lock YAMAHA YZ250F 2014 User Guide

[x] Cancel search | Manufacturer: YAMAHA, Model Year: 2014, Model line: YZ250F, Model: YAMAHA YZ250F 2014Pages: 356, PDF Size: 11.39 MB

Page 60 of 356

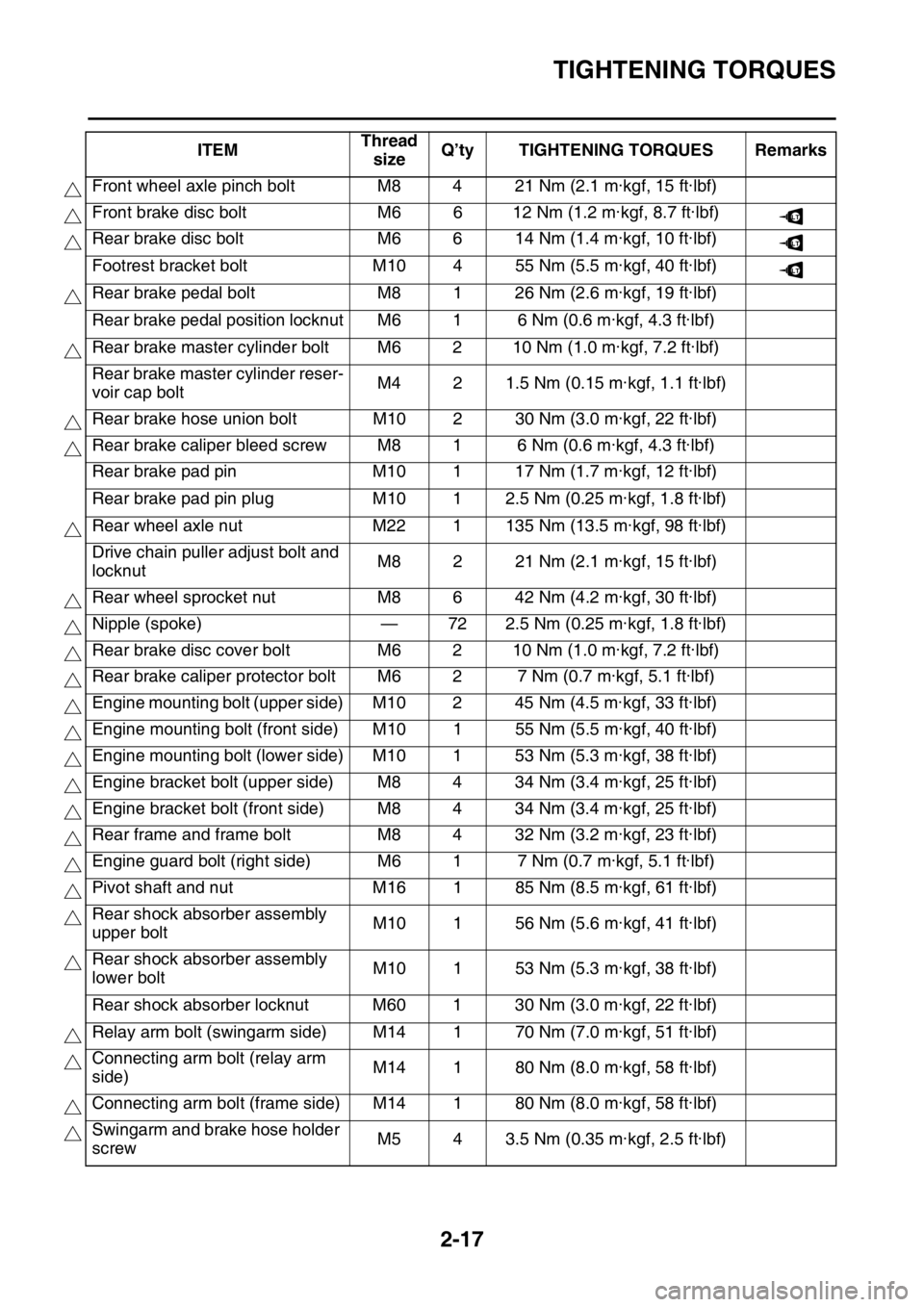

TIGHTENING TORQUES

2-17

Front wheel axle pinch bolt M8 4 21 Nm (2.1 m·kgf, 15 ft·lbf)

Front brake disc bolt M6 6 12 Nm (1.2 m·kgf, 8.7 ft·lbf)

Rear brake disc bolt M6 6 14 Nm (1.4 m·kgf, 10 ft·lbf)

Footrest bracket bolt M10 4 55 Nm (5.5 m·kgf, 40 ft·lbf)

Rear brake pedal bolt M8 1 26 Nm (2.6 m·kgf, 19 ft·lbf)

Rear brake pedal position locknut M6 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake master cylinder bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake master cylinder reser-

voir cap boltM4 2 1.5 Nm (0.15 m·kgf, 1.1 ft·lbf)

Rear brake hose union bolt M10 2 30 Nm (3.0 m·kgf, 22 ft·lbf)

Rear brake caliper bleed screw M8 1 6 Nm (0.6 m·kgf, 4.3 ft·lbf)

Rear brake pad pin M10 1 17 Nm (1.7 m·kgf, 12 ft·lbf)

Rear brake pad pin plug M10 1 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear wheel axle nut M22 1 135 Nm (13.5 m·kgf, 98 ft·lbf)

Drive chain puller adjust bolt and

locknutM8 2 21 Nm (2.1 m·kgf, 15 ft·lbf)

Rear wheel sprocket nut M8 6 42 Nm (4.2 m·kgf, 30 ft·lbf)

Nipple (spoke) — 72 2.5 Nm (0.25 m·kgf, 1.8 ft·lbf)

Rear brake disc cover bolt M6 2 10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Rear brake caliper protector bolt M6 2 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Engine mounting bolt (upper side) M10 2 45 Nm (4.5 m·kgf, 33 ft·lbf)

Engine mounting bolt (front side) M10 1 55 Nm (5.5 m·kgf, 40 ft·lbf)

Engine mounting bolt (lower side) M10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Engine bracket bolt (upper side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Engine bracket bolt (front side) M8 4 34 Nm (3.4 m·kgf, 25 ft·lbf)

Rear frame and frame bolt M8 4 32 Nm (3.2 m·kgf, 23 ft·lbf)

Engine guard bolt (right side) M6 1 7 Nm (0.7 m·kgf, 5.1 ft·lbf)

Pivot shaft and nut M16 1 85 Nm (8.5 m·kgf, 61 ft·lbf)

Rear shock absorber assembly

upper boltM10 1 56 Nm (5.6 m·kgf, 41 ft·lbf)

Rear shock absorber assembly

lower boltM10 1 53 Nm (5.3 m·kgf, 38 ft·lbf)

Rear shock absorber locknut M60 1 30 Nm (3.0 m·kgf, 22 ft·lbf)

Relay arm bolt (swingarm side) M14 1 70 Nm (7.0 m·kgf, 51 ft·lbf)

Connecting arm bolt (relay arm

side)M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Connecting arm bolt (frame side) M14 1 80 Nm (8.0 m·kgf, 58 ft·lbf)

Swingarm and brake hose holder

screwM5 4 3.5 Nm (0.35 m·kgf, 2.5 ft·lbf) ITEMThread

sizeQ’ty TIGHTENING TORQUES Remarks

LT

LT

LT

Page 75 of 356

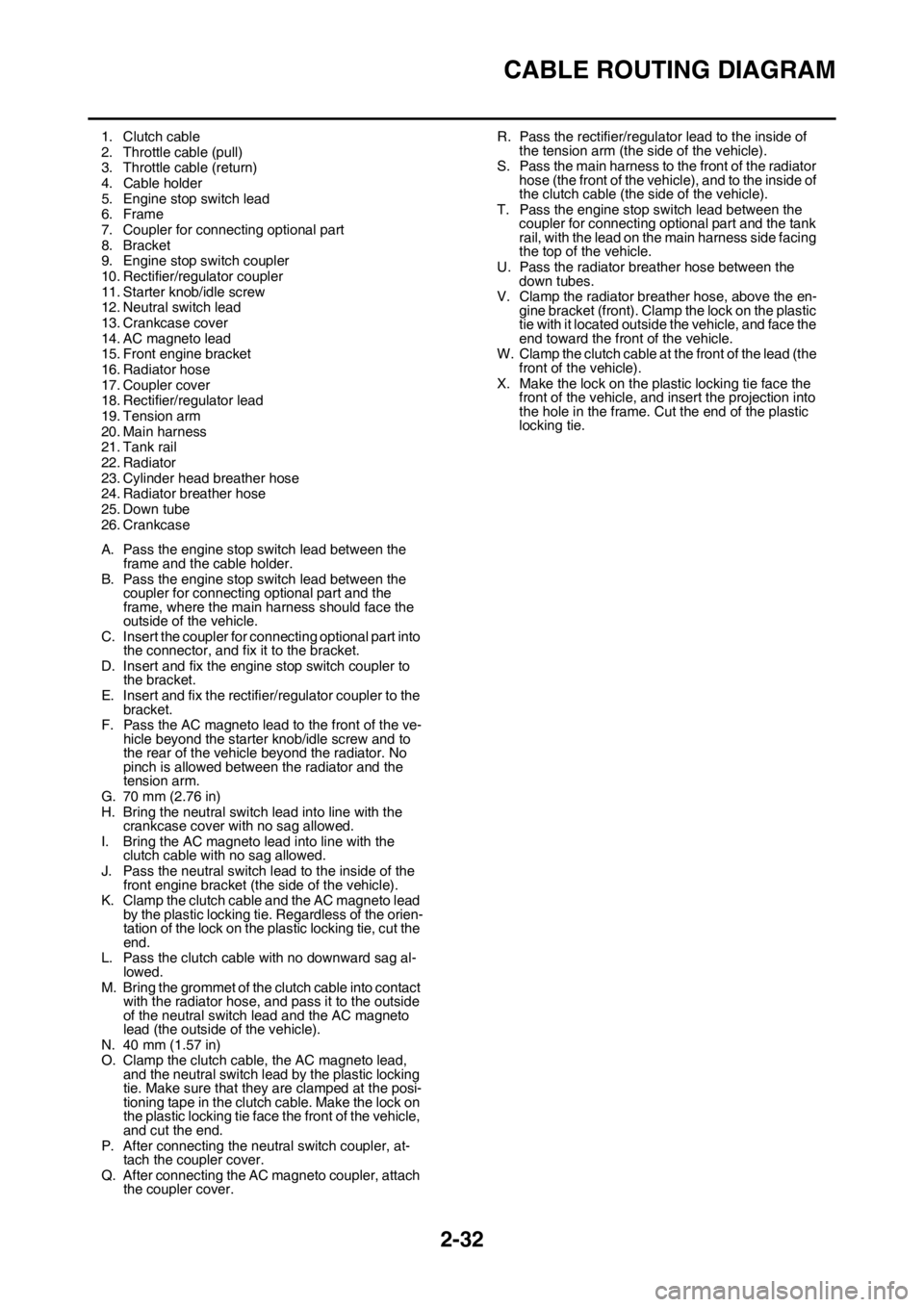

CABLE ROUTING DIAGRAM

2-32

1. Clutch cable

2. Throttle cable (pull)

3. Throttle cable (return)

4. Cable holder

5. Engine stop switch lead

6. Frame

7. Coupler for connecting optional part

8. Bracket

9. Engine stop switch coupler

10. Rectifier/regulator coupler

11. Starter knob/idle screw

12. Neutral switch lead

13. Crankcase cover

14. AC magneto lead

15. Front engine bracket

16. Radiator hose

17. Coupler cover

18. Rectifier/regulator lead

19. Tension arm

20. Main harness

21. Tank rail

22. Radiator

23. Cylinder head breather hose

24. Radiator breather hose

25. Down tube

26. Crankcase

A. Pass the engine stop switch lead between the

frame and the cable holder.

B. Pass the engine stop switch lead between the

coupler for connecting optional part and the

frame, where the main harness should face the

outside of the vehicle.

C. Insert the coupler for connecting optional part into

the connector, and fix it to the bracket.

D. Insert and fix the engine stop switch coupler to

the bracket.

E. Insert and fix the rectifier/regulator coupler to the

bracket.

F. Pass the AC magneto lead to the front of the ve-

hicle beyond the starter knob/idle screw and to

the rear of the vehicle beyond the radiator. No

pinch is allowed between the radiator and the

tension arm.

G. 70 mm (2.76 in)

H. Bring the neutral switch lead into line with the

crankcase cover with no sag allowed.

I. Bring the AC magneto lead into line with the

clutch cable with no sag allowed.

J. Pass the neutral switch lead to the inside of the

front engine bracket (the side of the vehicle).

K. Clamp the clutch cable and the AC magneto lead

by the plastic locking tie. Regardless of the orien-

tation of the lock on the plastic locking tie, cut the

end.

L. Pass the clutch cable with no downward sag al-

lowed.

M. Bring the grommet of the clutch cable into contact

with the radiator hose, and pass it to the outside

of the neutral switch lead and the AC magneto

lead (the outside of the vehicle).

N. 40 mm (1.57 in)

O. Clamp the clutch cable, the AC magneto lead,

and the neutral switch lead by the plastic locking

tie. Make sure that they are clamped at the posi-

tioning tape in the clutch cable. Make the lock on

the plastic locking tie face the front of the vehicle,

and cut the end.

P. After connecting the neutral switch coupler, at-

tach the coupler cover.

Q. After connecting the AC magneto coupler, attach

the coupler cover.R. Pass the rectifier/regulator lead to the inside of

the tension arm (the side of the vehicle).

S. Pass the main harness to the front of the radiator

hose (the front of the vehicle), and to the inside of

the clutch cable (the side of the vehicle).

T. Pass the engine stop switch lead between the

coupler for connecting optional part and the tank

rail, with the lead on the main harness side facing

the top of the vehicle.

U. Pass the radiator breather hose between the

down tubes.

V. Clamp the radiator breather hose, above the en-

gine bracket (front). Clamp the lock on the plastic

tie with it located outside the vehicle, and face the

end toward the front of the vehicle.

W. Clamp the clutch cable at the front of the lead (the

front of the vehicle).

X. Make the lock on the plastic locking tie face the

front of the vehicle, and insert the projection into

the hole in the frame. Cut the end of the plastic

locking tie.

Page 77 of 356

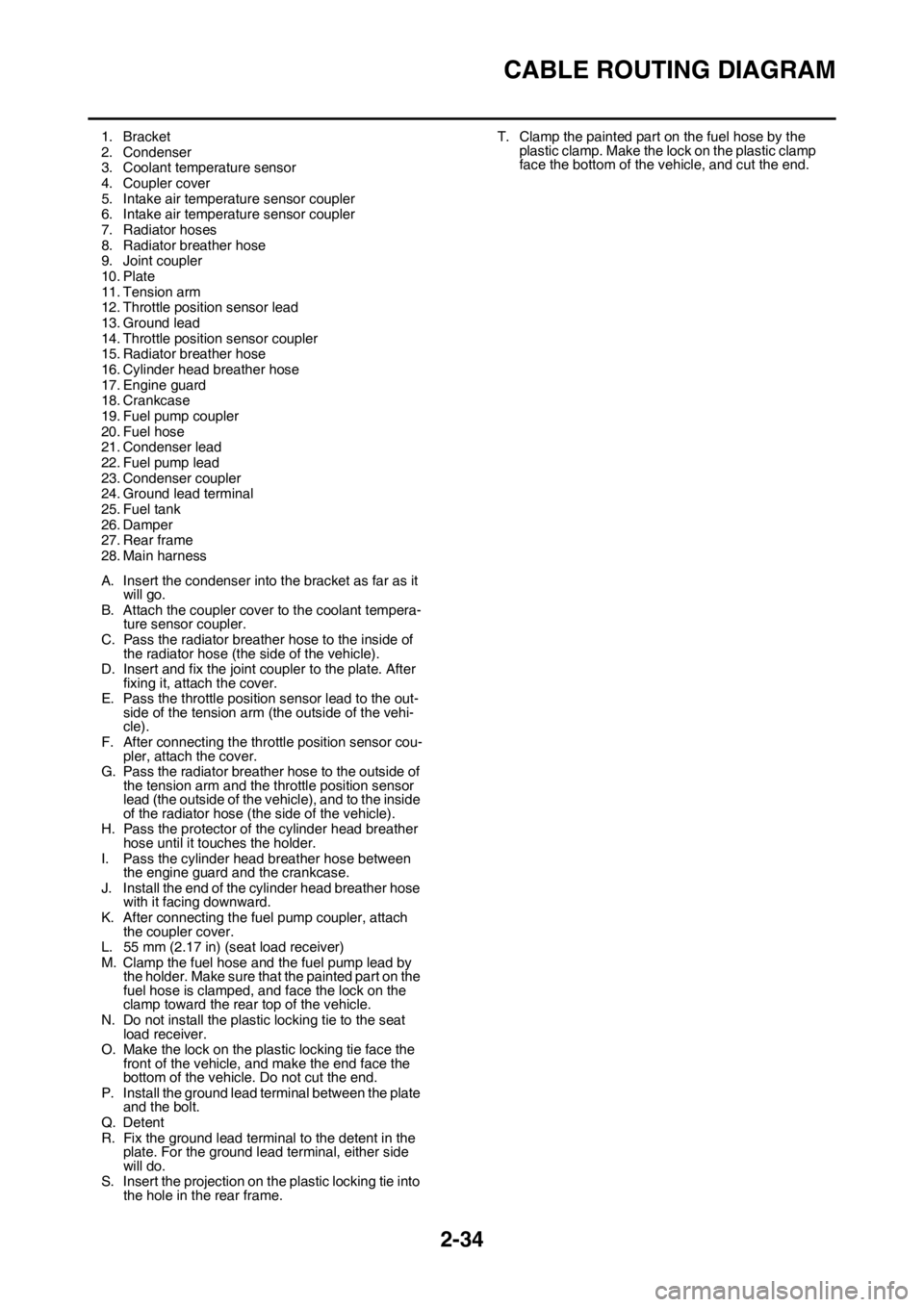

CABLE ROUTING DIAGRAM

2-34

1. Bracket

2. Condenser

3. Coolant temperature sensor

4. Coupler cover

5. Intake air temperature sensor coupler

6. Intake air temperature sensor coupler

7. Radiator hoses

8. Radiator breather hose

9. Joint coupler

10. Plate

11. Tension arm

12. Throttle position sensor lead

13. Ground lead

14. Throttle position sensor coupler

15. Radiator breather hose

16. Cylinder head breather hose

17. Engine guard

18. Crankcase

19. Fuel pump coupler

20. Fuel hose

21. Condenser lead

22. Fuel pump lead

23. Condenser coupler

24. Ground lead terminal

25. Fuel tank

26. Damper

27. Rear frame

28. Main harness

A. Insert the condenser into the bracket as far as it

will go.

B. Attach the coupler cover to the coolant tempera-

ture sensor coupler.

C. Pass the radiator breather hose to the inside of

the radiator hose (the side of the vehicle).

D. Insert and fix the joint coupler to the plate. After

fixing it, attach the cover.

E. Pass the throttle position sensor lead to the out-

side of the tension arm (the outside of the vehi-

cle).

F. After connecting the throttle position sensor cou-

pler, attach the cover.

G. Pass the radiator breather hose to the outside of

the tension arm and the throttle position sensor

lead (the outside of the vehicle), and to the inside

of the radiator hose (the side of the vehicle).

H. Pass the protector of the cylinder head breather

hose until it touches the holder.

I. Pass the cylinder head breather hose between

the engine guard and the crankcase.

J. Install the end of the cylinder head breather hose

with it facing downward.

K. After connecting the fuel pump coupler, attach

the coupler cover.

L. 55 mm (2.17 in) (seat load receiver)

M. Clamp the fuel hose and the fuel pump lead by

the holder. Make sure that the painted part on the

fuel hose is clamped, and face the lock on the

clamp toward the rear top of the vehicle.

N. Do not install the plastic locking tie to the seat

load receiver.

O. Make the lock on the plastic locking tie face the

front of the vehicle, and make the end face the

bottom of the vehicle. Do not cut the end.

P. Install the ground lead terminal between the plate

and the bolt.

Q. Detent

R. Fix the ground lead terminal to the detent in the

plate. For the ground lead terminal, either side

will do.

S. Insert the projection on the plastic locking tie into

the hole in the rear frame. T. Clamp the painted part on the fuel hose by the

plastic clamp. Make the lock on the plastic clamp

face the bottom of the vehicle, and cut the end.

Page 96 of 356

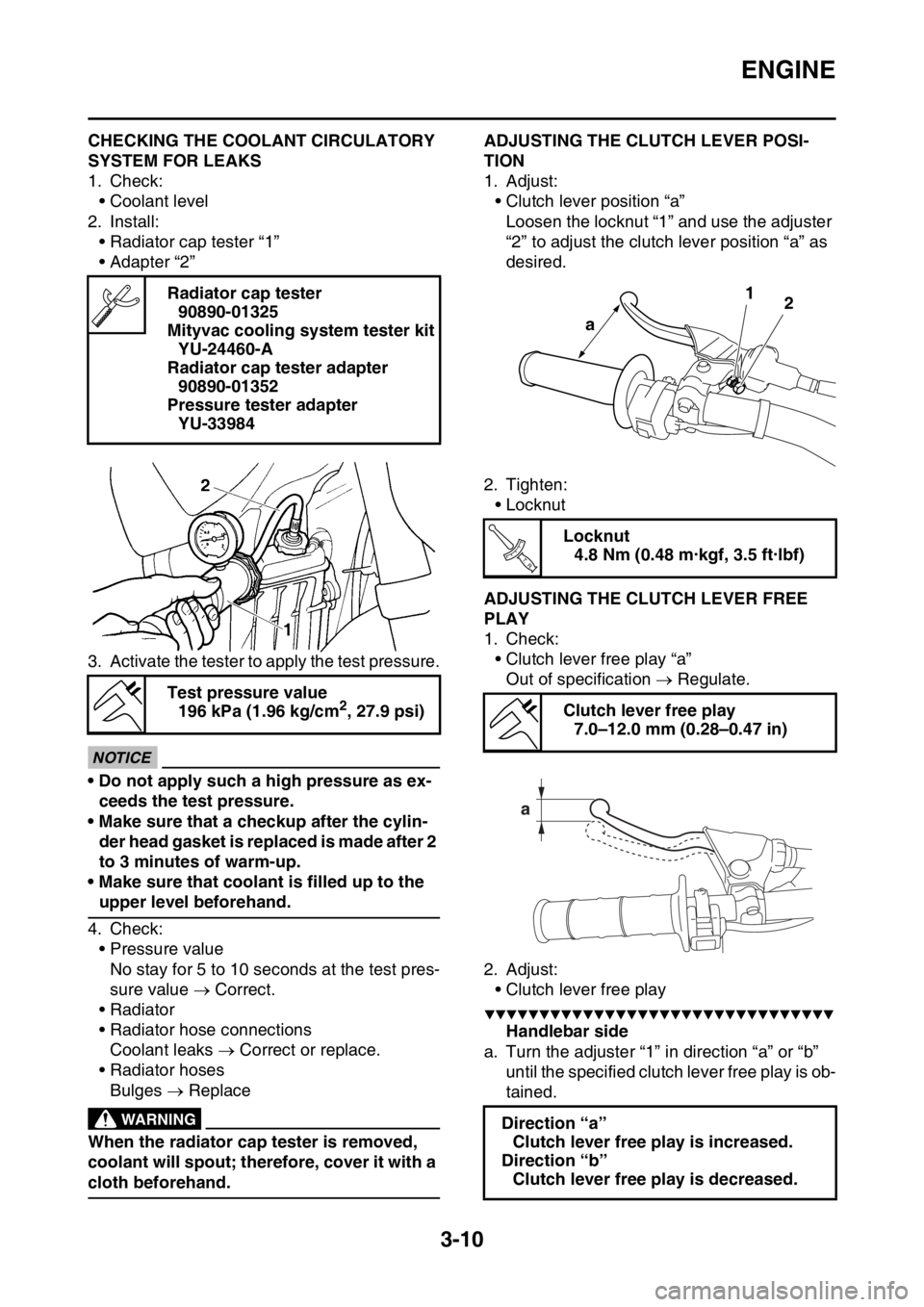

ENGINE

3-10

EAS1SM1075CHECKING THE COOLANT CIRCULATORY

SYSTEM FOR LEAKS

1. Check:

• Coolant level

2. Install:

• Radiator cap tester “1”

• Adapter “2”

3. Activate the tester to apply the test pressure.

ECA@

NOTICE

• Do not apply such a high pressure as ex-

ceeds the test pressure.

• Make sure that a checkup after the cylin-

der head gasket is replaced is made after 2

to 3 minutes of warm-up.

• Make sure that coolant is filled up to the

upper level beforehand.

4. Check:

• Pressure value

No stay for 5 to 10 seconds at the test pres-

sure value Correct.

• Radiator

• Radiator hose connections

Coolant leaks Correct or replace.

• Radiator hoses

Bulges Replace

EWA@

WARNING

When the radiator cap tester is removed,

coolant will spout; therefore, cover it with a

cloth beforehand.

EAS1SM1076ADJUSTING THE CLUTCH LEVER POSI-

TION

1. Adjust:

• Clutch lever position “a”

Loosen the locknut “1” and use the adjuster

“2” to adjust the clutch lever position “a” as

desired.

2. Tighten:

• Locknut

EAS1SM1077ADJUSTING THE CLUTCH LEVER FREE

PLAY

1. Check:

• Clutch lever free play “a”

Out of specification Regulate.

2. Adjust:

• Clutch lever free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Handlebar side

a. Turn the adjuster “1” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained. Radiator cap tester

90890-01325

Mityvac cooling system tester kit

YU-24460-A

Radiator cap tester adapter

90890-01352

Pressure tester adapter

YU-33984

Test pressure value

196 kPa (1.96 kg/cm

2, 27.9 psi)

Locknut

4.8 Nm (0.48 m·kgf, 3.5 ft·lbf)

Clutch lever free play

7.0–12.0 mm (0.28–0.47 in)

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

1

2

a

T R..

Page 97 of 356

ENGINE

3-11

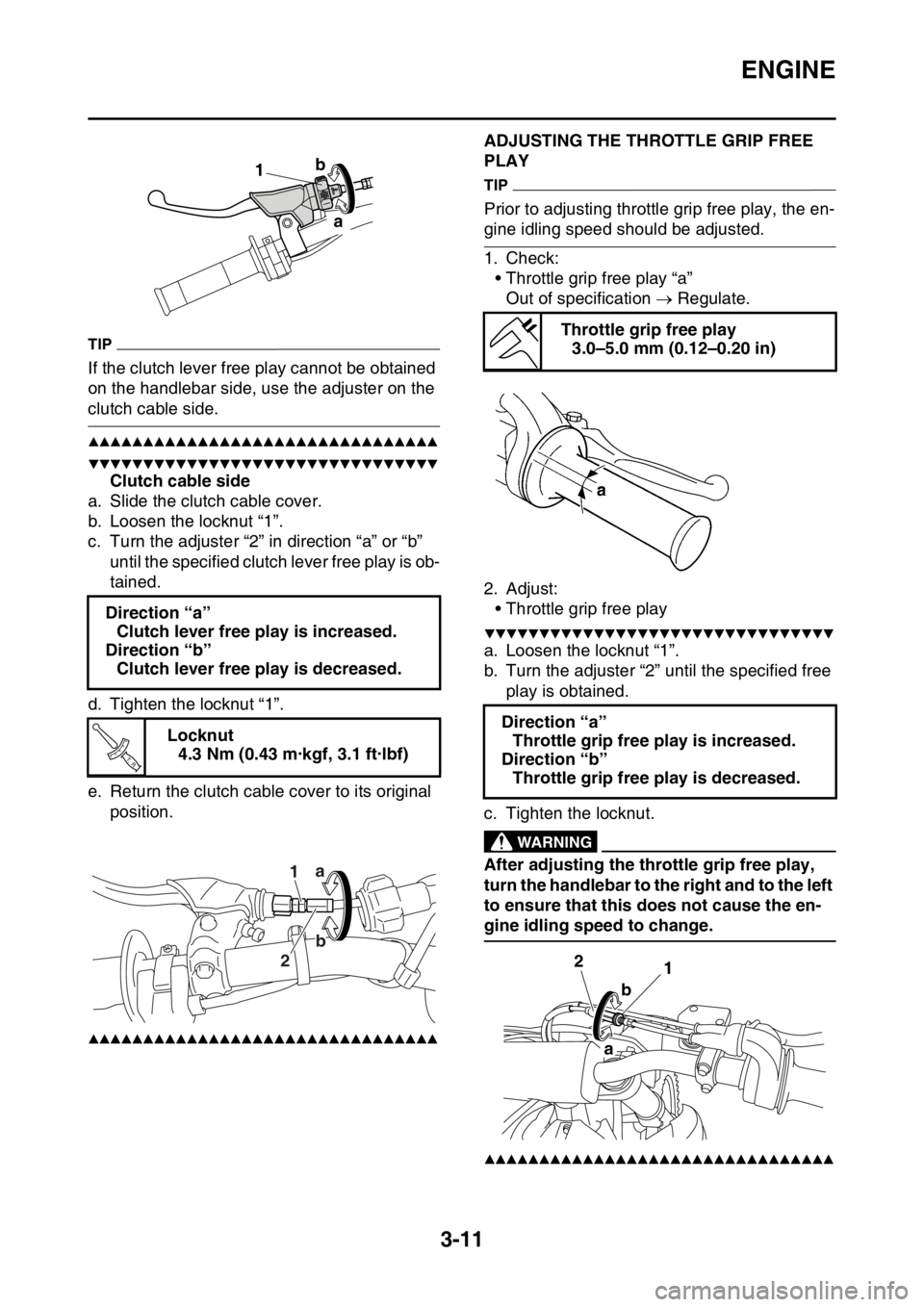

TIP

If the clutch lever free play cannot be obtained

on the handlebar side, use the adjuster on the

clutch cable side.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

Clutch cable side

a. Slide the clutch cable cover.

b. Loosen the locknut “1”.

c. Turn the adjuster “2” in direction “a” or “b”

until the specified clutch lever free play is ob-

tained.

d. Tighten the locknut “1”.

e. Return the clutch cable cover to its original

position.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM1078ADJUSTING THE THROTTLE GRIP FREE

PLAY

TIP

Prior to adjusting throttle grip free play, the en-

gine idling speed should be adjusted.

1. Check:

• Throttle grip free play “a”

Out of specification Regulate.

2. Adjust:

• Throttle grip free play

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjuster “2” until the specified free

play is obtained.

c. Tighten the locknut.

EWA33DD008

WARNING

After adjusting the throttle grip free play,

turn the handlebar to the right and to the left

to ensure that this does not cause the en-

gine idling speed to change.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Direction “a”

Clutch lever free play is increased.

Direction “b”

Clutch lever free play is decreased.

Locknut

4.3 Nm (0.43 m·kgf, 3.1 ft·lbf)

a b

1

T R..

1a

b

2

b

Throttle grip free play

3.0–5.0 mm (0.12–0.20 in)

Direction “a”

Throttle grip free play is increased.

Direction “b”

Throttle grip free play is decreased.

1 2

b

a

Page 102 of 356

ENGINE

3-16

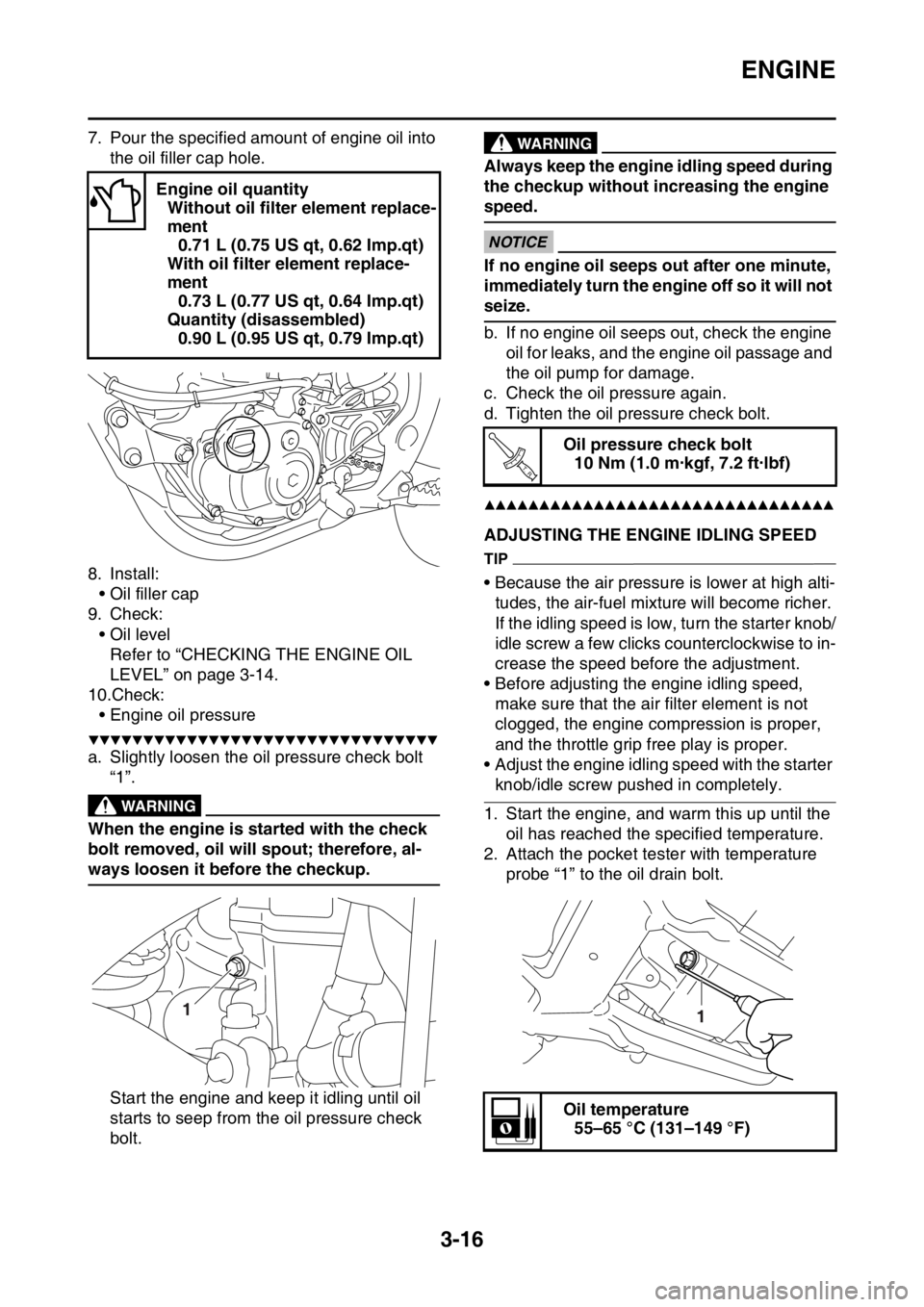

7. Pour the specified amount of engine oil into

the oil filler cap hole.

8. Install:

• Oil filler cap

9. Check:

• Oil level

Refer to “CHECKING THE ENGINE OIL

LEVEL” on page 3-14.

10.Check:

• Engine oil pressure

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Slightly loosen the oil pressure check bolt

“1”.

EWA

WARNING

When the engine is started with the check

bolt removed, oil will spout; therefore, al-

ways loosen it before the checkup.

Start the engine and keep it idling until oil

starts to seep from the oil pressure check

bolt.

EWA

WARNING

Always keep the engine idling speed during

the checkup without increasing the engine

speed.

ECA

NOTICE

If no engine oil seeps out after one minute,

immediately turn the engine off so it will not

seize.

b. If no engine oil seeps out, check the engine

oil for leaks, and the engine oil passage and

the oil pump for damage.

c. Check the oil pressure again.

d. Tighten the oil pressure check bolt.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM1087ADJUSTING THE ENGINE IDLING SPEED

TIP

• Because the air pressure is lower at high alti-

tudes, the air-fuel mixture will become richer.

If the idling speed is low, turn the starter knob/

idle screw a few clicks counterclockwise to in-

crease the speed before the adjustment.

• Before adjusting the engine idling speed,

make sure that the air filter element is not

clogged, the engine compression is proper,

and the throttle grip free play is proper.

• Adjust the engine idling speed with the starter

knob/idle screw pushed in completely.

1. Start the engine, and warm this up until the

oil has reached the specified temperature.

2. Attach the pocket tester with temperature

probe “1” to the oil drain bolt. Engine oil quantity

Without oil filter element replace-

ment

0.71 L (0.75 US qt, 0.62 Imp.qt)

With oil filter element replace-

ment

0.73 L (0.77 US qt, 0.64 Imp.qt)

Quantity (disassembled)

0.90 L (0.95 US qt, 0.79 Imp.qt)

1

Oil pressure check bolt

10 Nm (1.0 m·kgf, 7.2 ft·lbf)

Oil temperature

55–65 °C (131–149 °F)

T R..

1

Page 104 of 356

ENGINE

3-18

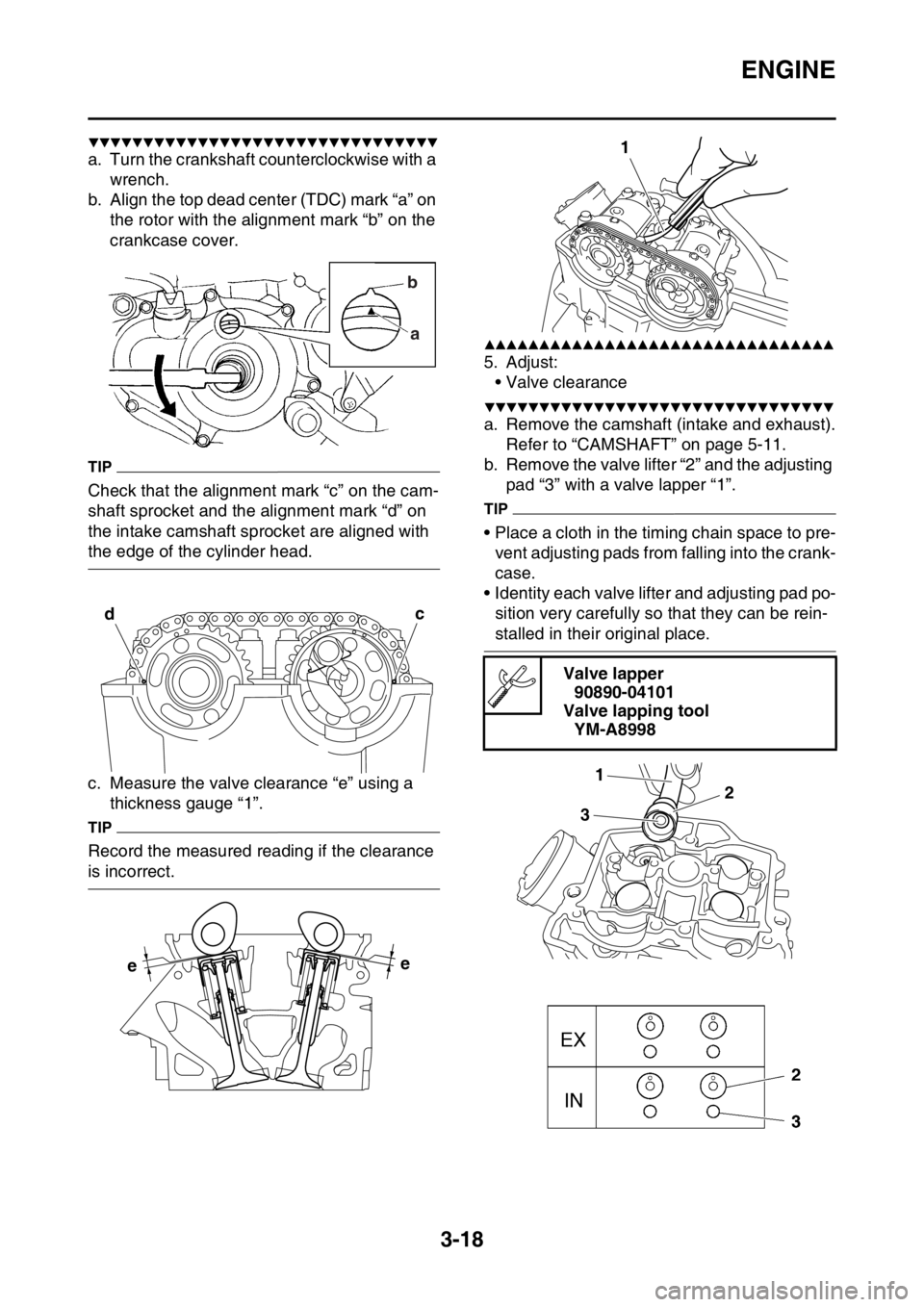

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Turn the crankshaft counterclockwise with a

wrench.

b. Align the top dead center (TDC) mark “a” on

the rotor with the alignment mark “b” on the

crankcase cover.

TIP

Check that the alignment mark “c” on the cam-

shaft sprocket and the alignment mark “d” on

the intake camshaft sprocket are aligned with

the edge of the cylinder head.

c. Measure the valve clearance “e” using a

thickness gauge “1”.

TIP

Record the measured reading if the clearance

is incorrect.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

5. Adjust:

• Valve clearance

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the camshaft (intake and exhaust).

Refer to “CAMSHAFT” on page 5-11.

b. Remove the valve lifter “2” and the adjusting

pad “3” with a valve lapper “1”.

TIP

• Place a cloth in the timing chain space to pre-

vent adjusting pads from falling into the crank-

case.

• Identity each valve lifter and adjusting pad po-

sition very carefully so that they can be rein-

stalled in their original place.

b

a

dc

ee

Valve lapper

90890-04101

Valve lapping tool

YM-A8998

1

1

32

Page 108 of 356

CHASSIS

3-22

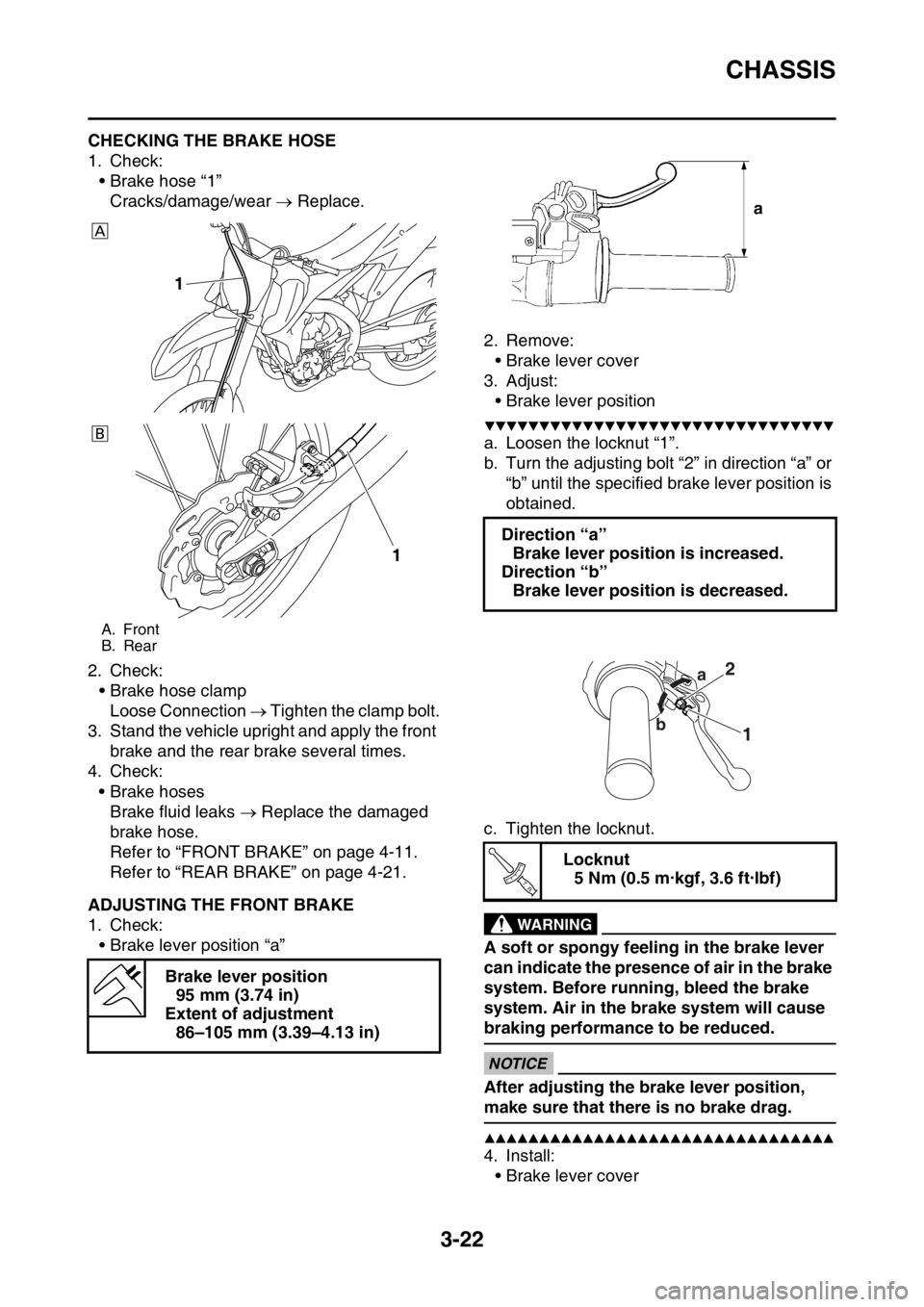

EAS1SM1091CHECKING THE BRAKE HOSE

1. Check:

• Brake hose “1”

Cracks/damage/wear Replace.

2. Check:

• Brake hose clamp

Loose Connection Tighten the clamp bolt.

3. Stand the vehicle upright and apply the front

brake and the rear brake several times.

4. Check:

• Brake hoses

Brake fluid leaks Replace the damaged

brake hose.

Refer to “FRONT BRAKE” on page 4-11.

Refer to “REAR BRAKE” on page 4-21.

EAS1SM1092ADJUSTING THE FRONT BRAKE

1. Check:

• Brake lever position “a”2. Remove:

• Brake lever cover

3. Adjust:

• Brake lever position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or

“b” until the specified brake lever position is

obtained.

c. Tighten the locknut.

EWA13050

WARNING

A soft or spongy feeling in the brake lever

can indicate the presence of air in the brake

system. Before running, bleed the brake

system. Air in the brake system will cause

braking performance to be reduced.

ECA13490

NOTICE

After adjusting the brake lever position,

make sure that there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

4. Install:

• Brake lever cover

A. Front

B. Rear

Brake lever position

95 mm (3.74 in)

Extent of adjustment

86–105 mm (3.39–4.13 in)

1

1

Direction “a”

Brake lever position is increased.

Direction “b”

Brake lever position is decreased.

Locknut

5 Nm (0.5 m·kgf, 3.6 ft·lbf)

a

b

T R..

Page 109 of 356

CHASSIS

3-23

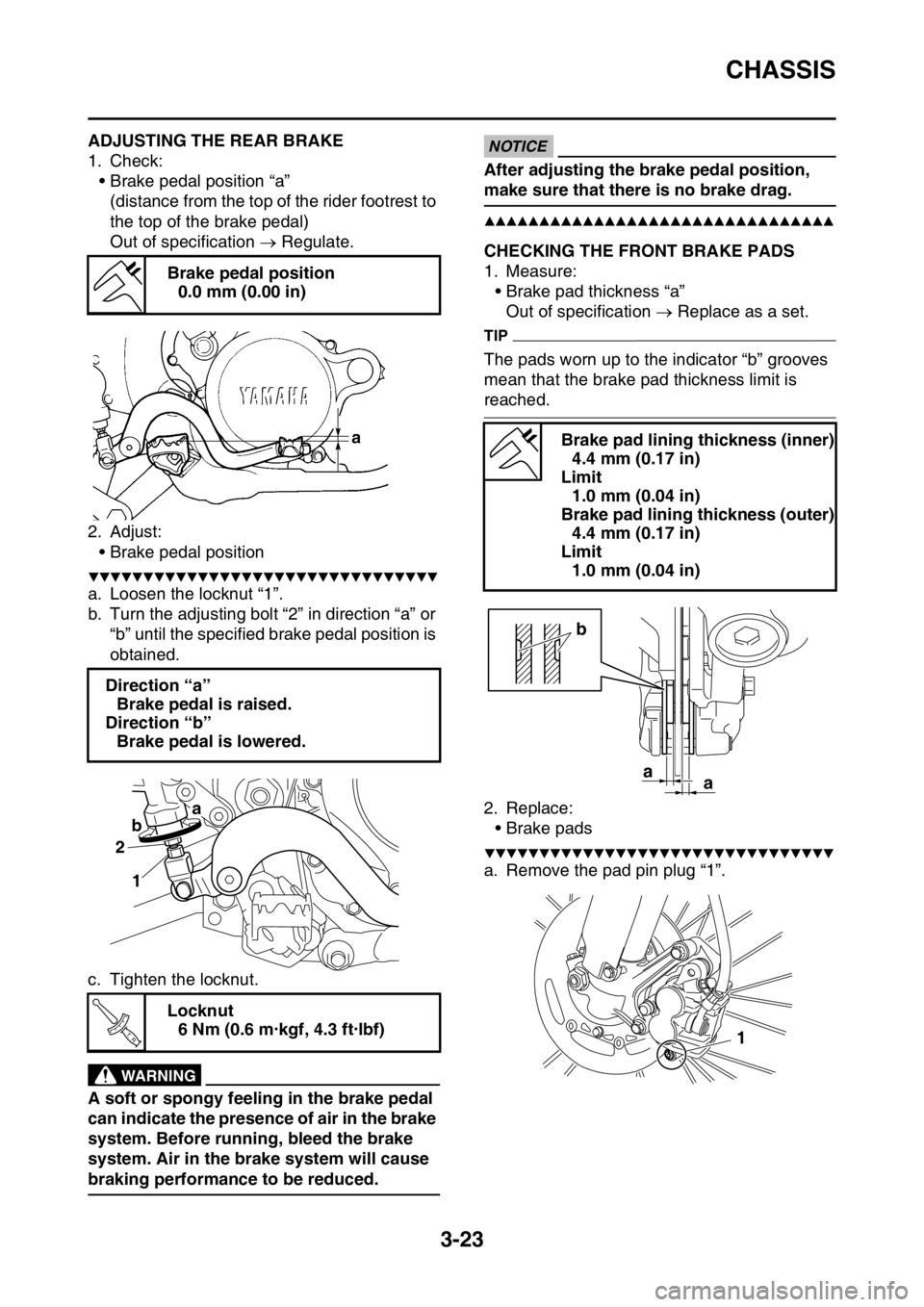

EAS1SM1093ADJUSTING THE REAR BRAKE

1. Check:

• Brake pedal position “a”

(distance from the top of the rider footrest to

the top of the brake pedal)

Out of specification Regulate.

2. Adjust:

• Brake pedal position

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the locknut “1”.

b. Turn the adjusting bolt “2” in direction “a” or

“b” until the specified brake pedal position is

obtained.

c. Tighten the locknut.

EWA1DX1001

WARNING

A soft or spongy feeling in the brake pedal

can indicate the presence of air in the brake

system. Before running, bleed the brake

system. Air in the brake system will cause

braking performance to be reduced.

ECA13510

NOTICE

After adjusting the brake pedal position,

make sure that there is no brake drag.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS1SM1094CHECKING THE FRONT BRAKE PADS

1. Measure:

• Brake pad thickness “a”

Out of specification Replace as a set.

TIP

The pads worn up to the indicator “b” grooves

mean that the brake pad thickness limit is

reached.

2. Replace:

• Brake pads

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Remove the pad pin plug “1”. Brake pedal position

0.0 mm (0.00 in)

Direction “a”

Brake pedal is raised.

Direction “b”

Brake pedal is lowered.

Locknut

6 Nm (0.6 m·kgf, 4.3 ft·lbf)1 2

a

b

T R..

Brake pad lining thickness (inner)

4.4 mm (0.17 in)

Limit

1.0 mm (0.04 in)

Brake pad lining thickness (outer)

4.4 mm (0.17 in)

Limit

1.0 mm (0.04 in)

a

b

a

1

Page 113 of 356

CHASSIS

3-27

EWA13090

WARNING

• Use only the designated brake fluid. Other

brake fluids may cause the rubber seals to

deteriorate, causing leakage and poor

brake performance.

• Refill with the same type of brake fluid that

is already in the system. Mixing brake flu-

ids may result in a harmful chemical reac-

tion, leading to poor brake performance.

• When pouring the brake fluid, be careful

that water does not enter the reservoir.

Water will significantly lower the boiling

point of the brake fluid and could cause

vapor lock.

ECA13540

NOTICE

Immediately wipe off the spilled brake fluid

to avoid damage to painted surfaces or

plastic parts.

EAS1SM1098ADJUSTING THE DRIVE CHAIN SLACKECA13550

NOTICE

A drive chain that is too tight will overload

the engine and other vital parts, and one

that is too loose can skip and damage the

swingarm or cause an accident. Therefore,

keep the drive chain slack within the speci-

fied limits.

1. Use a suitable stand to raise the rear wheel

off the ground.

EWA13120

WARNING

Securely support the vehicle so that there is

no danger of it falling over.

2. Shift the transmission into the neutral posi-

tion.

3. Pull the drive chain up above the drive chain

guide installation bolt with a force of about

50 N (5.0 kgf, 36 lbf).

4. Check:

• Drive chain slack “a”

Out of specification Regulate.

TIP

Measure drive chain slack between the drive

chain guide and the bottom of the chain as

shown.5. Adjust:

• Drive chain slack

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Loosen the wheel axle nut “1”.

b. Loosen both locknuts “2”.

c. Turn the drive chain puller “3” in direction “a”

or “b” until the specified drive chain slack is

obtained.

TIP

• To maintain the proper wheel alignment, ad-

just both sides evenly.

• Push the rear wheel forward to make sure that

there is no clearance between the swingarm

end plates and the ends of the swingarm.

d. Tighten the locknut.

e. Tighten the wheel axle nut.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

Drive chain slack

50–60 mm (1.97–2.36 in)

Direction “a”

The drive chain slack decreases.

Direction “b”

The drive chain slack increases.

Locknut

21 Nm (2.1 m·kgf, 15 ft·lbf)

Wheel axle nut

135 Nm (13.5 m·kgf, 98 ft·lbf)

a

1

32

a

b

T R..

T R..