check oil YAMAHA YZ250F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 89 of 356

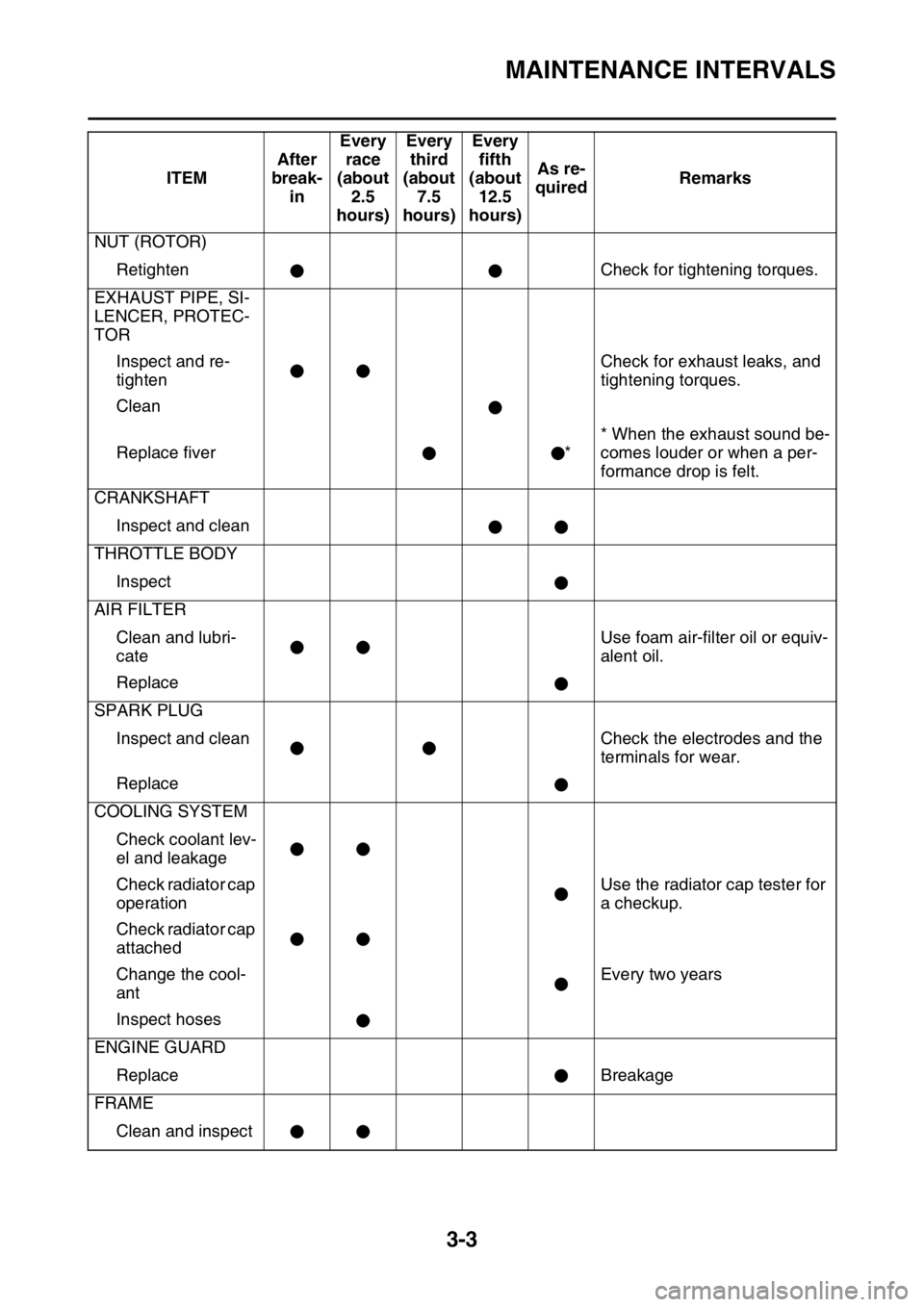

MAINTENANCE INTERVALS

3-3

NUT (ROTOR)

Retighten Check for tightening torques.

EXHAUST PIPE, SI-

LENCER, PROTEC-

TOR

Inspect and re-

tightenCheck for exhaust leaks, and

tightening torques.

Clean

Replace fiver ** When the exhaust sound be-

comes louder or when a per-

formance drop is felt.

CRANKSHAFT

Inspect and clean

THROTTLE BODY

Inspect

AIR FILTER

Clean and lubri-

cateUse foam air-filter oil or equiv-

alent oil.

Replace

SPARK PLUG

Inspect and clean Check the electrodes and the

terminals for wear.

Replace

COOLING SYSTEM

Check coolant lev-

el and leakage

Check radiator cap

operationUse the radiator cap tester for

a checkup.

Check radiator cap

attached

Change the cool-

antEvery two years

Inspect hoses

ENGINE GUARD

Replace Breakage

FRAME

Clean and inspectITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 90 of 356

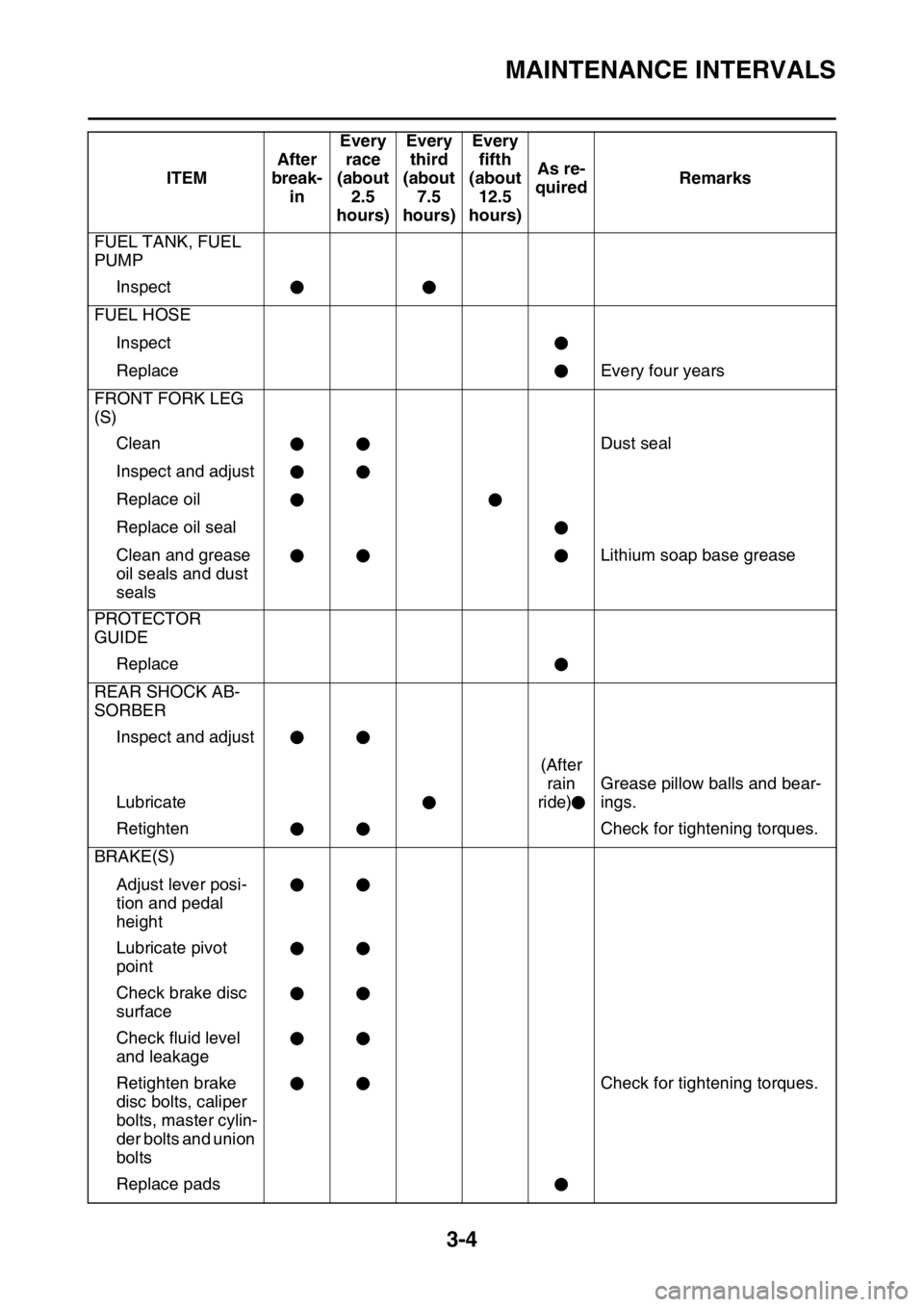

MAINTENANCE INTERVALS

3-4

FUEL TANK, FUEL

PUMP

Inspect

FUEL HOSE

Inspect

Replace Every four years

FRONT FORK LEG

(S)

Clean Dust seal

Inspect and adjust

Replace oil

Replace oil seal

Clean and grease

oil seals and dust

sealsLithium soap base grease

PROTECTOR

GUIDE

Replace

REAR SHOCK AB-

SORBER

Inspect and adjust

Lubricate(After

rain

ride)Grease pillow balls and bear-

ings.

Retighten Check for tightening torques.

BRAKE(S)

Adjust lever posi-

tion and pedal

height

Lubricate pivot

point

Check brake disc

surface

Check fluid level

and leakage

Retighten brake

disc bolts, caliper

bolts, master cylin-

der bolts and union

boltsCheck for tightening torques.

Replace padsITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 91 of 356

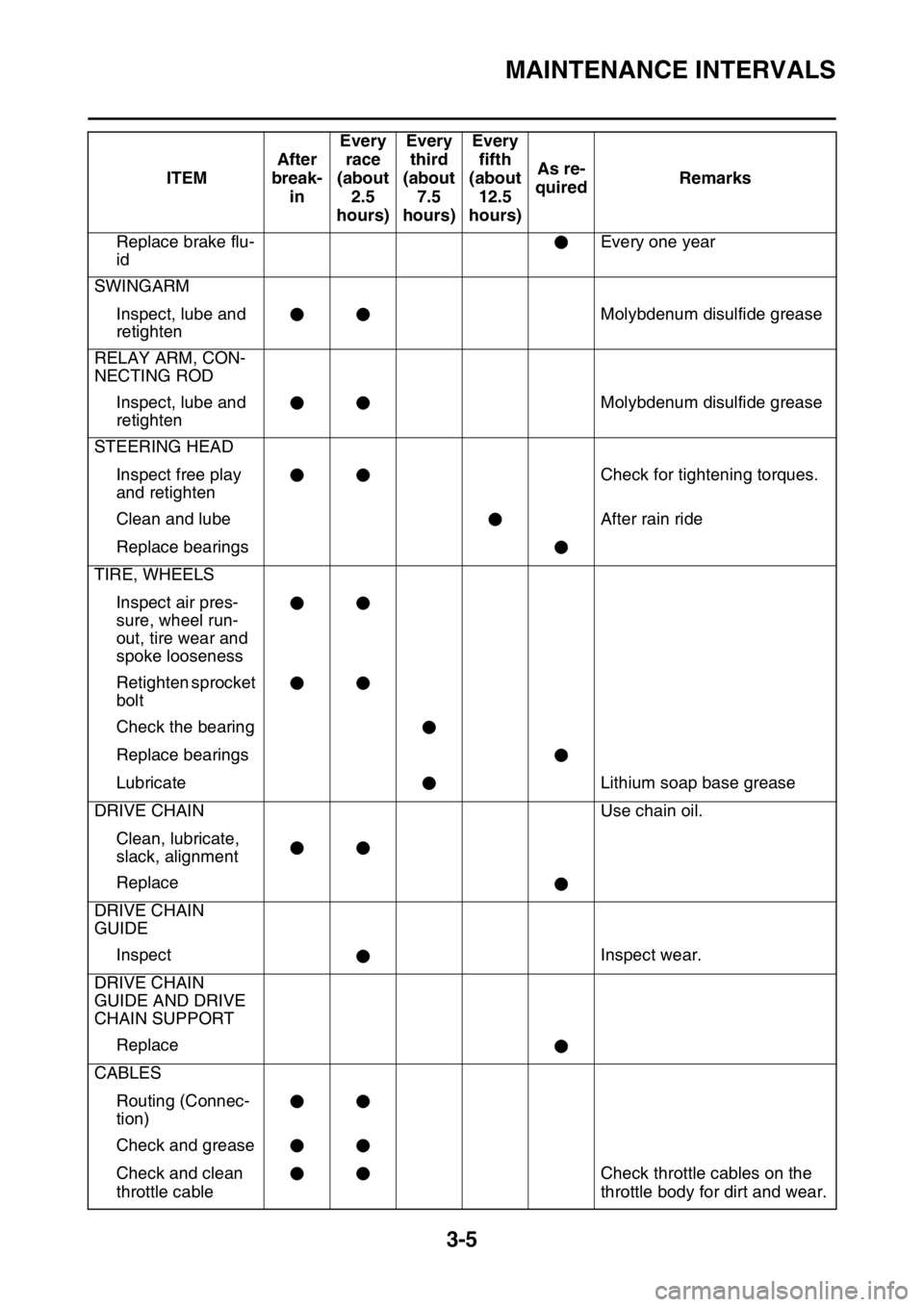

MAINTENANCE INTERVALS

3-5

Replace brake flu-

idEvery one year

SWINGARM

Inspect, lube and

retightenMolybdenum disulfide grease

RELAY ARM, CON-

NECTING ROD

Inspect, lube and

retightenMolybdenum disulfide grease

STEERING HEAD

Inspect free play

and retightenCheck for tightening torques.

Clean and lube After rain ride

Replace bearings

TIRE, WHEELS

Inspect air pres-

sure, wheel run-

out, tire wear and

spoke looseness

Retighten sprocket

bolt

Check the bearing

Replace bearings

Lubricate Lithium soap base grease

DRIVE CHAIN Use chain oil.

Clean, lubricate,

slack, alignment

Replace

DRIVE CHAIN

GUIDE

Inspect Inspect wear.

DRIVE CHAIN

GUIDE AND DRIVE

CHAIN SUPPORT

Replace

CABLES

Routing (Connec-

tion)

Check and grease

Check and clean

throttle cableCheck throttle cables on the

throttle body for dirt and wear. ITEMAfter

break-

inEvery

race

(about

2.5

hours)Every

third

(about

7.5

hours)Every

fifth

(about

12.5

hours)As re-

quiredRemarks

Page 93 of 356

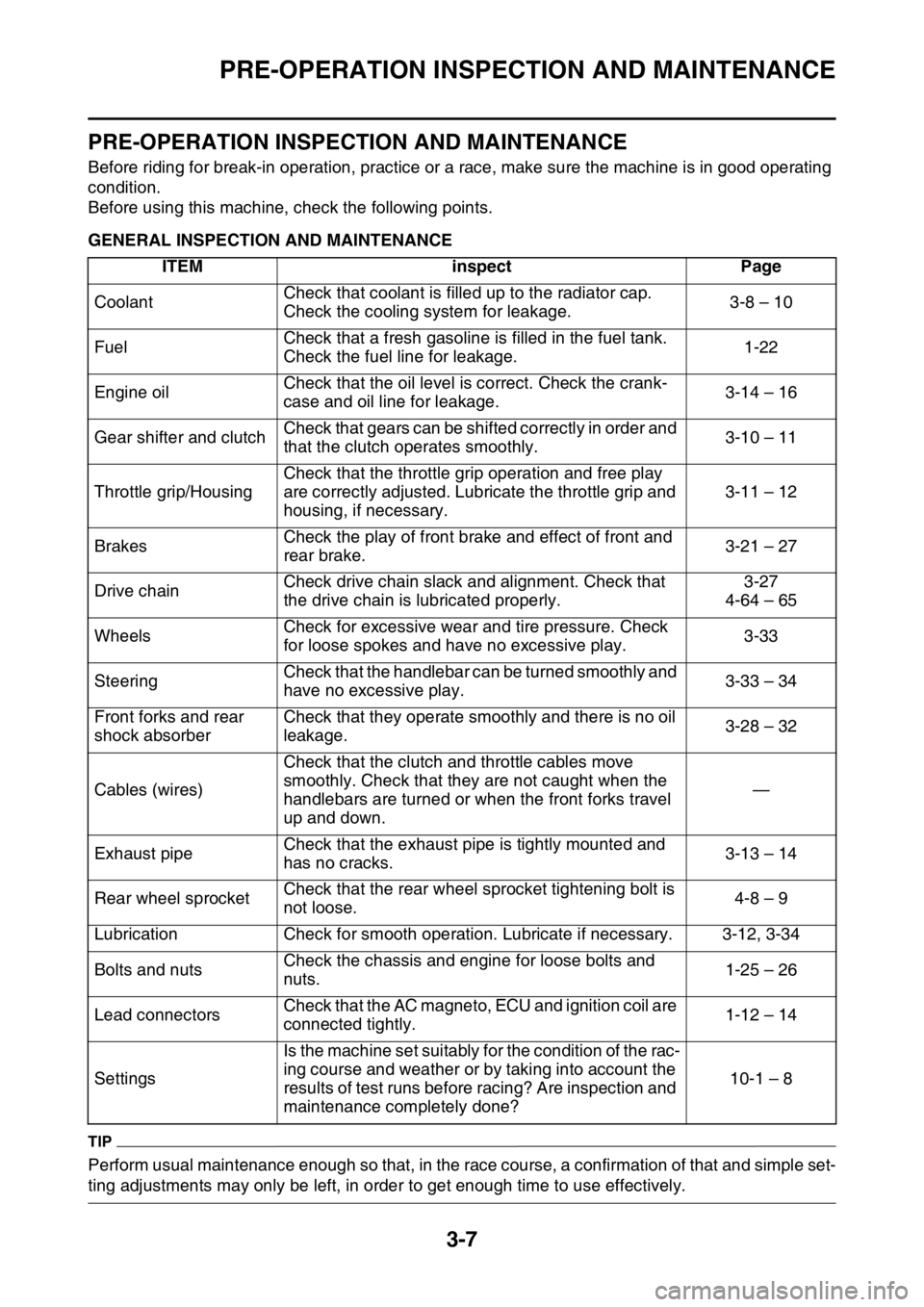

PRE-OPERATION INSPECTION AND MAINTENANCE

3-7

EAS1SM1067

PRE-OPERATION INSPECTION AND MAINTENANCE

Before riding for break-in operation, practice or a race, make sure the machine is in good operating

condition.

Before using this machine, check the following points.

EAS1SM1068GENERAL INSPECTION AND MAINTENANCE

TIP

Perform usual maintenance enough so that, in the race course, a confirmation of that and simple set-

ting adjustments may only be left, in order to get enough time to use effectively.ITEM inspect Page

CoolantCheck that coolant is filled up to the radiator cap.

Check the cooling system for leakage.3-8 – 10

FuelCheck that a fresh gasoline is filled in the fuel tank.

Check the fuel line for leakage.1-22

Engine oilCheck that the oil level is correct. Check the crank-

case and oil line for leakage.3-14 – 16

Gear shifter and clutchCheck that gears can be shifted correctly in order and

that the clutch operates smoothly.3-10 – 11

Throttle grip/HousingCheck that the throttle grip operation and free play

are correctly adjusted. Lubricate the throttle grip and

housing, if necessary.3-11 – 12

BrakesCheck the play of front brake and effect of front and

rear brake.3-21 – 27

Drive chainCheck drive chain slack and alignment. Check that

the drive chain is lubricated properly.3-27

4-64 – 65

WheelsCheck for excessive wear and tire pressure. Check

for loose spokes and have no excessive play.3-33

SteeringCheck that the handlebar can be turned smoothly and

have no excessive play.3-33 – 34

Front forks and rear

shock absorberCheck that they operate smoothly and there is no oil

leakage.3-28 – 32

Cables (wires)Check that the clutch and throttle cables move

smoothly. Check that they are not caught when the

handlebars are turned or when the front forks travel

up and down.—

Exhaust pipeCheck that the exhaust pipe is tightly mounted and

has no cracks.3-13 – 14

Rear wheel sprocketCheck that the rear wheel sprocket tightening bolt is

not loose.4-8 – 9

Lubrication Check for smooth operation. Lubricate if necessary. 3-12, 3-34

Bolts and nutsCheck the chassis and engine for loose bolts and

nuts.1-25 – 26

Lead connectorsCheck that the AC magneto, ECU and ignition coil are

connected tightly.1-12 – 14

SettingsIs the machine set suitably for the condition of the rac-

ing course and weather or by taking into account the

results of test runs before racing? Are inspection and

maintenance completely done?10-1 – 8

Page 98 of 356

ENGINE

3-12

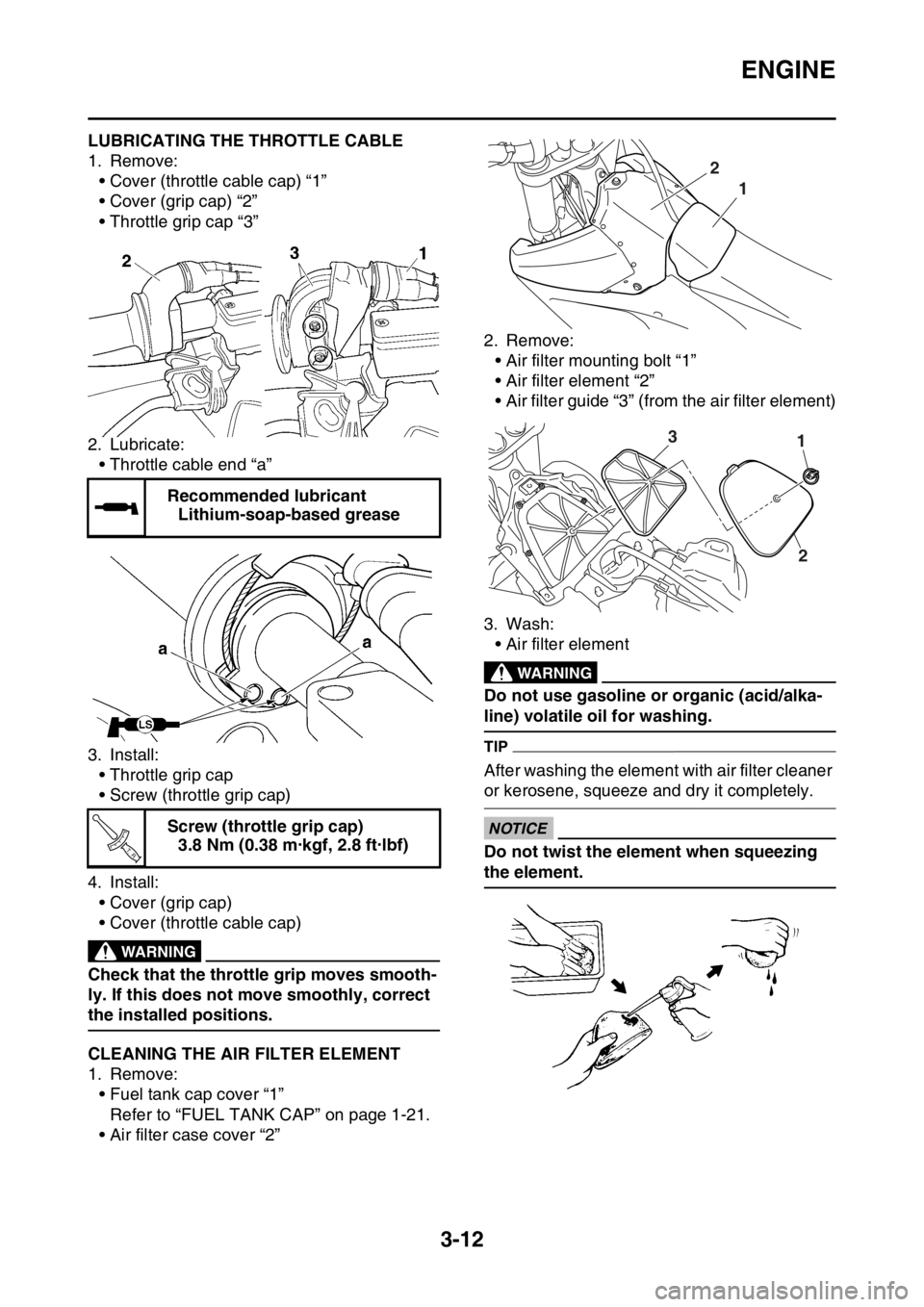

EAS1SM1079LUBRICATING THE THROTTLE CABLE

1. Remove:• Cover (throttle cable cap) “1”

• Cover (grip cap) “2”

• Throttle grip cap “3”

2. Lubricate: • Throttle cable end “a”

3. Install: • Throttle grip cap

• Screw (throttle grip cap)

4. Install: • Cover (grip cap)

• Cover (throttle cable cap)

EWA

WARNING

Check that the throttle grip moves smooth-

ly. If this does not move smoothly, correct

the installed positions.

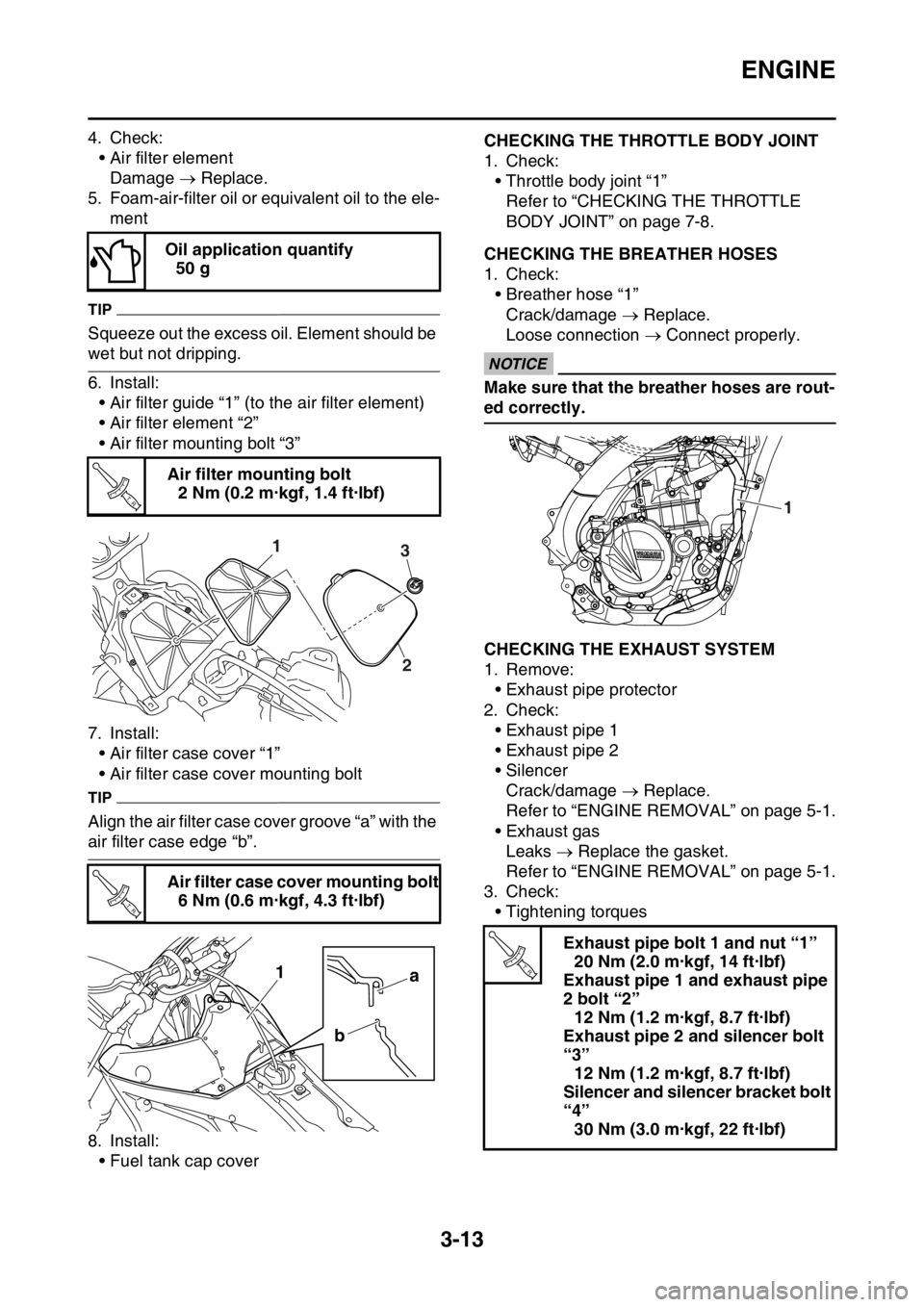

EAS1SM1080CLEANING THE AIR FILTER ELEMENT

1. Remove:• Fuel tank cap cover “1”

Refer to “FUEL TANK CAP” on page 1-21.

• Air filter case cover “2” 2. Remove:

• Air filter mounting bolt “1”

• Air filter element “2”

• Air filter guide “3” (from the air filter element)

3. Wash: • Air filter element

EWA

WARNING

Do not use gasoline or organic (acid/alka-

line) volatile oil for washing.

TIP

After washing the element with air filter cleaner

or kerosene, squeeze and dry it completely.

ECA33DD016

NOTICE

Do not twist the element when squeezing

the element.

Recommended lubricant

Lithium-soap-based grease

Screw (throttle grip cap) 3.8 Nm (0.38 m·kgf, 2.8 ft·lbf)

T R..

1

2

13

2

Page 99 of 356

ENGINE

3-13

4. Check:

• Air filter element

Damage Replace.

5. Foam-air-filter oil or equivalent oil to the ele-

ment

TIP

Squeeze out the excess oil. Element should be

wet but not dripping.

6. Install:

• Air filter guide “1” (to the air filter element)

• Air filter element “2”

• Air filter mounting bolt “3”

7. Install:

• Air filter case cover “1”

• Air filter case cover mounting bolt

TIP

Align the air filter case cover groove “a” with the

air filter case edge “b”.

8. Install:

• Fuel tank cap cover

EAS1SM1081CHECKING THE THROTTLE BODY JOINT

1. Check:

• Throttle body joint “1”

Refer to “CHECKING THE THROTTLE

BODY JOINT” on page 7-8.

EAS1SM1082CHECKING THE BREATHER HOSES

1. Check:

• Breather hose “1”

Crack/damage Replace.

Loose connection Connect properly.

ECA14920

NOTICE

Make sure that the breather hoses are rout-

ed correctly.

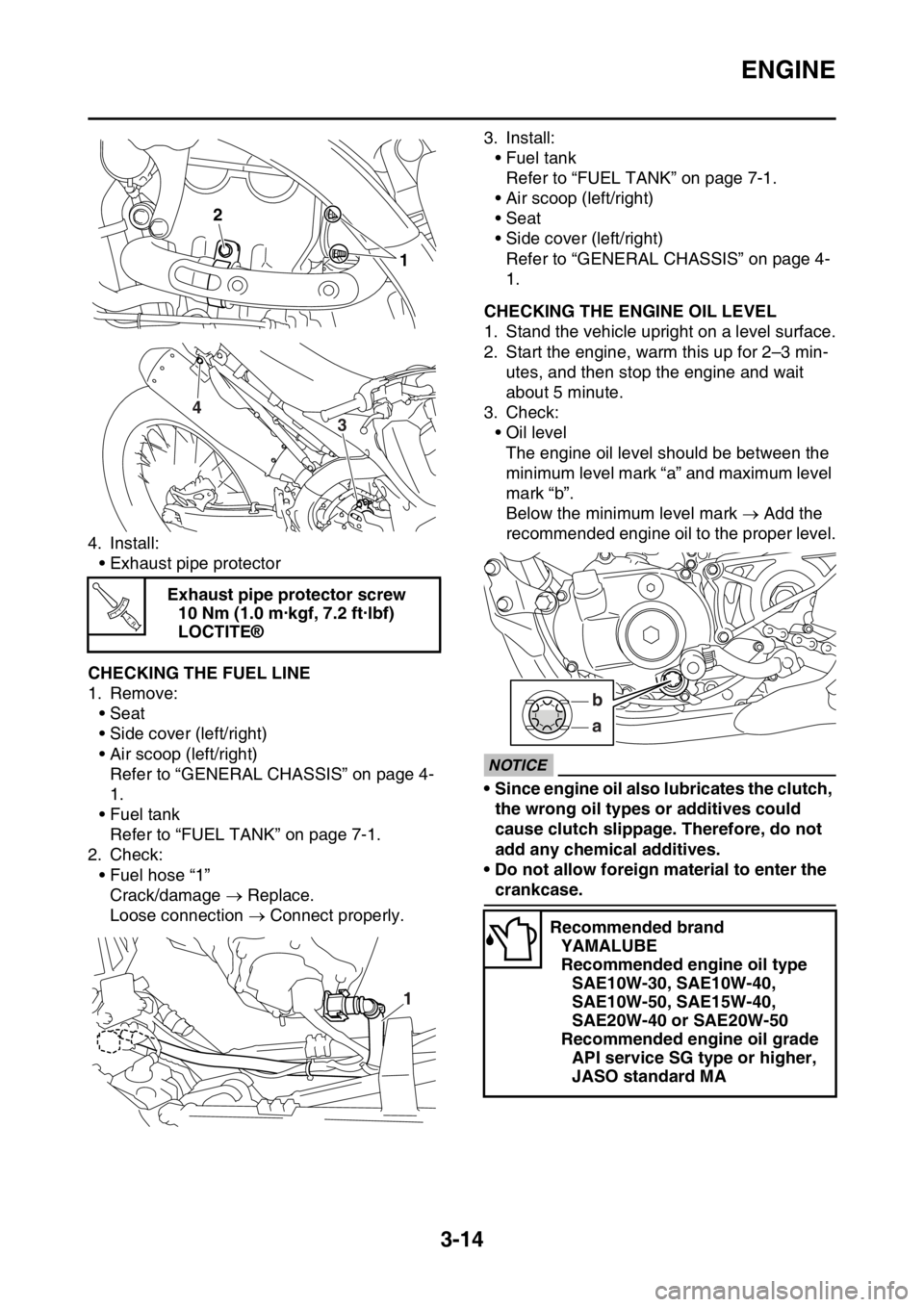

EAS1SM1083CHECKING THE EXHAUST SYSTEM

1. Remove:

• Exhaust pipe protector

2. Check:

• Exhaust pipe 1

• Exhaust pipe 2

• Silencer

Crack/damage Replace.

Refer to “ENGINE REMOVAL” on page 5-1.

• Exhaust gas

Leaks Replace the gasket.

Refer to “ENGINE REMOVAL” on page 5-1.

3. Check:

• Tightening torques Oil application quantify

50 g

Air filter mounting bolt

2 Nm (0.2 m·kgf, 1.4 ft·lbf)

Air filter case cover mounting bolt

6 Nm (0.6 m·kgf, 4.3 ft·lbf)

T R..

31

2

T R..

a

b 1

Exhaust pipe bolt 1 and nut “1”

20 Nm (2.0 m·kgf, 14 ft·lbf)

Exhaust pipe 1 and exhaust pipe

2 bolt “2”

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Exhaust pipe 2 and silencer bolt

“3”

12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Silencer and silencer bracket bolt

“4”

30 Nm (3.0 m·kgf, 22 ft·lbf)

1

T R..

Page 100 of 356

ENGINE

3-14

4. Install:

• Exhaust pipe protector

EAS1SM1084CHECKING THE FUEL LINE

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

2. Check:

• Fuel hose “1”

Crack/damage Replace.

Loose connection Connect properly.3. Install:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air scoop (left/right)

• Seat

• Side cover (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

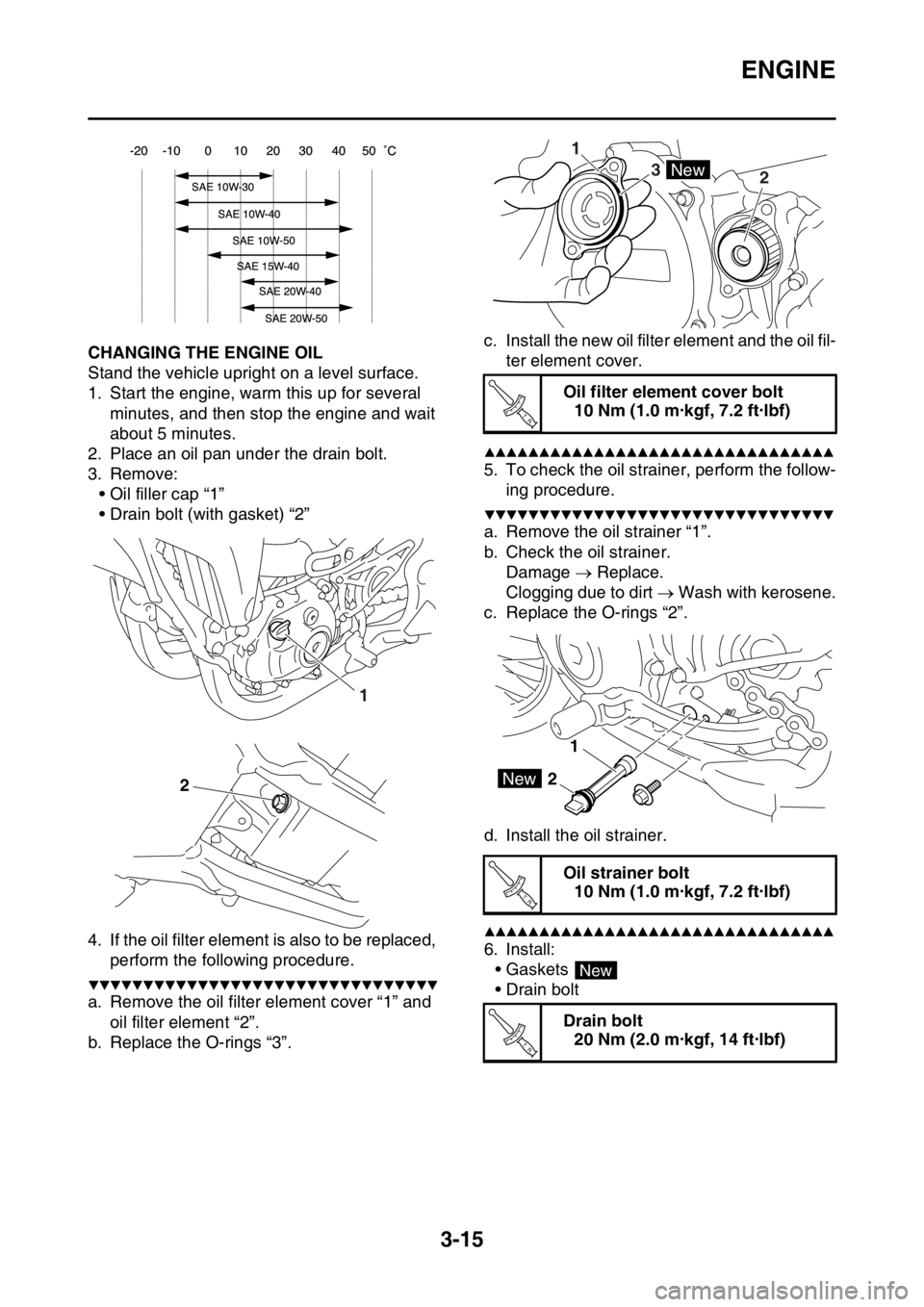

EAS1SM1085CHECKING THE ENGINE OIL LEVEL

1. Stand the vehicle upright on a level surface.

2. Start the engine, warm this up for 2–3 min-

utes, and then stop the engine and wait

about 5 minute.

3. Check:

• Oil level

The engine oil level should be between the

minimum level mark “a” and maximum level

mark “b”.

Below the minimum level mark Add the

recommended engine oil to the proper level.

ECA33DD018

NOTICE

• Since engine oil also lubricates the clutch,

the wrong oil types or additives could

cause clutch slippage. Therefore, do not

add any chemical additives.

• Do not allow foreign material to enter the

crankcase. Exhaust pipe protector screw

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

LOCTITE®

2

1

4

3

T R..

1

Recommended brand

YAMALUBE

Recommended engine oil type

SAE10W-30, SAE10W-40,

SAE10W-50, SAE15W-40,

SAE20W-40 or SAE20W-50

Recommended engine oil grade

API service SG type or higher,

JASO standard MA

a b

Page 101 of 356

ENGINE

3-15

EAS1SM1086CHANGING THE ENGINE OIL

Stand the vehicle upright on a level surface.

1. Start the engine, warm this up for several

minutes, and then stop the engine and wait

about 5 minutes.

2. Place an oil pan under the drain bolt.

3. Remove:

• Oil filler cap “1”

• Drain bolt (with gasket) “2”

4. If the oil filter element is also to be replaced,

perform the following procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil filter element cover “1” and

oil filter element “2”.

b. Replace the O-rings “3”.c. Install the new oil filter element and the oil fil-

ter element cover.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. To check the oil strainer, perform the follow-

ing procedure.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the oil strainer “1”.

b. Check the oil strainer.

Damage Replace.

Clogging due to dirt Wash with kerosene.

c. Replace the O-rings “2”.

d. Install the oil strainer.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

6. Install:

•Gaskets

• Drain bolt

1

2

Oil filter element cover bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil strainer bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Drain bolt

20 Nm (2.0 m·kgf, 14 ft·lbf)

1

3

2

New

T R..

1

2New

T R..

New

T R..

Page 102 of 356

ENGINE

3-16

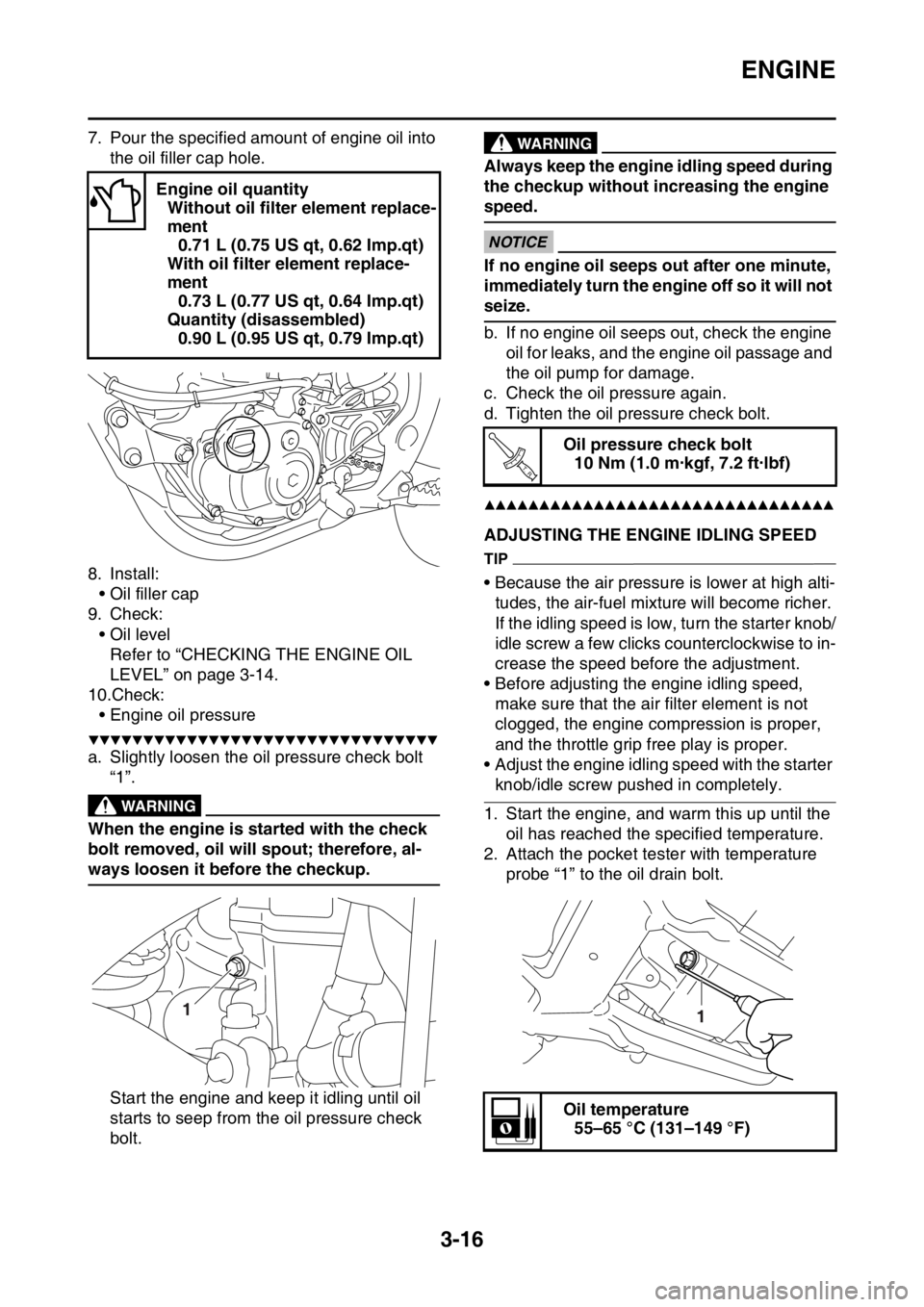

7. Pour the specified amount of engine oil into

the oil filler cap hole.

8. Install:

• Oil filler cap

9. Check:

• Oil level

Refer to “CHECKING THE ENGINE OIL

LEVEL” on page 3-14.

10.Check:

• Engine oil pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly loosen the oil pressure check bolt

“1”.

EWA

WARNING

When the engine is started with the check

bolt removed, oil will spout; therefore, al-

ways loosen it before the checkup.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt.

EWA

WARNING

Always keep the engine idling speed during

the checkup without increasing the engine

speed.

ECA

NOTICE

If no engine oil seeps out after one minute,

immediately turn the engine off so it will not

seize.

b. If no engine oil seeps out, check the engine

oil for leaks, and the engine oil passage and

the oil pump for damage.

c. Check the oil pressure again.

d. Tighten the oil pressure check bolt.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM1087ADJUSTING THE ENGINE IDLING SPEED

TIP

• Because the air pressure is lower at high alti-

tudes, the air-fuel mixture will become richer.

If the idling speed is low, turn the starter knob/

idle screw a few clicks counterclockwise to in-

crease the speed before the adjustment.

• Before adjusting the engine idling speed,

make sure that the air filter element is not

clogged, the engine compression is proper,

and the throttle grip free play is proper.

• Adjust the engine idling speed with the starter

knob/idle screw pushed in completely.

1. Start the engine, and warm this up until the

oil has reached the specified temperature.

2. Attach the pocket tester with temperature

probe “1” to the oil drain bolt. Engine oil quantity

Without oil filter element replace-

ment

0.71 L (0.75 US qt, 0.62 Imp.qt)

With oil filter element replace-

ment

0.73 L (0.77 US qt, 0.64 Imp.qt)

Quantity (disassembled)

0.90 L (0.95 US qt, 0.79 Imp.qt)

1

Oil pressure check bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil temperature

55–65 °C (131–149 °F)

T R..

1

Page 103 of 356

ENGINE

3-17

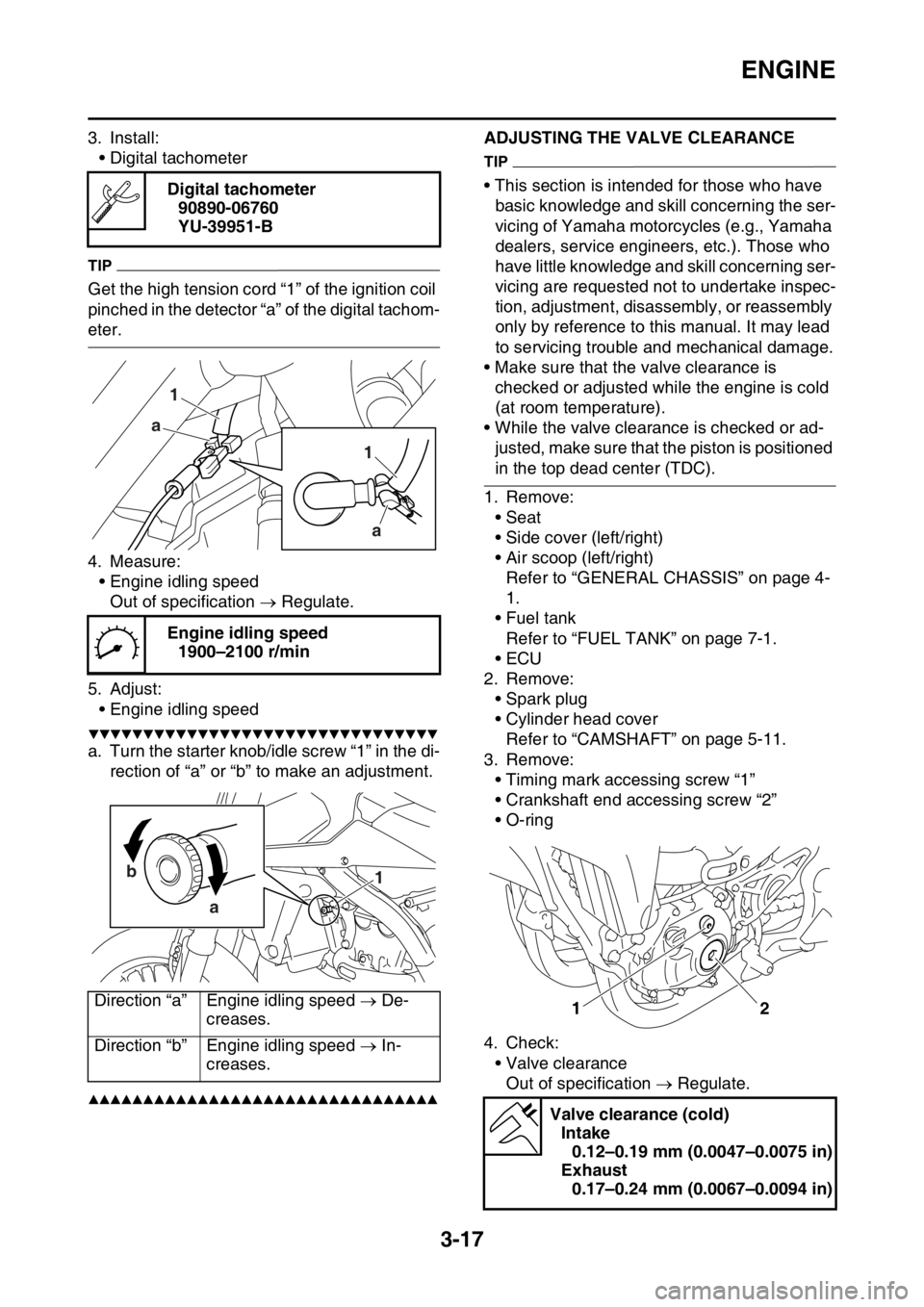

3. Install:

• Digital tachometer

TIP

Get the high tension cord “1” of the ignition coil

pinched in the detector “a” of the digital tachom-

eter.

4. Measure:

• Engine idling speed

Out of specification Regulate.

5. Adjust:

• Engine idling speed

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the starter knob/idle screw “1” in the di-

rection of “a” or “b” to make an adjustment.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM1088

ADJUSTING THE VALVE CLEARANCE

TIP

• This section is intended for those who have

basic knowledge and skill concerning the ser-

vicing of Yamaha motorcycles (e.g., Yamaha

dealers, service engineers, etc.). Those who

have little knowledge and skill concerning ser-

vicing are requested not to undertake inspec-

tion, adjustment, disassembly, or reassembly

only by reference to this manual. It may lead

to servicing trouble and mechanical damage.

• Make sure that the valve clearance is

checked or adjusted while the engine is cold

(at room temperature).

• While the valve clearance is checked or ad-

justed, make sure that the piston is positioned

in the top dead center (TDC).

1. Remove:

• Seat

• Side cover (left/right)

• Air scoop (left/right)

Refer to “GENERAL CHASSIS” on page 4-

1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

•ECU

2. Remove:

• Spark plug

• Cylinder head cover

Refer to “CAMSHAFT” on page 5-11.

3. Remove:

• Timing mark accessing screw “1”

• Crankshaft end accessing screw “2”

• O-ring

4. Check:

• Valve clearance

Out of specification Regulate. Digital tachometer

90890-06760

YU-39951-B

Engine idling speed

1900–2100 r/min

Direction “a” Engine idling speed De-

creases.

Direction “b” Engine idling speed In-

creases.

1 1

a a

1 b

a

Valve clearance (cold)

Intake

0.12–0.19 mm (0.0047–0.0075 in)

Exhaust

0.17–0.24 mm (0.0067–0.0094 in)

1

2