YAMAHA YZ250F 2012 Repair Manual

Manufacturer: YAMAHA, Model Year: 2012, Model line: YZ250F, Model: YAMAHA YZ250F 2012Pages: 198, PDF Size: 11.78 MB

Page 61 of 198

3-11

ENGINE

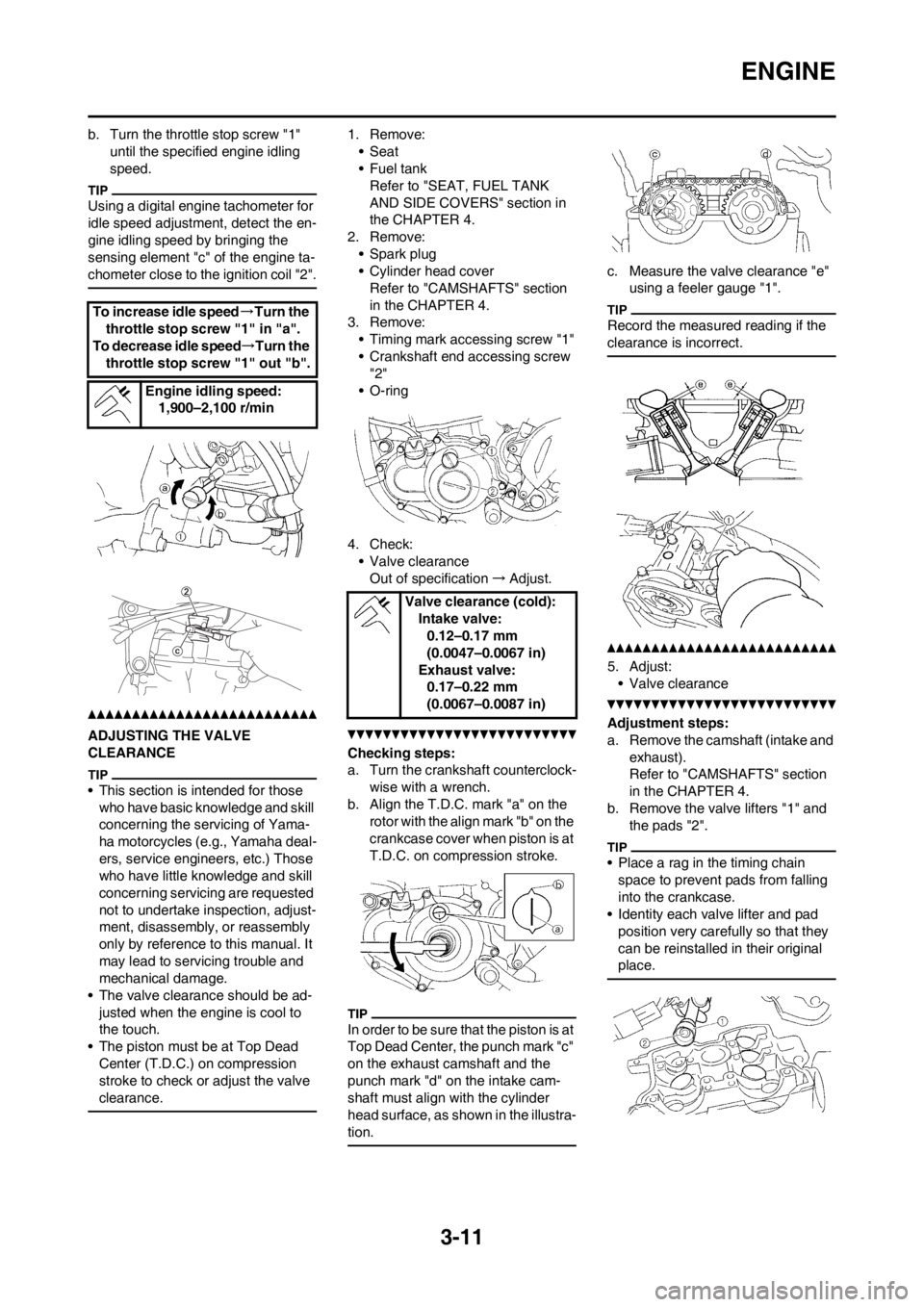

b. Turn the throttle stop screw "1"

until the specified engine idling

speed.

Using a digital engine tachometer for

idle speed adjustment, detect the en-

gine idling speed by bringing the

sensing element "c" of the engine ta-

chometer close to the ignition coil "2".

ADJUSTING THE VALVE

CLEARANCE

• This section is intended for those

who have basic knowledge and skill

concerning the servicing of Yama-

ha motorcycles (e.g., Yamaha deal-

ers, service engineers, etc.) Those

who have little knowledge and skill

concerning servicing are requested

not to undertake inspection, adjust-

ment, disassembly, or reassembly

only by reference to this manual. It

may lead to servicing trouble and

mechanical damage.

• The valve clearance should be ad-

justed when the engine is cool to

the touch.

• The piston must be at Top Dead

Center (T.D.C.) on compression

stroke to check or adjust the valve

clearance.

1. Remove:

•Seat

•Fuel tank

Refer to "SEAT, FUEL TANK

AND SIDE COVERS" section in

the CHAPTER 4.

2. Remove:

• Spark plug

• Cylinder head cover

Refer to "CAMSHAFTS" section

in the CHAPTER 4.

3. Remove:

• Timing mark accessing screw "1"

• Crankshaft end accessing screw

"2"

• O-ring

4. Check:

• Valve clearance

Out of specification→Adjust.

Checking steps:

a. Turn the crankshaft counterclock-

wise with a wrench.

b. Align the T.D.C. mark "a" on the

rotor with the align mark "b" on the

crankcase cover when piston is at

T.D.C. on compression stroke.

In order to be sure that the piston is at

Top Dead Center, the punch mark "c"

on the exhaust camshaft and the

punch mark "d" on the intake cam-

shaft must align with the cylinder

head surface, as shown in the illustra-

tion.

c. Measure the valve clearance "e"

using a feeler gauge "1".

Record the measured reading if the

clearance is incorrect.

5. Adjust:

• Valve clearance

Adjustment steps:

a. Remove the camshaft (intake and

exhaust).

Refer to "CAMSHAFTS" section

in the CHAPTER 4.

b. Remove the valve lifters "1" and

the pads "2".

• Place a rag in the timing chain

space to prevent pads from falling

into the crankcase.

• Identity each valve lifter and pad

position very carefully so that they

can be reinstalled in their original

place.

To increase idle speed→Turn the

throttle stop screw "1" in "a".

To decrease idle speed→Turn the

throttle stop screw "1" out "b".

Engine idling speed:

1,900–2,100 r/min

Valve clearance (cold):

Intake valve:

0.12–0.17 mm

(0.0047–0.0067 in)

Exhaust valve:

0.17–0.22 mm

(0.0067–0.0087 in)

Page 62 of 198

3-12

ENGINE

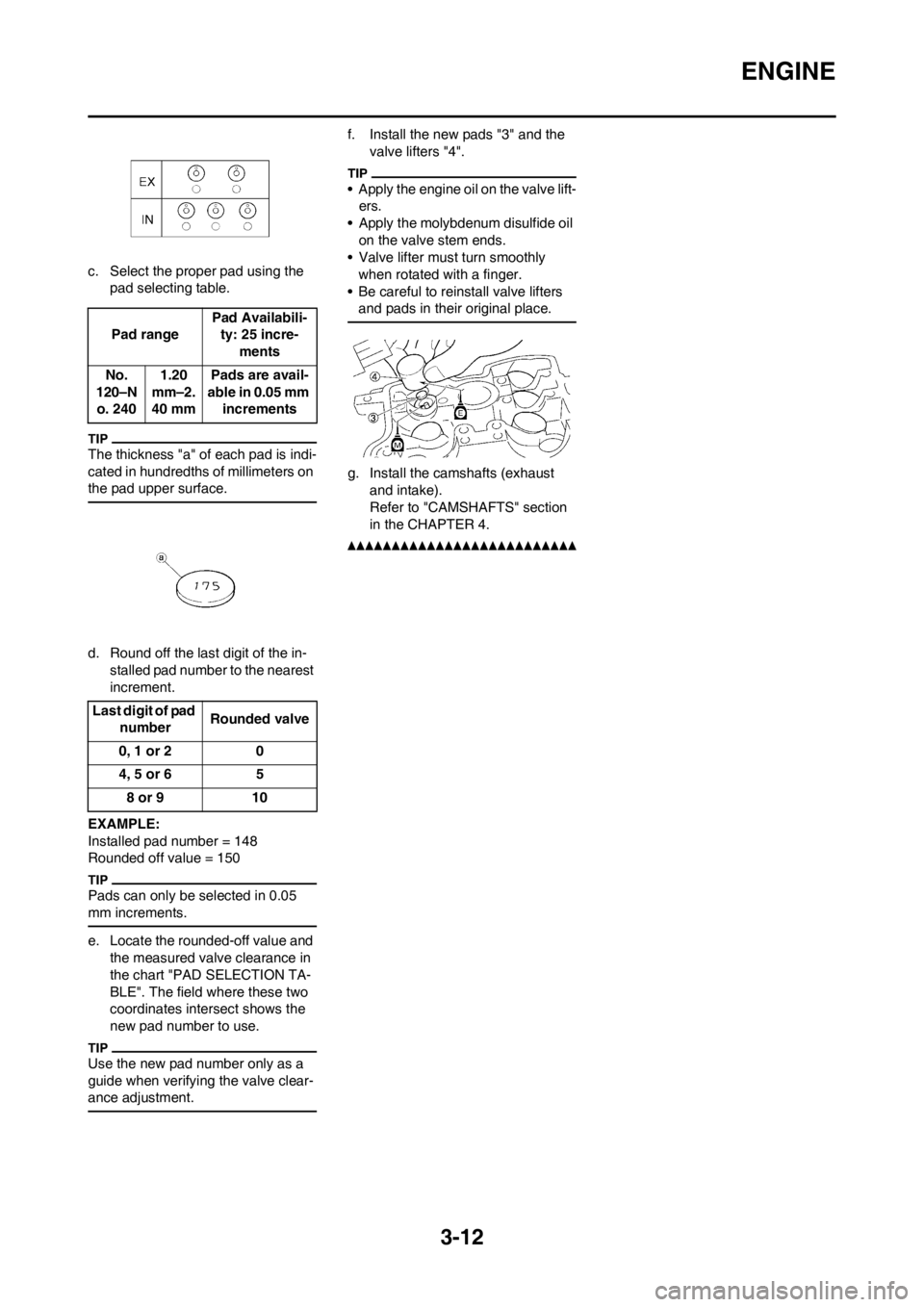

c. Select the proper pad using the

pad selecting table.

The thickness "a" of each pad is indi-

cated in hundredths of millimeters on

the pad upper surface.

d. Round off the last digit of the in-

stalled pad number to the nearest

increment.

EXAMPLE:

Installed pad number = 148

Rounded off value = 150

Pads can only be selected in 0.05

mm increments.

e. Locate the rounded-off value and

the measured valve clearance in

the chart "PAD SELECTION TA-

BLE". The field where these two

coordinates intersect shows the

new pad number to use.

Use the new pad number only as a

guide when verifying the valve clear-

ance adjustment.

f. Install the new pads "3" and the

valve lifters "4".

• Apply the engine oil on the valve lift-

ers.

• Apply the molybdenum disulfide oil

on the valve stem ends.

• Valve lifter must turn smoothly

when rotated with a finger.

• Be careful to reinstall valve lifters

and pads in their original place.

g. Install the camshafts (exhaust

and intake).

Refer to "CAMSHAFTS" section

in the CHAPTER 4.

Pad rangePad Availabili-

ty: 25 incre-

ments

No.

120–N

o. 2401.20

mm–2.

40 mmPads are avail-

able in 0.05 mm

increments

Last digit of pad

numberRounded valve

0, 1 or 2 0

4, 5 or 6 5

8 or 9 10

Page 63 of 198

3-13

ENGINE

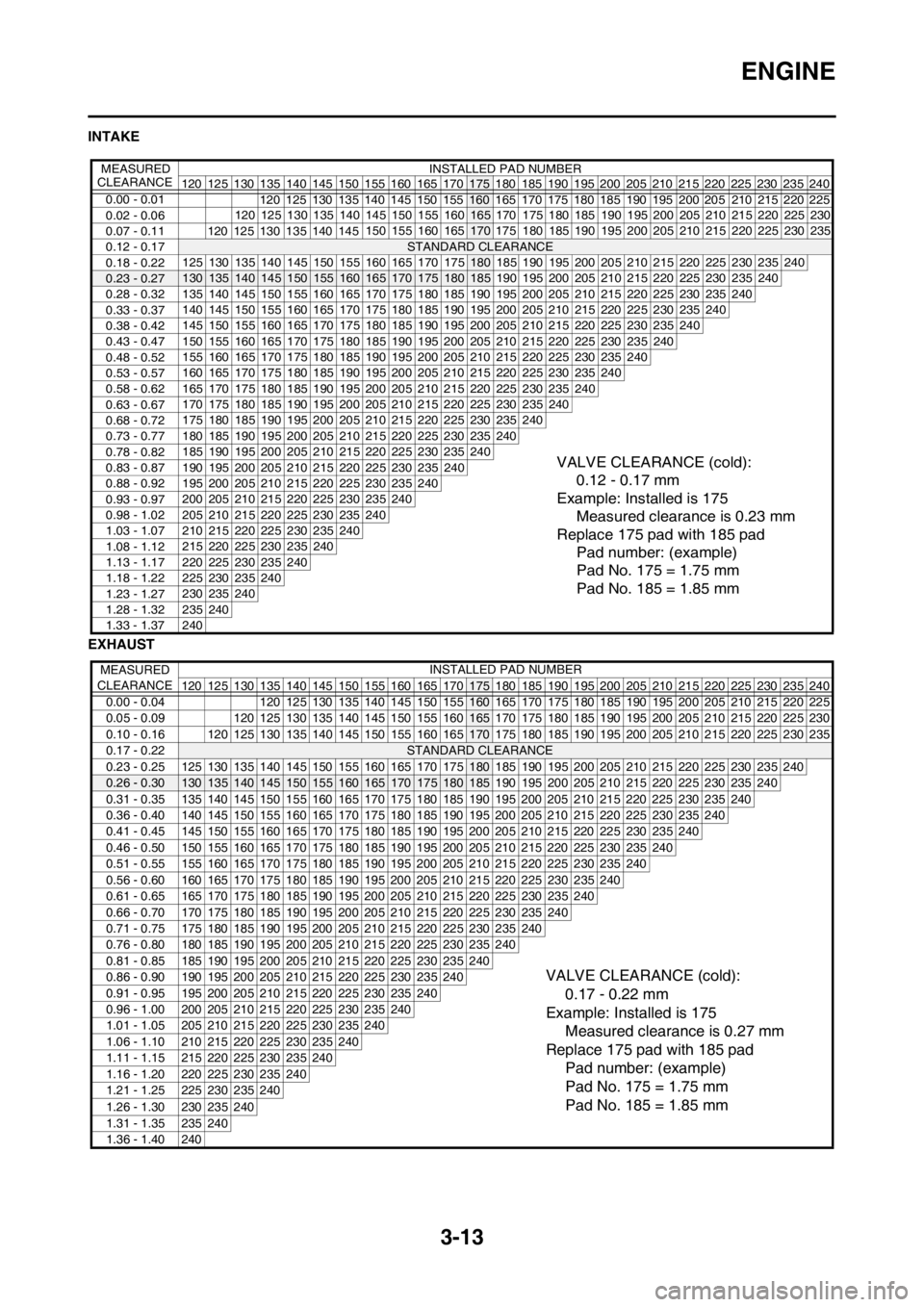

INTAKE

EXHAUST

120 125 130 135 140 145 150 155 160 165 170175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00 - 0.01

0.02 - 0.06

0.07 - 0.11

0.12 - 0.17

0.18 - 0.22

0.23 - 0.27

0.28 - 0.32

0.33 - 0.37

0.38 - 0.42

0.43 - 0.47

0.48 - 0.52

0.53 - 0.57

0.58 - 0.62

0.63 - 0.67

0.68 - 0.72

0.73 - 0.77

0.78 - 0.82

0.83 - 0.87

0.88 - 0.92

0.93 - 0.97

0.98 - 1.02

1.03 - 1.07

1.08 - 1.12

1.13 - 1.17

1.18 - 1.22

1.23 - 1.27

1.28 - 1.32

120 125 130 135 140 145 150 155160 165 170 175 180 185 190 195 200 205 210 215 220 225 230120 125 130 135 140 145

150 155 160 165

170 175 180 185 190 195 200 205 210 215 220 225 230 235

125130135140145150155160165170175180 185 190 195 200 205 210 215 220 225 230 235240

130135140145150155160165170175180185 190 195 200 205 210 215 220 225 230 235240

135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

165 170 175 180 185 190 195 200 205 210 215 220 225 230 235240

170 175 180 185 190 195 200 205 210 215 220 225 230 235240

175 180 185 190 195 200 205 210 215 220 225 230 235240

180 185 190 195 200 205 210 215 220 225 230 235 240

185 190 195 200 205 210 215 220 225 230 235

240

190 195 200 205 210 215 220 225 230 235240

195 200 205 210 215 220 225 230 235240

200 205 210 215 220 225 230 235240

205 210 215 220 225 230 235240

210 215 220 225 230 235240

215 220 225 230 235240

220 225 230 235240

225 230 235240

230 235240

235240

240

150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

120 125 130 135 140 145

1.33 - 1.37

VALVE CLEARANCE (cold):

0.12 - 0.17 mm

Example: Installed is 175

Measured clearance is 0.23 mm

Replace 175 pad with 185 pad

MEASURED

CLEARANCEINSTALLED PAD NUMBER

STANDARD CLEARANCE

Pad number: (example)

Pad No. 175 = 1.75 mm

Pad No. 185 = 1.85 mm

MEASURED

CLEARANCEINSTALLED PAD NUMBER

120 125 130 135 140 145 150 155 160 165 170

175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.00 - 0.04 120 125 130 135 140 145 150 155

160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.05 - 0.09

120 125 130 135 140 145 150 155 160165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.10 - 0.16

120125130135140145150155160165170 175 180 185 190 195 200 205 210 215 220 225230235

0.17 - 0.22STANDARD CLEARANCE

0.23 - 0.25 125 130 135 140 145 150 155 160 165 170 175

180 185 190 195 200 205 210 215 220 225230235240

0.26 - 0.30130135140145150155160165170175180185 190 195 200 205 210 215 220 225230235240

0.31 - 0.35 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.36 - 0.40 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.41 - 0.45 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.46 - 0.50 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.51 - 0.55 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.56 - 0.60 160 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.61 - 0.65 165 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.66 - 0.70 170 175 180 185 190 195 200 205 210 215 220 225230235240

0.71 - 0.75 175 180 185 190 195 200 205 210 215 220 225230235240

0.76 - 0.80 180 185 190 195 200 205 210 215 220 225230235240

0.81 - 0.85 185 190 195 200 205 210 215 220 225230235240

VALVE CLEARANCE (cold):

0.17 - 0.22 mm

Example: Installed is 175

Measured clearance is 0.27 mm

Replace 175 pad with 185 pad

Pad number: (example)

Pad No. 175 = 1.75 mm

Pad No. 185 = 1.85 mm0.86 - 0.90 190 195 200 205 210 215 220 225230235240

0.91 - 0.95 195 200 205 210 215 220 225230235240

0.96 - 1.00 200 205 210 215 220 225230235240

1.01 - 1.05 205 210 215 220 225230235240

1.06 - 1.10 210 215 220 225230235240

1.11 - 1.15 215 220 225230235240

1.16 - 1.20 220 225230235240

1.21 - 1.25 225230235240

1.26 - 1.30 230235240

1.31 - 1.35 235240

1.36 - 1.40 240

Page 64 of 198

3-14

CHASSIS

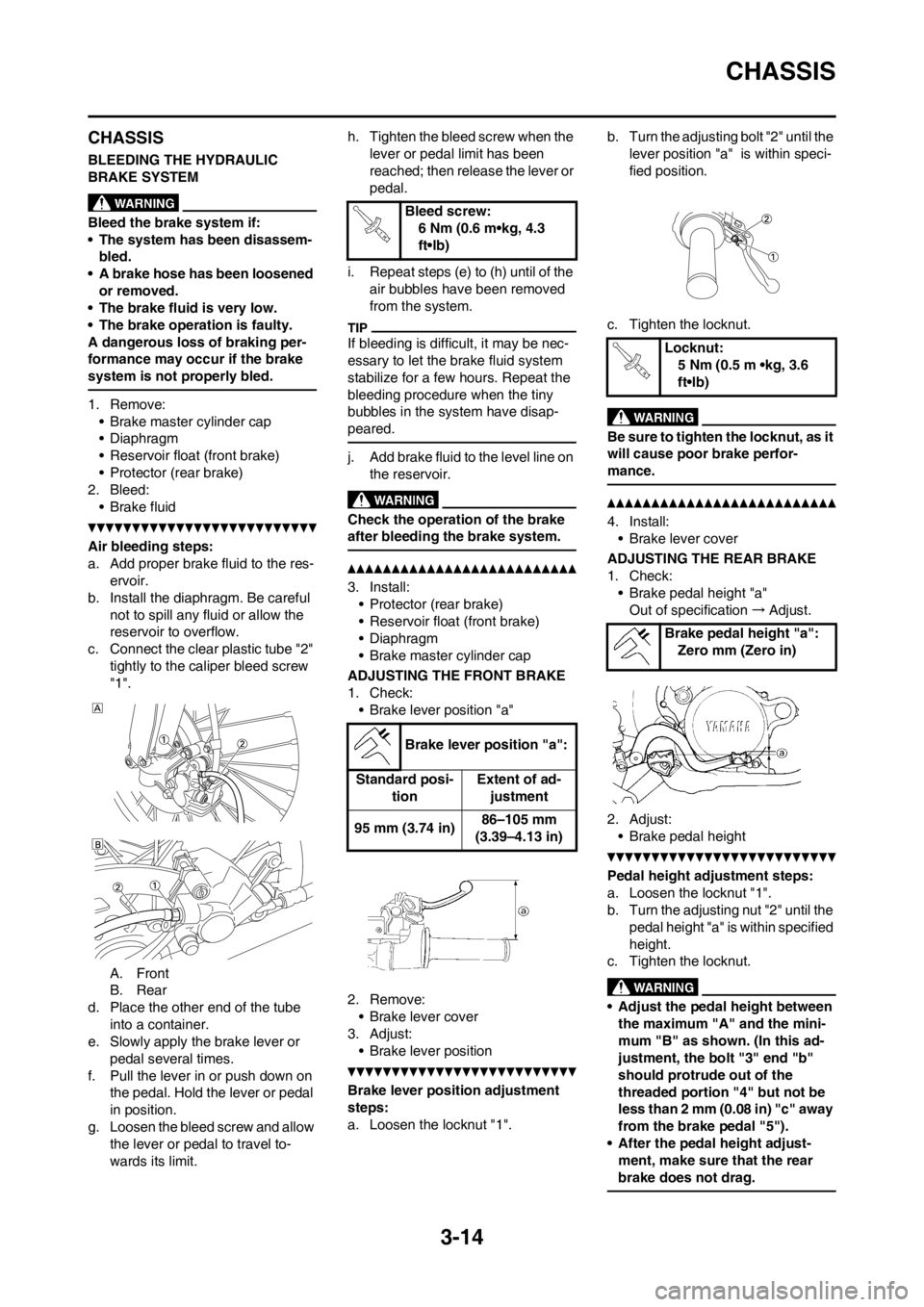

CHASSIS

BLEEDING THE HYDRAULIC

BRAKE SYSTEM

Bleed the brake system if:

• The system has been disassem-

bled.

• A brake hose has been loosened

or removed.

• The brake fluid is very low.

• The brake operation is faulty.

A dangerous loss of braking per-

formance may occur if the brake

system is not properly bled.

1. Remove:

• Brake master cylinder cap

• Diaphragm

• Reservoir float (front brake)

• Protector (rear brake)

2. Bleed:

• Brake fluid

Air bleeding steps:

a. Add proper brake fluid to the res-

ervoir.

b. Install the diaphragm. Be careful

not to spill any fluid or allow the

reservoir to overflow.

c. Connect the clear plastic tube "2"

tightly to the caliper bleed screw

"1".

A. Front

B. Rear

d. Place the other end of the tube

into a container.

e. Slowly apply the brake lever or

pedal several times.

f. Pull the lever in or push down on

the pedal. Hold the lever or pedal

in position.

g. Loosen the bleed screw and allow

the lever or pedal to travel to-

wards its limit.h. Tighten the bleed screw when the

lever or pedal limit has been

reached; then release the lever or

pedal.

i. Repeat steps (e) to (h) until of the

air bubbles have been removed

from the system.

If bleeding is difficult, it may be nec-

essary to let the brake fluid system

stabilize for a few hours. Repeat the

bleeding procedure when the tiny

bubbles in the system have disap-

peared.

j. Add brake fluid to the level line on

the reservoir.

Check the operation of the brake

after bleeding the brake system.

3. Install:

• Protector (rear brake)

• Reservoir float (front brake)

• Diaphragm

• Brake master cylinder cap

ADJUSTING THE FRONT BRAKE

1. Check:

• Brake lever position "a"

2. Remove:

• Brake lever cover

3. Adjust:

• Brake lever position

Brake lever position adjustment

steps:

a. Loosen the locknut "1".b. Turn the adjusting bolt "2" until the

lever position "a" is within speci-

fied position.

c. Tighten the locknut.

Be sure to tighten the locknut, as it

will cause poor brake perfor-

mance.

4. Install:

• Brake lever cover

ADJUSTING THE REAR BRAKE

1. Check:

• Brake pedal height "a"

Out of specification→Adjust.

2. Adjust:

• Brake pedal height

Pedal height adjustment steps:

a. Loosen the locknut "1".

b. Turn the adjusting nut "2" until the

pedal height "a" is within specified

height.

c. Tighten the locknut.

• Adjust the pedal height between

the maximum "A" and the mini-

mum "B" as shown. (In this ad-

justment, the bolt "3" end "b"

should protrude out of the

threaded portion "4" but not be

less than 2 mm (0.08 in) "c" away

from the brake pedal "5").

• After the pedal height adjust-

ment, make sure that the rear

brake does not drag.

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Brake lever position "a":

Standard posi-

tionExtent of ad-

justment

95 mm (3.74 in)86–105 mm

(3.39–4.13 in)

Locknut:

5 Nm (0.5 m •kg, 3.6

ft•lb)

Brake pedal height "a":

Zero mm (Zero in)

Page 65 of 198

3-15

CHASSIS

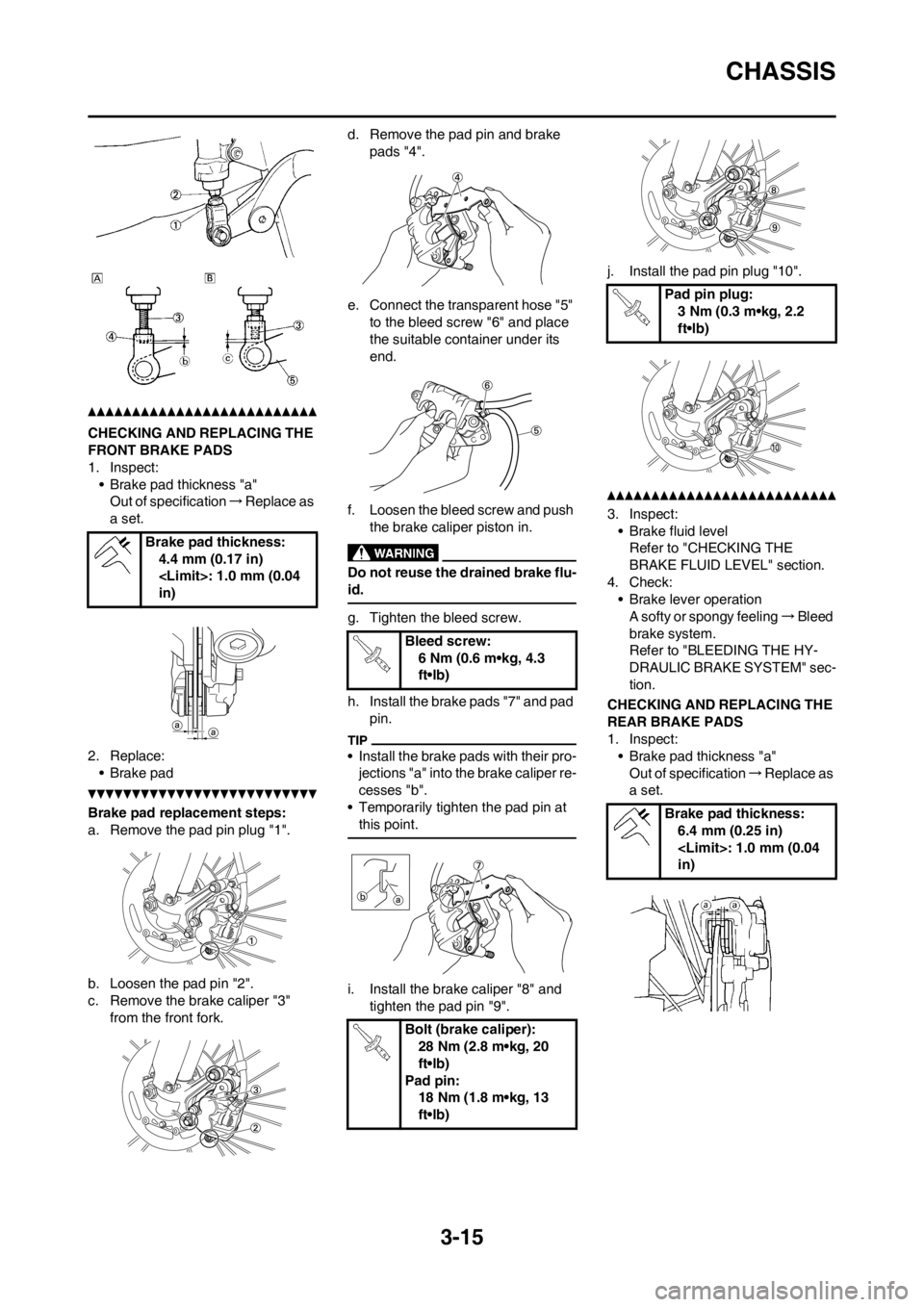

CHECKING AND REPLACING THE

FRONT BRAKE PADS

1. Inspect:

• Brake pad thickness "a"

Out of specification→Replace as

a set.

2. Replace:

• Brake pad

Brake pad replacement steps:

a. Remove the pad pin plug "1".

b. Loosen the pad pin "2".

c. Remove the brake caliper "3"

from the front fork.d. Remove the pad pin and brake

pads "4".

e. Connect the transparent hose "5"

to the bleed screw "6" and place

the suitable container under its

end.

f. Loosen the bleed screw and push

the brake caliper piston in.

Do not reuse the drained brake flu-

id.

g. Tighten the bleed screw.

h. Install the brake pads "7" and pad

pin.

• Install the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at

this point.

i. Install the brake caliper "8" and

tighten the pad pin "9".j. Install the pad pin plug "10".

3. Inspect:

• Brake fluid level

Refer to "CHECKING THE

BRAKE FLUID LEVEL" section.

4. Check:

• Brake lever operation

A softy or spongy feeling→Bleed

brake system.

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion.

CHECKING AND REPLACING THE

REAR BRAKE PADS

1. Inspect:

• Brake pad thickness "a"

Out of specification→Replace as

a set. Brake pad thickness:

4.4 mm (0.17 in)

in)

Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Bolt (brake caliper):

28 Nm (2.8 m•kg, 20

ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Brake pad thickness:

6.4 mm (0.25 in)

in)

Page 66 of 198

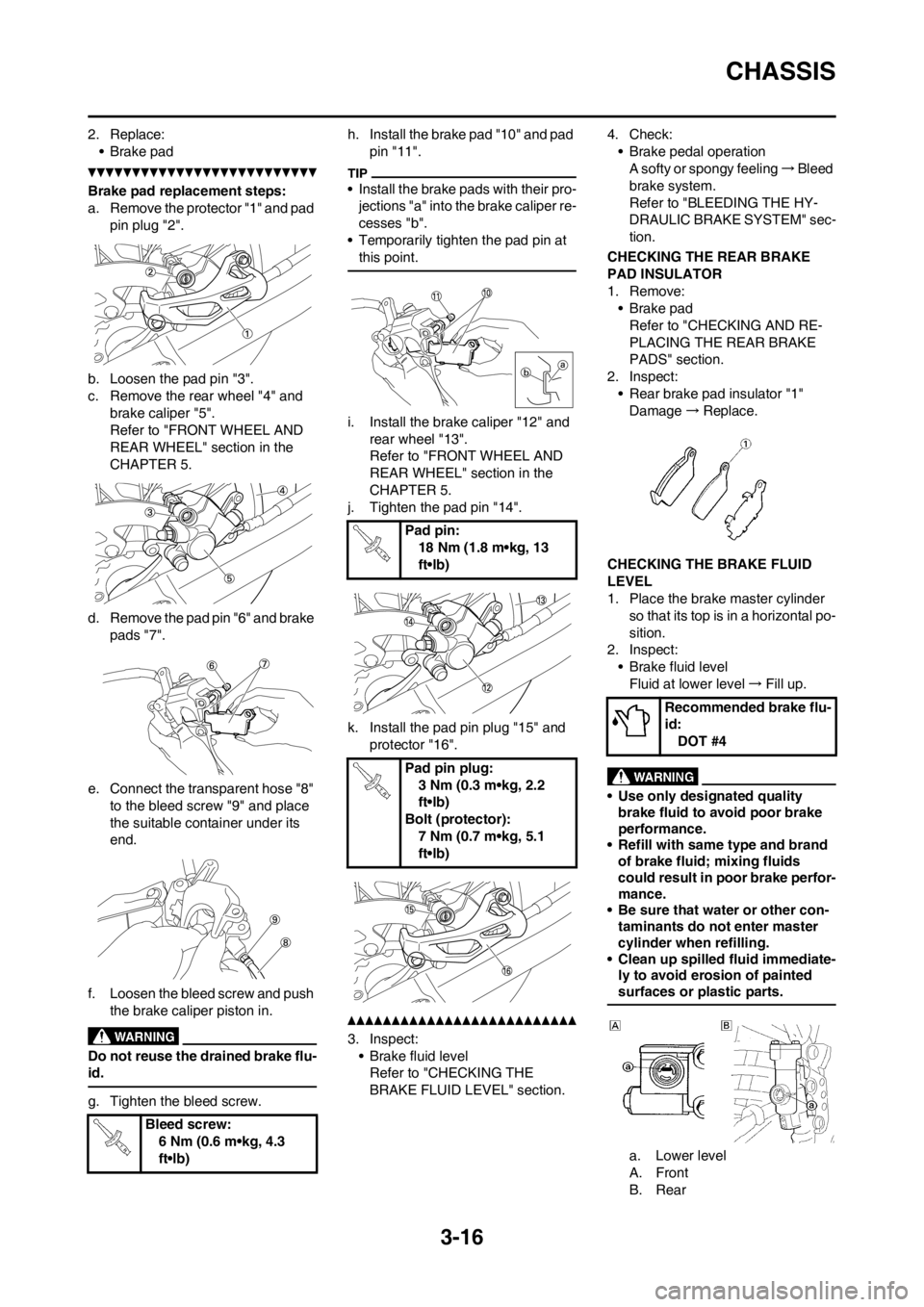

3-16

CHASSIS

2. Replace:

• Brake pad

Brake pad replacement steps:

a. Remove the protector "1" and pad

pin plug "2".

b. Loosen the pad pin "3".

c. Remove the rear wheel "4" and

brake caliper "5".

Refer to "FRONT WHEEL AND

REAR WHEEL" section in the

CHAPTER 5.

d. Remove the pad pin "6" and brake

pads "7".

e. Connect the transparent hose "8"

to the bleed screw "9" and place

the suitable container under its

end.

f. Loosen the bleed screw and push

the brake caliper piston in.

Do not reuse the drained brake flu-

id.

g. Tighten the bleed screw.h. Install the brake pad "10" and pad

pin "11".

• Install the brake pads with their pro-

jections "a" into the brake caliper re-

cesses "b".

• Temporarily tighten the pad pin at

this point.

i. Install the brake caliper "12" and

rear wheel "13".

Refer to "FRONT WHEEL AND

REAR WHEEL" section in the

CHAPTER 5.

j. Tighten the pad pin "14".

k. Install the pad pin plug "15" and

protector "16".

3. Inspect:

• Brake fluid level

Refer to "CHECKING THE

BRAKE FLUID LEVEL" section.4. Check:

• Brake pedal operation

A softy or spongy feeling→Bleed

brake system.

Refer to "BLEEDING THE HY-

DRAULIC BRAKE SYSTEM" sec-

tion.

CHECKING THE REAR BRAKE

PAD INSULATOR

1. Remove:

• Brake pad

Refer to "CHECKING AND RE-

PLACING THE REAR BRAKE

PADS" section.

2. Inspect:

• Rear brake pad insulator "1"

Damage→Replace.

CHECKING THE BRAKE FLUID

LEVEL

1. Place the brake master cylinder

so that its top is in a horizontal po-

sition.

2. Inspect:

• Brake fluid level

Fluid at lower level→Fill up.

• Use only designated quality

brake fluid to avoid poor brake

performance.

• Refill with same type and brand

of brake fluid; mixing fluids

could result in poor brake perfor-

mance.

• Be sure that water or other con-

taminants do not enter master

cylinder when refilling.

• Clean up spilled fluid immediate-

ly to avoid erosion of painted

surfaces or plastic parts.

a. Lower level

A. Front

B. Rear Bleed screw:

6 Nm (0.6 m•kg, 4.3

ft•lb)

Pad pin:

18 Nm (1.8 m•kg, 13

ft•lb)

Pad pin plug:

3 Nm (0.3 m•kg, 2.2

ft•lb)

Bolt (protector):

7 Nm (0.7 m•kg, 5.1

ft•lb)

Recommended brake flu-

id:

DOT #4

Page 67 of 198

3-17

CHASSIS

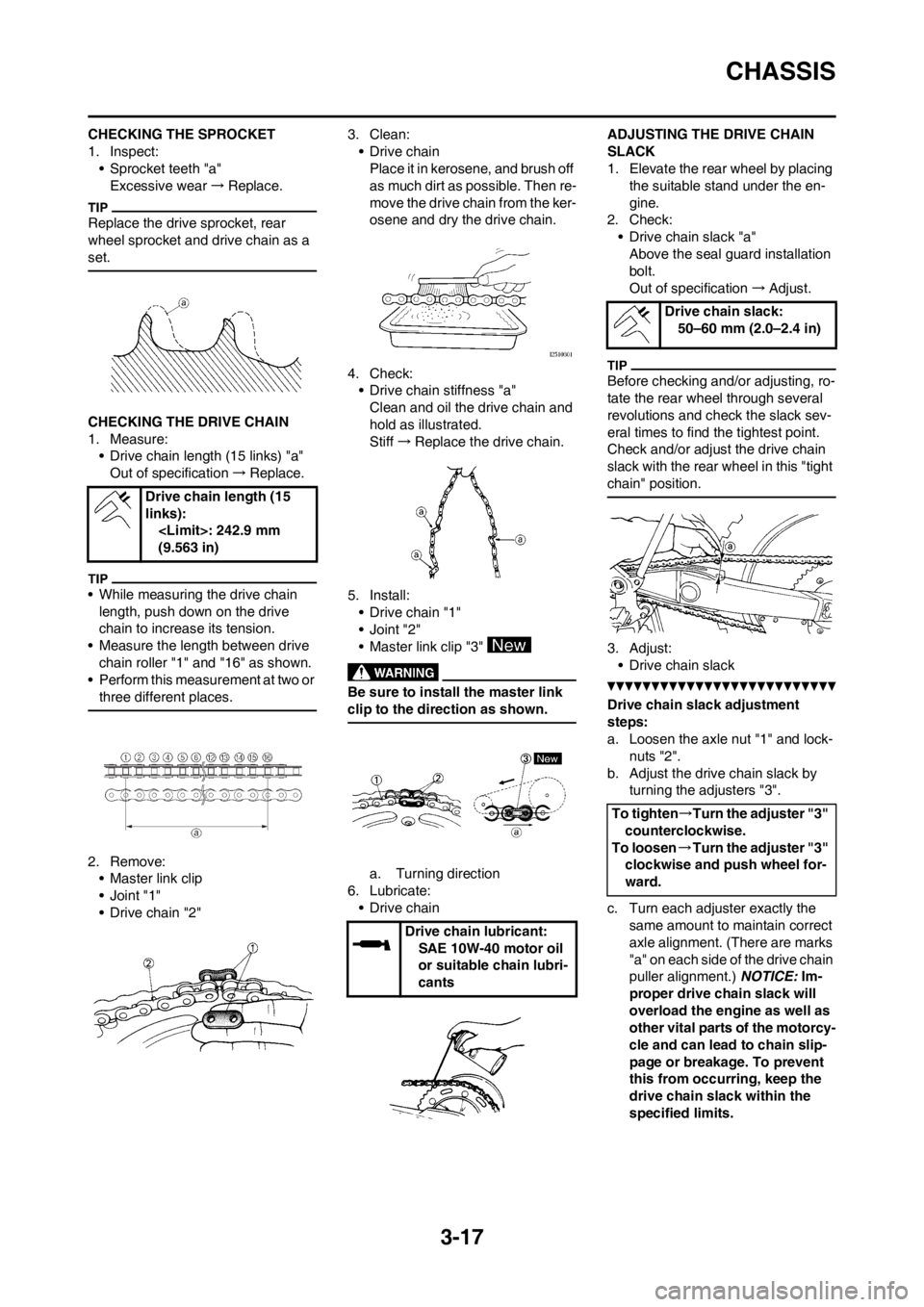

CHECKING THE SPROCKET

1. Inspect:

• Sprocket teeth "a"

Excessive wear→Replace.

Replace the drive sprocket, rear

wheel sprocket and drive chain as a

set.

CHECKING THE DRIVE CHAIN

1. Measure:

• Drive chain length (15 links) "a"

Out of specification→Replace.

• While measuring the drive chain

length, push down on the drive

chain to increase its tension.

• Measure the length between drive

chain roller "1" and "16" as shown.

• Perform this measurement at two or

three different places.

2. Remove:

• Master link clip

•Joint "1"

• Drive chain "2"3. Clean:

• Drive chain

Place it in kerosene, and brush off

as much dirt as possible. Then re-

move the drive chain from the ker-

osene and dry the drive chain.

4. Check:

• Drive chain stiffness "a"

Clean and oil the drive chain and

hold as illustrated.

Stiff→Replace the drive chain.

5. Install:

• Drive chain "1"

•Joint "2"

• Master link clip "3"

Be sure to install the master link

clip to the direction as shown.

a. Turning direction

6. Lubricate:

• Drive chainADJUSTING THE DRIVE CHAIN

SLACK

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Check:

• Drive chain slack "a"

Above the seal guard installation

bolt.

Out of specification→Adjust.

Before checking and/or adjusting, ro-

tate the rear wheel through several

revolutions and check the slack sev-

eral times to find the tightest point.

Check and/or adjust the drive chain

slack with the rear wheel in this "tight

chain" position.

3. Adjust:

• Drive chain slack

Drive chain slack adjustment

steps:

a. Loosen the axle nut "1" and lock-

nuts "2".

b. Adjust the drive chain slack by

turning the adjusters "3".

c. Turn each adjuster exactly the

same amount to maintain correct

axle alignment. (There are marks

"a" on each side of the drive chain

puller alignment.) NOTICE: Im-

proper drive chain slack will

overload the engine as well as

other vital parts of the motorcy-

cle and can lead to chain slip-

page or breakage. To prevent

this from occurring, keep the

drive chain slack within the

specified limits. Drive chain length (15

links):

(9.563 in)

Drive chain lubricant:

SAE 10W-40 motor oil

or suitable chain lubri-

cants

Drive chain slack:

50–60 mm (2.0–2.4 in)

To tighten→Turn the adjuster "3"

counterclockwise.

To loosen→Turn the adjuster "3"

clockwise and push wheel for-

ward.

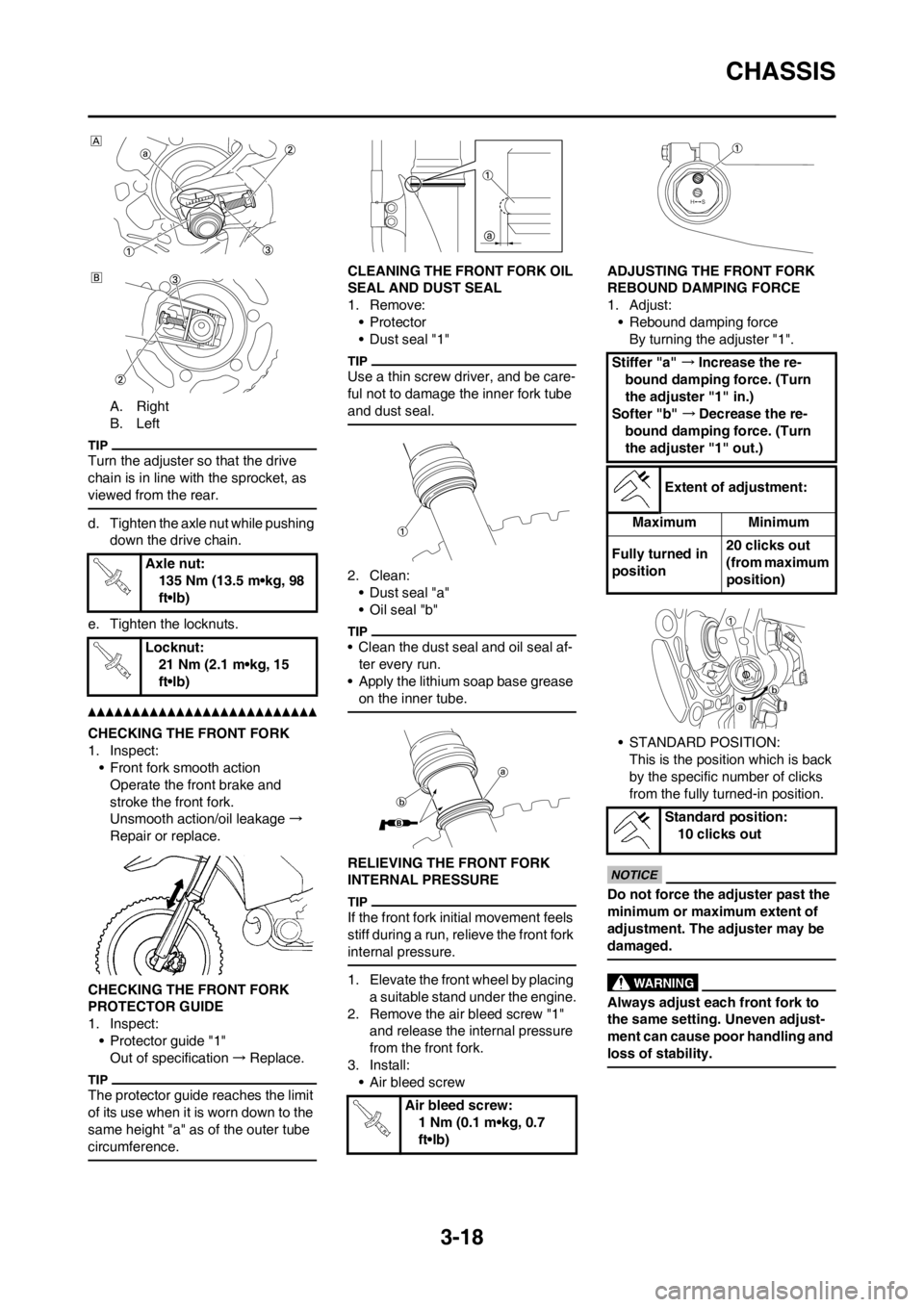

Page 68 of 198

3-18

CHASSIS

A. Right

B. Left

Turn the adjuster so that the drive

chain is in line with the sprocket, as

viewed from the rear.

d. Tighten the axle nut while pushing

down the drive chain.

e. Tighten the locknuts.

CHECKING THE FRONT FORK

1. Inspect:

• Front fork smooth action

Operate the front brake and

stroke the front fork.

Unsmooth action/oil leakage→

Repair or replace.

CHECKING THE FRONT FORK

PROTECTOR GUIDE

1. Inspect:

• Protector guide "1"

Out of specification→Replace.

The protector guide reaches the limit

of its use when it is worn down to the

same height "a" as of the outer tube

circumference.

CLEANING THE FRONT FORK OIL

SEAL AND DUST SEAL

1. Remove:

•Protector

• Dust seal "1"

Use a thin screw driver, and be care-

ful not to damage the inner fork tube

and dust seal.

2. Clean:

• Dust seal "a"

• Oil seal "b"

• Clean the dust seal and oil seal af-

ter every run.

• Apply the lithium soap base grease

on the inner tube.

RELIEVING THE FRONT FORK

INTERNAL PRESSURE

If the front fork initial movement feels

stiff during a run, relieve the front fork

internal pressure.

1. Elevate the front wheel by placing

a suitable stand under the engine.

2. Remove the air bleed screw "1"

and release the internal pressure

from the front fork.

3. Install:

• Air bleed screwADJUSTING THE FRONT FORK

REBOUND DAMPING FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1".

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

Axle nut:

135 Nm (13.5 m•kg, 98

ft•lb)

Locknut:

21 Nm (2.1 m•kg, 15

ft•lb)

Air bleed screw:

1 Nm (0.1 m•kg, 0.7

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

10 clicks out

Page 69 of 198

3-19

CHASSIS

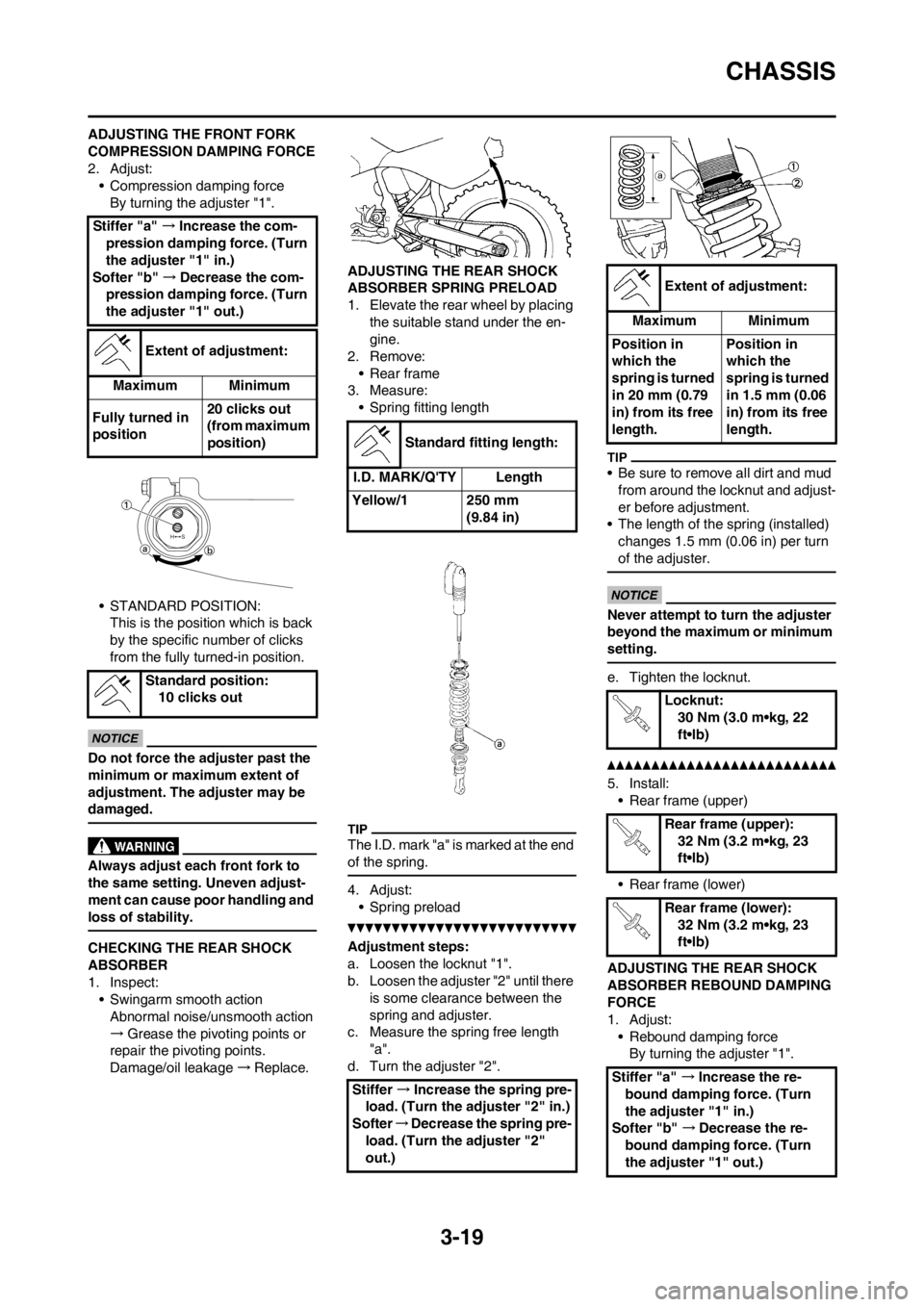

ADJUSTING THE FRONT FORK

COMPRESSION DAMPING FORCE

2. Adjust:

• Compression damping force

By turning the adjuster "1".

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

Always adjust each front fork to

the same setting. Uneven adjust-

ment can cause poor handling and

loss of stability.

CHECKING THE REAR SHOCK

ABSORBER

1. Inspect:

• Swingarm smooth action

Abnormal noise/unsmooth action

→Grease the pivoting points or

repair the pivoting points.

Damage/oil leakage→Replace.ADJUSTING THE REAR SHOCK

ABSORBER SPRING PRELOAD

1. Elevate the rear wheel by placing

the suitable stand under the en-

gine.

2. Remove:

• Rear frame

3. Measure:

• Spring fitting length

The I.D. mark "a" is marked at the end

of the spring.

4. Adjust:

• Spring preload

Adjustment steps:

a. Loosen the locknut "1".

b. Loosen the adjuster "2" until there

is some clearance between the

spring and adjuster.

c. Measure the spring free length

"a".

d. Turn the adjuster "2".

• Be sure to remove all dirt and mud

from around the locknut and adjust-

er before adjustment.

• The length of the spring (installed)

changes 1.5 mm (0.06 in) per turn

of the adjuster.

Never attempt to turn the adjuster

beyond the maximum or minimum

setting.

e. Tighten the locknut.

5. Install:

• Rear frame (upper)

• Rear frame (lower)

ADJUSTING THE REAR SHOCK

ABSORBER REBOUND DAMPING

FORCE

1. Adjust:

• Rebound damping force

By turning the adjuster "1". Stiffer "a" →Increase the com-

pression damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the com-

pression damping force. (Turn

the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

10 clicks out

Standard fitting length:

I.D. MARK/Q'TY Length

Yellow/1 250 mm

(9.84 in)

Stiffer →Increase the spring pre-

load. (Turn the adjuster "2" in.)

Softer→Decrease the spring pre-

load. (Turn the adjuster "2"

out.)

Extent of adjustment:

Maximum Minimum

Position in

which the

spring is turned

in 20 mm (0.79

in) from its free

length.Position in

which the

spring is turned

in 1.5 mm (0.06

in) from its free

length.

Locknut:

30 Nm (3.0 m•kg, 22

ft•lb)

Rear frame (upper):

32 Nm (3.2 m•kg, 23

ft•lb)

Rear frame (lower):

32 Nm (3.2 m•kg, 23

ft•lb)

Stiffer "a" →Increase the re-

bound damping force. (Turn

the adjuster "1" in.)

Softer "b" →Decrease the re-

bound damping force. (Turn

the adjuster "1" out.)

Page 70 of 198

3-20

CHASSIS

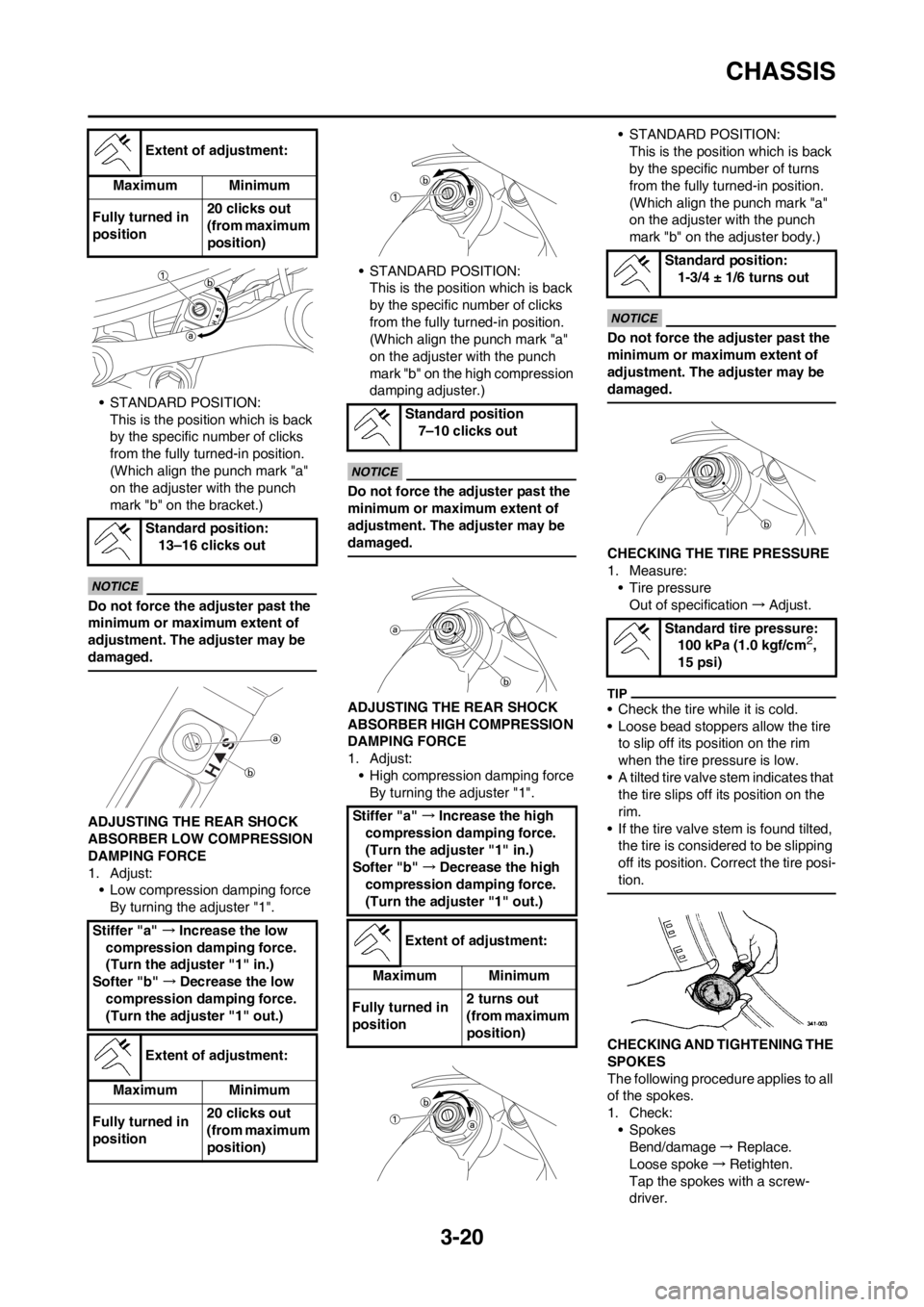

• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the bracket.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

ADJUSTING THE REAR SHOCK

ABSORBER LOW COMPRESSION

DAMPING FORCE

1. Adjust:

• Low compression damping force

By turning the adjuster "1".• STANDARD POSITION:

This is the position which is back

by the specific number of clicks

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the high compression

damping adjuster.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

ADJUSTING THE REAR SHOCK

ABSORBER HIGH COMPRESSION

DAMPING FORCE

1. Adjust:

• High compression damping force

By turning the adjuster "1".• STANDARD POSITION:

This is the position which is back

by the specific number of turns

from the fully turned-in position.

(Which align the punch mark "a"

on the adjuster with the punch

mark "b" on the adjuster body.)

Do not force the adjuster past the

minimum or maximum extent of

adjustment. The adjuster may be

damaged.

CHECKING THE TIRE PRESSURE

1. Measure:

• Tire pressure

Out of specification→Adjust.

• Check the tire while it is cold.

• Loose bead stoppers allow the tire

to slip off its position on the rim

when the tire pressure is low.

• A tilted tire valve stem indicates that

the tire slips off its position on the

rim.

• If the tire valve stem is found tilted,

the tire is considered to be slipping

off its position. Correct the tire posi-

tion.

CHECKING AND TIGHTENING THE

SPOKES

The following procedure applies to all

of the spokes.

1. Check:

• Spokes

Bend/damage→Replace.

Loose spoke→Retighten.

Tap the spokes with a screw-

driver. Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position:

13–16 clicks out

Stiffer "a" →Increase the low

compression damping force.

(Turn the adjuster "1" in.)

Softer "b" →Decrease the low

compression damping force.

(Turn the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position20 clicks out

(from maximum

position)

Standard position

7–10 clicks out

Stiffer "a" →Increase the high

compression damping force.

(Turn the adjuster "1" in.)

Softer "b" →Decrease the high

compression damping force.

(Turn the adjuster "1" out.)

Extent of adjustment:

Maximum Minimum

Fully turned in

position2 turns out

(from maximum

position)

Standard position:

1-3/4 ± 1/6 turns out

Standard tire pressure:

100 kPa (1.0 kgf/cm

2,

15 psi)