crankcase with a clean

rag to prevent the piston pin clip

from falling into the crankcase.

End gap:

Standard

Top

ring0.15–0.25 mm

(0.006–0.010 in)0.50

mm

(0.020

in)

2nd

ring0.30–0.45 mm

(0.012–0.018 in)0.80

mm

(0.031

in)

Oil

ring0.10–0.40 mm

(0.004–0.016 in)—

Outside diameter (piston

pin):

15.991–16.000 mm

(0.6296–0.6299 in)

Inside diameter (piston):

16.002–16.013 mm

(0.6300–0.6304 in)

Piston pin-to-piston clearance =

Inside diameter (piston) "b" -

Outside diameter (piston pin)

"a"

Piston pin-to-piston

clearance:

0.002–0.022 mm

(0.0001–0.0009 in)

in)

Page 107 of 198

4-33

CLUTCH

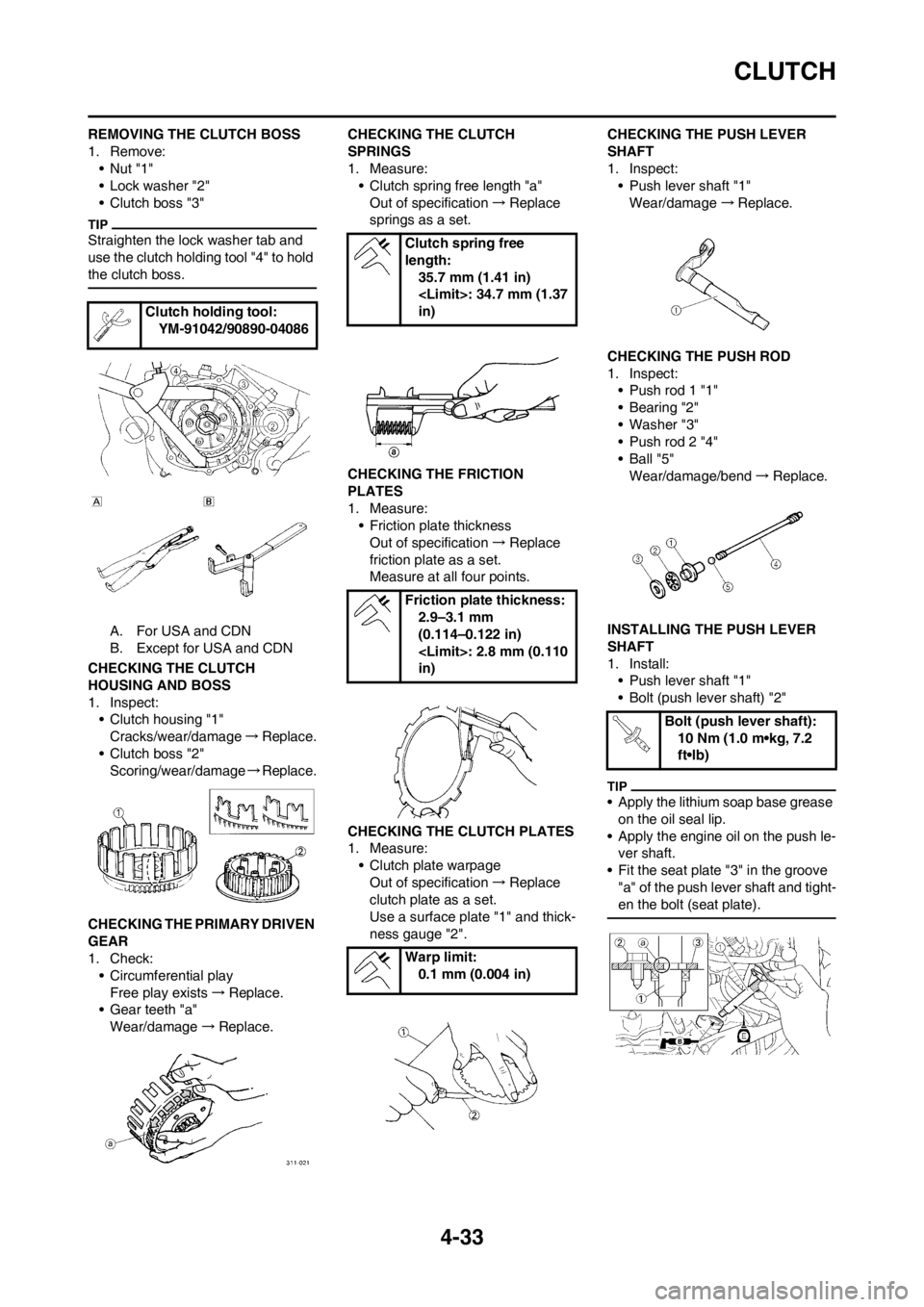

REMOVING THE CLUTCH BOSS

1. Remove:

•Nut "1"

• Lock washer "2"

• Clutch boss "3"

Straighten the lock washer tab and

use the clutch holding tool "4" to hold

the clutch boss.

A. For USA and CDN

B. Except for USA and CDN

CHECKING THE CLUTCH

HOUSING AND BOSS

1. Inspect:

• Clutch housing "1"

Cracks/wear/damage→Replace.

• Clutch boss "2"

Scoring/wear/damage→Replace.

CHECKING THE PRIMARY DRIVEN

GEAR

1. Check:

• Circumferential play

Free play exists→Replace.

• Gear teeth "a"

Wear/damage→Replace.CHECKING THE CLUTCH

SPRINGS

1. Measure:

• Clutch spring free length "a"

Out of specification→Replace

springs as a set.

CHECKING THE FRICTION

PLATES

1. Measure:

• Friction plate thickness

Out of specification→Replace

friction plate as a set.

Measure at all four points.

CHECKING THE CLUTCH PLATES

1. Measure:

• Clutch plate warpage

Out of specification→Replace

clutch plate as a set.

Use a surface plate "1" and thick-

ness gauge "2".CHECKING THE PUSH LEVER

SHAFT

1. Inspect:

• Push lever shaft "1"

Wear/damage→Replace.

CHECKING THE PUSH ROD

1. Inspect:

• Push rod 1 "1"

• Bearing "2"

• Washer "3"

• Push rod 2 "4"

•Ball "5"

Wear/damage/bend→Replace.

INSTALLING THE PUSH LEVER

SHAFT

1. Install:

• Push lever shaft "1"

• Bolt (push lever shaft) "2"

• Apply the lithium soap base grease

on the oil seal lip.

• Apply the engine oil on the push le-

ver shaft.

• Fit the seat plate "3" in the groove

"a" of the push lever shaft and tight-

en the bolt (seat plate).

Clutch holding tool:

YM-91042/90890-04086

Clutch spring free

length:

35.7 mm (1.41 in)

in)

Friction plate thickness:

2.9–3.1 mm

(0.114–0.122 in)

in)

Warp limit:

0.1 mm (0.004 in)

Bolt (push lever shaft):

10 Nm (1.0 m•kg, 7.2

ft•lb)

Page 111 of 198

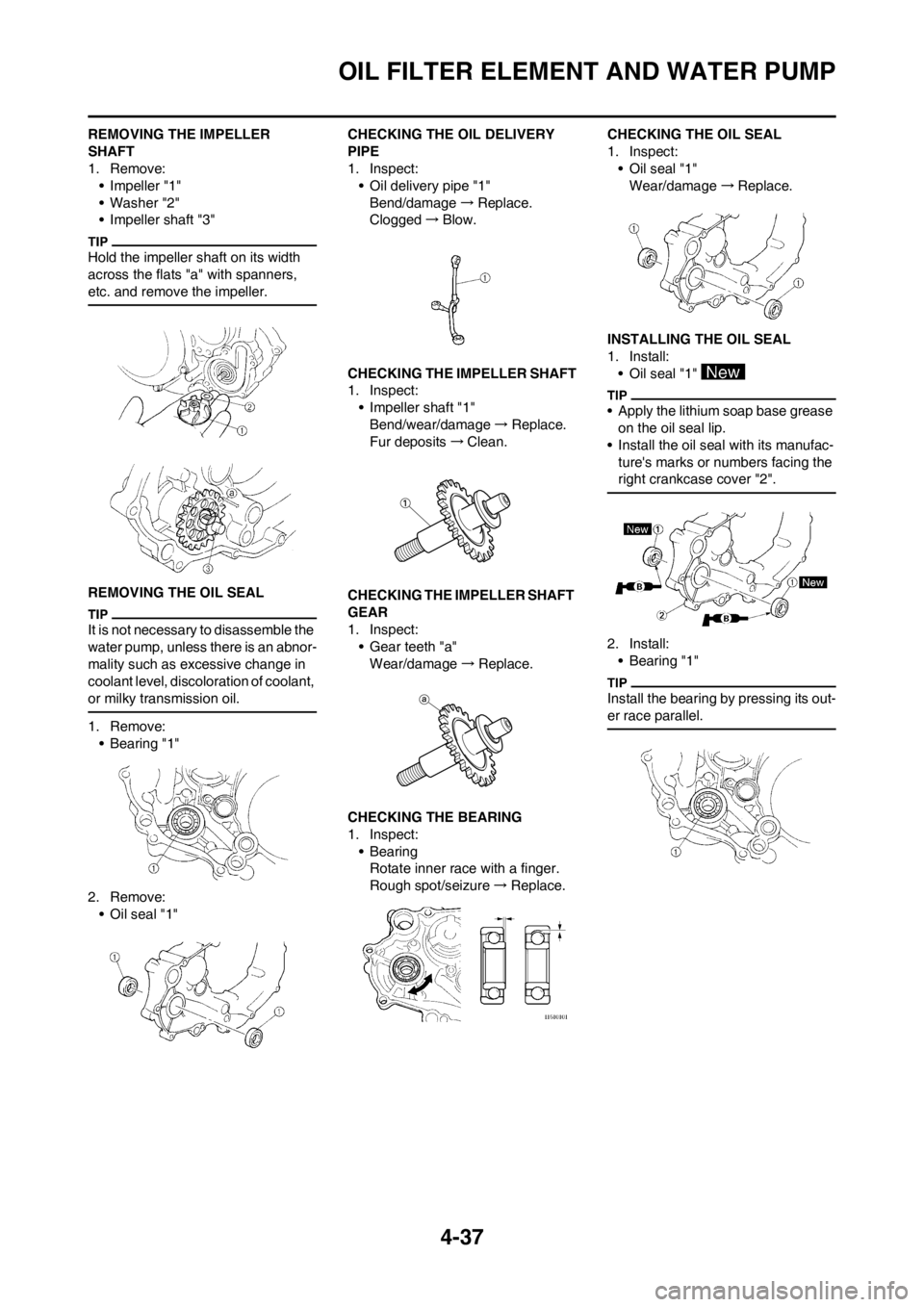

4-37

OIL FILTER ELEMENT AND WATER PUMP

REMOVING THE IMPELLER

SHAFT

1. Remove:

• Impeller "1"

• Washer "2"

• Impeller shaft "3"

Hold the impeller shaft on its width

across the flats "a" with spanners,

etc. and remove the impeller.

REMOVING THE OIL SEAL

It is not necessary to disassemble the

water pump, unless there is an abnor-

mality such as excessive change in

coolant level, discoloration of coolant,

or milky transmission oil.

1. Remove:

• Bearing "1"

2. Remove:

• Oil seal "1"CHECKING THE OIL DELIVERY

PIPE

1. Inspect:

• Oil delivery pipe "1"

Bend/damage→Replace.

Clogged→Blow.

CHECKING THE IMPELLER SHAFT

1. Inspect:

• Impeller shaft "1"

Bend/wear/damage→Replace.

Fur deposits→Clean.

CHECKING THE IMPELLER SHAFT

GEAR

1. Inspect:

• Gear teeth "a"

Wear/damage→Replace.

CHECKING THE BEARING

1. Inspect:

•Bearing

Rotate inner race with a finger.

Rough spot/seizure→Replace.CHECKING THE OIL SEAL

1. Inspect:

• Oil seal "1"

Wear/damage→Replace.

INSTALLING THE OIL SEAL

1. Install:

• Oil seal "1"

• Apply the lithium soap base grease

on the oil seal lip.

• Install the oil seal with its manufac-

ture's marks or numbers facing the

right crankcase cover "2".

2. Install:

• Bearing "1"

Install the bearing by pressing its out-

er race parallel.

Page 115 of 198

4-41

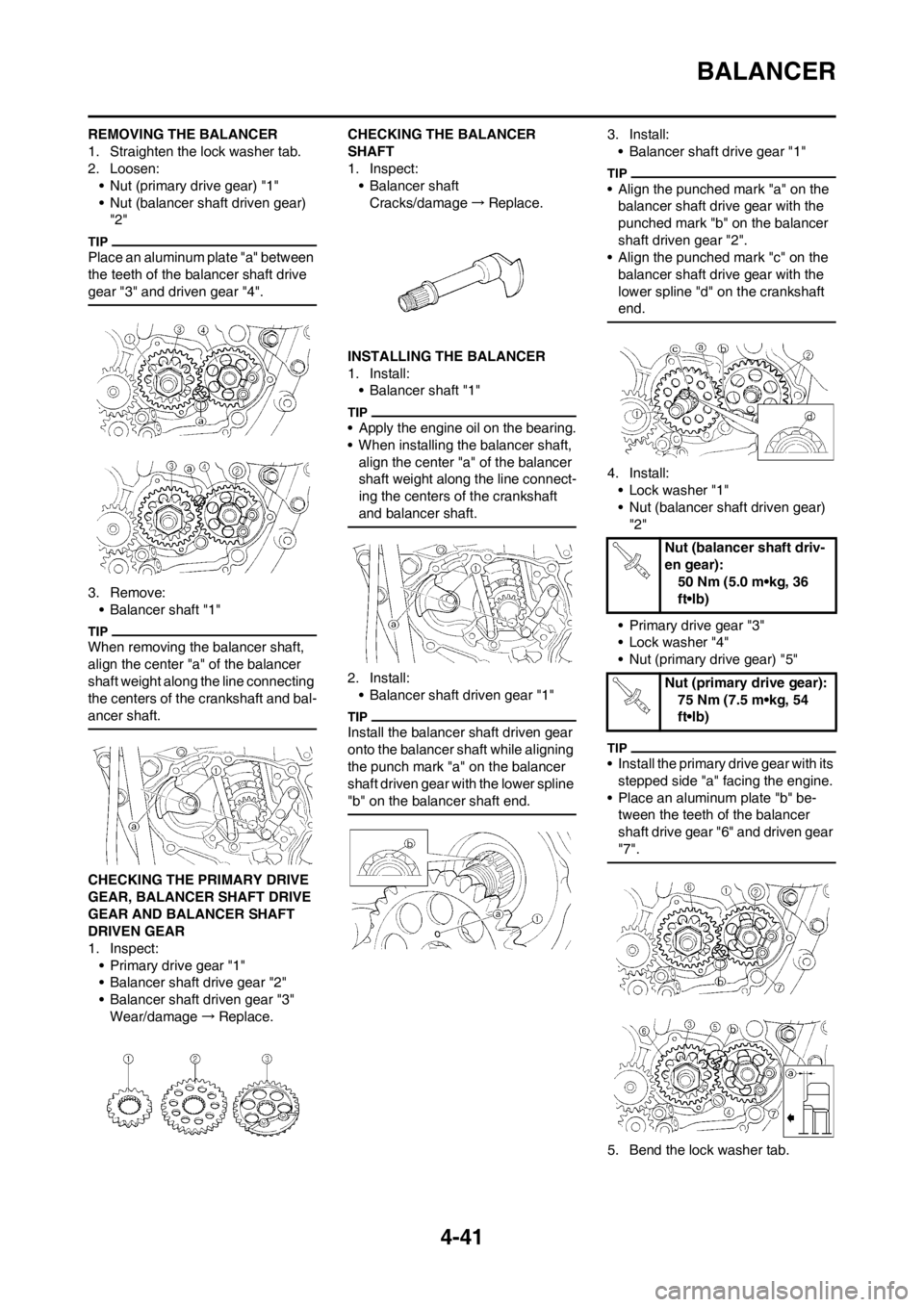

BALANCER

REMOVING THE BALANCER

1. Straighten the lock washer tab.

2. Loosen:

• Nut (primary drive gear) "1"

• Nut (balancer shaft driven gear)

"2"

Place an aluminum plate "a" between

the teeth of the balancer shaft drive

gear "3" and driven gear "4".

3. Remove:

• Balancer shaft "1"

When removing the balancer shaft,

align the center "a" of the balancer

shaft weight along the line connecting

the centers of the crankshaft and bal-

ancer shaft.

CHECKING THE PRIMARY DRIVE

GEAR, BALANCER SHAFT DRIVE

GEAR AND BALANCER SHAFT

DRIVEN GEAR

1. Inspect:

• Primary drive gear "1"

• Balancer shaft drive gear "2"

• Balancer shaft driven gear "3"

Wear/damage→Replace.CHECKING THE BALANCER

SHAFT

1. Inspect:

• Balancer shaft

Cracks/damage→Replace.

INSTALLING THE BALANCER

1. Install:

• Balancer shaft "1"

• Apply the engine oil on the bearing.

• When installing the balancer shaft,

align the center "a" of the balancer

shaft weight along the line connect-

ing the centers of the crankshaft

and balancer shaft.

2. Install:

• Balancer shaft driven gear "1"

Install the balancer shaft driven gear

onto the balancer shaft while aligning

the punch mark "a" on the balancer

shaft driven gear with the lower spline

"b" on the balancer shaft end.

3. Install:

• Balancer shaft drive gear "1"

• Align the punched mark "a" on the

balancer shaft drive gear with the

punched mark "b" on the balancer

shaft driven gear "2".

• Align the punched mark "c" on the

balancer shaft drive gear with the

lower spline "d" on the crankshaft

end.

4. Install:

• Lock washer "1"

• Nut (balancer shaft driven gear)

"2"

• Primary drive gear "3"

• Lock washer "4"

• Nut (primary drive gear) "5"

• Install the primary drive gear with its

stepped side "a" facing the engine.

• Place an aluminum plate "b" be-

tween the teeth of the balancer

shaft drive gear "6" and driven gear

"7".

5. Bend the lock washer tab.

Nut (balancer shaft driv-

en gear):

50 Nm (5.0 m•kg, 36

ft•lb)

Nut (primary drive gear):

75 Nm (7.5 m•kg, 54

ft•lb)